化工学报 ›› 2022, Vol. 73 ›› Issue (1): 384-392.DOI: 10.11949/0438-1157.20210849

赵旭1( ),卜昌盛1(

),卜昌盛1( ),王昕晔1,张鑫2,程晓磊2,王乃继2,朴桂林1

),王昕晔1,张鑫2,程晓磊2,王乃继2,朴桂林1

收稿日期:2021-06-24

修回日期:2021-10-11

出版日期:2022-01-05

发布日期:2022-01-18

通讯作者:

卜昌盛

作者简介:赵旭(1996—),男,硕士研究生,基金资助:

Xu ZHAO1( ),Changsheng BU1(

),Changsheng BU1( ),Xinye WANG1,Xin ZHANG2,Xiaolei CHENG2,Naiji WANG2,Guilin PIAO1

),Xinye WANG1,Xin ZHANG2,Xiaolei CHENG2,Naiji WANG2,Guilin PIAO1

Received:2021-06-24

Revised:2021-10-11

Online:2022-01-05

Published:2022-01-18

Contact:

Changsheng BU

摘要:

流化床铁基载氧体辅助富氧燃烧下传统石英砂床料被铁基载氧体替代,铁基载氧体扩展了传统床料的“热载体”的功能,另承担了“氧载体”的角色,为调节炉内氧分布与煤燃烧过程匹配提供了新思路。本文在热重实验平台探究了10%O2/90%CO2气氛下分析纯Fe2O3、赤铁矿及钢渣三种铁基载氧体辅助无烟煤焦燃烧特性及动力学。结果表明,相较于纯无烟煤焦燃烧,铁基载氧体辅助燃烧下无烟煤焦的燃烧特性得到显著改善,其中燃烧速率提高29%以上,燃尽温度降低65℃以上,综合燃烧指数提升2倍以上,活化能与指前因子同步增加且表现出“补偿效应”。三种铁基载氧体中分析纯Fe2O3对无烟煤焦燃烧特性的改善略优于赤铁矿和钢渣,钢渣可作为流化床铁基载氧体辅助富氧燃烧的床料替代石英砂。

中图分类号:

赵旭, 卜昌盛, 王昕晔, 张鑫, 程晓磊, 王乃继, 朴桂林. 铁基载氧体辅助无烟煤焦富氧燃烧动力学分析[J]. 化工学报, 2022, 73(1): 384-392.

Xu ZHAO, Changsheng BU, Xinye WANG, Xin ZHANG, Xiaolei CHENG, Naiji WANG, Guilin PIAO. Kinetics investigation on iron-based oxygen carrier aided oxy-fuel combustion of anthracite char[J]. CIESC Journal, 2022, 73(1): 384-392.

| 含量(工业分析)/%(mass, ad) | 含量(元素分析)/%(mass, ad) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| M | A | V | FC | C | H | O | N | S | |

| 1.12 | 35.01 | 9.63 | 54.24 | 55.26 | 2.4 | 4.16 | 0.83 | 1.22 | |

表1 无烟煤工业分析及元素分析

Table 1 Proximate and ultimate analyses of anthracite coal

| 含量(工业分析)/%(mass, ad) | 含量(元素分析)/%(mass, ad) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| M | A | V | FC | C | H | O | N | S | |

| 1.12 | 35.01 | 9.63 | 54.24 | 55.26 | 2.4 | 4.16 | 0.83 | 1.22 | |

| 含量/%(mass) | ||||||

|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | K2O | MgO | Na2O |

| 52.41 | 32.91 | 4.5 | 3.87 | 1.76 | 0.53 | 0.15 |

表2 无烟煤灰成分分析

Table 2 Ash analysis of anthracite coal

| 含量/%(mass) | ||||||

|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | K2O | MgO | Na2O |

| 52.41 | 32.91 | 4.5 | 3.87 | 1.76 | 0.53 | 0.15 |

| 载氧体 | 含量/%(mass) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Fe2O3 | SiO2 | CaO | MgO | Al2O3 | MnO | P2O5 | TiO2 | 其他 | |

| Fe2O3 | 99.9 | ― | ― | ― | ― | ― | ― | ― | 0.1 |

| 赤铁矿 | 85.92 | 8.17 | 0.52 | 1.34 | 1.53 | ― | ― | ― | 2.52 |

| 钢渣 | 27.76 | 13.51 | 36.15 | 9.44 | 3.78 | 4.76 | 1.64 | 1.18 | 1.78 |

表3 三种铁基载氧体的主要化学组成成分

Table 3 Chemical composition of three types of iron-based oxygen carriers

| 载氧体 | 含量/%(mass) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Fe2O3 | SiO2 | CaO | MgO | Al2O3 | MnO | P2O5 | TiO2 | 其他 | |

| Fe2O3 | 99.9 | ― | ― | ― | ― | ― | ― | ― | 0.1 |

| 赤铁矿 | 85.92 | 8.17 | 0.52 | 1.34 | 1.53 | ― | ― | ― | 2.52 |

| 钢渣 | 27.76 | 13.51 | 36.15 | 9.44 | 3.78 | 4.76 | 1.64 | 1.18 | 1.78 |

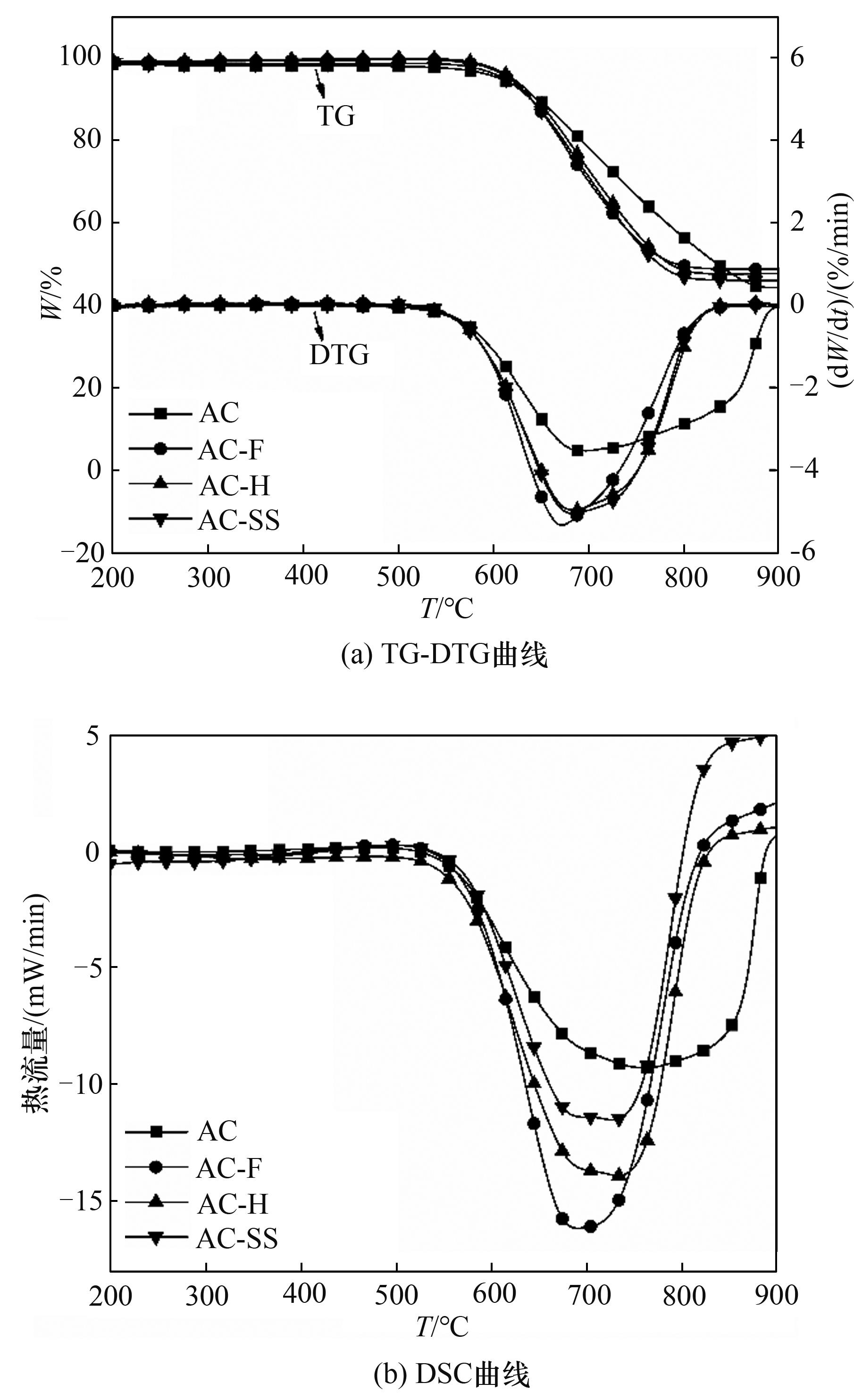

图3 15℃/min升温速率下无烟煤焦及三种铁基载氧体辅助燃烧下的TG-DTG-DSC曲线

Fig.3 TG-DTG-DSC curves of anthracite coal char and three types of iron-based oxygen carriers aided combustion at the heating rate of 15℃/min

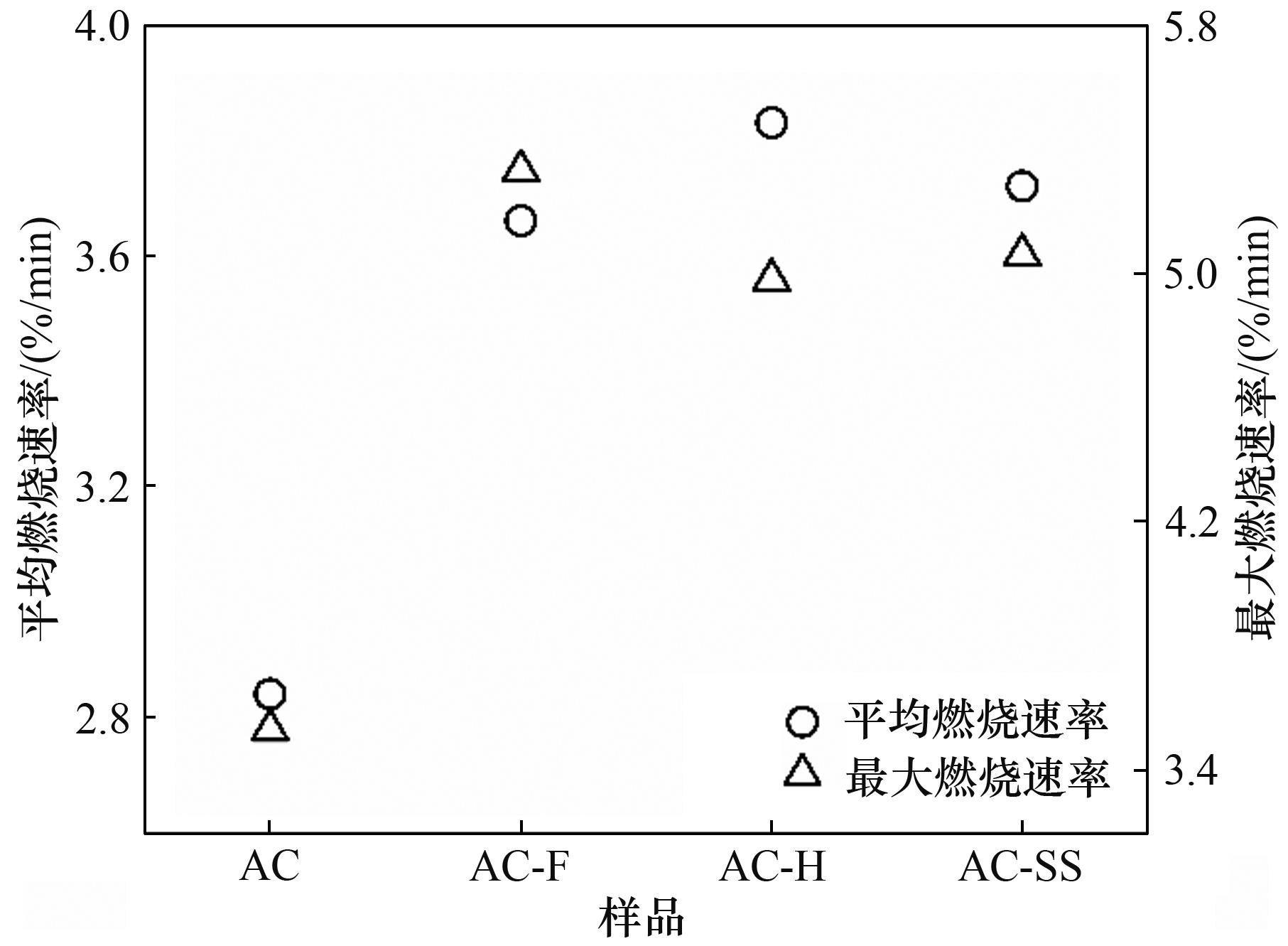

图4 15℃/min升温速率下无烟煤焦及三种铁基载氧体辅助燃烧下的平均与最大燃烧速率

Fig.4 Average and maximum burning rate of anthracite char and three types of iron-based oxygen carriers aided combustion at the heating rate of 15℃/min

| 样品 | ti/min | Ti/℃ | tb/min | Tb/℃ |

|---|---|---|---|---|

| AC | 39.2 | 617 | 56.2 | 878 |

| AC-F | 39.09 | 616 | 51.5 | 803 |

| AC-H | 39.26 | 619 | 51.4 | 802 |

| AC-SS | 39.24 | 619 | 51.9 | 810 |

表4 15℃/min升温速率下无烟煤焦及三种铁基载氧体辅助燃烧下的燃烧特性参数

Table 4 Combustion characteristics of anthracite char and three iron-based oxygen carriers aided combustion at the heating rate of 15℃/min

| 样品 | ti/min | Ti/℃ | tb/min | Tb/℃ |

|---|---|---|---|---|

| AC | 39.2 | 617 | 56.2 | 878 |

| AC-F | 39.09 | 616 | 51.5 | 803 |

| AC-H | 39.26 | 619 | 51.4 | 802 |

| AC-SS | 39.24 | 619 | 51.9 | 810 |

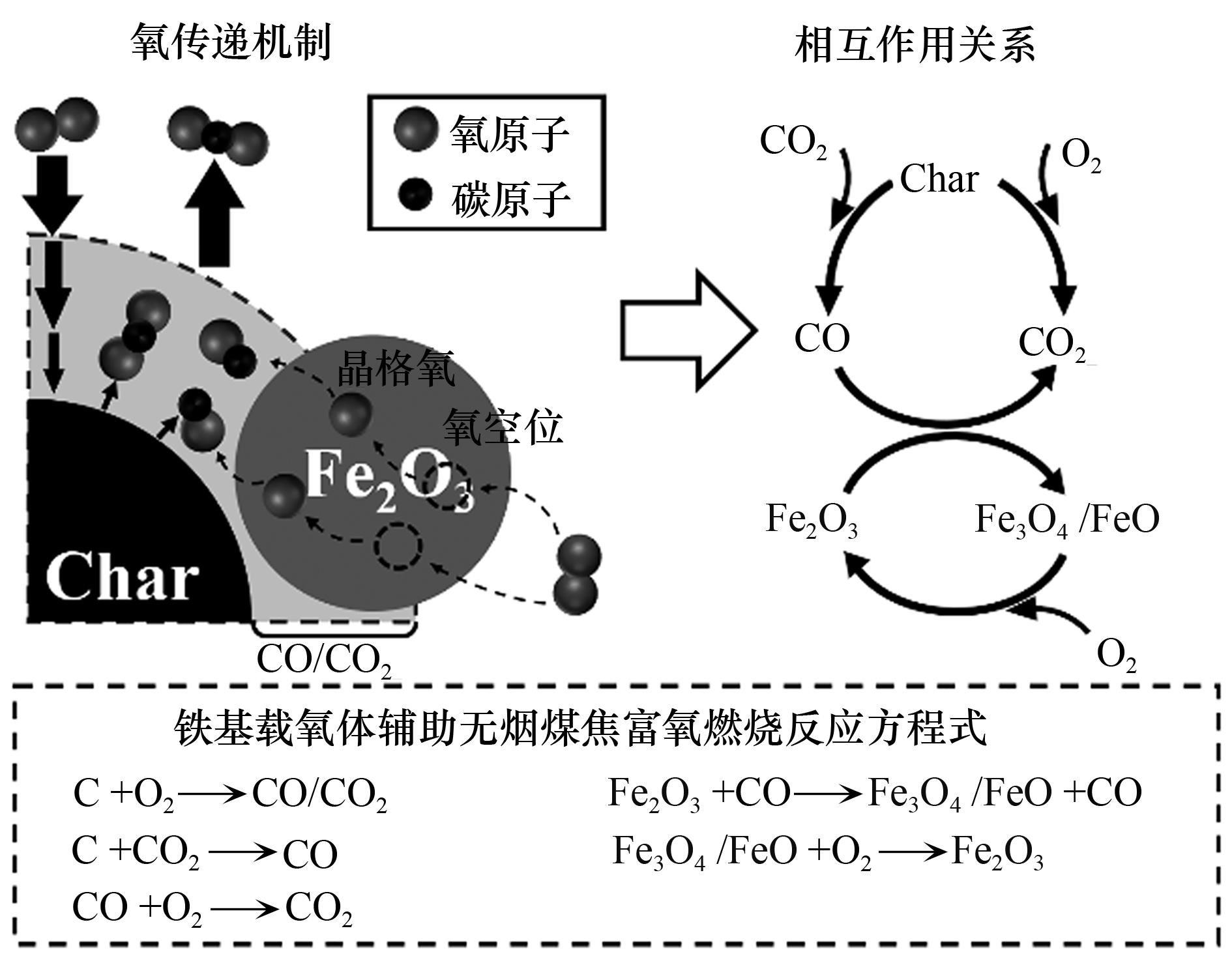

图5 铁基载氧体辅助无烟煤焦富氧燃烧下氧传递机制示意图

Fig.5 Schematic diagram of the mechanism of the oxygen transfer in iron-based oxygen aided oxy-fuel combustion of anthracite coal char

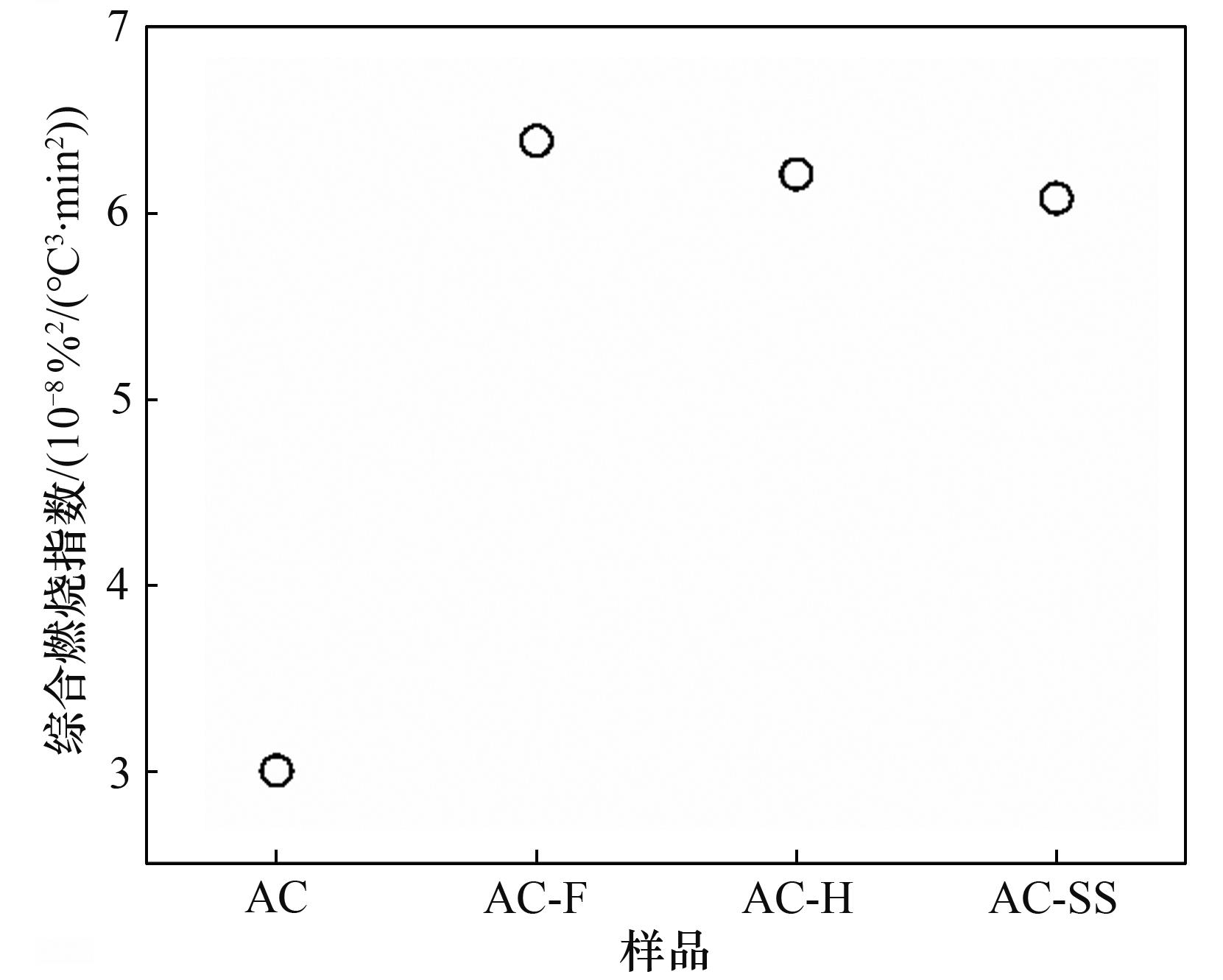

图6 15℃/min升温速率下无烟煤焦及三种铁基载氧体辅助燃烧下的综合燃烧指数

Fig.6 Comprehensive combustion index of anthracite coal char and three types of iron-based oxygen carriers aided combustion at the heating rate of 15℃/min

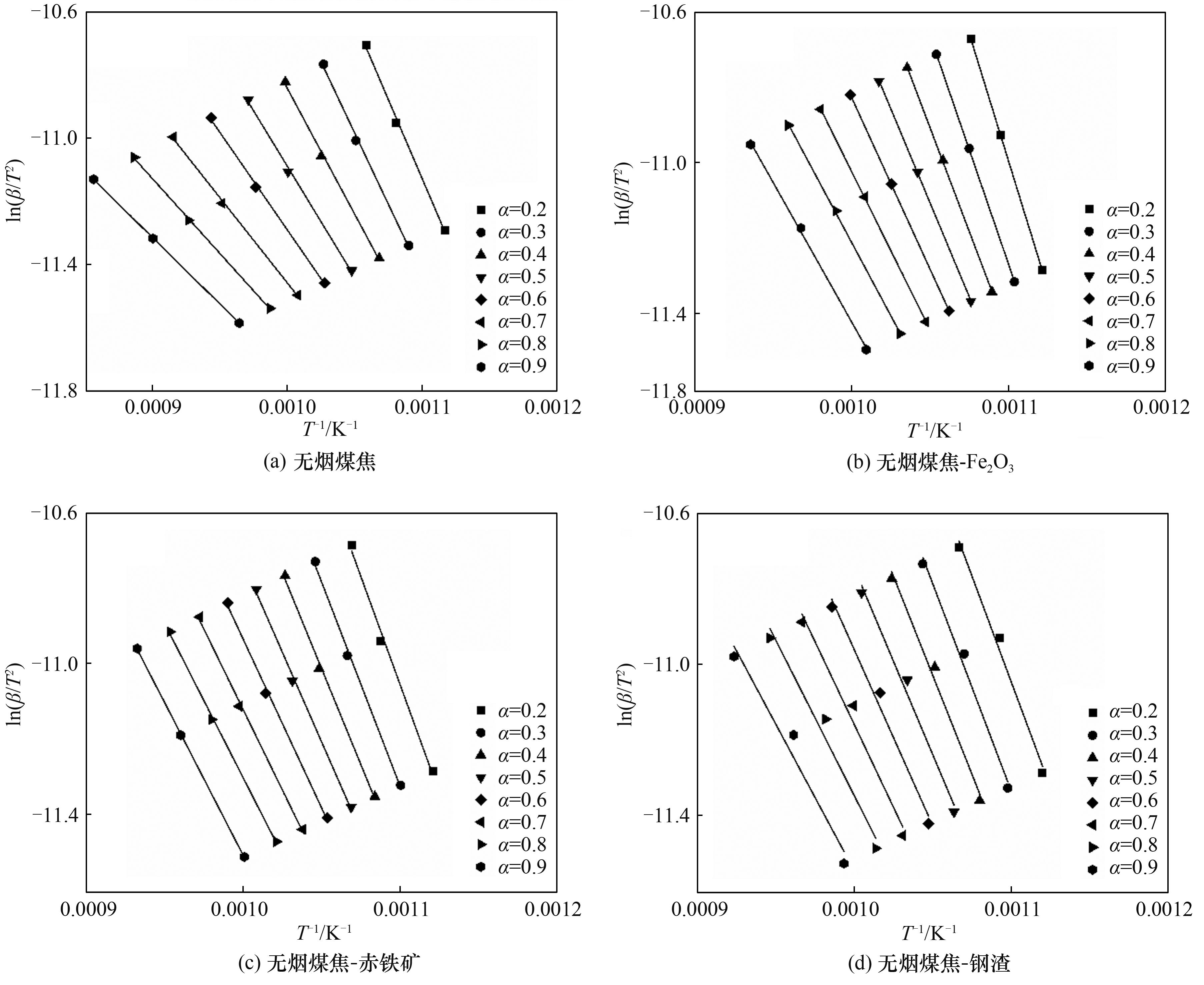

图7 无烟煤焦及三种铁基载氧体辅助燃烧下KAS法计算动力学参数拟合图

Fig.7 Fitting curves of the KAS method for anthracite char and three types of iron-based oxygen carriers aided combustion

| 转化率α | AC | AC-F | AC-H | AC-SS | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| E/(kJ/mol) | A/min-1 | R2 | E/(kJ/mol) | A/min-1 | R2 | E/(kJ/mol) | A/min-1 | R2 | E/(kJ/mol) | A/min-1 | R2 | |

| 0.2 | 82.84 | 8.45×103 | 0.99847 | 111.77 | 5.96×105 | 0.99999 | 95.07 | 5.27×104 | 0.99442 | 92.90 | 3.88×104 | 0.99015 |

| 0.3 | 74.94 | 1.97×103 | 0.99794 | 100.46 | 9.14×104 | 0.99994 | 89.67 | 1.86×104 | 0.99727 | 91.05 | 2.23×104 | 0.99032 |

| 0.4 | 66.11 | 442.17 | 0.99817 | 91.23 | 2.03×104 | 0.99988 | 84.29 | 7.04×103 | 0.99776 | 86.99 | 1.00×104 | 0.98957 |

| 0.5 | 58.24 | 117.99 | 0.99811 | 82.67 | 5.11×103 | 0.99992 | 78.78 | 2.70×103 | 0.99777 | 81.88 | 4.02×103 | 0.98765 |

| 0.6 | 51.24 | 36.56 | 0.99868 | 75.44 | 1.57×103 | 0.99993 | 74.17 | 1.20×103 | 0.99787 | 77.28 | 1.76×103 | 0.98532 |

| 0.7 | 44.80 | 12.47 | 0.99915 | 69.60 | 591.09 | 0.99987 | 70.69 | 621.41 | 0.99831 | 72.80 | 792.38 | 0.98131 |

| 0.8 | 39.31 | 4.89 | 0.99962 | 64.45 | 244.07 | 0.99975 | 67.69 | 346.58 | 0.99896 | 68.32 | 359.50 | 0.97437 |

| 0.9 | 34.94 | 2.25 | 0.99998 | 61.29 | 128.66 | 0.99905 | 67.09 | 260.15 | 0.99986 | 64.39 | 173.31 | 0.96528 |

| 平均值 | 56.55 | 1.38×103 | ― | 82.11 | 8.94×104 | ― | 78.43 | 1.04×104 | ― | 79.45 | 9.79×103 | ― |

表5 无烟煤焦及三种铁基载氧体辅助燃烧下的反应动力学活化能和指前因子

Table 5 Activation energy and pre-exponential factor of anthracite char and three types of iron-based oxygen carriers aided combustion

| 转化率α | AC | AC-F | AC-H | AC-SS | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| E/(kJ/mol) | A/min-1 | R2 | E/(kJ/mol) | A/min-1 | R2 | E/(kJ/mol) | A/min-1 | R2 | E/(kJ/mol) | A/min-1 | R2 | |

| 0.2 | 82.84 | 8.45×103 | 0.99847 | 111.77 | 5.96×105 | 0.99999 | 95.07 | 5.27×104 | 0.99442 | 92.90 | 3.88×104 | 0.99015 |

| 0.3 | 74.94 | 1.97×103 | 0.99794 | 100.46 | 9.14×104 | 0.99994 | 89.67 | 1.86×104 | 0.99727 | 91.05 | 2.23×104 | 0.99032 |

| 0.4 | 66.11 | 442.17 | 0.99817 | 91.23 | 2.03×104 | 0.99988 | 84.29 | 7.04×103 | 0.99776 | 86.99 | 1.00×104 | 0.98957 |

| 0.5 | 58.24 | 117.99 | 0.99811 | 82.67 | 5.11×103 | 0.99992 | 78.78 | 2.70×103 | 0.99777 | 81.88 | 4.02×103 | 0.98765 |

| 0.6 | 51.24 | 36.56 | 0.99868 | 75.44 | 1.57×103 | 0.99993 | 74.17 | 1.20×103 | 0.99787 | 77.28 | 1.76×103 | 0.98532 |

| 0.7 | 44.80 | 12.47 | 0.99915 | 69.60 | 591.09 | 0.99987 | 70.69 | 621.41 | 0.99831 | 72.80 | 792.38 | 0.98131 |

| 0.8 | 39.31 | 4.89 | 0.99962 | 64.45 | 244.07 | 0.99975 | 67.69 | 346.58 | 0.99896 | 68.32 | 359.50 | 0.97437 |

| 0.9 | 34.94 | 2.25 | 0.99998 | 61.29 | 128.66 | 0.99905 | 67.09 | 260.15 | 0.99986 | 64.39 | 173.31 | 0.96528 |

| 平均值 | 56.55 | 1.38×103 | ― | 82.11 | 8.94×104 | ― | 78.43 | 1.04×104 | ― | 79.45 | 9.79×103 | ― |

图8 无烟煤焦及三种铁基载氧体辅助燃烧下活化能E与指前因子A间的补偿效应

Fig.8 Fitting curves of compensation effect between the activation energy E and the pre-exponential factor A for anthracite char and three types of iron-based oxygen carriers aided combustion

| 样品 | a | b | R2 |

|---|---|---|---|

| AC | 0.170 | 5.13 | 0.999 |

| AC-F | 0.166 | 5.19 | 0.999 |

| AC-H | 0.185 | 6.68 | 0.998 |

| AC-SS | 0.185 | 6.81 | 0.998 |

表6 无烟煤焦及三种铁基载氧体辅助燃烧的补偿因子及线性相关性系数

Table 6 Compensation factors and fitting coefficients for anthracite char and three iron-based oxygen carriers aided combustion

| 样品 | a | b | R2 |

|---|---|---|---|

| AC | 0.170 | 5.13 | 0.999 |

| AC-F | 0.166 | 5.19 | 0.999 |

| AC-H | 0.185 | 6.68 | 0.998 |

| AC-SS | 0.185 | 6.81 | 0.998 |

| 1 | Leckner B, Gómez-Barea A. Oxy-fuel combustion in circulating fluidized bed boilers[J]. Applied Energy, 2014, 125: 308-318. |

| 2 | Duan L B, Li L, Liu D Y, et al. Fundamental study on fuel-staged oxy-fuel fluidized bed combustion[J]. Combustion and Flame, 2019, 206: 227-238. |

| 3 | Duan L B, Sun H C, Zhao C S, et al. Coal combustion characteristics on an oxy-fuel circulating fluidized bed combustor with warm flue gas recycle[J]. Fuel, 2014, 127: 47-51. |

| 4 | Bu C S, Pallarès D, Chen X P, et al. Oxy-fuel combustion of a single fuel particle in a fluidized bed: char combustion characteristics, an experimental study[J]. Chemical Engineering Journal, 2016, 287: 649-656. |

| 5 | Salinero J, Gómez-Barea A, Fuentes-Cano D, et al. The influence of CO2 gas concentration on the char temperature and conversion during oxy-fuel combustion in a fluidized bed[J]. Applied Energy, 2018, 215: 116-130. |

| 6 | Jin X Z, Lu J F, Yang H R, et al. Comprehensive mathematical model for coal combustion in a circulating fluidized bed combustor[J]. Tsinghua Science and Technology, 2001, 6(4): 319-325. |

| 7 | Fernandez M J, Lyngfelt A, Johnsson F. Gas concentrations in the lower part of the combustion chamber of a circulating fluidized bed boiler:influence of bed height[J]. Energy & Fuels, 2000, 14(6): 1127-1132. |

| 8 | Yue G X, Lu J F, Zhang H, et al. Design theory of circulating fluidized bed boilers[C]//Proceedings of 18th International Conference on Fluidized Bed Combustion. Toronto, Ontario, Canada, 2008: 135-146. |

| 9 | Leckner B. Fluidized bed combustion: mixing and pollutant limitation[J]. Progress in Energy and Combustion Science, 1998, 24(1): 31-61. |

| 10 | Thunman H, Lind F, Breitholtz C, et al. Using an oxygen-carrier as bed material for combustion of biomass in a 12-MWth circulating fluidized-bed boiler[J]. Fuel, 2013, 113: 300-309. |

| 11 | Lind F, Corcoran A, Thunman H. Validation of the oxygen buffering ability of bed materials used for OCAC in a large scale CFB boiler[J]. Powder Technology, 2017, 316: 462-468. |

| 12 | Corcoran A, Knutsson P, Lind F, et al. Mechanism for migration and layer growth of biomass ash on ilmenite used for oxygen carrier aided combustion[J]. Energy & Fuels, 2018, 32(8): 8845-8856. |

| 13 | Hildor F, Mattisson T, Leion H, et al. Steel converter slag as an oxygen carrier in a 12 MWth CFB boiler—ash interaction and material evolution[J]. International Journal of Greenhouse Gas Control, 2019, 88: 321-331. |

| 14 | Wang P N, Leion H, Yang H R. Oxygen-carrier-aided combustion in a bench-scale fluidized bed[J]. Energy & Fuels, 2017, 31(6): 6463-6471. |

| 15 | Hughes R W, Lu D Y, Symonds R T. Improvement of oxy-FBC using oxygen carriers: concept and combustion performance[J]. Energy & Fuels, 2017, 31(9): 10101-10115. |

| 16 | Rydén M, Hanning M L, Lind F. Oxygen carrier aided combustion (OCAC) of wood chips in a 12 MWth circulating fluidized bed boiler using steel converter slag as bed material[J]. Applied Sciences, 2018, 8(12): 2657. |

| 17 | Adanez J, Abad A, Garcia-Labiano F, et al. Progress in chemical-looping combustion and reforming technologies[J]. Progress in Energy and Combustion Science, 2012, 38(2): 215-282. |

| 18 | Adánez J, Abad A, Mendiara T, et al. Chemical looping combustion of solid fuels[J]. Progress in Energy and Combustion Science, 2018, 65: 6-66. |

| 19 | 卜昌盛, 王昕晔, 张居兵, 等. 一种流化床载氧体辅助富氧燃烧系统及方法: 110094722B[P]. 2020-08-18. |

| Bu C S, Wang X Y, Zhang J B, et al. System and method of oxygen carrier aided oxy-fuel fluidized bed combustion: 110094722B[P]. 2020-08-18 | |

| 20 | Ismail M, Liu W, Dunstan M T, et al. Development and performance of iron based oxygen carriers containing calcium ferrites for chemical looping combustion and production of hydrogen[J]. International Journal of Hydrogen Energy, 2016, 41(7): 4073-4084. |

| 21 | Sun Z, Chen S Y, Hu J, et al. Ca2Fe2O5: a promising oxygen carrier for CO/CH4 conversion and almost-pure H2 production with inherent CO2 capture over a two-step chemical looping hydrogen generation process[J]. Applied Energy, 2018, 211: 431-442. |

| 22 | Feng Y C, Wang N N, Guo X. Reaction mechanism of methane conversion over Ca2Fe2O5 oxygen carrier in chemical looping hydrogen production[J]. Fuel, 2021, 290: 120094-120102 |

| 23 | Lin Y S, Ma X Q, Ning X X, et al. TGA-FTIR analysis of co-combustion characteristics of paper sludge and oil-palm solid wastes[J]. Energy Conversion and Management, 2015, 89: 727-734. |

| 24 | Parshetti G K, Quek A, Betha R, et al. TGA-FTIR investigation of co-combustion characteristics of blends of hydrothermally carbonized oil palm biomass (EFB) and coal[J]. Fuel Processing Technology, 2014, 118: 228-234. |

| 25 | Su W, Ma H Z, Wang Q H, et al. Thermal behavior and gaseous emission analysis during co-combustion of ethanol fermentation residue from food waste and coal using TG-FTIR[J]. Journal of Analytical and Applied Pyrolysis, 2013, 99: 79-84. |

| 26 | Li X G, Lv Y, Ma B G, et al. Thermogravimetric investigation on co-combustion characteristics of tobacco residue and high-ash anthracite coal[J]. Bioresource Technology, 2011, 102(20): 9783-9787. |

| 27 | Zhang L H, Duan F, Huang Y J. Thermogravimetric investigation on characteristic of biomass combustion under the effect of organic calcium compounds[J]. Bioresource Technology, 2015, 175: 174-181. |

| 28 | Gong X Z, Guo Z C, Wang Z. Reactivity of pulverized coals during combustion catalyzed by CeO2 and Fe2O3[J]. Combustion and Flame, 2010, 157(2): 351-356. |

| 29 | Basu P. Combustion of coal in circulating fluidized-bed boilers: a review[J]. Chemical Engineering Science, 1999, 54(22): 5547-5557. |

| 30 | Arthur J R. Reactions between carbon and oxygen[J]. Transactions of the Faraday Society, 1951, 47: 164. |

| 31 | van Devener B, Anderson S L. Breakdown and combustion of JP-10 fuel catalyzed by nanoparticulate CeO2 and Fe2O3[J]. Energy & Fuels, 2006, 20(5): 1886-1894. |

| 32 | Gong X Z, Guo Z C, Wang Z. Variation on anthracite combustion efficiency with CeO2 and Fe2O3 addition by Differential Thermal Analysis (DTA)[J]. Energy, 2010, 35(2): 506-511. |

| 33 | Kongkaew N, Pruksakit W, Patumsawad S. Thermogravimetric kinetic analysis of the pyrolysis of rice straw[J]. Energy Procedia, 2015, 79: 663-670. |

| 34 | 胡荣祖, 高胜利, 赵凤起. 热分析动力学[M]. 2版. 北京: 科学出版社, 2008. |

| Hu R Z, Gao S L, Zhao F Q. Kinetics of Thermal Analysis[M]. 2nd ed. Beijing: Science Press, 2008. | |

| 35 | 谢克昌. 煤的结构与反应性[M]. 北京: 科学出版社, 2002. |

| Xie K C. Structure and Reactivity of Coal[M]. Beijing: Science Press, 2002. | |

| 36 | Brown M E, Galwey A K. The significance of “compensation effects” appearing in data published in “computational aspects of kinetic analysis”: ICTAC project, 2000[J]. Thermochimica Acta, 2002, 387(2): 173-183. |

| [1] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [2] | 汪林正, 陆俞冰, 张睿智, 罗永浩. 基于分子动力学模拟的VOCs热氧化特性分析[J]. 化工学报, 2023, 74(8): 3242-3255. |

| [3] | 张蒙蒙, 颜冬, 沈永峰, 李文翠. 电解液类型对双离子电池阴阳离子储存行为的影响[J]. 化工学报, 2023, 74(7): 3116-3126. |

| [4] | 毛磊, 刘冠章, 袁航, 张光亚. 可捕集CO2的纳米碳酸酐酶粒子的高效制备及性能研究[J]. 化工学报, 2023, 74(6): 2589-2598. |

| [5] | 卫雪岩, 钱勇. 微米级铁粉燃料中低温氧化反应特性及其动力学研究[J]. 化工学报, 2023, 74(6): 2624-2638. |

| [6] | 王皓, 唐思扬, 钟山, 梁斌. MEA吸收CO2富液解吸过程中固体颗粒表面的强化作用分析[J]. 化工学报, 2023, 74(4): 1539-1548. |

| [7] | 禹进, 余彬彬, 蒋新生. 一种基于虚拟组分的燃烧调控化学作用量化及分析方法研究[J]. 化工学报, 2023, 74(3): 1303-1312. |

| [8] | 王煦清, 严圣林, 朱礼涛, 张希宝, 罗正鸿. 填料塔中有机胺吸收CO2气液传质的研究进展[J]. 化工学报, 2023, 74(1): 237-256. |

| [9] | 陈晨, 杨倩, 陈云, 张睿, 刘冬. 不同氧浓度下煤挥发分燃烧的化学动力学研究[J]. 化工学报, 2022, 73(9): 4133-4146. |

| [10] | 刘新华, 韩振南, 韩健, 梁斌, 张楠, 胡善伟, 白丁荣, 许光文. 基于热解与燃烧反应重构的低NO x 解耦燃烧原理与技术[J]. 化工学报, 2022, 73(8): 3355-3368. |

| [11] | 张劢, 田瑶, 郭之旗, 王叶, 窦广进, 宋浩. 光催化-生物杂合系统设计优化用于燃料和化学品绿色合成[J]. 化工学报, 2022, 73(7): 2774-2789. |

| [12] | 陈玉弓, 陈昊, 黄耀松. 基于分子反应动力学模拟的六甲基二硅氧烷热解机理研究[J]. 化工学报, 2022, 73(7): 2844-2857. |

| [13] | 李淼, 赵虹, 姜标, 陈思远, 闫龙. 煤制乙炔关键中间体BaC2合成的热力学分析[J]. 化工学报, 2022, 73(5): 1908-1919. |

| [14] | 何聪, 钟文琪, 周冠文, 陈曦. 高海拔地区水泥生料悬浮炉分解特性研究[J]. 化工学报, 2022, 73(5): 2120-2129. |

| [15] | 李雪, 东明, 张璜, 谢俊. 潮湿环境下微尺度颗粒撞击平板的动力学研究[J]. 化工学报, 2022, 73(5): 1940-1946. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号