化工学报 ›› 2021, Vol. 72 ›› Issue (10): 5247-5256.DOI: 10.11949/0438-1157.20210527

李子祎1( ),潘恩泽2(

),潘恩泽2( ),王佳轩1,鲁金明1,杨建华1(

),王佳轩1,鲁金明1,杨建华1( )

)

收稿日期:2021-04-15

修回日期:2021-06-09

出版日期:2021-10-05

发布日期:2021-10-05

通讯作者:

潘恩泽,杨建华

作者简介:李子祎(1996—),男,硕士研究生,基金资助:

Ziyi LI1( ),Enze PAN2(

),Enze PAN2( ),Jiaxuan WANG1,Jinming LU1,Jianhua YANG1(

),Jiaxuan WANG1,Jinming LU1,Jianhua YANG1( )

)

Received:2021-04-15

Revised:2021-06-09

Online:2021-10-05

Published:2021-10-05

Contact:

Enze PAN,Jianhua YANG

摘要:

淡水资源日益短缺,发展膜法海水淡化技术是满足世界淡水供应需求的重要途径,但是寻找合适的膜材料依然是人类面临的挑战。ZSM-5沸石分子筛膜(简称沸石膜)具有规则的孔道结构、合适的孔径尺寸(0.51~0.56 nm)以及可调变的硅铝比,在有机物脱水分离应用中展示了优异的选择性及良好的渗透性和稳定性。基于其孔径尺寸介于水分子和盐离子之间,其在海水淡化脱盐领域也具有应用潜力。在大孔α-Al2O3载体上采用二次生长法制备了ZSM-5沸石膜,考察了晶化时间与合成液的硅铝比对ZSM-5沸石膜成膜和渗透蒸发脱盐性能的影响,并采用XRD、SEM、EDS与水接触角表征了合成膜的相结构与结晶度、骨架组成表面特性等膜的结构性质。结果表明:通过二次水热法采用合成液摩尔配比为n(Al2O3)∶n(SiO2)∶n(Na2O)∶n(NaF)∶n(H2O)=0.05∶1∶0.21∶1.01∶55的合成液在175℃下晶化48 h为最佳的合成条件,制备了Si/Al比为10、接触角为17.5°的亲水纯相致密ZSM-5沸石膜,并在75℃下对3.5%(质量)的NaCl水溶液进行了渗透蒸发测试,水的通量和盐离子截留率达到8.35 kg·m-2·h-1和99.99%,且性能在60 h的时间依存性测试后依然稳定,表现出了很高的海水淡化工业应用潜力。

中图分类号:

李子祎,潘恩泽,王佳轩,鲁金明,杨建华. ZSM-5沸石分子筛膜的制备及脱盐性能研究[J]. 化工学报, 2021, 72(10): 5247-5256.

Ziyi LI,Enze PAN,Jiaxuan WANG,Jinming LU,Jianhua YANG. Preparation of ZSM-5 zeolite membrane and its application in desalination[J]. CIESC Journal, 2021, 72(10): 5247-5256.

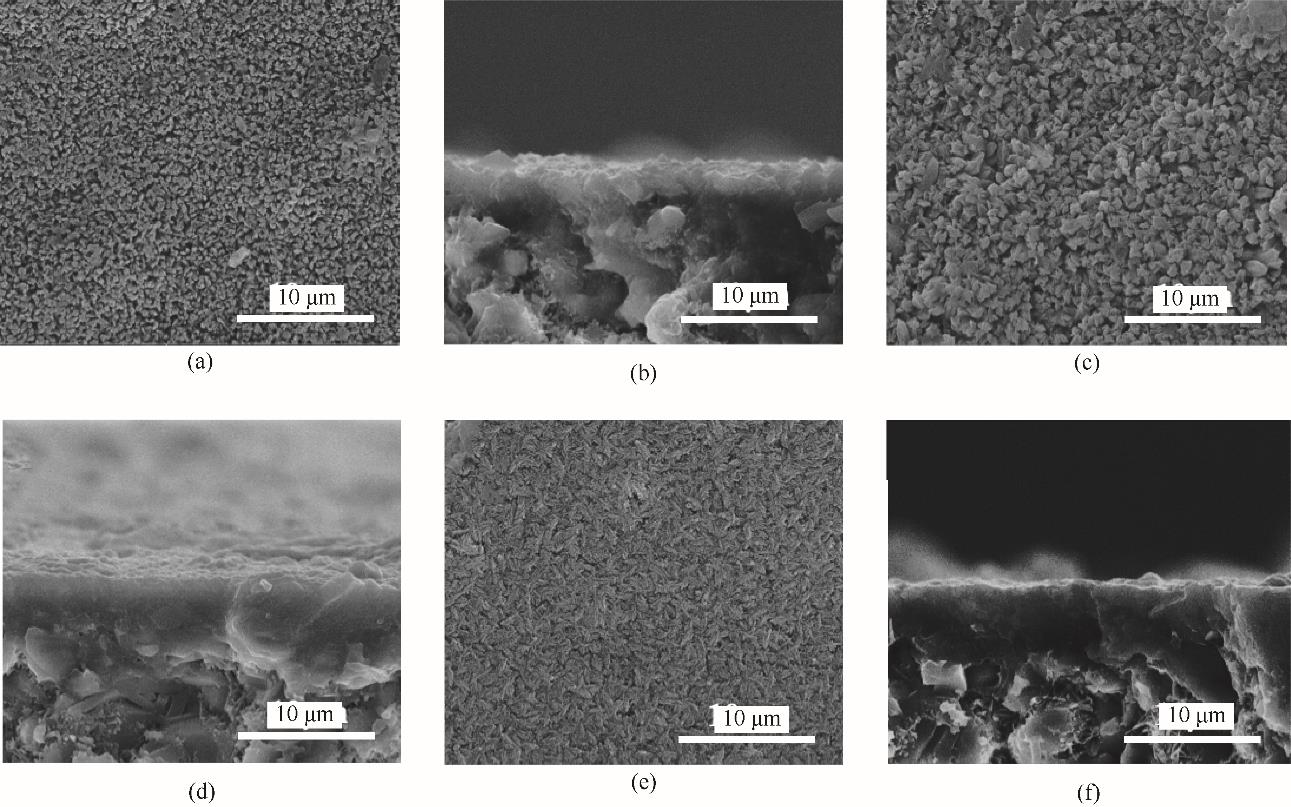

图3 不同硅铝比合成液制备ZSM-5沸石膜的SEM图。Si/Al =7.5[(a)、(b)]、10 [(c)、(d)]、12.5[(e)、(f)]

Fig.3 SEM images of ZSM-5 zeolite membranes prepared by different Si-Al ratios of synthetic liquid. Si/Al =7.5[(a),(b)], 10 [(c),(d)], 12.5[(e),(f)]

| 编号 | 硅铝比 | 渗透蒸发性能(50%(质量)乙酸水溶液) | |

|---|---|---|---|

| 分离因子α | 渗透通量/ (kg·m-2·h-1) | ||

| M1 | 7.5 | 224 | 0.78 |

| M2 | 10 | >10000 | 2.00 |

| M3 | 12.5 | >10000 | 0.64 |

表1 不同条件下制备的ZSM-5沸石膜的渗透汽化乙酸脱水性能

Table 1 Pervaporation properties of ZSM-5 zeolite membrane prepared under different conditions

| 编号 | 硅铝比 | 渗透蒸发性能(50%(质量)乙酸水溶液) | |

|---|---|---|---|

| 分离因子α | 渗透通量/ (kg·m-2·h-1) | ||

| M1 | 7.5 | 224 | 0.78 |

| M2 | 10 | >10000 | 2.00 |

| M3 | 12.5 | >10000 | 0.64 |

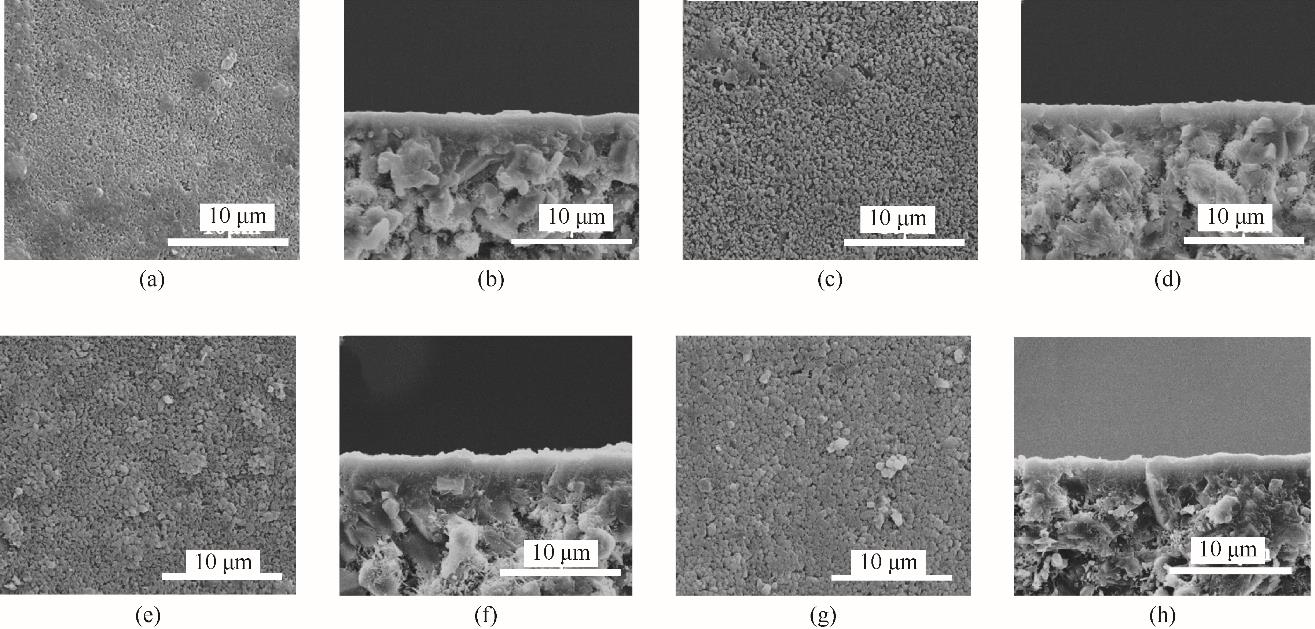

图5 不同晶化时间制备ZSM-5沸石膜的SEM图:24 h [(a)、(b)]、36 h [(c)、(d)]、48 h[(e)、(f)]、72 h[(g)、(h)]

Fig.5 SEM images of ZSM-5 zeolite membranes prepared with different crystallization time: 24 h [(a),(b)],36 h [(c),(d)],48 h[(e),(f)],72 h[(g),(h)]

| 编号 | 合成条件 | 渗透蒸发脱盐性能 | ||||

|---|---|---|---|---|---|---|

| 晶种 | 晶化温度/℃ | 硅铝比 | 晶化时间/h | 截留率/% | 渗透通量/(kg·m-2·h-1) | |

| M2 | ZSM-5 | 175 | 10 | 48 | 99.99 | 8.35 |

| M4 | ZSM-5 | 175 | 10 | 24 | 99.98 | 5.84 |

| M5 | ZSM-5 | 175 | 10 | 36 | 99.97 | 6.63 |

| M6 | ZSM-5 | 175 | 10 | 72 | 99.92 | 7.15 |

表2 不同晶化时间制备的ZSM-5沸石膜的渗透蒸发脱盐性能

Table 2 Pervaporation properties for desalination of ZSM-5 zeolite membrane prepared under different conditions

| 编号 | 合成条件 | 渗透蒸发脱盐性能 | ||||

|---|---|---|---|---|---|---|

| 晶种 | 晶化温度/℃ | 硅铝比 | 晶化时间/h | 截留率/% | 渗透通量/(kg·m-2·h-1) | |

| M2 | ZSM-5 | 175 | 10 | 48 | 99.99 | 8.35 |

| M4 | ZSM-5 | 175 | 10 | 24 | 99.98 | 5.84 |

| M5 | ZSM-5 | 175 | 10 | 36 | 99.97 | 6.63 |

| M6 | ZSM-5 | 175 | 10 | 72 | 99.92 | 7.15 |

图7 ZSM-5沸石膜M2用于不同浓度NaCl水溶液的渗透汽化脱盐测试

Fig.7 Pervaporation desalination test of ZSM-5 zeolite membrane M2 in different concentration NaCl aqueous solution

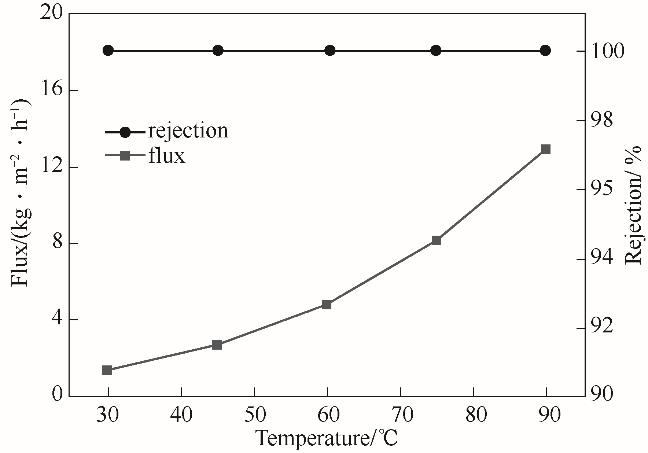

图8 ZSM-5沸石膜M2在不同温度下对3.5%(质量) NaCl水溶液的渗透汽化脱盐测试

Fig.8 Pervaporation desalination test of ZSM-5 zeolite membrane M2 in 3.5%(mass) NaCl aqueous solution at different temperatures

图9 ZSM-5沸石膜M2用于3.5%(质量) NaCl水溶液渗透汽化脱盐的Arrhenius方程拟合图

Fig. 9 Arrhenius equation fitting diagram of ZSM-5 zeolite membrane for pervaporation desalination of 3.5%(mass) NaCl salt solution

图10 ZSM-5沸石膜M2对于75℃3.5%(质量) NaCl水溶液渗透汽化脱盐的时间依存性测试

Fig.10 Time dependence of ZSM-5 zeolite membrane M2 for pervaporation desalination of NaCl aqueous solution at 75°C

| 盐 | 浓度/(g·L-1) |

|---|---|

| NaCl | 24.53 |

| Na2SO4 | 4.09 |

| KCl | 0.695 |

| KBr | 0.101 |

| SrCl2 | 0.025 |

| MgCl2 | 5.2 |

| CaCl2 | 1.16 |

| NaHCO3 | 0.201 |

| H3BO3 | 0.027 |

| NaF | 0.03 |

表3 模拟海水中的盐离子浓度

Table 3 Ion concentrations of simulated seawater

| 盐 | 浓度/(g·L-1) |

|---|---|

| NaCl | 24.53 |

| Na2SO4 | 4.09 |

| KCl | 0.695 |

| KBr | 0.101 |

| SrCl2 | 0.025 |

| MgCl2 | 5.2 |

| CaCl2 | 1.16 |

| NaHCO3 | 0.201 |

| H3BO3 | 0.027 |

| NaF | 0.03 |

| 无机分子筛膜 | 膜厚度/μm | 操作条件 | 渗透通量/ (kg·m-2·h-1) | 离子截留率/% | 文献 | |

|---|---|---|---|---|---|---|

| 料液 | 温度/℃ | |||||

| FAU | 2.3 | 3.5%(质量)模拟海水 | 90 | 5.64 | >99.8 | [ |

| ZSM-5 | 3.5 | 3.5%(质量)NaCl溶液 | 75 | 5.5 | 90.0 | [ |

| Sil.-1 | 6 | 3.5%(质量)NaCl溶液 | 75 | 5 | 96 | [ |

| NaA | 2 | 3.5%(质量)NaCl溶液 | 75 | 9.58 | >99.9 | [ |

| SOD | 1 | 海水 | 177 | 3.5 | 99.99 | [ |

| NaA | 4 | 海水 | 69 | 1.9 | >99.9 | [ |

| ZSM-5沸石膜 M2 | 3.5 | 3.5%(质量)NaCl溶液 | 75 | 8.35 | >99.9 | 本文 |

| ZSM-5沸石膜 M7 | 3.5 | 模拟海水 | 75 | 6.92 | >99.9 | 本文 |

表4 不同种类无机分子筛膜的脱盐性能对比

Table 4 Comparison of desalination performance of different kinds of inorganic membranes

| 无机分子筛膜 | 膜厚度/μm | 操作条件 | 渗透通量/ (kg·m-2·h-1) | 离子截留率/% | 文献 | |

|---|---|---|---|---|---|---|

| 料液 | 温度/℃ | |||||

| FAU | 2.3 | 3.5%(质量)模拟海水 | 90 | 5.64 | >99.8 | [ |

| ZSM-5 | 3.5 | 3.5%(质量)NaCl溶液 | 75 | 5.5 | 90.0 | [ |

| Sil.-1 | 6 | 3.5%(质量)NaCl溶液 | 75 | 5 | 96 | [ |

| NaA | 2 | 3.5%(质量)NaCl溶液 | 75 | 9.58 | >99.9 | [ |

| SOD | 1 | 海水 | 177 | 3.5 | 99.99 | [ |

| NaA | 4 | 海水 | 69 | 1.9 | >99.9 | [ |

| ZSM-5沸石膜 M2 | 3.5 | 3.5%(质量)NaCl溶液 | 75 | 8.35 | >99.9 | 本文 |

| ZSM-5沸石膜 M7 | 3.5 | 模拟海水 | 75 | 6.92 | >99.9 | 本文 |

| 1 | Garcı́a-Rodrı́guez L. Renewable energy applications in desalination: state of the art[J]. Solar Energy, 2003, 75(5): 381-393. |

| 2 | Charcosset C. A review of membrane processes and renewable energies for desalination[J]. Desalination, 2009, 245(1/2/3): 214-231. |

| 3 | Feng X S, Huang R Y M. Liquid separation by membrane pervaporation: a review[J]. Industrial & Engineering Chemistry Research, 1997, 36(4): 1048-1066. |

| 4 | Chapman P D, Oliveira T, Livingston A G, et al. Membranes for the dehydration of solvents by pervaporation[J]. Journal of Membrane Science, 2008, 318(1/2): 5-37. |

| 5 | Shao P, Huang R Y M. Polymeric membrane pervaporation[J]. Journal of Membrane Science, 2007, 287(2): 162-179. |

| 6 | McLeary E E, Jansen J C, Kapteijn F. Zeolite based films, membranes and membrane reactors: progress and prospects[J]. Microporous and Mesoporous Materials, 2006, 90(1/2/3): 198-220. |

| 7 | Yu M, Noble R D, Falconer J L. Zeolite membranes: microstructure characterization and permeation mechanisms[J]. Accounts of Chemical Research, 2011, 44(11): 1196-1206. |

| 8 | Ladewig B P, Tan Y H, Lin C X C, et al. Preparation, characterization and performance of templated silica membranes in non-osmotic desalination[J]. Materials, 2011, 4(5): 845-856. |

| 9 | Liang B, Zhan W, Qi G G, et al. High performance graphene oxide/polyacrylonitrile composite pervaporation membranes for desalination applications[J]. Journal of Materials Chemistry A, 2015, 3(9): 5140-5147. |

| 10 | Yuan W H, Lin Y S, Yang W S. Molecular sieving MFI-type zeolite membranes for pervaporation separation of xylene isomers[J]. Journal of the American Chemical Society, 2004, 126(15): 4776-4777. |

| 11 | Wang Z B, Ge Q Q, Shao J, et al. High performance zeolite LTA pervaporation membranes on ceramic hollow fibers by dipcoating-wiping seed deposition[J]. Journal of the American Chemical Society, 2009, 131(20): 6910-6911. |

| 12 | Yamanaka N, Itakura M, Kiyozumi Y, et al. Acid stability evaluation of CHA-type zeolites synthesized by interzeolite conversion of FAU-type zeolite and their membrane application for dehydration of acetic acid aqueous solution[J]. Microporous and Mesoporous Materials, 2012, 158: 141-147. |

| 13 | Li X S, Kita H, Zhu H, et al. Synthesis of long-term acid-stable zeolite membranes and their potential application to esterification reactions[J]. Journal of Membrane Science, 2009, 339(1/2): 224-232. |

| 14 | Li J J, Li L Q. Organotemplate-free synthesis of ZSM-5 membrane for pervaporation dehydration of isopropanol[J]. Membrane Water Treatment, 2018, 10(5): 353-360. |

| 15 | Gao X, Zou X, Zhang F, et al. Eco-friendly fabrication of hydrophilic ZSM-5 membranes for alcohol upgrading[J]. Chemical Communications, 2013, 49(78): 8839-8841. |

| 16 | Zhu M H, Kumakiri I, Tanaka K, et al. Dehydration of acetic acid and esterification product by acid-stable ZSM-5 membrane[J]. Microporous and Mesoporous Materials, 2013, 181: 47-53. |

| 17 | Lai Z, Griselda B, Isabel D, et al. Microstructural optimization of a zeolite membrane for organic vapor separation[J]. Science, 2013, 300(5618): 456-460 |

| 18 | Yang J, Li L, Li W, et al. Tuning aluminum spatial distribution in ZSM-5 membranes: a new strategy to fabricate high performance and stable zeolite membranes for dehydration of acetic acid[J]. Chemical Communications, 2014, 50(93): 14654-14657. |

| 19 | Li L Q, Yang J H, Li J J, et al. Synthesis of high performance mordenite membranes from fluoride-containing dilute solution under microwave-assisted heating[J]. Journal of Membrane Science, 2016, 512: 83-92. |

| 20 | Li L Q, Yang J H, Li J J, et al. High performance ZSM-5 membranes on coarse macroporous α-Al2O3 supports for dehydration of alcohols[J]. AIChE Journal, 2016, 62(8): 2813-2824. |

| 21 | Raza W, Wang J X, Yang J H, et al. Progress in pervaporation membranes for dehydration of acetic acid[J]. Separation and Purification Technology, 2021, 262: 118338. |

| 22 | 刘秀凤, 徐凯, 张宝泉. ZSM-5和Fe-ZSM-5分子筛膜的合成与表面改性[J]. 化工学报, 2014, 65: 304-309. |

| Liu X F, Xu K, Zhang B Q. Synthesis and surface modification of ZSM-5 and Fe-ZSM-5 zeolite membranes[J]. CIESC Journal, 2014, 65: 304-309. | |

| 23 | Wu Y H, Tan H F, Li T M, et al. Pervaporation of aqueous solution of acetaldehyde through ZSM-5 filled PDMS composite membrane[J]. Chinese Journal of Chemical Engineering, 2012, 20(4): 625-632. |

| 24 | Duke M C, O'brien-Abraham J, Milne N, et al. Seawater desalination performance of MFI type membranes made by secondary growth[J]. Separation and Purification Technology, 2009, 68(3): 343-350. |

| 25 | Drobek M, Yacou C, Motuzas J, et al. Long term pervaporation desalination of tubular MFI zeolite membranes[J]. Journal of Membrane Science, 2012, 415/416: 816-823. |

| 26 | Cheng C H, Juttu G, Mitchell S F, et al. Synthesis, characterization, and growth rates of germanium silicalite-1 grown from clear solutions[J]. The Journal of Physical Chemistry B, 2006, 110(43): 21430-21437. |

| 27 | Cho C H, Oh K Y, Kim S K, et al. Pervaporative seawater desalination using NaA zeolite membrane: mechanisms of high water flux and high salt rejection[J]. Journal of Membrane Science, 2011, 371(1/2): 226-238. |

| 28 | Volkov A G, Paula S, Deamer D W. Two mechanisms of permeation of small neutral molecules and hydrated ions across phospholipid bilayers[J]. Bioelectrochemistry and Bioenergetics, 1997, 42(2): 153-160. |

| 29 | Zhou C, Zhou J J, Huang A S. Seeding-free synthesis of zeolite FAU membrane for seawater desalination by pervaporation[J]. Microporous and Mesoporous Materials, 2016, 234: 377-383. |

| 30 | Wang L, Yang J H, Wang J Q, et al. Microwave synthesis of NaA zeolite membranes on coarse macroporous α-Al2O3 tubes for desalination[J]. Microporous and Mesoporous Materials, 2020, 306: 110360. |

| 31 | Khajavi S, Jansen J C, Kapteijn F. Production of ultra pure water by desalination of seawater using a hydroxy sodalite membrane[J]. Journal of Membrane Science, 2010, 356(1/2): 52-57. |

| [1] | 邵苛苛, 宋孟杰, 江正勇, 张旋, 张龙, 高润淼, 甄泽康. 水平方向上冰中受陷气泡形成和分布实验研究[J]. 化工学报, 2023, 74(S1): 161-164. |

| [2] | 吴延鹏, 李晓宇, 钟乔洋. 静电纺丝纳米纤维双疏膜油性细颗粒物过滤性能实验分析[J]. 化工学报, 2023, 74(S1): 259-264. |

| [3] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [4] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [5] | 胡建波, 刘洪超, 胡齐, 黄美英, 宋先雨, 赵双良. 有机笼跨细胞膜易位行为的分子动力学模拟研究[J]. 化工学报, 2023, 74(9): 3756-3765. |

| [6] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [7] | 胡亚丽, 胡军勇, 马素霞, 孙禹坤, 谭学诣, 黄佳欣, 杨奉源. 逆电渗析热机新型工质开发及电化学特性研究[J]. 化工学报, 2023, 74(8): 3513-3521. |

| [8] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| [9] | 张贲, 王松柏, 魏子亚, 郝婷婷, 马学虎, 温荣福. 超亲水多孔金属结构驱动的毛细液膜冷凝及传热强化[J]. 化工学报, 2023, 74(7): 2824-2835. |

| [10] | 韩奎奎, 谭湘龙, 李金芝, 杨婷, 张春, 张永汾, 刘洪全, 于中伟, 顾学红. 四通道中空纤维MFI分子筛膜用于二甲苯异构体分离[J]. 化工学报, 2023, 74(6): 2468-2476. |

| [11] | 蔡斌, 张效林, 罗倩, 党江涛, 左栗源, 刘欣梅. 导电薄膜材料的研究进展[J]. 化工学报, 2023, 74(6): 2308-2321. |

| [12] | 陈朝光, 贾玉香, 汪锰. 以低浓度废酸驱动中和渗析脱盐的模拟与验证[J]. 化工学报, 2023, 74(6): 2486-2494. |

| [13] | 顾浩, 张福建, 刘珍, 周文轩, 张鹏, 张忠强. 力电耦合作用下多孔石墨烯膜时间维度的脱盐性能及机理研究[J]. 化工学报, 2023, 74(5): 2067-2074. |

| [14] | 袁子涵, 王淑彦, 邵宝力, 谢磊, 陈曦, 马一玫. 基于幂律液固曳力模型流化床内湿颗粒流动特性的研究[J]. 化工学报, 2023, 74(5): 2000-2012. |

| [15] | 孙永尧, 高秋英, 曾文广, 王佳铭, 陈艺飞, 周永哲, 贺高红, 阮雪华. 面向含氮油田伴生气提质利用的膜耦合分离工艺设计优化[J]. 化工学报, 2023, 74(5): 2034-2045. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号