化工学报 ›› 2022, Vol. 73 ›› Issue (12): 5592-5604.DOI: 10.11949/0438-1157.20221018

尚慧俊1,2( ), 黎亨利2,3, 刘家义2, 潘锋2(

), 黎亨利2,3, 刘家义2, 潘锋2( ), 杜占2(

), 杜占2( ), 孙林兵1

), 孙林兵1

收稿日期:2022-07-16

修回日期:2022-11-26

出版日期:2022-12-05

发布日期:2023-01-17

通讯作者:

潘锋,杜占

作者简介:尚慧俊(1996—),男,硕士研究生, 1293287496@qq.com

基金资助:

Huijun SHANG1,2( ), Hengli LI2,3, Jiayi LIU2, Feng PAN2(

), Hengli LI2,3, Jiayi LIU2, Feng PAN2( ), Zhan DU2(

), Zhan DU2( ), Linbing SUN1

), Linbing SUN1

Received:2022-07-16

Revised:2022-11-26

Online:2022-12-05

Published:2023-01-17

Contact:

Feng PAN, Zhan DU

摘要:

为避免超细WC-Co粉体制备过程中形成对烧结过程及其产物带来不利影响的η相(Co6W6C或Co3W3C),提出了WO3-Co3O4预还原至WO2-Co,再深度还原碳化至WC-Co的技术路线。主要考察了600℃,H2-C2H4-Ar气氛条件下,Co含量及钴源粒径对WO3-Co3O4预还原过程的影响规律,并对预还原产物进行了深度还原碳化性能测试。结果表明,Co的存在可催化C2H4裂解析出H2和C,显著加快WO3预还原速率,且随着Co含量增加其预还原速率显著增加;乙烯析碳速率和析碳量也随Co含量增加而增加。钴源粒径对WO3还原速率和C2H4析碳速率有显著影响,本实验体系下,纳米钴源体系中C2H4析碳速率大约是微米钴源体系的2倍;同时,纳米钴源体系中WO3也具有较快的还原速率。8%Co含量的预还原产物在950℃、甲烷分压1.25%条件下焙烧60 min,可获得无η相的WC-Co复合粉体。

中图分类号:

尚慧俊, 黎亨利, 刘家义, 潘锋, 杜占, 孙林兵. Co对WO3-Co3O4预还原的影响及其产物碳化性能[J]. 化工学报, 2022, 73(12): 5592-5604.

Huijun SHANG, Hengli LI, Jiayi LIU, Feng PAN, Zhan DU, Linbing SUN. Effect of Co on the pre-reduction process of WO3-Co3O4 and carbonization performance of its product[J]. CIESC Journal, 2022, 73(12): 5592-5604.

| 氧化钨 | K |

|---|---|

| WO3 | 6.00 |

| WO2.9 | 6.23 |

| WO2.72 | 6.65 |

| WO2 | 14.69 |

表1 不同钨氧化物的K值

Table 1 The RIR values of different tungsten oxides

| 氧化钨 | K |

|---|---|

| WO3 | 6.00 |

| WO2.9 | 6.23 |

| WO2.72 | 6.65 |

| WO2 | 14.69 |

图5 0.3 kmol C2H4-0.4 kmol H2-0.5 kmol Ar体系物相平衡曲线及相关反应的Gibbs自由能变化曲线

Fig.5 Phase equilibrium curves of 0.3 kmol C2H4-0.4 kmol H2-0.5 kmol Ar system and Gibbs free energy change curves of the related reactions

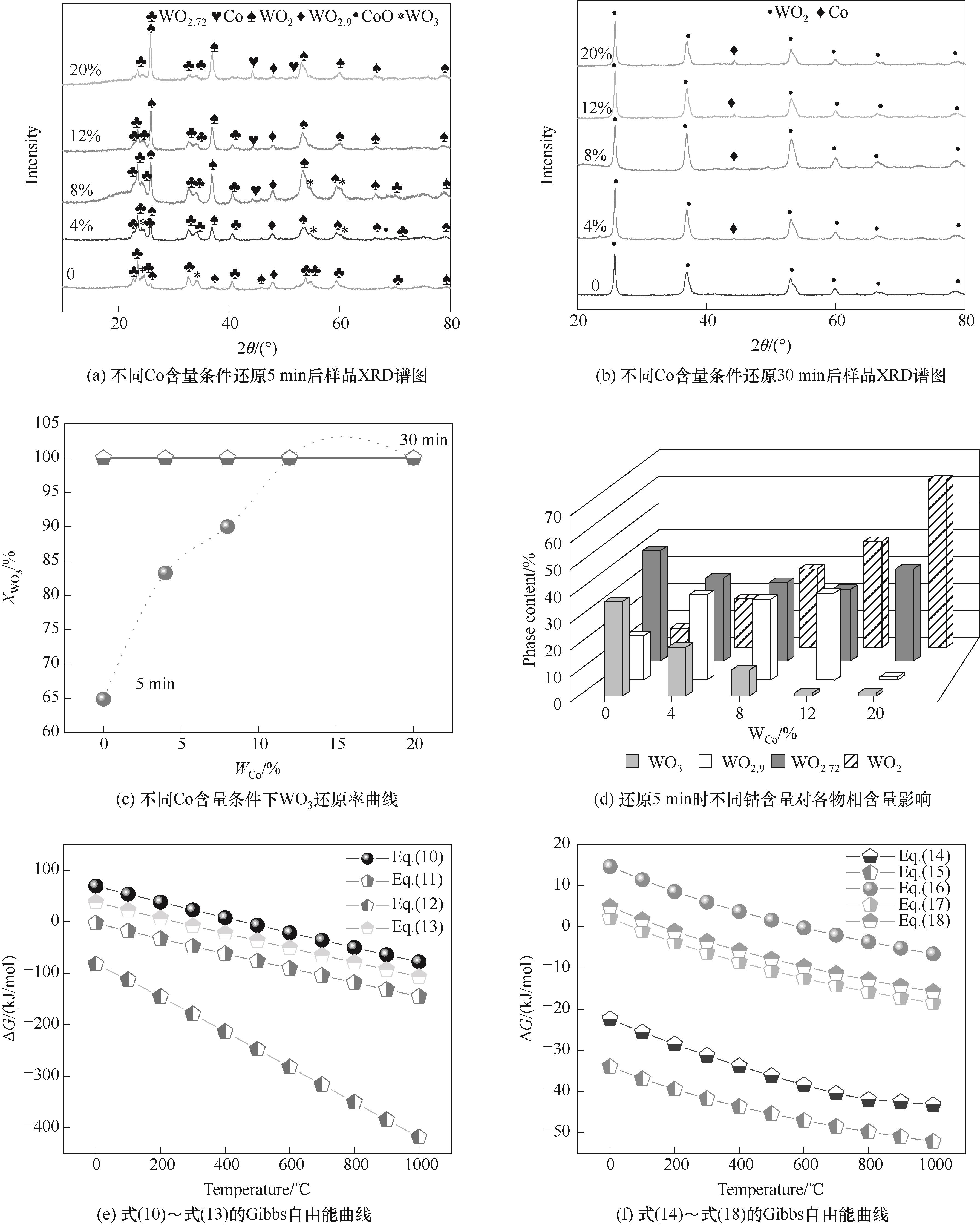

图6 不同Co含量条件下还原产物的还原率、物相含量以及反应体系中相关反应的 Gibbs自由能曲线

Fig.6 The reduction ratio, phase content and Gibbs free energy curves of the related reactions in the reaction system with different Co contents

图11 不同粒径Co3O4原料预还原产物的XRD谱图、物相含量以及还原率

Fig.11 XRD patterns, phase content, reduction ratio and pre-reduction rate of the pre-reduced products under different Co3O4 with sizes

| 1 | Ryu T, Sohn H Y, Han G, et al. Nanograined WC-Co composite powders by chemical vapor synthesis[J]. Metallurgical & Materials Transactions B, 2008, 39(1): 1-6. |

| 2 | Liu W, Song X, Zhang J, et al. Preparation of ultrafine WC-Co composite powder by in situ reduction and carbonization reactions[J]. International Journal of Refractory Metals & Hard Materials, 2009, 27(1): 115-120. |

| 3 | Fu L, Cao L H, Fan Y S. Two-step synthesis of nanostructured tungsten carbide-cobalt powders[J]. Scripta Materialia, 2001, 44(7): 1061-1068. |

| 4 | Zawrah M F. Synthesis and characterization of WC-Co nanocomposites by novel chemical method[J]. Ceramics International, 2007, 33(2): 155-161. |

| 5 | Ma J, Du Y. Synthesis of nanocrystalline hexagonal tungsten carbide via co-reduction of tungsten hexachloride and sodium carbonate with metallic magnesium[J]. Journal of Alloys & Compounds, 2008, 448(1/2): 215-218. |

| 6 | El-Eskandarany M S, Mahday A A, Ahmed H A, et al. Synthesis and characterizations of ball-milled nanocrystalline WC and nanocomposite WC-Co powders and subsequent consolidations[J]. Journal of Alloys & Compounds, 2000, 312(1/2): 315-325. |

| 7 | Yang J G, Hai L, et al. Synthesis of ultrafine WC-10Co composite powders with carbon boat added and densification by sinter-HIP[J]. International Journal of Refractory Metals & Hard Materials, 2017, 62(Pt.B): 104-109. |

| 8 | Pan Y, Xiong H, Li Z, et al. Synthesis of WC-Co composite powders with two-step carbonization and sintering performance study[J]. International Journal of Refractory Metals & Hard Materials, 2019, 81: 127-136. |

| 9 | Choongkwon P, Jiwoong K, Kang S. Effect of cobalt on the synthesis and sintering of WC-Co composite powders[J]. Journal of Alloys & Compounds, 2018, 766: 564-571. |

| 10 | Davidson C F, Wadsworth A. Catalytic effect of cobalt on the carburization kinetics of tungsten[J]. Metallurgical & Materials Transactions A, 1979, 10: 1059-1069. |

| 11 | Wang H, Hou C, Liu X, et al. Phase evolution in synthesis of nanocrystalline WC-η composite powder by solid-state in situ reactions[J]. International Journal of Refractory Metals & Hard Materials, 2017, 71: 21-27. |

| 12 | French G J, Sale F R. The hydrogen reduction of cobalt-tungsten mixed oxides[J]. Journal of Materials Science, 1985, 20: 1291-1300. |

| 13 | 徐仰涛, 李淮, 马腾飞, 等. B和Ce对Co-8.8Al-9.8W-2Ta合金组织和性能的影响[J]. 稀有金属材料与工程, 2022, 51(3): 921-926. |

| Xu Y T, Li H, Ma T F, et al. Effect of B and Ce on microstructure and properties of Co-8.8Al-9.8W-2Ta superalloys[J]. Rare Metal Materials and Engineering, 2022, 51(3): 921-926. | |

| 14 | Pan F, Liu J, Du Z, et al. Reaction process of WC prepared under a CO atmosphere in a fluidized bed[J]. Industrial & Engineering Chemistry Research, 2021, 60:162-172. |

| 15 | Popovics, Grzeta P. The doping method in quantitative X-ray diffraction phase analysis. Addendum[J]. Journal of Applied Crystallography, 1983, 16(5): 505-507. |

| 16 | Lan Y Q, Deng B L, Kim C, et al. Catalysis of elemental sulfur nanoparticles on chromium(Ⅵ) reduction by sulfide under anaerobic conditions[J]. Environmental Science & Technology, 2005, 39(7): 2087-2094. |

| 17 | Pasquazzi A, Schubert W D, Weissenbacher R, et al. Cobalt oxide as a raw material for the production of WC-Co cemented carbides and its advantages for the pressing process[J]. International Journal of Refractory Metals and Hard Materials, 2017, 72:104-109. |

| 18 | Narkiewicz U, Podsiad Y M, Drzejewski R J, et al. Catalytic decomposition of hydrocarbons on cobalt, nickel and iron catalysts to obtain carbon nanomaterials[J]. Applied Catalysis A General, 2010, 384(1/2): 27-35. |

| 19 | Babutina T E, Uvarova I V, Konchakovskaya L D, et al. Preparation of hard alloy WC and WC-Co mixtures with reduction and carbidizing treatment of oxidized tungsten containing scrap[J]. Powder Metallurgy & Metal Ceramics, 2004, 43(3/4): 111-116. |

| 20 | Hu Y, Yu Y. A density functional theory study on ethylene decomposition to carbon monomer on Cu(410) surface[J]. Computational Materials Science, 2019, 161: 321-329. |

| 21 | 赵岁春, 刘宁, 陈爱华. 含碳量对WC-13Co硬质合金组织和性能的影响[J]. 热处理, 2017(5): 38-43. |

| Zhao S C, Liu N, Chen A H. Effects of carbon content on microstructure and property of WC-13Co cemented carbide[J]. Heat Treatment, 2017(5): 38-43. | |

| 22 | Zhang Z, Yu Z, Muhammed M. The reduction of cobalt doped ammonium paratungstate to nanostructured W-Co powder[J]. International Journal of Refractory Metals & Hard Materials, 2002, 20(3): 227-233. |

| 23 | Hong W A, Gg A, Qiang C A, et al. Cobalt sulfide catalysts for single-walled carbon nanotube synthesis[J]. Diamond and Related Materials, 2021, 114:108288-108298. |

| 24 | Tan G L, Wu X J, Li Z Q. Carbon nanotubes strengthened nanophase WC-Co hard alloys[J]. Advanced Engineering Materials, 2006, 8(1/2): 62-72. |

| 25 | Zhang F, Shen J, Sun J. Processing and properties of carbon nanotubes-nano-WC-Co composites[J]. Materials Science and Engineering: A, 2004, 381(1/2): 86-91. |

| 26 | 冯艳艳. 碳源对碳纳米管的结构及其电化学性能的影响[J]. 纳米科技, 2015(4): 8-12. |

| Feng Y Y. Effect of carbon source on the structure and electrochemical properties of carbon nanotubes[J]. Nanomaterial & Application, 2015(4): 8-12. | |

| 27 | Sinnott S B, Andrews R, Qian D, et al.Model of carbon nanotube growth through chemical vapor deposition[J]. Chemical Physics Letters, 1999, 315(1/2): 25-30. |

| 28 | Sawa P G, Polychronopoulou K, Ryzkov V A. Low-temperature catalytic decomposition of ethylene into H2 and secondary carbon nanotubes over Ni/CNTs[J]. Applied Catalysis B: Environmental, 2010, 93(3/4): 314-324. |

| 29 | Shaikhutdinov S K, Zaikovskii V I, Avdeeva L B. Coprecipitated Ni-alumina and Ni-Cu-alumina catalysts of methane decomposition and carbon deposition Ⅲ. Morphology and surface structure of the carbon filaments[J]. Applied Catalysis A: General, 1996, 148(1): 123-133. |

| 30 | 郭建忠, 侯昭胤, 高静, 等. 不同粒径的Ni/SiO2催化剂上CH4和CO2吸附活化的漫反射傅里叶变换红外光谱研究[J]. 催化学报, 2007(1): 22-26. |

| Guo J Z, Hou Z Y, Gao J, et al. Drifts study on adsorption and activation of CH4 and CO2 on Ni/SiO2 catalyst with various Ni particle sizes[J]. Chinese Journal of Catalysis, 2007(1): 22-26. | |

| 31 | Ma L, Yan L, Lu A H, et al. Recommended practices and benchmark activity for hydrogen and oxygen electrocatalysis in water splitting and fuel cells[J]. Journal of Catalysis, 2019, 31:1806296-1806320. |

| 32 | 吴志坚. 钴粉粒度对超细硬质合金性能的影响[C]//第十次全国硬质合金学术会议. 西宁, 2010. |

| Wu Z J.Effect of particle size of cobalt powder on properties of ultrafine cemented carbide [C]//Proceedings of the 10th National Cemented Carbide Academic Conference. Xining, 2010. | |

| 33 | 丁晨旭, 汤睿, 钱渊, 等. Ni基催化剂中Ni颗粒粒径对甲烷干气重整反应的影响及其应用展望[J]. 天然气化工—C1化学与化工, 2022, 47(2): 1-10. |

| Ding C X, Tang R, Qian Y, et al. Effect of Ni-based catalyst Ni particle size on dry reforming of methane reaction and its application prospect[J]. Natural Gas Chemical Industry, 2022, 47(2): 1-10. | |

| 34 | Narayanan R, El-Sayed M A. Catalysis with Transition metal nanoparticles in colloidal solution:nanoparticle shape dependence and stability[J]. The Journal of Physical Chemistry B, 2005, 109:12663-12676. |

| 35 | Won J J, Shim J O, Kim H M, et al. A review on dry reforming of methane in aspect of catalytic properties[J]. Catalysis Today, 2019, 324: 15-26. |

| 36 | 吴爱华, 唐建成, 覃德清, 等. 硬质合金用钴粉的发展现状[J]. 江西科学, 2014(4): 433-438. |

| Wu A H, Tang J C, Qin D Q, et al. The development status of cobalt powders for cemented carbide[J]. Jiangxi Science, 2014(4): 433-438. | |

| 37 | 王忠华, 高鹏哲, 尚根峰, 等. 碳源对喷雾转化法制备WC-Co复合粉末的影响[J]. 功能材料, 2017(11): 11210-11215. |

| Wang Z H, Gao P Z, Shang G F, et al. Effect of carbon source on the preparation of WC-CO composite powders by spray conversion process[J]. Journal of Functional Materials, 2017(11): 11210-11215. |

| [1] | 范孝雄, 郝丽芳, 范垂钢, 李松庚. LaMnO3/生物炭催化剂低温NH3-SCR催化脱硝性能研究[J]. 化工学报, 2023, 74(9): 3821-3830. |

| [2] | 李珍宝, 李超, 王虎, 王绍瑞, 黎泉. MPP抑制铝镁合金粉尘爆炸微观机理研究[J]. 化工学报, 2023, 74(8): 3608-3614. |

| [3] | 李盼, 马俊洋, 陈志豪, 王丽, 郭耘. Ru/α-MnO2催化剂形貌对NH3-SCO反应性能的影响[J]. 化工学报, 2023, 74(7): 2908-2918. |

| [4] | 张琦钰, 高利军, 苏宇航, 马晓博, 王翊丞, 张亚婷, 胡超. 碳基催化材料在电化学还原二氧化碳中的研究进展[J]. 化工学报, 2023, 74(7): 2753-2772. |

| [5] | 张谭, 刘光, 李晋平, 孙予罕. Ru基氮还原电催化剂性能调控策略[J]. 化工学报, 2023, 74(6): 2264-2280. |

| [6] | 杨峥豪, 何臻, 常玉龙, 靳紫恒, 江霞. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| [7] | 陈巨辉, 张谦, 舒崚峰, 李丹, 徐鑫, 刘晓刚, 赵晨希, 曹希峰. 基于DEM方法的旋转流化床纳米颗粒流动特性研究[J]. 化工学报, 2023, 74(6): 2374-2381. |

| [8] | 张媛媛, 曲江源, 苏欣欣, 杨静, 张锴. 循环流化床燃煤机组SNCR脱硝过程气液传质和反应特性[J]. 化工学报, 2023, 74(6): 2404-2415. |

| [9] | 张艳梅, 袁涛, 李江, 刘亚洁, 孙占学. 高效SRB混合菌群构建及其在酸胁迫条件下的性能研究[J]. 化工学报, 2023, 74(6): 2599-2610. |

| [10] | 胡南, 陶德敏, 杨照岚, 王学兵, 张向旭, 刘玉龙, 丁德馨. 铁炭微电解与硫酸盐还原菌耦合修复铀尾矿库渗滤水的研究[J]. 化工学报, 2023, 74(6): 2655-2667. |

| [11] | 何汉兵, 刘真, 陈勇, 王小锋, 曾婧. 直写成型电极锰氧化物粉末的合成与浆料调控[J]. 化工学报, 2023, 74(5): 2239-2247. |

| [12] | 袁子涵, 王淑彦, 邵宝力, 谢磊, 陈曦, 马一玫. 基于幂律液固曳力模型流化床内湿颗粒流动特性的研究[J]. 化工学报, 2023, 74(5): 2000-2012. |

| [13] | 衣思敏, 马亚丽, 刘伟强, 张金帅, 岳岩, 郑强, 贾松岩, 李雪. 微晶菱镁矿蒸氨及水化动力学研究[J]. 化工学报, 2023, 74(4): 1578-1586. |

| [14] | 查坦捷, 杨涵, 秦荷杰, 关小红. 仿生材料的构建及其在水环境化学领域中的研究进展[J]. 化工学报, 2023, 74(2): 585-598. |

| [15] | 李鑫, 曾少娟, 彭奎霖, 袁磊, 张香平. CO2电催化还原制合成气研究进展及趋势[J]. 化工学报, 2023, 74(1): 313-329. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号