化工学报 ›› 2022, Vol. 73 ›› Issue (1): 461-469.DOI: 10.11949/0438-1157.20211267

纪文涛1,2,3( ),李璐1,2,3,李忠1,2,3,何佳1,2,3,杨晶晶1,2,3,王燕1,2,3(

),李璐1,2,3,李忠1,2,3,何佳1,2,3,杨晶晶1,2,3,王燕1,2,3( )

)

收稿日期:2021-09-01

修回日期:2021-09-24

出版日期:2022-01-05

发布日期:2022-01-18

通讯作者:

王燕

作者简介:纪文涛(1989—),男,博士,讲师,基金资助:

Wentao JI1,2,3( ),Lu LI1,2,3,Zhong LI1,2,3,Jia HE1,2,3,Jingjing YANG1,2,3,Yan WANG1,2,3(

),Lu LI1,2,3,Zhong LI1,2,3,Jia HE1,2,3,Jingjing YANG1,2,3,Yan WANG1,2,3( )

)

Received:2021-09-01

Revised:2021-09-24

Online:2022-01-05

Published:2022-01-18

Contact:

Yan WANG

摘要:

为研究聚磷酸铵(APP)对聚甲基丙烯酸甲酯(PMMA)粉尘爆炸的抑制特性,从最大爆炸压力Pex、最大爆炸压力上升速率(dP/dt)ex、最小点火能量(MIE)和最小点火温度(MIT)等多方面分析了APP对PMMA粉尘爆炸特性的影响。结果表明,APP可有效降低PMMA粉尘最大爆炸压力和最大爆炸压力上升速率,并延迟最大爆炸压力峰值到达时间;对于不同浓度PMMA粉尘的MIE,APP均有显著的抑制效果,且存在临界抑制浓度配比1∶1,在该浓度配比条件下PMMA粉尘很难通过静电点火;对于不同浓度PMMA粉尘的MIT,APP同样均具有一定抑制作用,且相同浓度配比条件下,抑制作用随PMMA浓度的增大而增大。此外,结合APP和PMMA热特性及红外光谱分析结果,分析了APP抑制PMMA粉尘爆炸机理。

中图分类号:

纪文涛, 李璐, 李忠, 何佳, 杨晶晶, 王燕. 聚磷酸铵抑制PMMA粉尘爆炸特性研究[J]. 化工学报, 2022, 73(1): 461-469.

Wentao JI, Lu LI, Zhong LI, Jia HE, Jingjing YANG, Yan WANG. Study on suppression of PMMA dust explosion by ammonium polyphosphate[J]. CIESC Journal, 2022, 73(1): 461-469.

图6 不同浓度PMMA粉尘的最大爆炸压力及最大爆炸压力上升速率

Fig.6 Maximum explosion pressure and maximum rate of pressure rise of the PMMA particles as a function of dust concentration

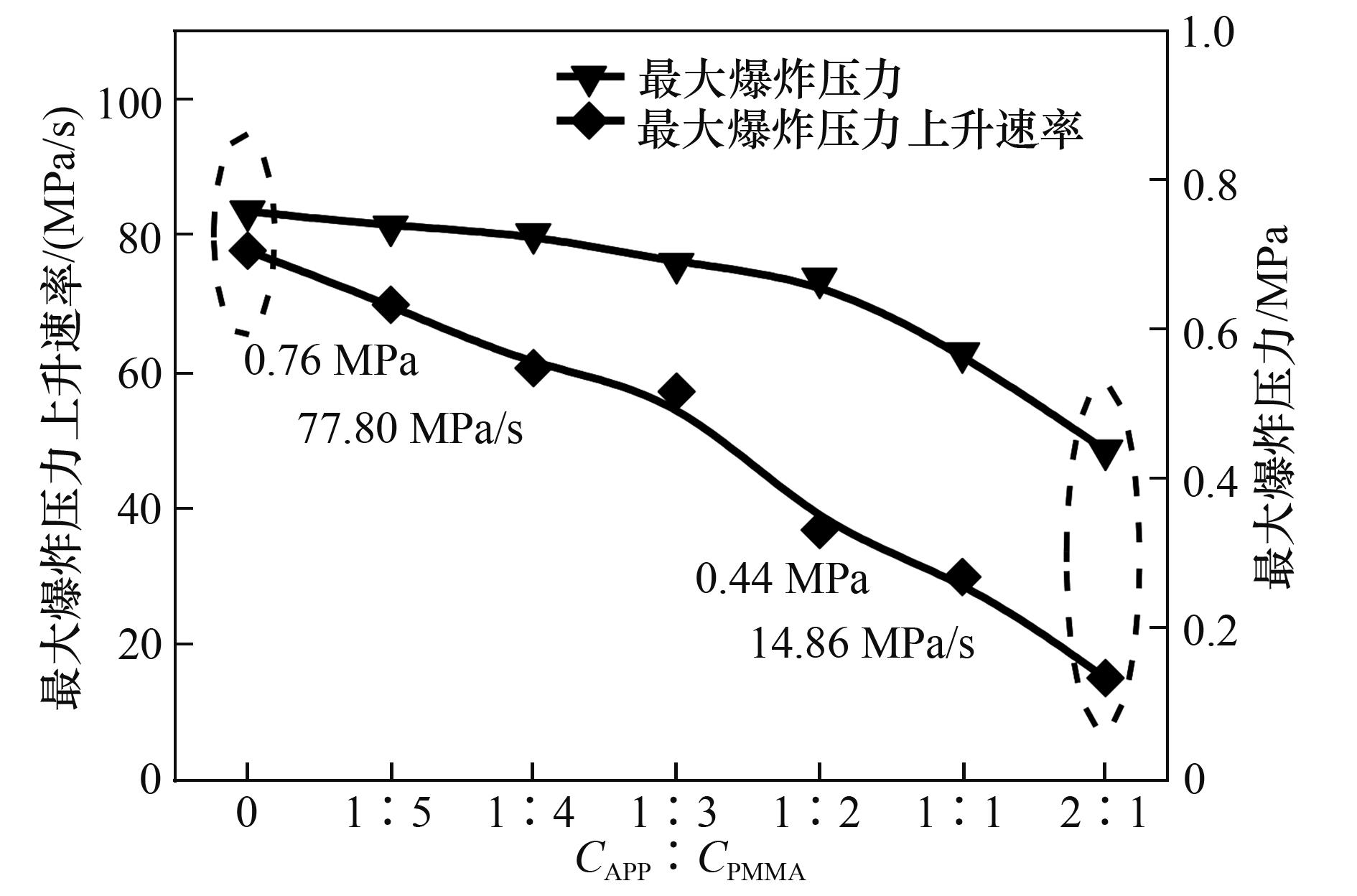

图7 PMMA最大爆炸压力和最大爆炸压力上升速率随APP浓度配比变化规律

Fig.7 Maximum explosion pressure and rate of increase of the maximum explosion pressure of PMMA varied with APP concentration ratio

| 1 | 邵久亮. 浅谈有机玻璃的特性与用途[J]. 农业科技与信息, 2008(10): 64. |

| Shao J L. Discussion of characteristics and application of organic glass [J]. Information of Agricultural Science and Technology,2008(10): 64. | |

| 2 | 甘波, 高伟, 张新燕, 等. 不同粒径PMMA粉尘云火焰温度特性研究[J]. 爆炸与冲击, 2019, 39(1): 140-147. |

| Gan B, Gao W, Zhang X Y, et al. Flame temperatures of PMMA dust clouds with different particle size distributions[J]. Explosion and Shock Waves, 2019, 39(1): 140-147. | |

| 3 | 张新燕. 纳米PMMA粉尘爆炸火焰传播特性研究[D]. 大连: 大连理工大学, 2017. |

| Zhang X Y. Flame propagation behaviors of nano PMMA dust explosions[D]. Dalian: Dalian University of Technology, 2017. | |

| 4 | Zhang X Y, Yu J L, Yan X Q, et al. Flame propagation behaviors of nano-and micro-scale PMMA dust explosions[J]. Journal of Loss Prevention in the Process Industries, 2016, 40: 101-111. |

| 5 | Huang L, Jiang H P, Gao W. Effect of particle size and dust layer size on ignition characteristics of PMMA dust layer on hot surface[J]. Journal of Loss Prevention in the Process Industries, 2021, 71: 104515. |

| 6 | Yuzuriha Y, Gao W, Mogi T, et al. Effects of particle size distributions on flame propagation behavior through dust clouds of PMMA[J]. Journal of Loss Prevention in the Process Industries, 2017, 49: 852-858. |

| 7 | 李岳, 李健, 高伟, 等. 不同粒径PMMA粉尘爆炸特性研究[J]. 安全、健康和环境, 2017, 17(11): 18-22. |

| Li Y, Li J, Gao W, et al. Experimental investigation on explosion characteristic of PMMA dust with different particle sizes[J].Safety Health & Environment, 2017, 17(11): 18-22. | |

| 8 | Zhang X Y, Yu J L, Sun J H, et al. Effects of turbulent intensity on nano-PMMA flame propagation behaviors[J]. Journal of Loss Prevention in the Process Industries, 2016, 44: 119-124. |

| 9 | 蒋笠, 潘勇, 管进, 等. 微米级聚甲基丙烯酸甲酯最小点火能[J]. 消防科学与技术, 2017, 36(7): 893-895. |

| Jiang L, Pan Y, Guan J, et al. Minimum ignition energy of micron PMMA[J]. Fire Science and Technology, 2017, 36(7):893-895. | |

| 10 | Gao W, Yu J L, Li J, et al. Experimental investigation on micro- and nano-PMMA dust explosion venting at elevated static activation overpressures[J]. Powder Technology, 2016, 301: 713-722. |

| 11 | Zhang X Y, Yu J L, Gao W, et al. Effects of particle size distributions on PMMA dust flame propagation behaviors[J]. Powder Technology, 2017, 317: 197-208. |

| 12 | 李键. 微纳米PMMA粉尘爆炸及泄放实验研究[D]. 大连: 大连理工大学, 2015. |

| Li J. Experimental investigation on explosion and venting of micron and nano PMMA dusts[D]. Dalian: Dalian University of Technology, 2015. | |

| 13 | Zhang X Y, Gao W, Yu J L, et al. Effect of flame propagation regime on pressure evolution of nano and micron PMMA dust explosions[J]. Journal of Loss Prevention in the Process Industries, 2020, 63: 104037. |

| 14 | 胡源, 宋磊, 尤飞, 等. 火灾化学导论[M]. 北京: 化学工业出版社, 2007. |

| Hu Y, Song L, You F, et al. An Introduction to Fire Chemistry[M]. Beijing: Chemical Industry Press, 2007. | |

| 15 | 孟祥卿. 气/固两相抑制剂的甲烷抑爆特性研究[D]. 焦作: 河南理工大学, 2019. |

| Meng X Q. Suppression characteristics of gas/solid two-phase inhibitors on methane explosion[D]. Jiaozuo: Henan Polytechnic University, 2019. | |

| 16 | Wang Y, Lin C D, Qi Y Q, et al. Suppression of polyethylene dust explosion by sodium bicarbonate[J]. Powder Technology, 2020, 367: 206-212. |

| 17 | 周建华. 纳米PMMA粉尘爆炸抑制机理研究[D]. 大连: 大连理工大学, 2019. |

| Zhou J H. Suppression mechanism of nano PMMA dust explosions[D]. Dalian: Dalian University of Technology, 2019. | |

| 18 | Zhou J H, Jiang H P, Zhou Y H, et al. Flame suppression of 100 nm PMMA dust explosion by KHCO3 with different particle size[J]. Process Safety and Environmental Protection, 2019, 132: 303-312. |

| 19 | Zhou J H, Li B, Ma D Q, et al. Suppression of nano-polymethyl methacrylate dust explosions by ABC powder[J]. Process Safety and Environmental Protection, 2019, 122: 144-152. |

| 20 | Gan B, Li B, Jiang H P, et al. Suppression of polymethyl methacrylate dust explosion by ultrafine water mist/additives[J]. Journal of Hazardous Materials, 2018, 351: 346-355. |

| 21 | Huang L, Jiang H P, Zhang T J, et al. Effect of superfine KHCO3 and ABC powder on ignition sensitivity of PMMA dust layer[J]. Journal of Loss Prevention in the Process Industries, 2021, 72: 104567. |

| 22 | Korobeinichev O P, Trubachev S A, Joshi A K, et al. Experimental and numerical studies of downward flame spread over PMMA with and without addition of triphenyl phosphate[J]. Proceedings of the Combustion Institute, 2021, 38(3): 4867-4875. |

| 23 | Trubachev S A, Korobeinichev O P, Karpov A I, et al. The effect of triphenyl phosphate inhibition on flame propagation over cast PMMA slabs[J]. Proceedings of the Combustion Institute, 2021, 38(3): 4635-4644. |

| 24 | 胡红丹. 聚磷酸铵阻燃剂对森林可燃物阻燃作用的研究[D]. 哈尔滨: 东北林业大学, 2013. |

| Hu H D. Investigation of ammonium polyphosphate flame retardant on the forest fuels[D]. Harbin: Northeast Forestry University, 2013. | |

| 25 | 员亚龙, 陈先锋, 袁必和, 等. 聚磷酸铵对糖粉火焰传播特性的影响研究[J]. 中国安全科学学报, 2019, 29(11): 71-76. |

| Yuan Y L,Chen X F,Yuan B H, et al. Effects of ammonium polyphosphate on flame propagation characteristics of sugardust[J].China Safety Science Journal, 2019, 29(11): 71-76. | |

| 26 | Yang J, Yu Y, Li Y H, et al. Inerting effects of ammonium polyphosphate on explosion characteristics of polypropylene dust[J].Process Safety and Environmental Protection, 2019, 130: 221-230. |

| 27 | European Committee for Standardization (ECS). Potentially Explosive Atmospheres, Explosion Prevention and Protection, Determination of Minimum Ignition Energy of Dust/Air Mixtures:EN 13821[S]. Brussels, Belgium: ECS, 2003. |

| 28 | Yu Y, Li Y H, Zhang Q W, et al. Experimental investigation of the inerting effect of crystalline Ⅱ type ammonium polyphosphate on explosion characteristics of micron-size acrylates copolymer dust[J]. Journal of Hazardous Materials, 2018, 344: 558-565. |

| 29 | BSI. Code of Practice for Control of Undesirable Static Electricity: [S]. General Considerations. London, British:BSI, 1991. |

| 30 | 罗振敏. 链式反应理论在矿井瓦斯抑爆中的应用[J]. 煤矿安全, 2009, 40(2): 67-69. |

| Luo Z M. Application of chain reaction theory in mine gas explosion suppression[J]. Safety in Coal Mines, 2009, 40(2):67-69. | |

| 31 | 陈勇, 谭晓明, 熊航行, 等. 聚甲基丙烯酸甲酯微球表面镀银的研究[J]. 贵金属, 2020, 41(1): 37-42. |

| Chen Y, Tan X M, Xiong H X, et al. Study on silver plating on the surface of PMMA microspheres[J]. Precious Metals, 2020, 41(1):37-42. | |

| 32 | 于守武, 肖淑娟, 赵泽文, 等. 蜜胺-环氧树脂双层包覆聚磷酸铵及其阻燃PP的研究[J]. 化工学报, 2019, 70(6): 2370-2376. |

| Yu S W, Xiao S J, Zhao Z W, et al. Study on ammonium polyphosphate coated with melamine-epoxy resin and its application in PP[J]. CIESC Journal, 2019, 70(6): 2370-2376. | |

| 33 | Jiang H P, Bi M S, Zhang T J, et al. A novel reactive P-containing composite with an ordered porous structure for suppressing nano-Al dust explosions[J]. Chemical Engineering Journal, 2021, 416: 129156. |

| 34 | Jiang H P, Bi M S, Huang L, et al. Suppression mechanism of ultrafine water mist containing phosphorus compounds in methane/coal dust explosions[J]. Energy, 2022, 239: 121987. |

| [1] | 李珍宝, 李超, 王虎, 王绍瑞, 黎泉. MPP抑制铝镁合金粉尘爆炸微观机理研究[J]. 化工学报, 2023, 74(8): 3608-3614. |

| [2] | 杨克, 贾岳, 纪虹, 邢志祥, 蒋军成. 垃圾焚烧飞灰对瓦斯爆炸压力及火焰传播的抑制作用及机理研究[J]. 化工学报, 2023, 74(8): 3597-3607. |

| [3] | 刘晓洋, 喻健良, 侯玉洁, 闫兴清, 张振华, 吕先舒. 螺旋微通道对掺氢甲烷爆轰传播的影响[J]. 化工学报, 2023, 74(7): 3139-3148. |

| [4] | 何汉兵, 刘真, 陈勇, 王小锋, 曾婧. 直写成型电极锰氧化物粉末的合成与浆料调控[J]. 化工学报, 2023, 74(5): 2239-2247. |

| [5] | 贠程, 王倩琳, 陈锋, 张鑫, 窦站, 颜廷俊. 基于社团结构的化工过程风险演化路径深度挖掘[J]. 化工学报, 2023, 74(4): 1639-1650. |

| [6] | 衣思敏, 马亚丽, 刘伟强, 张金帅, 岳岩, 郑强, 贾松岩, 李雪. 微晶菱镁矿蒸氨及水化动力学研究[J]. 化工学报, 2023, 74(4): 1578-1586. |

| [7] | 肖忠良, 尹碧露, 宋刘斌, 匡尹杰, 赵亭亭, 刘成, 袁荣耀. 废旧锂离子电池回收工艺研究进展及其安全风险分析[J]. 化工学报, 2023, 74(4): 1446-1456. |

| [8] | 武子超, 汪志雷, 李荣业, 李可昕, 华敏, 潘旭海, 王三明, 蒋军成. 点火方式对欠膨胀氢气射流爆炸超压影响规律研究[J]. 化工学报, 2023, 74(3): 1409-1418. |

| [9] | 杜江龙, 杨雯棋, 黄凯, 练成, 刘洪来. 复合相变材料/空冷复合式锂离子电池模块散热性能[J]. 化工学报, 2023, 74(2): 674-689. |

| [10] | 杨克, 王辰升, 纪虹, 郑凯, 邢志祥, 毕海普, 蒋军成. 聚多巴胺包覆混合粉体抑制甲烷爆炸的实验研究[J]. 化工学报, 2022, 73(9): 4245-4254. |

| [11] | 廖珊珊, 张少刚, 陶骏骏, 刘家豪, 汪金辉. 竖直射流火撞击障碍管道数值模拟分析[J]. 化工学报, 2022, 73(9): 4226-4234. |

| [12] | 王燕, 何佳, 杨晶晶, 林晨迪, 纪文涛. 草酸盐和碳酸氢盐抑制聚乙烯粉尘爆炸特性[J]. 化工学报, 2022, 73(9): 4207-4216. |

| [13] | 张经纬, 周弋惟, 陈卓, 徐建鸿. 微反应器内的有机合成前沿进展[J]. 化工学报, 2022, 73(8): 3472-3482. |

| [14] | 葛世轶, 杨遥, 黄正梁, 孙婧元, 王靖岱, 阳永荣. 基于静电分选解析聚乙烯颗粒生长与形貌演变[J]. 化工学报, 2022, 73(4): 1585-1596. |

| [15] | 周梦雅, 周魁斌, 王朝, 黄梦源, 王一凡, 蒋军成. 坑道限制条件下水平丙烷喷射火火焰行为研究[J]. 化工学报, 2022, 73(2): 960-971. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号