化工学报 ›› 2022, Vol. 73 ›› Issue (6): 2552-2562.DOI: 10.11949/0438-1157.20220087

收稿日期:2022-01-17

修回日期:2022-02-11

出版日期:2022-06-05

发布日期:2022-06-30

通讯作者:

陈光文

作者简介:许非石(1990—),男,博士后,基金资助:

Feishi XU( ),Lixia YANG,Guangwen CHEN(

),Lixia YANG,Guangwen CHEN( )

)

Received:2022-01-17

Revised:2022-02-11

Online:2022-06-05

Published:2022-06-30

Contact:

Guangwen CHEN

摘要:

采用CFD方法对超声微反应器内的Taylor气液两相流的传质过程进行了模拟。针对传质过程中主要的介尺度结构,包括气泡表面波、空化声流、液相内的局部浓度,分析了其空间分布和时间演化规律。模拟结果有效捕捉了实验难以观测的液膜区域,并将液膜厚度与气泡表面波振动进行了关联,阐释了气液界面附近的空化声流对传质过程的强化作用。根据超声微反应器内Taylor流的传质特点,分别研究了不同流动和超声条件对液弹内和液膜处传质过程的影响,比较了各局部传质对整体传质效率的贡献。通过分析整体/局部Sherwood数与Peclet数间的关系,研究了超声效应对气液传质速率的影响。分析结果从介尺度角度验证了文献关于超声微反应器传质系数的计算,完善了超声微反应器内气液传质过程的强化理论。

中图分类号:

许非石, 杨丽霞, 陈光文. 超声微反应器内气液传质过程的介尺度强化机制[J]. 化工学报, 2022, 73(6): 2552-2562.

Feishi XU, Lixia YANG, Guangwen CHEN. Mesoscale enhancement mechanism of gas-liquid mass transfer in ultrasonic microreactor[J]. CIESC Journal, 2022, 73(6): 2552-2562.

| 参数 | 液相 | 气相 |

|---|---|---|

| 水 | 二氧化碳 | |

| 密度ρ/(kg/m3) | 998.2 | 1.7878 |

| 黏度 μ/(mPa·s) | 1.003 | 0.0137 |

| 摩尔质量 /(kg/mol) | 18.0152 | 44.00995 |

| 表面张力系数σ/(N/m) | 0.072 | |

| 饱和浓度 /(kg/m3) | — | 1.688 |

| 液相扩散系数 /(m2/s) | — | 2×10-9 |

表1 模拟采用的物性参数

Table 1 Physical parameters used in this study

| 参数 | 液相 | 气相 |

|---|---|---|

| 水 | 二氧化碳 | |

| 密度ρ/(kg/m3) | 998.2 | 1.7878 |

| 黏度 μ/(mPa·s) | 1.003 | 0.0137 |

| 摩尔质量 /(kg/mol) | 18.0152 | 44.00995 |

| 表面张力系数σ/(N/m) | 0.072 | |

| 饱和浓度 /(kg/m3) | — | 1.688 |

| 液相扩散系数 /(m2/s) | — | 2×10-9 |

| 项目 | 轴向3000 μm | 径向 | 总数 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 中心区域200 μm | 过渡区域45 μm | 壁面区域5 μm | |||||||

| 尺寸/μm | 数量 | 尺寸/μm | 数量 | 尺寸/μm | 数量 | 尺寸/μm | 数量 | ||

| Mesh 1 | 20 | 150 | 20 | 10 | 10~1.34 | 9 | 1 | 5 | 7200 |

| Mesh 2 | 10 | 300 | 10 | 20 | 10~1.34 | 9 | 1 | 5 | 20400 |

| Mesh 3 | 5 | 600 | 5 | 40 | 4.8~1.3 | 16 | 1 | 5 | 73200 |

| Mesh 4 | 2.5 | 1200 | 2.5 | 80 | 2.5~1.2 | 25 | 1 | 5 | 264000 |

表2 网格独立测试中的网格单元的大小和分布

Table 2 Size and distribution of mesh cells for mesh independency test

| 项目 | 轴向3000 μm | 径向 | 总数 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 中心区域200 μm | 过渡区域45 μm | 壁面区域5 μm | |||||||

| 尺寸/μm | 数量 | 尺寸/μm | 数量 | 尺寸/μm | 数量 | 尺寸/μm | 数量 | ||

| Mesh 1 | 20 | 150 | 20 | 10 | 10~1.34 | 9 | 1 | 5 | 7200 |

| Mesh 2 | 10 | 300 | 10 | 20 | 10~1.34 | 9 | 1 | 5 | 20400 |

| Mesh 3 | 5 | 600 | 5 | 40 | 4.8~1.3 | 16 | 1 | 5 | 73200 |

| Mesh 4 | 2.5 | 1200 | 2.5 | 80 | 2.5~1.2 | 25 | 1 | 5 | 264000 |

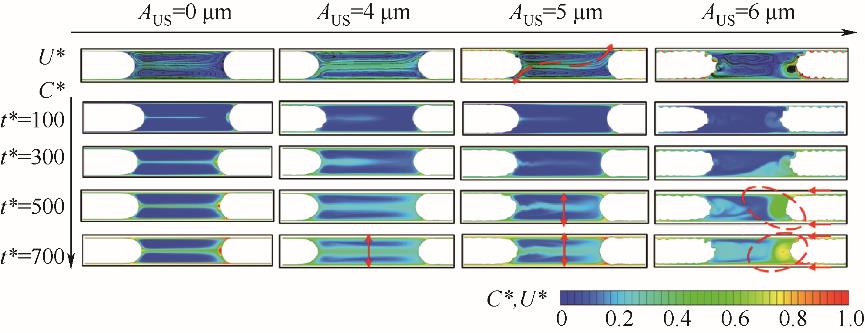

图6 不同振动幅度下液弹中流场分布和溶质浓度分布随时间的演变

Fig.6 Flow pattern and temporal evolution of the concentration field in the liquid slug under different oscillation amplitudes

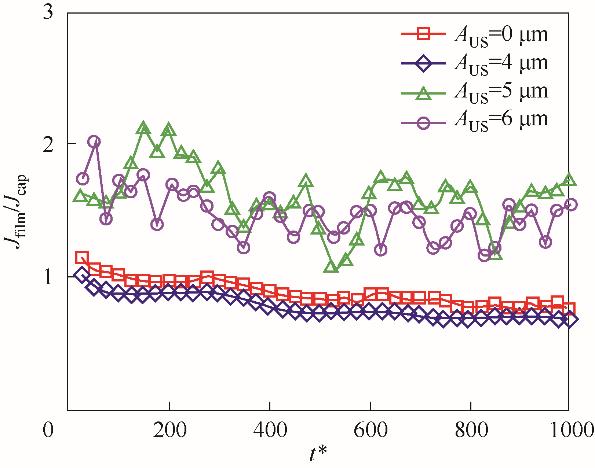

图8 不同振幅下液膜处传质通量与液弹(气泡头部)通量比值随时间的变化

Fig.8 Temporal evolution of the ratio of the flux at the liquid film to liquid slug (bubble cap) under different oscillation amplitudes

| 1 | 李静海, 胡英, 袁权. 探索介尺度科学: 从新角度审视老问题[J]. 中国科学: 化学, 2014, 44(3): 277-281. |

| Li J H, Hu Y, Yuan Q. Mesoscience: exploring old problems from a new angle[J]. Scientia Sinica Chimica, 2014, 44(3): 277-281. | |

| 2 | Huang W L, Li J H, Edwards P P. Mesoscience: exploring the common principle at mesoscales[J]. National Science Review, 2017, 5(3): 321-326. |

| 3 | Yao C Q, Zhao Y C, Ma H Y, et al. Two-phase flow and mass transfer in microchannels: a review from local mechanism to global models[J]. Chemical Engineering Science, 2021, 229: 116017. |

| 4 | Jensen K F. Microreaction engineering—is small better? [J]. Chemical Engineering Science, 2001, 56(2): 293-303. |

| 5 | Dong Z Y, Delacour C, Mc Carogher K, et al. Continuous ultrasonic reactors: design, mechanism and application[J]. Materials, 2020, 13(2): 344. |

| 6 | Friend J, Yeo L Y. Microscale acoustofluidics: microfluidics driven via acoustics and ultrasonics[J]. Reviews of Modern Physics, 2011, 83(2): 647-704. |

| 7 | Zhao S N, Yao C Q, Dong Z Y, et al. Role of ultrasonic oscillation in chemical processes in microreactors: a mesoscale issue[J]. Particuology, 2020, 48: 88-99. |

| 8 | Butler C, Cid E, Billet A M. Modelling of mass transfer in Taylor flow: investigation with the PLIF-I technique[J]. Chemical Engineering Research and Design, 2016, 115: 292-302. |

| 9 | Xu F S, Hébrard G, Dietrich N. Comparison of three different techniques for gas-liquid mass transfer visualization[J]. International Journal of Heat and Mass Transfer, 2020, 150: 119261. |

| 10 | Yang L X, Loubière K, Dietrich N, et al. Local investigations on the gas-liquid mass transfer around Taylor bubbles flowing in a meandering millimetric square channel[J]. Chemical Engineering Science, 2017, 165: 192-203. |

| 11 | Hagsäter S M, Jensen T G, Bruus H, et al. Acoustic resonances in microfluidic chips: full-image micro-PIV experiments and numerical simulations[J]. Lab on a Chip, 2007, 7(10): 1336-1344. |

| 12 | Xu F S, Jimenez M, Dietrich N, et al. Fast determination of gas-liquid diffusion coefficient by an innovative double approach[J]. Chemical Engineering Science, 2017, 170: 68-76. |

| 13 | 王炳捷, 李辉, 杨晓勇, 等. CFD数值模拟技术在液滴微流控多相流特性研究的应用进展[J]. 化工进展, 2021, 40(4): 1715-1735. |

| Wang B J, Li H, Yang X Y, et al. Application process of CFD-numerical simulation technology for multiphase flow characteristics study in droplet-microfluidic systems[J]. Chemical Industry and Engineering Progress, 2021, 40(4): 1715-1735. | |

| 14 | Wörner M. Numerical modeling of multiphase flows in microfluidics and micro process engineering: a review of methods and applications[J]. Microfluidics and Nanofluidics, 2012, 12(6): 841-886. |

| 15 | Hoang D A, van Steijn V, Portela L M, et al. Benchmark numerical simulations of segmented two-phase flows in microchannels using the Volume of Fluid method[J]. Computers & Fluids, 2013, 86: 28-36. |

| 16 | 尧超群, 陈光文, 袁权. 微通道内气-液两相传质过程行为及其应用[J]. 化工学报, 2019, 70(10): 3635-3644. |

| Yao C Q, Chen G W, Yuan Q. Mass transfer characteristics of gas-liquid two-phase flow in microchannels and applications[J]. CIESC Journal, 2019, 70(10): 3635-3644. | |

| 17 | Yao C Q, Liu Y Y, Xu C, et al. Formation of liquid-liquid slug flow in a microfluidic T-junction: effects of fluid properties and leakage flow[J]. AIChE Journal, 2018, 64(1): 346-357. |

| 18 | Talimi V, Muzychka Y S, Kocabiyik S. A review on numerical studies of slug flow hydrodynamics and heat transfer in microtubes and microchannels[J]. International Journal of Multiphase Flow, 2012, 39: 88-104. |

| 19 | Dong Z Y, Yao C Q, Zhang Y C, et al. Hydrodynamics and mass transfer of oscillating gas-liquid flow in ultrasonic microreactors[J]. AIChE Journal, 2016, 62(4): 1294-1307. |

| 20 | Zhang Q, Dong Z Y, Zhao S N, et al. Ultrasound-assisted gas-liquid mass transfer process in microreactors: the influence of surfactant, channel size and ultrasound frequency[J]. Chemical Engineering Journal, 2021, 405: 126720. |

| 21 | Xu F S, Yang L X, Liu Z K, et al. Numerical investigation on the hydrodynamics of Taylor flow in ultrasonically oscillating microreactors[J]. Chemical Engineering Science, 2021, 235: 116477. |

| 22 | Yang L X, Xu F S, Chen G W. Enhancement of gas-liquid mass transfer and mixing in zigzag microreactor under ultrasonic oscillation[J]. Chemical Engineering Science, 2022, 247: 117094. |

| 23 | Yang L X, Xu F S, Zhang Q, et al. Gas-liquid hydrodynamics and mass transfer in microreactors under ultrasonic oscillation[J]. Chemical Engineering Journal, 2020, 397: 125411. |

| 24 | Butler C, Cid E, Billet A M, et al. Numerical simulation of mass transfer dynamics in Taylor flows[J]. International Journal of Heat and Mass Transfer, 2021, 179: 121670. |

| 25 | Yang L, Nieves-Remacha M J, Jensen K F. Simulations and analysis of multiphase transport and reaction in segmented flow microreactors[J]. Chemical Engineering Science, 2017, 169: 106-116. |

| 26 | Silva M F, Campos J B L M, Miranda J M, et al. Numerical study of single Taylor bubble movement through a microchannel using different CFD packages[J]. Processes, 2020, 8(11): 1418. |

| 27 | Özkan F, Wenka A, Hansjosten E, et al. Numerical investigation of interfacial mass transfer in two phase flows using the VOF method[J]. Engineering Applications of Computational Fluid Mechanics, 2016, 10(1): 100-110. |

| 28 | Soh G Y, Yeoh G H, Timchenko V. A CFD model for the coupling of multiphase, multicomponent and mass transfer physics for micro-scale simulations[J]. International Journal of Heat and Mass Transfer, 2017, 113: 922-934. |

| 29 | Gupta R, Fletcher D F, Haynes B S. On the CFD modelling of Taylor flow in microchannels[J]. Chemical Engineering Science, 2009, 64(12): 2941-2950. |

| 30 | Aussillous P, Quéré D. Quick deposition of a fluid on the wall of a tube[J]. Physics of Fluids, 2000, 12(10): 2367-2371. |

| 31 | Maksimov A, Leighton T, Birkin P. Acoustic microstreaming induced by pattern of Faraday waves on a bubble wall[J]. The Journal of the Acoustical Society of America, 2012, 131(4): 3338. |

| 32 | Yao C Q, Dong Z Y, Zhang Y C, et al. On the leakage flow around gas bubbles in slug flow in a microchannel[J]. AIChE Journal, 2015, 61(11): 3964-3972. |

| 33 | Higbie R. The rate of absorption of a pure gas into a still liquid during short periods of exposure[J]. Transactions of the AIChE, 1935, 31: 365-389. |

| 34 | Figueroa-Espinoza B, Legendre D. Mass or heat transfer from spheroidal gas bubbles rising through a stationary liquid[J]. Chemical Engineering Science, 2010, 65(23): 6296-6309. |

| [1] | 吴馨, 龚建英, 靳龙, 王宇涛, 黄睿宁. 超声波激励下铝板表面液滴群输运特性的研究[J]. 化工学报, 2023, 74(S1): 104-112. |

| [2] | 邵苛苛, 宋孟杰, 江正勇, 张旋, 张龙, 高润淼, 甄泽康. 水平方向上冰中受陷气泡形成和分布实验研究[J]. 化工学报, 2023, 74(S1): 161-164. |

| [3] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [4] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [5] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [6] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [7] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [8] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [9] | 岳林静, 廖艺涵, 薛源, 李雪洁, 李玉星, 刘翠伟. 凹坑缺陷对厚孔板喉部空化流动特性影响研究[J]. 化工学报, 2023, 74(8): 3292-3308. |

| [10] | 王海, 林宏, 王晨, 许浩洁, 左磊, 王军锋. 高压静电场强化多孔介质表面沸腾传热特性研究[J]. 化工学报, 2023, 74(7): 2869-2879. |

| [11] | 张媛媛, 曲江源, 苏欣欣, 杨静, 张锴. 循环流化床燃煤机组SNCR脱硝过程气液传质和反应特性[J]. 化工学报, 2023, 74(6): 2404-2415. |

| [12] | 王泽栋, 石至平, 刘丽艳. 考虑气泡非均匀耗散的矩形反应器声流场数值模拟及结构优化[J]. 化工学报, 2023, 74(5): 1965-1973. |

| [13] | 王皓, 唐思扬, 钟山, 梁斌. MEA吸收CO2富液解吸过程中固体颗粒表面的强化作用分析[J]. 化工学报, 2023, 74(4): 1539-1548. |

| [14] | 王倩倩, 刘明言, 马永丽. 水中超声波脱气的效应研究[J]. 化工学报, 2023, 74(4): 1693-1702. |

| [15] | 张银宁, 王进卿, 冯致, 詹明秀, 徐旭, 张光学, 池作和. 升温条件下多孔介质内气泡的生长和聚并行为[J]. 化工学报, 2023, 74(4): 1509-1518. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号