化工学报 ›› 2022, Vol. 73 ›› Issue (3): 1184-1193.DOI: 10.11949/0438-1157.20211523

徐一鸣1( ),袁华2,刘素丽2,李平1(

),袁华2,刘素丽2,李平1( ),严佩蓉1,赵曦1,卢俊华1,赵唯1,张学兰1

),严佩蓉1,赵曦1,卢俊华1,赵唯1,张学兰1

收稿日期:2021-10-26

修回日期:2021-12-11

出版日期:2022-03-15

发布日期:2022-03-14

通讯作者:

李平

作者简介:徐一鸣(1994—),女,硕士研究生,基金资助:

Yiming XU1( ),Hua YUAN2,Suli LIU2,Ping LI1(

),Hua YUAN2,Suli LIU2,Ping LI1( ),Peirong YAN1,Xi ZHAO1,Junhua LU1,Wei ZHAO1,Xuelan ZHANG1

),Peirong YAN1,Xi ZHAO1,Junhua LU1,Wei ZHAO1,Xuelan ZHANG1

Received:2021-10-26

Revised:2021-12-11

Online:2022-03-15

Published:2022-03-14

Contact:

Ping LI

摘要:

直链烷基苯磺酸是一种重要的阴离子表面活性剂,由其合成的直链烷基苯磺酸盐是价格低廉的表面活性剂之一,广泛应用于洗涤和三次采油等领域。以某煤制油企业的工业混合烯烃生产的直链烷基苯为原料,在微通道反应器中连续合成直链烷基苯磺酸,考察磺化温度、原料摩尔比以及磺化剂浓度等工艺条件对磺酸产物的影响规律,并与纯十六烷基苯磺化规律进行对比。研究发现混合直链烷基苯磺化过程中各个工艺条件对产品收率的影响较大。在反应温度为50℃,SO3与LAB摩尔比为1.0∶1,停留时间为5.09 s条件下,最终产品中活性物含量可达到94.5%(质量)。同时,设计并搭建了微反应器小试平台,实现连续合成混合烷基苯磺酸盐,磺酸盐产品收率在90%以上,可为该工艺的工业应用提供技术支持。

中图分类号:

徐一鸣, 袁华, 刘素丽, 李平, 严佩蓉, 赵曦, 卢俊华, 赵唯, 张学兰. 微通道反应器中工业混合直链烷基苯磺酸盐的连续合成工艺研究[J]. 化工学报, 2022, 73(3): 1184-1193.

Yiming XU, Hua YUAN, Suli LIU, Ping LI, Peirong YAN, Xi ZHAO, Junhua LU, Wei ZHAO, Xuelan ZHANG. Study on the continuous synthesis process of industrial mixed linear alkyl benzene sulfonates in a microchannel reactor[J]. CIESC Journal, 2022, 73(3): 1184-1193.

| 碳数 | 分子量 |

|---|---|

| 10 | 218 |

| 11 | 232 |

| 12 | 246 |

| 13 | 260 |

| 14 | 274 |

表1 各碳数烷基苯的分子量

Table 1 Relative molecular weight of alkylbenzene at each carbon number

| 碳数 | 分子量 |

|---|---|

| 10 | 218 |

| 11 | 232 |

| 12 | 246 |

| 13 | 260 |

| 14 | 274 |

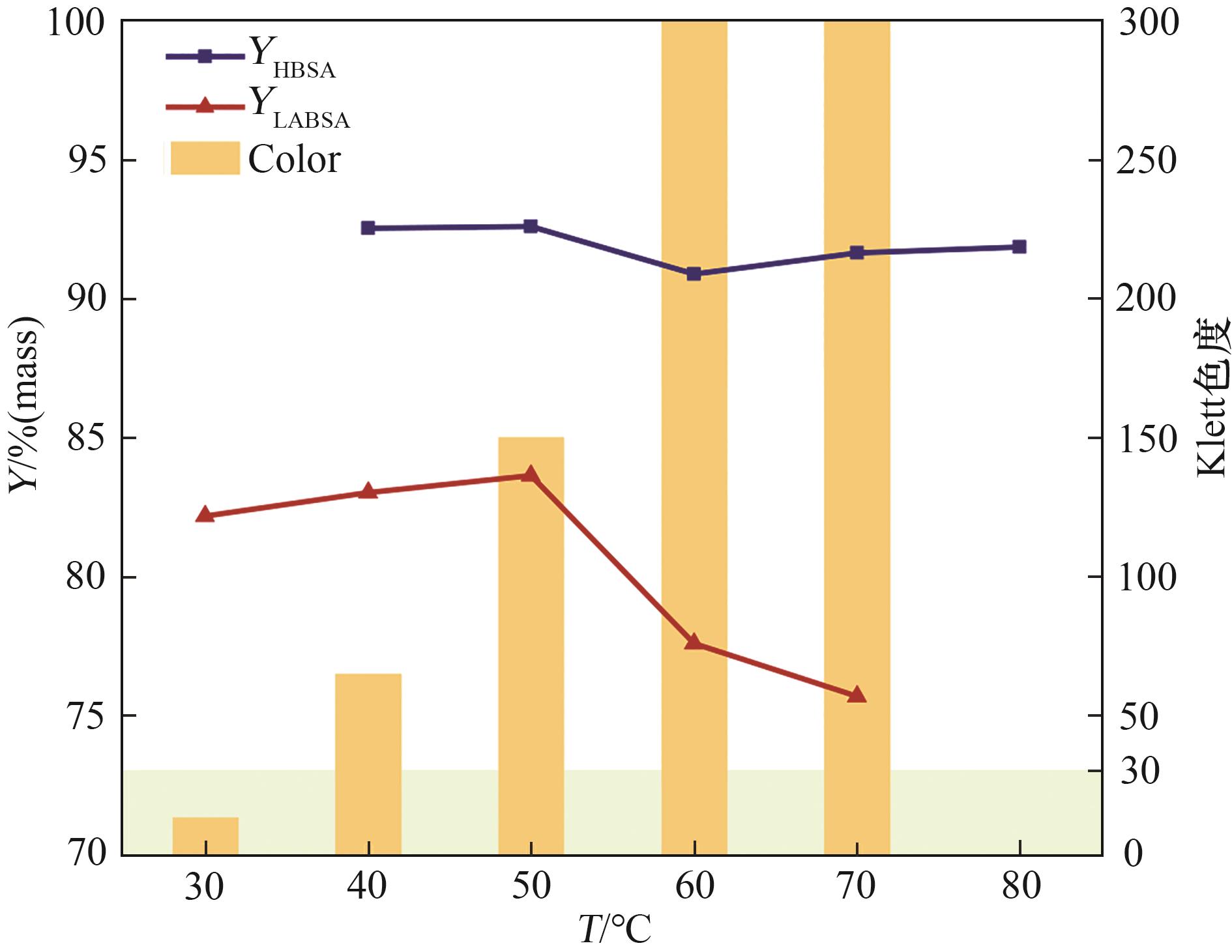

图5 反应温度对HBSA产率和LABSA产率和色泽的影响SO3∶LAB(摩尔比)为0.94∶1, SO3质量分数= 10%,停留时间是5.09 s(绿色部分表明了优质产品色泽的范围)

Fig.5 Effect of reaction temperature on the yield of HBSA and the yield and color of LABSA

| 老化前后 | Klett色度 | ||||

|---|---|---|---|---|---|

| 30℃ | 40℃ | 50℃ | 60℃ | 70℃ | |

| 老化前 |  |  |  |  |  |

| 老化后 |  |  |  |  |  |

表2 不同温度下产品老化前后色泽对比

Table 2 Color comparison of products before and after aging at different temperatures

| 老化前后 | Klett色度 | ||||

|---|---|---|---|---|---|

| 30℃ | 40℃ | 50℃ | 60℃ | 70℃ | |

| 老化前 |  |  |  |  |  |

| 老化后 |  |  |  |  |  |

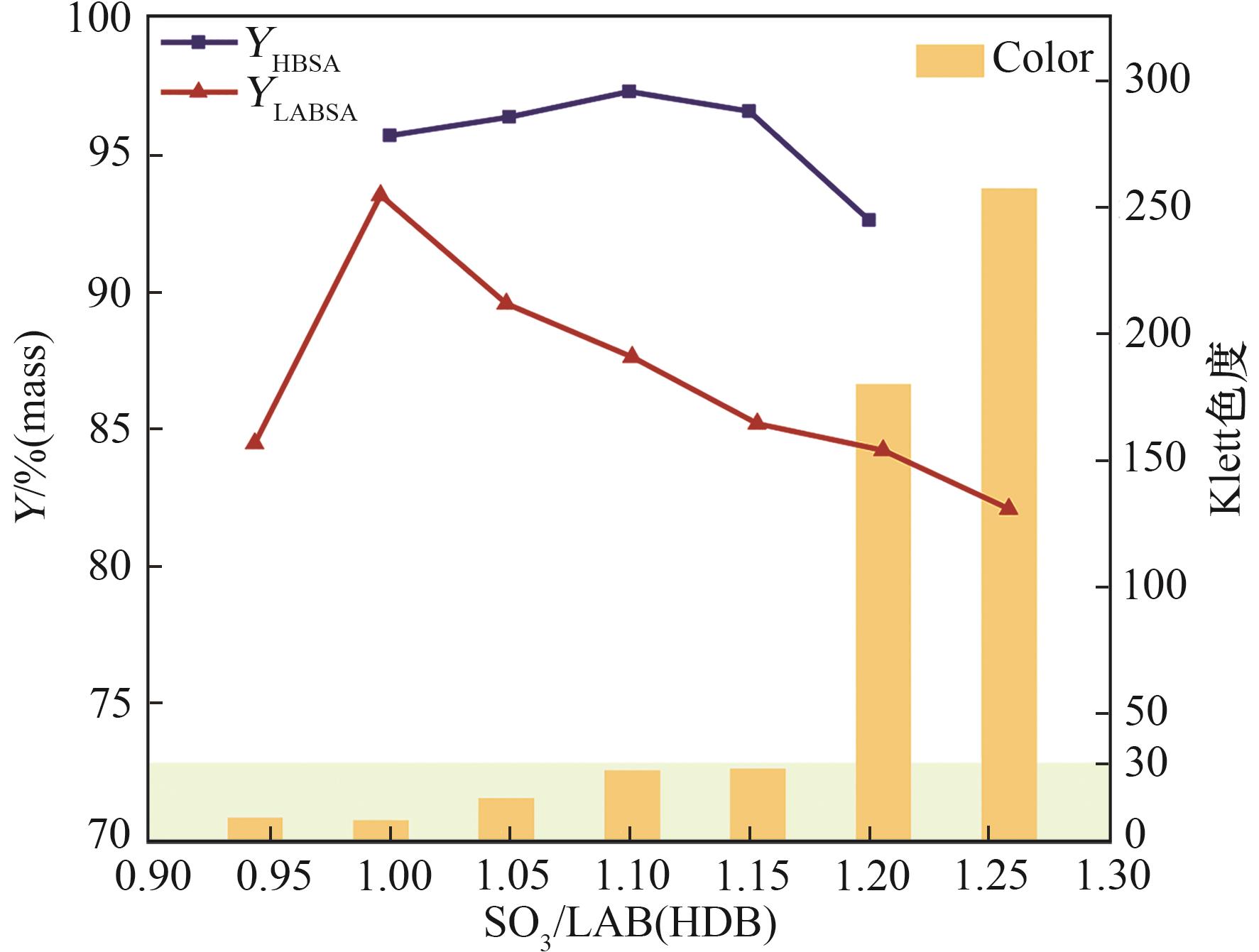

图6 原料摩尔比对HBSA产率以及LABSA产率和色泽的影响反应温度为50℃, SO3质量分数为10%,停留时间是5.09 s(绿色部分表明了优质产品色泽的范围)

Fig.6 Effect of molar ratio of raw materials on the yield of LBSA as well as the yield and color of LABSA

| Klett色度 | ||||||

|---|---|---|---|---|---|---|

| SO3/LAB=0.94 | SO3/LAB=1.00 | SO3/LAB=1.05 | SO3/LAB=1.10 | SO3/LAB=1.15 | SO3/LAB=1.21 | SO3/LAB=1.26 |

|  |  |  |  |  |  |

表3 不同原料摩尔比产品色泽对比

Table 3 Comparison of product color under different raw material molar ratio

| Klett色度 | ||||||

|---|---|---|---|---|---|---|

| SO3/LAB=0.94 | SO3/LAB=1.00 | SO3/LAB=1.05 | SO3/LAB=1.10 | SO3/LAB=1.15 | SO3/LAB=1.21 | SO3/LAB=1.26 |

|  |  |  |  |  |  |

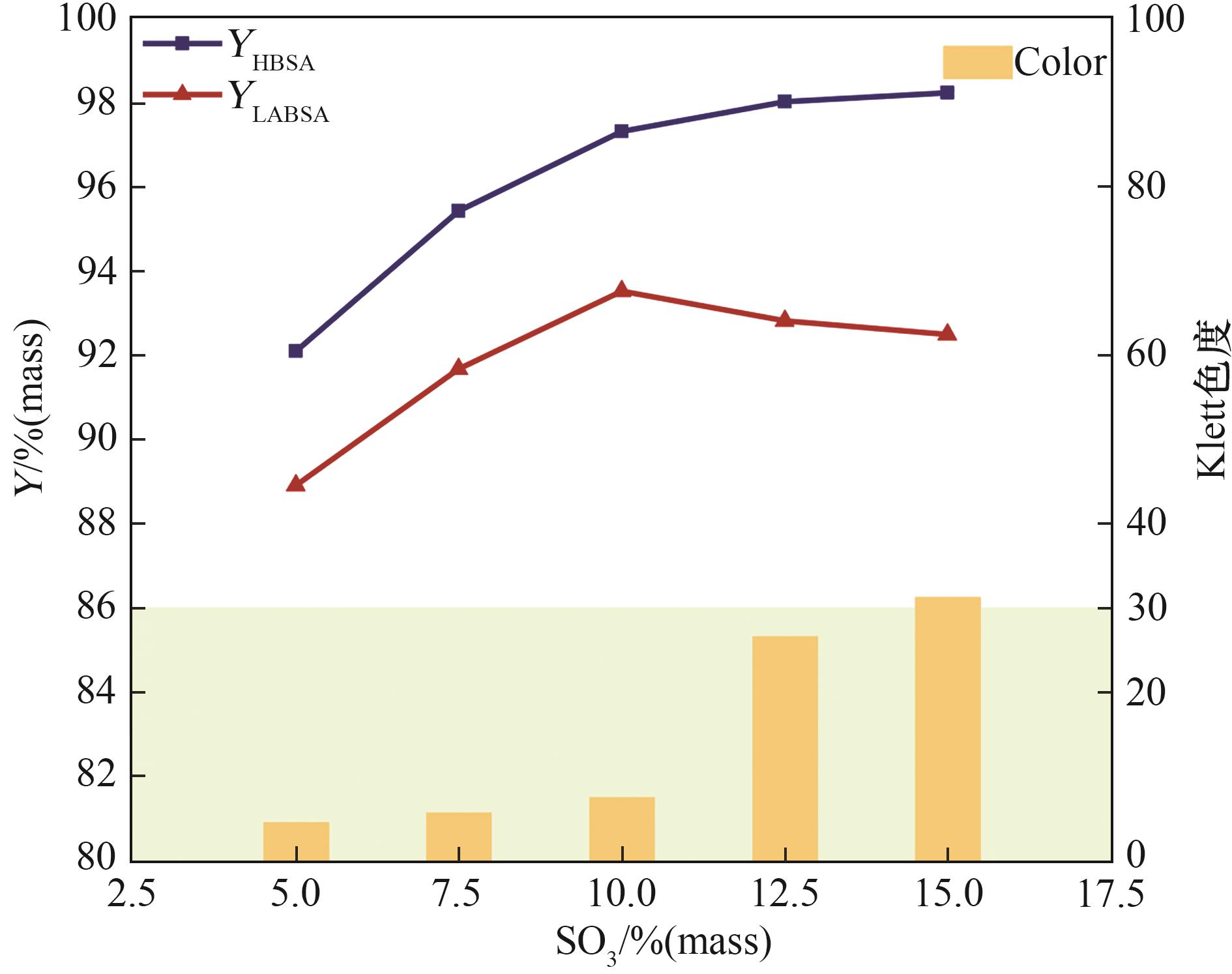

图7 磺化剂浓度对HBSA产率以及LABSA产率和色泽的影响反应温度为50℃, SO3∶LAB(摩尔比)为1.0∶1, 停留时间是5.09 s(绿色部分表明了优质产品色泽的范围)

Fig.7 Effect of sulfonation agent concentration on the yield of LBSA as well as the yield and color of LABSA

| 1 | 张松山, 柯昌美, 邱德芬,等. 煤焦油加氢制备可燃油的研究进展[J]. 炭素, 2014(4): 4. |

| Zhang S S, Ke C M, Qiu D F, et al. Research progress of the preparation of the combustible oil by coal tar hydrogenation[J]. Carbon, 2014(4): 4. | |

| 2 | Xie K, Li W, Wei Z. Coal chemical industry and its sustainable development in China[J]. Energy, 2010, 35(11): 4349-4355. |

| 3 | 袁华, 董永花, 袁炜. 低温费-托合成轻油加工利用[J]. 炼油技术与工程, 2016, 46(12): 5. |

| Yuan H, Dong Y H, Yuan W. Processing and utilization of low-tempreature Fischer-Tropsch light syncrude oil[J]. Petroleum Refinery Engineering, 2016, 46(12): 5. | |

| 4 | 张国华, 支林轩, 赵东睿, 等. 多产品品种SO3磺化装置的工程设计[J]. 日用化学品科学, 2021, 44(5): 36-39. |

| Zhang G H, Zhi L X, Zhao D R, et al. Engineering design of multi-product SO3 sulfonation plant[J]. Detergent & Cosmetics, 2021, 44(5): 36-39. | |

| 5 | Kordoghli B, Khiari R, Mhenni M F, et al. Sulfonation of polyester fabrics by gaseous sulfur oxide activated by UV irradiation[J]. Applied Surface Science, 2012, 258(24): 9737-9741. |

| 6 | Kucera F, Jancar J. Sulfonation of solid polystyrene using gaseous sulfur trioxide[J]. Polymer Engineering & Science, 2009, 49(9): 1839-1845. |

| 7 | Pu X, Li G X, Song Y, et al. Droplet coalescence phenomena during liquid–liquid heterogeneous reactions in microreactors[J]. Industrial & Engineering Chemistry Research, 2017, 56(43): 12316-12325. |

| 8 | 汪宝和, 吴金川, 张德利, 等. 喷射环流反应器中甲苯气相三氧化硫磺化[J]. 化工学报, 1997, 48(3): 378-381. |

| Wang B H, Wu J C, Zhang D L, et al. Sulfonation of toluene by gaseous sulphur trioxide in a jet loop reactor[J]. Journal of Chemical Industry and Engineering (China), 1997, 48(3): 378-381. | |

| 9 | Hajipour A R, Mirjalili B B F, Zarei A, et al. A novel method for sulfonation of aromatic rings with silica sulfuric acid[J]. Tetrahedron Letters, 2004, 45(35): 6607-6609. |

| 10 | Gilbert E E, Veldhuis B, Carlson E J, et al. Sulfonation and sulfation with sulfur trioxide[J]. Industrial & Engineering Chemistry, 1953, 45(9): 2065-2072. |

| 11 | Gerhart K R, Popova D O. Sulfonation with sulfur trioxide[J]. Journal of the American Oil Chemists’ Society, 1954, 31(5): 200-203. |

| 12 | Morley J O, Roberts D W, Watson S P. Experimental and molecular modelling studies on aromatic sulfonation[J]. Journal of the Chemical Society, Perkin Transactions 2, 2002(3): 538-544. |

| 13 | Roberts D W. Optimisation of the linear alkyl benzene sulfonation process for surfactant manufacture[J]. Organic Process Research & Development, 2003, 7(2): 172-184. |

| 14 | Zaı̈d T A, Benmaza K, Chitour C E. Sulfonation of linear alkyl benzene (LAB) in a corrugated wall falling film reactor[J]. Chemical Engineering Journal, 2000, 76(2): 99-102. |

| 15 | Roberts D W. Sulfonation technology for anionic surfactant manufacture[J]. Organic Process Research & Development, 1998, 2(3): 194-202. |

| 16 | Xie T M, Zeng C F, Wang C Q, et al. Preparation of methyl ester sulfonates based on sulfonation in a falling film microreactor from hydrogenated palm oil methyl esters with gaseous SO3 [J]. Industrial & Engineering Chemistry Research, 2013, 52(10): 3714-3722. |

| 17 | 王晓立, 田桂芝, 孟兆海. 合成高纯对甲苯磺酸新工艺[J]. 当代化工, 2002, 31(4): 206-208. |

| Wang X L, Tian G Z, Meng Z H. New technology on synthesizing high purification toluene-P-sulfonic acid[J]. Shenyang Chemical Industry, 2002, 31(4): 206-208. | |

| 18 | Sun B C, Zhang L L, Weng Z, et al. Sulfonation of alkylbenzene using liquid sulfonating agent in rotating packed bed: experimental and numerical study[J]. Chemical Engineering and Processing: Process Intensification, 2017, 119: 93-100. |

| 19 | Wu J, Wang B, Zhang D, et al. Production of p-toluenesulfonic acid by sulfonating toluene with gaseous sulfur trioxide[J]. Journal of Chemical Technology & Biotechnology, 2001, 76(6): 619-623. |

| 20 | 陈光文. 微化工技术研究进展[J]. 现代化工, 2007, 27(10): 8-13. |

| Chen G W. Advance and prospect of microchemical engineering and technology[J]. Modern Chemical Industry, 2007, 27(10): 8-13. | |

| 21 | Roberge D M, Ducry L, Bieler N, et al. Microreactor technology: a revolution for the fine chemical and pharmaceutical industries? [J]. Chemical Engineering & Technology, 2005, 28(3): 318-323. |

| 22 | 陈光文, 袁权. 微化工技术[J]. 化工学报, 2003, 54(4): 427-439. |

| Chen G W, Yuan Q. Micro-chemical technology[J]. Journal of Chemical Industry and Engineering (China), 2003, 54(4): 427-439. | |

| 23 | 陈光文, 赵玉潮, 乐军, 等. 微化工过程中的传递现象[J]. 化工学报, 2013, 64(1): 63-75. |

| Chen G W, Zhao Y C, Yue J, et al. Transport phenomena in micro-chemical engineering[J]. CIESC Journal, 2013, 64(1): 63-75. | |

| 24 | Tuvell M E, Kuehnhanss G O, Heidebrecht G D, et al. AOS—An anionic surfactant system: its manufacture, composition, properties, and potential application[J]. Journal of the American Oil Chemists’ Society, 1978, 55(1): 70-80. |

| 25 | Zhao Y C, Su Y H, Chen G W, et al. Effect of surface properties on the flow characteristics and mass transfer performance in microchannels[J]. Chemical Engineering Science, 2010, 65(5): 1563-1570. |

| 26 | Lin X Y, Wang K, Zhang J S, et al. Process intensification of the synthesis of poly(vinyl butyral) using a microstructured chemical system[J]. Industrial & Engineering Chemistry Research, 2015, 54(14): 3582-3588. |

| 27 | 主凯, 赵玉潮, 张博宇, 等. 微反应器中十二烷基苯液相SO3磺化过程[J]. 化学反应工程与工艺, 2015, 31(3): 201-207. |

| Zhu K, Zhao Y C, Zhang B Y, et al. Process performance of dodecylbenzene sulfonation with liquid SO3 in a microreactor[J]. Chemical Reaction Engineering and Technology, 2015, 31(3): 201-207. | |

| 28 | 陈彦全, 韩梅, 焦凤军, 等. 微反应器中甲苯液相SO3磺化工艺研究[J]. 化学反应工程与工艺, 2013, 29(3): 253-259. |

| Chen Y Q, Han M, Jiao F J, et al. Study on the sulfonation of toluene with SO3 in microreactor[J]. Chemical Reaction Engineering and Technology, 2013, 29(3): 253-259. | |

| 29 | Geng Y H, Huang J P, Tan B, et al. Efficient synthesis of dodecylbenzene sulfonic acid in microreaction systems[J]. Chemical Engineering and Processing - Process Intensification, 2020, 149: 107858. |

| 30 | Xu Y M, Liu S L, Meng W J, et al. Continuous sulfonation of hexadecylbenzene in a microreactor[J]. Green Processing and Synthesis, 2021, 10(1): 219-229. |

| 31 | Epton S R. A new method for the rapid titrimetric analysis of sodium alkyl sulphates and related compounds[J]. Trans Faraday Soc, 1948, 44: 226-230. |

| 32 | 李之平, 巩效牧, 李庆莹. 用百里酚蓝-次甲基蓝混合指示剂测定阴离子表面活性剂[J]. 分析化学, 1984, 12(12): 1058-1061. |

| Li Z P, Gong X M, Li Q Y. A mixed indicator of thymol blue-methylene blue for determination of anionic surfactants[J]. Analytical Chemistry, 1984, 12(12): 1058-1061. | |

| 33 | 唐凯, 俞稼镛. 阴离子表面活性剂的测定方法: 混合指示剂程序加入法[J]. 兰州大学学报, 2000, 36(4): 61-65. |

| Tang K, Yu J Y. An improved method to determine anionic surfactant in complex system[J]. Journal of Lanzhou University, 2000, 36(4): 61-65. | |

| 34 | 魏鑫, 王延安, 杨广彬. 烷基苯磺酸色泽与磺化反应条件控制[J]. 河南化工, 2003, 20(8): 28-29. |

| Wei X, Wang Y A, Yang G B. Color control of alkyl benzenesulfonic acid and sulfonation reaction conditions [J]. Henan Chemical Industry, 2003, 20(8): 28-29. |

| [1] | 杨欣, 彭啸, 薛凯茹, 苏梦威, 吴燕. 分子印迹-TiO2光电催化降解增溶PHE废水性能研究[J]. 化工学报, 2023, 74(8): 3564-3571. |

| [2] | 徐文超, 孙志高, 李翠敏, 李娟, 黄海峰. 静态条件下表面活性剂E-1310对HCFC-141b水合物生成的影响[J]. 化工学报, 2023, 74(5): 2179-2185. |

| [3] | 葛运通, 王玮, 李楷, 肖帆, 于志鹏, 宫敬. 多相分散体系中微油滴与改性二氧化硅表面间作用力的AFM研究[J]. 化工学报, 2023, 74(4): 1651-1659. |

| [4] | 章承浩, 罗京, 张吉松. 微反应器内基于氮氧自由基催化剂连续氧气/空气氧化反应的研究进展[J]. 化工学报, 2023, 74(2): 511-524. |

| [5] | 谢煜, 张民, 胡卫国, 王玉军, 骆广生. 利用膜分散微反应器高效溶解D-7-ACA的研究[J]. 化工学报, 2023, 74(2): 748-755. |

| [6] | 杨星宇, 马优, 朱春英, 付涛涛, 马友光. 梳状并行微通道内液液分布规律研究[J]. 化工学报, 2023, 74(2): 698-706. |

| [7] | 付家崴, 陈帅帅, 方凯伦, 蒋新. 微反应器共沉淀反应制备铜锰催化剂[J]. 化工学报, 2023, 74(2): 776-783. |

| [8] | 裴仁花, 王永洪, 张新儒, 李晋平. 碳纳米管/环糊精金属有机骨架协同强化混合基质膜的CO2分离[J]. 化工学报, 2022, 73(9): 3904-3914. |

| [9] | 廖艺, 牛亚宾, 潘艳秋, 俞路. 复配表面活性剂对油水界面行为和性质影响的模拟研究[J]. 化工学报, 2022, 73(9): 4003-4014. |

| [10] | 顾仁杰, 张加威, 靳雪阳, 文利雄. 微撞击流反应器制备镍钴复合氢氧化物超级电容器材料及其性能研究[J]. 化工学报, 2022, 73(8): 3749-3757. |

| [11] | 张经纬, 周弋惟, 陈卓, 徐建鸿. 微反应器内的有机合成前沿进展[J]. 化工学报, 2022, 73(8): 3472-3482. |

| [12] | 侯跃辉, 刘璇, 廉应江, 韩梅, 尧超群, 陈光文. 超声微反应器内三硝基间苯三酚合成工艺研究[J]. 化工学报, 2022, 73(8): 3597-3607. |

| [13] | 许非石, 杨丽霞, 陈光文. 超声微反应器内气液传质过程的介尺度强化机制[J]. 化工学报, 2022, 73(6): 2552-2562. |

| [14] | 苏晓辉, 张弛, 徐志锋, 金辉, 王治国. 黏弹性表面活性剂溶液中颗粒沉降特性研究[J]. 化工学报, 2022, 73(5): 1974-1985. |

| [15] | 王宜飞, 王清强, 姬德生, 李申芳, 金楠, 赵玉潮. 微通道壁面浸润性对气-液两相流的影响规律研究[J]. 化工学报, 2022, 73(4): 1501-1514. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号