化工学报 ›› 2022, Vol. 73 ›› Issue (4): 1501-1514.DOI: 10.11949/0438-1157.20211786

收稿日期:2021-12-20

修回日期:2022-03-08

出版日期:2022-04-05

发布日期:2022-04-25

通讯作者:

赵玉潮

作者简介:王宜飞(1997—),男,硕士研究生,基金资助:

Yifei WANG( ),Qingqiang WANG,Desheng JI,Shenfang LI,Nan JIN,Yuchao ZHAO(

),Qingqiang WANG,Desheng JI,Shenfang LI,Nan JIN,Yuchao ZHAO( )

)

Received:2021-12-20

Revised:2022-03-08

Online:2022-04-05

Published:2022-04-25

Contact:

Yuchao ZHAO

摘要:

通道壁面浸润性对微通道内的气-液两相流具有重要影响。利用等离子体辅助接枝改性,将甲基丙烯酰乙基磺基甜菜碱(SBMA)及1H, 1H, 2H, 2H-全氟癸基三乙氧基硅烷接枝在聚甲基丙烯酸甲酯(PMMA)材料表面,得到了10°、40°、70°和110°四种接触角的微通道,并考察了浸润性对流型、气泡长度和压降的影响。结果表明,随接触角增大,气泡截断位置下移,膨胀阶段缩短,挤压阶段变长;低流量时,气泡长度随接触角增加而增大,高流量时则减小;建立了与材料表面水接触角相关的气泡尺寸预测关联式,与Garstecki经典预测关联式相比,预测精度更高;θ<90°时,接触角增加,压降减小;θ>90°时,三相接触线使流动阻力和压降增加。

中图分类号:

王宜飞, 王清强, 姬德生, 李申芳, 金楠, 赵玉潮. 微通道壁面浸润性对气-液两相流的影响规律研究[J]. 化工学报, 2022, 73(4): 1501-1514.

Yifei WANG, Qingqiang WANG, Desheng JI, Shenfang LI, Nan JIN, Yuchao ZHAO. Effects of the wall wettability of microchannel on the gas-liquid two-phase flow hydrodynamics[J]. CIESC Journal, 2022, 73(4): 1501-1514.

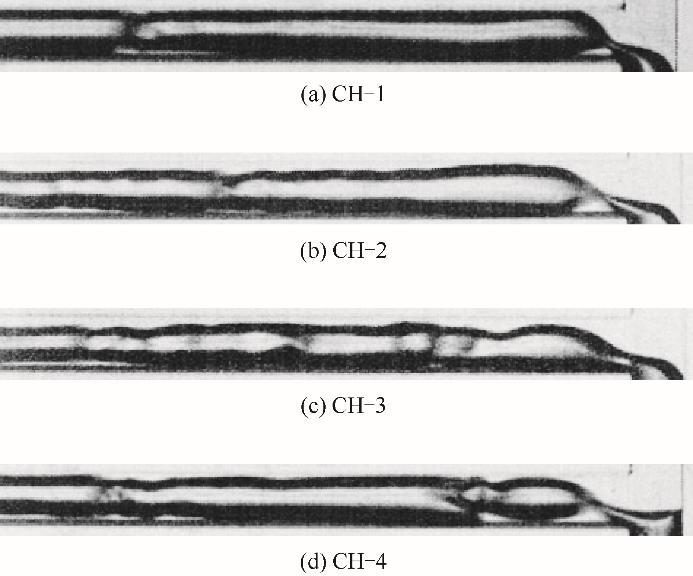

图7 jG= jL =0.116 m/s条件下的气-液弹状流形成过程特性(流动方向为自右向左;以微通道宽度0.6 mm为标尺)

Fig.7 Formation process characteristics of gas-liquid slug flow at jG= jL =0.116 m/s(The flow direction is from right to left. The microchannel width was 0.6 mm as a scale bar)

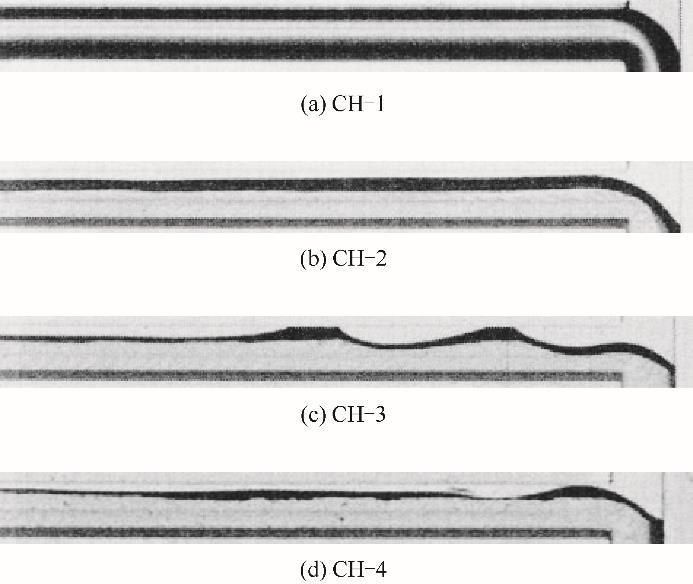

图8 jG=0.162 m/s、jL=0.023 m/s条件下的气-液弹状-环形流特性(流动方向为自右向左;以微通道宽度0.6 mm为标尺)(The flow direction is from right to left. The microchannel width was 0.6 mm as a scale bar)

Fig.8 Characteristics of gas-liquid slug-annular flow at jG=0.162 m/s, jL=0.023 m/s

图9 jG=1.389 m/s、jL=0.463 m/s条件下的环状流特性(流动方向为自右向左;以微通道宽度0.6 mm为标尺)

Fig.9 Annular flow characteristics at jG=1.389 m/s, jL=0.463 m/s(The flow direction is from right to left. The microchannel width was 0.6 mm as a scale bar)

图10 jG=3.704 m/s、jL=0.023 m/s条件下的并行流特性(流动方向为自右向左;以微通道宽度0.6 mm为标尺)

Fig.10 Parallel flow characteristics at jG=3.704 m/s, jL=0.023 m/s(The flow direction is from right to left. The microchannel width was 0.6 mm as a scale bar)

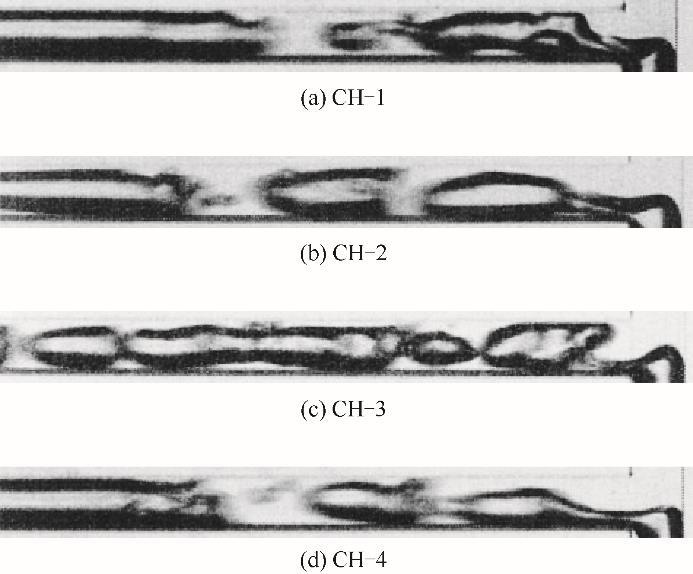

图11 jG=2.315 m/s、jL=1.389 m/s条件下的搅拌流特性(流动方向为自右向左;以微通道宽度0.6 mm为标尺)

Fig.11 Churning flow characteristics at jG=2.315 m/s, jL=1.389 m/s(The flow direction is from right to left. The microchannel width was 0.6 mm as a scale bar)

图12 jG=0.231 m/s、jL=0.926 m/s条件下的泡状流特性(流动方向为自右向左;以微通道宽度0.6 mm为标尺)

Fig.12 Bubbly flow characteristics at jG=0.231 m/s, jL=0.926 m/s(The flow direction is from right to left. The microchannel width was 0.6 mm as a scale bar)

| 1 | 陈光文, 袁权. 微化工技术[J]. 化工学报, 2003, 54(4): 427-439. |

| Chen G W, Yuan Q. Micro-chemical technology[J]. Journal of Chemical Industry and Engineering (China), 2003, 54(4): 427-439. | |

| 2 | Wang K, Luo G S. Microflow extraction: a review of recent development[J]. Chemical Engineering Science, 2017, 169: 18-33. |

| 3 | Fu T T, Ma Y G, Funfschilling D, et al. Squeezing-to-dripping transition for bubble formation in a microfluidic T-junction[J]. Chemical Engineering Science, 2010, 65(12): 3739-3748. |

| 4 | Zhou Y F, Yao C Q, Zhang P, et al. Dynamic coupling of mass transfer and chemical reaction for Taylor flow along a serpentine microchannel[J]. Industrial & Engineering Chemistry Research, 2020, 59(19): 9279-9292. |

| 5 | Zhang P, Yao C Q, Ma H Y, et al. Dynamic changes in gas-liquid mass transfer during Taylor flow in long serpentine square microchannels[J]. Chemical Engineering Science, 2018, 182: 17-27. |

| 6 | Yao C Q, Zhao Y C, Ma H Y, et al. Two-phase flow and mass transfer in microchannels: a review from local mechanism to global models[J]. Chemical Engineering Science, 2021, 229: 116017. |

| 7 | Elvira K S, Solvas X C i, Wootton R C R, et al. The past, present and potential for microfluidic reactor technology in chemical synthesis[J]. Nature Chemistry, 2013, 5(11): 905-915. |

| 8 | Zhao C X, Middelberg A P J. Two-phase microfluidic flows[J]. Chemical Engineering Science, 2011, 66(7): 1394-1411. |

| 9 | Zhao Y C, Su Y H, Chen G W, et al. Effect of surface properties on the flow characteristics and mass transfer performance in microchannels[J]. Chemical Engineering Science, 2010, 65(5): 1563-1570. |

| 10 | Squires T M, Quake S R. Microfluidics: fluid physics at the nanoliter scale[J]. Reviews of Modern Physics, 2005, 77(3): 977-1026. |

| 11 | Santos R M, Kawaji M. Developments on wetting effects in microfluidic slug flow[J]. Chemical Engineering Communications, 2012, 199(12): 1626-1641. |

| 12 | Zhou Y L, Chang H, Qi T Y. Gas-liquid two-phase flow in serpentine microchannel with different wall wettability[J]. Chinese Journal of Chemical Engineering, 2017, 25(7): 874-881. |

| 13 | Barajas A M, Panton R L. The effects of contact angle on two-phase flow in capillary tubes[J]. International Journal of Multiphase Flow, 1993, 19(2): 337-346. |

| 14 | Wielhorski Y, Ben Abdelwahed M A, Bizet L, et al. Wetting effect on bubble shapes formed in a cylindrical T-junction[J]. Chemical Engineering Science, 2012, 84: 100-106. |

| 15 | Garstecki P, Fuerstman M J, Stone H A, et al. Formation of droplets and bubbles in a microfluidic T-junction-scaling and mechanism of break-up[J]. Lab on a Chip, 2006, 6(3): 437-446. |

| 16 | Xu J H, Luo G S, Li S W, et al. Shear force induced monodisperse droplet formation in a microfluidic device by controlling wetting properties[J]. Lab on a Chip, 2006, 6(1): 131-136. |

| 17 | Ma Y G, Fu T T, Zhu C Y, et al. Formation mechanism and size prediction of bubble in opposite-flowing T-shaped microchannel[J]. Transactions of Tianjin University, 2010, 16(4): 251-255. |

| 18 | 孙俊杰, 郝婷婷, 马学虎, 等. 壁面润湿性对微通道内二氧化碳-水两相流流动及传质性能的影响[J]. 化工学报, 2015, 66(9): 3405-3412. |

| Sun J J, Hao T T, Ma X H, et al. Surface wettability effect on carbon dioxide-water two-phase flow and mass transfer in rectangular microchannel[J]. CIESC Journal, 2015, 66(9): 3405-3412. | |

| 19 | Cubaud T, Ulmanella U, Ho C M. Two-phase flow in microchannels with surface modifications[J]. Fluid Dynamics Research, 2006, 38(11): 772-786. |

| 20 | Choi C, Yu D I, Kim M. Surface wettability effect on flow pattern and pressure drop in adiabatic two-phase flows in rectangular microchannels with T-junction mixer[J]. Experimental Thermal and Fluid Science, 2011, 35(6): 1086-1096. |

| 21 | Sairiam S, Loh C H, Wang R, et al. Surface modification of PVDF hollow fiber membrane to enhance hydrophobicity using organosilanes[J]. Journal of Applied Polymer Science, 2013, 130(1): 610-621. |

| 22 | Hong Y, You X Q, Zeng Y, et al. Air-plasma surface modification of epoxy resin substrate to improve electroless copper plating of printed circuit board[J]. Vacuum, 2019, 170: 108967. |

| 23 | Shi T N, Shao M L, Zhang H R, et al. Surface modification of porous poly(tetrafluoroethylene) film via cold plasma treatment[J]. Applied Surface Science, 2011, 258(4): 1474-1479. |

| 24 | Pykönen M, Sundqvist H, Järnström J, et al. Effects of atmospheric plasma activation on surface properties of pigment-coated and surface-sized papers[J]. Applied Surface Science, 2008, 255(5): 3217-3229. |

| 25 | Li M S, Zhao Z P, Wang M X. Controllable modification of polymer membranes by LDDLT plasma flow: membrane module scale-up and hydrophilic stability[J]. Chemical Engineering Science, 2015, 122: 53-63. |

| 26 | 梁邦. 基于两性离子聚合物超亲水表面的制备及应用研究[D]. 合肥: 中国科学技术大学, 2019. |

| Liang B. The preparation of superhydrophilic surface based on the zwitterionic polymer and its application[D]. Hefei: University of Science and Technology of China, 2019. | |

| 27 | Wang C G, Yong H W, Goto A. Effective synthesis of patterned polymer brushes with tailored multiple graft densities[J]. ACS Applied Materials & Interfaces, 2019, 11(15): 14478-14484. |

| 28 | Wang Y X, Deng J P, Zhong W B, et al. Facile surface superhydrophilic modification: NVP/MBA inverse microemulsion surface-grafting polymerization initiated by UV light[J]. Macromolecular Rapid Communications, 2005, 26(22): 1788-1793. |

| 29 | Saxena S, Ray A R, Mindemart J, et al. Plasma-induced graft polymerization of acrylic acid onto poly(propylene) monofilament: characterization[J]. Plasma Processes and Polymers, 2010, 7(7): 610-618. |

| 30 | Yao C Q, Dong Z Y, Zhang Y C, et al. On the leakage flow around gas bubbles in slug flow in a microchannel[J]. AIChE Journal, 2015, 61(11): 3964-3972. |

| 31 | Hoang D A, Portela L M, Kleijn C R, et al. Dynamics of droplet breakup in a T-junction[J]. Journal of Fluid Mechanics, 2013, 717: R4. |

| 32 | 丛振霞, 朱春英, 付涛涛, 等. Y型分岔微通道内气泡的破裂动力学[J]. 中国科学: 化学, 2015, 45(1): 34-41. |

| Cong Z X, Zhu C Y, Fu T T, et al. Dynamics of bubble breakup in a microfluidic Y-bifurcation[J]. Scientia Sinica Chimica, 2015, 45(1): 34-41. | |

| 33 | Xu J H, Li S W, Tan J, et al. Correlations of droplet formation in T-junction microfluidic devices: from squeezing to dripping[J]. Microfluidics and Nanofluidics, 2008, 5(6): 711-717. |

| 34 | Yao C Q, Zhao Y C, Ye C B, et al. Characteristics of slug flow with inertial effects in a rectangular microchannel[J]. Chemical Engineering Science, 2013, 95: 246-256. |

| 35 | Fuerstman M J, Lai A, Thurlow M E, et al. The pressure drop along rectangular microchannels containing bubbles[J]. Lab on a Chip, 2007, 7(11): 1479-1489. |

| 36 | 齐红媛. 液体管道内壁润湿性及流动特性研究[D]. 成都: 西南石油大学, 2017. |

| Qi H Y. Study on inner wall wettability and flow property in liquid pipe[D]. Chengdu: Southwest Petroleum University, 2017. | |

| 37 | Bretherton F P. The motion of long bubbles in tubes[J]. Journal of Fluid Mechanics, 1961, 10(2): 166-188. |

| 38 | Wong H, Radke C J, Morris S. The motion of long bubbles in polygonal capillaries(Part 1): Thin films[J]. Journal of Fluid Mechanics, 1995, 292: 71-94. |

| 39 | Wong H, Radke C J, Morris S. The motion of long bubbles in polygonal capillaries(Part 2): Drag, fluid pressure and fluid flow[J]. Journal of Fluid Mechanics, 1995, 292: 95-110. |

| 40 | Lee C Y. An experimental study on effect of surface wettability on two-phase flow pattern and pressure drop in round mini-channels[D]. Korea :Korea Advanced Institute of Science and Technology, 2009. |

| 41 | Blake T D. The physics of moving wetting lines[J]. Journal of Colloid and Interface Science, 2006, 299(1): 1-13. |

| 42 | Rapolu P, Son S Y. Characterization of wettability effects on pressure drop of two-phase flow in microchannel[J]. Experiments in Fluids, 2011, 51(4): 1101-1108. |

| [1] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [2] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [3] | 贾露凡, 王艺颖, 董钰漫, 李沁园, 谢鑫, 苑昊, 孟涛. 微流控双水相贴壁液滴流动强化酶促反应研究[J]. 化工学报, 2023, 74(3): 1239-1246. |

| [4] | 张雪婷, 胡激江, 赵晶, 李伯耿. 高分子量聚丙二醇在微通道反应器中的制备[J]. 化工学报, 2023, 74(3): 1343-1351. |

| [5] | 何万媛, 陈一宇, 朱春英, 付涛涛, 高习群, 马友光. 阵列凸起微通道内气液两相传质特性研究[J]. 化工学报, 2023, 74(2): 690-697. |

| [6] | 章承浩, 罗京, 张吉松. 微反应器内基于氮氧自由基催化剂连续氧气/空气氧化反应的研究进展[J]. 化工学报, 2023, 74(2): 511-524. |

| [7] | 谢煜, 张民, 胡卫国, 王玉军, 骆广生. 利用膜分散微反应器高效溶解D-7-ACA的研究[J]. 化工学报, 2023, 74(2): 748-755. |

| [8] | 付家崴, 陈帅帅, 方凯伦, 蒋新. 微反应器共沉淀反应制备铜锰催化剂[J]. 化工学报, 2023, 74(2): 776-783. |

| [9] | 杨星宇, 马优, 朱春英, 付涛涛, 马友光. 梳状并行微通道内液液分布规律研究[J]. 化工学报, 2023, 74(2): 698-706. |

| [10] | 项星宇, 王忠东, 董艳鹏, 李守川, 朱春英, 马友光, 付涛涛. 微通道内屈服应力型流体的流变特性及多相流研究进展[J]. 化工学报, 2023, 74(2): 546-558. |

| [11] | 盛林, 昌宇, 邓建, 骆广生. 阶梯式T型微通道内有序气泡群的形成和流动特性研究[J]. 化工学报, 2023, 74(1): 416-427. |

| [12] | 顾仁杰, 张加威, 靳雪阳, 文利雄. 微撞击流反应器制备镍钴复合氢氧化物超级电容器材料及其性能研究[J]. 化工学报, 2022, 73(8): 3749-3757. |

| [13] | 张经纬, 周弋惟, 陈卓, 徐建鸿. 微反应器内的有机合成前沿进展[J]. 化工学报, 2022, 73(8): 3472-3482. |

| [14] | 侯跃辉, 刘璇, 廉应江, 韩梅, 尧超群, 陈光文. 超声微反应器内三硝基间苯三酚合成工艺研究[J]. 化工学报, 2022, 73(8): 3597-3607. |

| [15] | 董宜放, 于樱迎, 胡学功, 裴刚. 电场对竖直微槽润湿及毛细流动特性影响[J]. 化工学报, 2022, 73(7): 2952-2961. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号