化工学报 ›› 2023, Vol. 74 ›› Issue (11): 4487-4500.DOI: 10.11949/0438-1157.20230844

收稿日期:2023-08-16

修回日期:2023-10-30

出版日期:2023-11-25

发布日期:2024-01-22

通讯作者:

刘剑

作者简介:周昉(2000—),女,硕士研究生,220220465@seu.edu.cn

基金资助:

Fang ZHOU1( ), Jian LIU1,2(

), Jian LIU1,2( ), Xiaosong ZHANG1,2

), Xiaosong ZHANG1,2

Received:2023-08-16

Revised:2023-10-30

Online:2023-11-25

Published:2024-01-22

Contact:

Jian LIU

摘要:

高温热泵因其能将低温废热转化为高温热能,成为低温废热再利用的一项关键节能技术。其中,针对高温热泵的混合工质筛选问题是当前研究焦点之一。基于由低沸点工质CO2和中高沸点工质HC类、HFO类组成的低GWP三元非共沸混合工质,提出了一种广泛适用的基于工作压力、温度滑移、可燃性和能效等关键因素的热泵用非共沸混合工质筛选方法,并对高温热泵系统进行了能效评估。结果表明,当混合工质CO2/R600a/R1234ze(Z)的质量分数为0.1/0.1/0.8时,设定工况下的热泵系统最大热力性能系数(COPh)为4.31,对应的单位容积热容量(VHC)为2766 kJ/m3,㶲效率(ηex)为0.50。

中图分类号:

周昉, 刘剑, 张小松. 基于多参数评估原则筛选高温热泵用三元非共沸混合工质[J]. 化工学报, 2023, 74(11): 4487-4500.

Fang ZHOU, Jian LIU, Xiaosong ZHANG. Selection of ternary zeotropic mixtures for high-temperature heat pumps on multiparameter evaluation principles[J]. CIESC Journal, 2023, 74(11): 4487-4500.

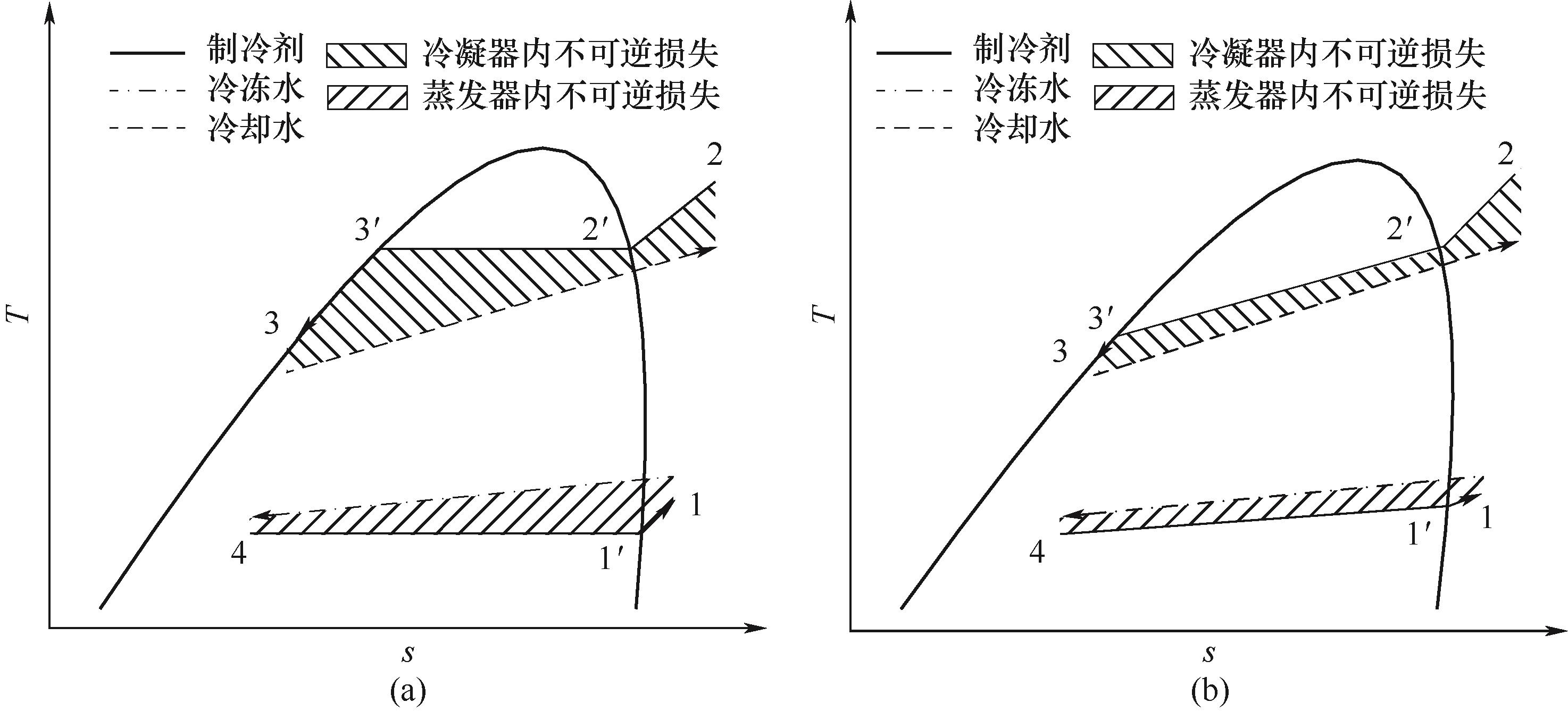

图1 单温工质(a)与非共沸混合工质(b)的换热过程不可逆损失对比

Fig.1 Comparison of irreversible losses during heat transfer between single-temperature refrigerant (a) and zeotropic mixture (b)

| 年份 | 工质 | 出水温度/冷凝温度 | COP | 热泵类型 | 文献 |

|---|---|---|---|---|---|

| 2023 | R1234ze(Z)/acetone R1234ze(Z)/isohexane | 200℃ | 4.5 | 带中间换热器的高温热泵 | [ |

| 2023 | CO2/R600 CO2/R601 | 115℃ | 3.6 | 级联蒸汽压缩式 | [ |

| 2023 | R600a/R601a | 80℃ | 4.82 | 单级蒸汽压缩式 | [ |

| 2023 | CO2/acetone | 200℃ | 5.15 | 带中间换热器的高温热泵 | [ |

| 2022 | CO2/R134a | 50℃ | 3.07 | 级联蒸汽压缩式 | [ |

| 2020 | R290/R600a/R13I1 | 90℃ | 3.8 | 两级压缩高温热泵 | [ |

| 2019 | CO2/R32 CO2/R41 | 99℃ | 5.28 | 带中间换热器的高温热泵 | [ |

| 2010 | R152a/R245fa | 90℃ | 3.4 | 单级蒸汽压缩式 | [ |

表1 高温热泵用混合工质研究现状

Table 1 Summary of zeotropic mixtures for high-temperature heat pump

| 年份 | 工质 | 出水温度/冷凝温度 | COP | 热泵类型 | 文献 |

|---|---|---|---|---|---|

| 2023 | R1234ze(Z)/acetone R1234ze(Z)/isohexane | 200℃ | 4.5 | 带中间换热器的高温热泵 | [ |

| 2023 | CO2/R600 CO2/R601 | 115℃ | 3.6 | 级联蒸汽压缩式 | [ |

| 2023 | R600a/R601a | 80℃ | 4.82 | 单级蒸汽压缩式 | [ |

| 2023 | CO2/acetone | 200℃ | 5.15 | 带中间换热器的高温热泵 | [ |

| 2022 | CO2/R134a | 50℃ | 3.07 | 级联蒸汽压缩式 | [ |

| 2020 | R290/R600a/R13I1 | 90℃ | 3.8 | 两级压缩高温热泵 | [ |

| 2019 | CO2/R32 CO2/R41 | 99℃ | 5.28 | 带中间换热器的高温热泵 | [ |

| 2010 | R152a/R245fa | 90℃ | 3.4 | 单级蒸汽压缩式 | [ |

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 废水入口温度(T5) | 30℃ | 蒸发器中露点温度(Tevap,dew) | T5-5℃ |

| 废水出口温度(T6) | 5℃ | 冷凝器中露点温度(Tcond,dew) | T8+5℃ |

| 热水进口温度(T7) | 30℃ | 蒸发器中过热度(Tsh) | 5℃ |

| 热水出口温度(T8) | 85℃ | 冷凝器中过冷度(Tsc) | 3℃ |

表2 高温热泵系统运行参数

Table 2 Operating parameters of high-temperature heat pump system

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 废水入口温度(T5) | 30℃ | 蒸发器中露点温度(Tevap,dew) | T5-5℃ |

| 废水出口温度(T6) | 5℃ | 冷凝器中露点温度(Tcond,dew) | T8+5℃ |

| 热水进口温度(T7) | 30℃ | 蒸发器中过热度(Tsh) | 5℃ |

| 热水出口温度(T8) | 85℃ | 冷凝器中过冷度(Tsc) | 3℃ |

| 部件 | 能量平衡 | 㶲平衡② |

|---|---|---|

| 压缩机 | ||

| 冷凝器 | ||

| 膨胀阀 | ||

| 蒸发器 |

表3 系统各部件能量平衡和㶲平衡

Table 3 Energy and exergy balance of each component

| 部件 | 能量平衡 | 㶲平衡② |

|---|---|---|

| 压缩机 | ||

| 冷凝器 | ||

| 膨胀阀 | ||

| 蒸发器 |

| 工质 | 标准沸点/℃ | 临界温度/℃ | 临界压力/MPa | ODP | GWP100 | 可燃性 | LFL/%(体积分数) | UFL/%(体积分数) |

|---|---|---|---|---|---|---|---|---|

| CO2 | -78.46 | 30.98 | 7.38 | 0 | 1 | A1 | — | — |

| R600a | -11.75 | 134.66 | 3.63 | 0 | 约20 | A3 | 1.8 | 8.4 |

| R290 | -42.11 | 96.74 | 4.25 | 0 | 5 | A3 | 2.1 | 9.5 |

| R1270 | -47.62 | 91.06 | 4.56 | 0 | 1.8 | A3 | 2 | 11.1 |

| RE170 | -24.78 | 127.23 | 5.34 | 0 | 1 | A3 | 3.4 | 27 |

| R1336mzz(Z) | 33.45 | 171.35 | 2.90 | 0 | 2 | A1 | — | — |

| R1234ze(Z) | 9.75 | 150.12 | 3.53 | 0 | <1 | A2L | 7.5 | 16.4 |

表4 所选工质的物性参数及其环境性能[34]

Table 4 Physical parameters and environmental performance of common pure refrigerants[34]

| 工质 | 标准沸点/℃ | 临界温度/℃ | 临界压力/MPa | ODP | GWP100 | 可燃性 | LFL/%(体积分数) | UFL/%(体积分数) |

|---|---|---|---|---|---|---|---|---|

| CO2 | -78.46 | 30.98 | 7.38 | 0 | 1 | A1 | — | — |

| R600a | -11.75 | 134.66 | 3.63 | 0 | 约20 | A3 | 1.8 | 8.4 |

| R290 | -42.11 | 96.74 | 4.25 | 0 | 5 | A3 | 2.1 | 9.5 |

| R1270 | -47.62 | 91.06 | 4.56 | 0 | 1.8 | A3 | 2 | 11.1 |

| RE170 | -24.78 | 127.23 | 5.34 | 0 | 1 | A3 | 3.4 | 27 |

| R1336mzz(Z) | 33.45 | 171.35 | 2.90 | 0 | 2 | A1 | — | — |

| R1234ze(Z) | 9.75 | 150.12 | 3.53 | 0 | <1 | A2L | 7.5 | 16.4 |

| 反应物 | 生成物 | ||

|---|---|---|---|

| 工质 | 生成焓/(kJ/mol) | 工质 | 生成焓/(kJ/mol) |

| CO2 | -393.51 | CO2 | -393.51 |

| R600a | -134.20 | COF2 | -638.90 |

| R290 | -104.70 | H2O | -241.83 |

| R1270 | 20.41 | HF | -273.30 |

| RE170 | -184.10 | ||

| R1336mzz(Z) | — | ||

| R1234ze(Z) | -781.82 | ||

表5 纯工质的生成焓(298 K)[34]

Table 5 Enthalpy of formation of various pure refrigerants (298 K)[34]

| 反应物 | 生成物 | ||

|---|---|---|---|

| 工质 | 生成焓/(kJ/mol) | 工质 | 生成焓/(kJ/mol) |

| CO2 | -393.51 | CO2 | -393.51 |

| R600a | -134.20 | COF2 | -638.90 |

| R290 | -104.70 | H2O | -241.83 |

| R1270 | 20.41 | HF | -273.30 |

| RE170 | -184.10 | ||

| R1336mzz(Z) | — | ||

| R1234ze(Z) | -781.82 | ||

| 工质对 | 质量分数比例 | 冷凝器侧水温/℃ | 蒸发器侧水温/℃ | 过热度/℃ | COPth | COPref | COPerror |

|---|---|---|---|---|---|---|---|

CO2/R32/ R1234yf | 0.04/0.44/0.52 | 20→30 | 15→9 | 3 | 7.81 | 8.2 | 4.99% |

| 0.05/0.28/0.67 | 7.88 | 7.4 | 6.09% |

表6 数学模型验证条件和结果[43]

Table 6 Compared working conditions and results[43]

| 工质对 | 质量分数比例 | 冷凝器侧水温/℃ | 蒸发器侧水温/℃ | 过热度/℃ | COPth | COPref | COPerror |

|---|---|---|---|---|---|---|---|

CO2/R32/ R1234yf | 0.04/0.44/0.52 | 20→30 | 15→9 | 3 | 7.81 | 8.2 | 4.99% |

| 0.05/0.28/0.67 | 7.88 | 7.4 | 6.09% |

| 混合工质 | 质量分数比例 | 运行压力 | |||

|---|---|---|---|---|---|

| CO2/R600a/R1336mzz(Z) | CO2 | R600a | R1336mzz(Z) | Pevap/MPa | Pcond/MPa |

| 0.4 | 0.1~0 | 0.5~0.6 | 0.34~0.26 | 2.90~2.23 | |

| 0.3 | 0.3~0 | 0.4~0.7 | 0.41~0.19 | 2.88~1.57 | |

| 0.2 | 0.8~0.1 | 0~0.7 | 0.47~0.18 | 2.37~1.43 | |

| 0.1 | 0.9~0.2 | 0~0.7 | 0.41~0.17 | 1.96~1.28 | |

| 0 | 1~0.3 | 0~0.7 | 0.35~0.16 | 1.64~1.12 | |

| CO2/R290/R1336mzz(Z) | CO2 | R290 | R1336mzz(Z) | Pevap/MPa | Pcond/MPa |

| 0.3 | 0.1~0 | 0.6~0.7 | 0.26~0.19 | 2.19~1.57 | |

| 0.2 | 0.3~0.1 | 0.5~0.7 | 0.35~0.19 | 2.87~1.56 | |

| 0.1 | 0.4~0.2 | 0.5~0.7 | 0.35~0.19 | 2.63~1.54 | |

| 0 | 0.6~0.3 | 0.4~0.7 | 0.46~0.19 | 2.76~1.49 | |

| CO2/R1270/R1336mzz(Z) | CO2 | R1270 | R1336mzz(Z) | Pevap/MPa | Pcond/MPa |

| 0.3 | 0.1~0 | 0.6~0.7 | 0.26~0.19 | 2.22~1.57 | |

| 0.2 | 0.2~0.1 | 0.6~0.7 | 0.26~0.20 | 2.20~1.58 | |

| 0.1 | 0.4~0.2 | 0.5~0.7 | 0.36~0.20 | 2.84~1.59 | |

| 0 | 0.6~0.3 | 0.4~0.7 | 0.46~0.19 | 2.76~1.49 | |

| CO2/RE170/R1336mzz(Z) | CO2 | RE170 | R1336mzz(Z) | Pevap/MPa | Pcond/MPa |

| 0.4 | 0.1~0 | 0.5~0.6 | 0.33~0.26 | 2.75~2.23 | |

| 0.3 | 0.3~0 | 0.4~0.7 | 0.39~0.19 | 2.74~1.57 | |

| 0.2 | 0.6~0.1 | 0.2~0.7 | 0.53~0.18 | 2.97~1.43 | |

| 0.1 | 0.8~0.2 | 0.1~0.7 | 0.56~0.17 | 2.84~1.29 | |

| 0 | 1~0.3 | 0~0.7 | 0.59~0.17 | 2.72~1.17 | |

| CO2/R600a/R1234ze(Z) | CO2 | R600a | R1234ze(Z) | Pevap/MPa | Pcond/MPa |

| 0.3 | 0.1~0 | 0.6~0.7 | 0.44~0.38 | 2.91~2.55 | |

| 0.2 | 0.8~0 | 0~0.8 | 0.47~0.30 | 2.37~1.92 | |

| 0.1 | 0.9~0 | 0~0.9 | 0.41~0.23 | 1.96~1.46 | |

| 0 | 1~0 | 0~1 | 0.35~0.18 | 1.64~1.08 | |

| CO2/R290/R1234ze(Z) | CO2 | R290 | R1234ze(Z) | Pevap/MPa | Pcond/MPa |

| 0.2 | 0.1~0 | 0.7~0.8 | 0.37~0.30 | 2.47~1.92 | |

| 0.1 | 0.3~0 | 0.6~0.9 | 0.47~0.23 | 2.86~1.46 | |

| 0 | 0.5~0 | 0.5~1 | 0.56~0.18 | 2.90~1.08 | |

| CO2/R1270/R1234ze(Z) | CO2 | R1270 | R1234ze(Z) | Pevap/MPa | Pcond/MPa |

| 0.2 | 0.1~0 | 0.7~0.8 | 0.38~0.30 | 2.50~1.92 | |

| 0.1 | 0.2~0.1 | 0.7~0.9 | 0.38~0.23 | 2.42~1.46 | |

| 0 | 0.5~0 | 0.5~1 | 0.56~0.18 | 2.90~1.08 | |

| CO2/RE170/R1234ze(Z) | CO2 | RE170 | R1234ze(Z) | Pevap/MPa | Pcond/MPa |

| 0.3 | 0.1~0 | 0.6~0.7 | 0.45~0.38 | 2.89~2.55 | |

| 0.2 | 0.4~0 | 0.4~0.8 | 0.52~0.30 | 2.91~1.92 | |

| 0.1 | 0.8~0 | 0.1~0.9 | 0.61~0.23 | 2.95~1.46 | |

| 0 | 1~0.3 | 0~0.7 | 0.59~0.18 | 2.72~1.08 | |

表7 根据运行压力挑选出的混合工质组分比

Table 7 Selected results with the operated pressure

| 混合工质 | 质量分数比例 | 运行压力 | |||

|---|---|---|---|---|---|

| CO2/R600a/R1336mzz(Z) | CO2 | R600a | R1336mzz(Z) | Pevap/MPa | Pcond/MPa |

| 0.4 | 0.1~0 | 0.5~0.6 | 0.34~0.26 | 2.90~2.23 | |

| 0.3 | 0.3~0 | 0.4~0.7 | 0.41~0.19 | 2.88~1.57 | |

| 0.2 | 0.8~0.1 | 0~0.7 | 0.47~0.18 | 2.37~1.43 | |

| 0.1 | 0.9~0.2 | 0~0.7 | 0.41~0.17 | 1.96~1.28 | |

| 0 | 1~0.3 | 0~0.7 | 0.35~0.16 | 1.64~1.12 | |

| CO2/R290/R1336mzz(Z) | CO2 | R290 | R1336mzz(Z) | Pevap/MPa | Pcond/MPa |

| 0.3 | 0.1~0 | 0.6~0.7 | 0.26~0.19 | 2.19~1.57 | |

| 0.2 | 0.3~0.1 | 0.5~0.7 | 0.35~0.19 | 2.87~1.56 | |

| 0.1 | 0.4~0.2 | 0.5~0.7 | 0.35~0.19 | 2.63~1.54 | |

| 0 | 0.6~0.3 | 0.4~0.7 | 0.46~0.19 | 2.76~1.49 | |

| CO2/R1270/R1336mzz(Z) | CO2 | R1270 | R1336mzz(Z) | Pevap/MPa | Pcond/MPa |

| 0.3 | 0.1~0 | 0.6~0.7 | 0.26~0.19 | 2.22~1.57 | |

| 0.2 | 0.2~0.1 | 0.6~0.7 | 0.26~0.20 | 2.20~1.58 | |

| 0.1 | 0.4~0.2 | 0.5~0.7 | 0.36~0.20 | 2.84~1.59 | |

| 0 | 0.6~0.3 | 0.4~0.7 | 0.46~0.19 | 2.76~1.49 | |

| CO2/RE170/R1336mzz(Z) | CO2 | RE170 | R1336mzz(Z) | Pevap/MPa | Pcond/MPa |

| 0.4 | 0.1~0 | 0.5~0.6 | 0.33~0.26 | 2.75~2.23 | |

| 0.3 | 0.3~0 | 0.4~0.7 | 0.39~0.19 | 2.74~1.57 | |

| 0.2 | 0.6~0.1 | 0.2~0.7 | 0.53~0.18 | 2.97~1.43 | |

| 0.1 | 0.8~0.2 | 0.1~0.7 | 0.56~0.17 | 2.84~1.29 | |

| 0 | 1~0.3 | 0~0.7 | 0.59~0.17 | 2.72~1.17 | |

| CO2/R600a/R1234ze(Z) | CO2 | R600a | R1234ze(Z) | Pevap/MPa | Pcond/MPa |

| 0.3 | 0.1~0 | 0.6~0.7 | 0.44~0.38 | 2.91~2.55 | |

| 0.2 | 0.8~0 | 0~0.8 | 0.47~0.30 | 2.37~1.92 | |

| 0.1 | 0.9~0 | 0~0.9 | 0.41~0.23 | 1.96~1.46 | |

| 0 | 1~0 | 0~1 | 0.35~0.18 | 1.64~1.08 | |

| CO2/R290/R1234ze(Z) | CO2 | R290 | R1234ze(Z) | Pevap/MPa | Pcond/MPa |

| 0.2 | 0.1~0 | 0.7~0.8 | 0.37~0.30 | 2.47~1.92 | |

| 0.1 | 0.3~0 | 0.6~0.9 | 0.47~0.23 | 2.86~1.46 | |

| 0 | 0.5~0 | 0.5~1 | 0.56~0.18 | 2.90~1.08 | |

| CO2/R1270/R1234ze(Z) | CO2 | R1270 | R1234ze(Z) | Pevap/MPa | Pcond/MPa |

| 0.2 | 0.1~0 | 0.7~0.8 | 0.38~0.30 | 2.50~1.92 | |

| 0.1 | 0.2~0.1 | 0.7~0.9 | 0.38~0.23 | 2.42~1.46 | |

| 0 | 0.5~0 | 0.5~1 | 0.56~0.18 | 2.90~1.08 | |

| CO2/RE170/R1234ze(Z) | CO2 | RE170 | R1234ze(Z) | Pevap/MPa | Pcond/MPa |

| 0.3 | 0.1~0 | 0.6~0.7 | 0.45~0.38 | 2.89~2.55 | |

| 0.2 | 0.4~0 | 0.4~0.8 | 0.52~0.30 | 2.91~1.92 | |

| 0.1 | 0.8~0 | 0.1~0.9 | 0.61~0.23 | 2.95~1.46 | |

| 0 | 1~0.3 | 0~0.7 | 0.59~0.18 | 2.72~1.08 | |

| 混合工质 | 质量分数比例 | 温度滑移 | 混合工质 | 质量分数比例 | 温度滑移 | ||||

|---|---|---|---|---|---|---|---|---|---|

CO2/R600a/ R1336mzz(Z) | CO2 | R600a | R1336mzz(Z) | ΔTglide/K | CO2/R600a/ R1234ze(Z) | CO2 | R600a | R1234ze(Z) | ΔTglide/K |

| 0.2 | 0.8~0.6 | 0~0.2 | 56.55~58.90 | 0.2 | 0.8~0.2 | 0~0.6 | 56.55~58.79 | ||

| 0.1 | 0.6~0.3 | 0.3~0.6 | 40.22~58.57 | 0.1 | 0.2~0 | 0.7~0.9 | 42.62~53.44 | ||

CO2/R290/ R1336mzz(Z) | CO2 | R290 | R1336mzz(Z) | ΔTglide/K | CO2/R290/ R1234ze(Z) | CO2 | R290 | R1234ze(Z) | ΔTglide/K |

| 0.1 | 0.4~0.3 | 0.5~0.6 | 48.76~59.95 | 0.1 | 0.2~0 | 0.7~0.9 | 44.38~53.44 | ||

CO2/R1270/ R1336mzz(Z) | CO2 | R1270 | R1336mzz(Z) | ΔTglide/K | CO2/R1270/ R1234ze(Z) | CO2 | R1270 | R1234ze(Z) | ΔTglide/K |

| 0.1 | 0.4~0.3 | 0.5~0.6 | 45.59~56.39 | 0.1 | 0.2~0 | 0.7~0.9 | 42.83~53.44 | ||

CO2/RE170/ R1336mzz(Z) | CO2 | RE170 | R1336mzz(Z) | ΔTglide/K | CO2/RE170/ R1234ze(Z) | CO2 | RE170 | R1234ze(Z) | ΔTglide/K |

| 0.2 | 0.5~0.4 | 0.3~0.4 | 41.83~50.67 | 0.2 | 0.3~0.1 | 0.5~0.7 | 42.42~58.39 | ||

| 0.1 | 0.4~0.3 | 0.5~0.6 | 40.38~49.63 | 0.1 | 0.1~0 | 0.8~0.9 | 43.09~53.44 | ||

表8 根据温度滑移挑选出的混合工质组分比

Table 8 Selected results with the glide temperature

| 混合工质 | 质量分数比例 | 温度滑移 | 混合工质 | 质量分数比例 | 温度滑移 | ||||

|---|---|---|---|---|---|---|---|---|---|

CO2/R600a/ R1336mzz(Z) | CO2 | R600a | R1336mzz(Z) | ΔTglide/K | CO2/R600a/ R1234ze(Z) | CO2 | R600a | R1234ze(Z) | ΔTglide/K |

| 0.2 | 0.8~0.6 | 0~0.2 | 56.55~58.90 | 0.2 | 0.8~0.2 | 0~0.6 | 56.55~58.79 | ||

| 0.1 | 0.6~0.3 | 0.3~0.6 | 40.22~58.57 | 0.1 | 0.2~0 | 0.7~0.9 | 42.62~53.44 | ||

CO2/R290/ R1336mzz(Z) | CO2 | R290 | R1336mzz(Z) | ΔTglide/K | CO2/R290/ R1234ze(Z) | CO2 | R290 | R1234ze(Z) | ΔTglide/K |

| 0.1 | 0.4~0.3 | 0.5~0.6 | 48.76~59.95 | 0.1 | 0.2~0 | 0.7~0.9 | 44.38~53.44 | ||

CO2/R1270/ R1336mzz(Z) | CO2 | R1270 | R1336mzz(Z) | ΔTglide/K | CO2/R1270/ R1234ze(Z) | CO2 | R1270 | R1234ze(Z) | ΔTglide/K |

| 0.1 | 0.4~0.3 | 0.5~0.6 | 45.59~56.39 | 0.1 | 0.2~0 | 0.7~0.9 | 42.83~53.44 | ||

CO2/RE170/ R1336mzz(Z) | CO2 | RE170 | R1336mzz(Z) | ΔTglide/K | CO2/RE170/ R1234ze(Z) | CO2 | RE170 | R1234ze(Z) | ΔTglide/K |

| 0.2 | 0.5~0.4 | 0.3~0.4 | 41.83~50.67 | 0.2 | 0.3~0.1 | 0.5~0.7 | 42.42~58.39 | ||

| 0.1 | 0.4~0.3 | 0.5~0.6 | 40.38~49.63 | 0.1 | 0.1~0 | 0.8~0.9 | 43.09~53.44 | ||

| 混合工质 | 工质对 | 质量分数比例 | 可燃等级 | 混合工质 | 工质对 | 质量分数比例 | 可燃等级 |

|---|---|---|---|---|---|---|---|

CO2/R600a/ R1336mzz(Z) | R1 | 0.1/0.6/0.3 | ≤A2 | CO2/R600a/ R1234ze(Z) | R13 | 0.2/0.3/0.5 | ≤A2 |

| R2 | 0.1/0.5/0.4 | ≤A2 | R14 | 0.2/0.2/0.6 | ≤A2 | ||

| R3 | 0.1/0.4/0.5 | ≤A2 | R15 | 0.1/0.2/0.7 | ≤A2 | ||

| R4 | 0.1/0.3/0.6 | ≤A2 | R16 | 0.1/0.1/0.8 | ≤A2 | ||

CO2/R290/ R1336mzz(Z) | R5 | 0.1/0.4/0.5 | ≤A2 | CO2/R290/ R1234ze(Z) | R17 | 0.1/0.2/0.7 | ≤A2 |

| R6 | 0.1/0.3/0.6 | ≤A2 | R18 | 0.1/0.1/0.8 | ≤A2 | ||

CO2/R1270/ R1336mzz(Z) | R7 | 0.1/0.4/0.5 | ≤A2 | CO2/R1270/ R1234ze(Z) | R19 | 0.1/0.2/0.7 | ≤A2 |

| R8 | 0.1/0.3/0.6 | ≤A2 | R20 | 0.1/0.1/0.8 | ≤A2 | ||

CO2/RE170/ R1336mzz(Z) | R9 | 0.2/0.5/0.3 | ≤A2 | CO2/RE170/ R1234ze(Z) | R21 | 0.2/0.3/0.5 | ≤A2 |

| R10 | 0.2/0.4/0.4 | ≤A2 | R22 | 0.2/0.2/0.6 | ≤A2 | ||

| R11 | 0.1/0.4/0.5 | ≤A2 | R23 | 0.2/0.1/0.7 | ≤A2 | ||

| R12 | 0.1/0.3/0.6 | ≤A2 | R24 | 0.1/0.1/0.8 | ≤A2 |

表9 根据安全性和可燃性挑选出的混合工质组分比

Table 9 Selected results with the safety and flammability

| 混合工质 | 工质对 | 质量分数比例 | 可燃等级 | 混合工质 | 工质对 | 质量分数比例 | 可燃等级 |

|---|---|---|---|---|---|---|---|

CO2/R600a/ R1336mzz(Z) | R1 | 0.1/0.6/0.3 | ≤A2 | CO2/R600a/ R1234ze(Z) | R13 | 0.2/0.3/0.5 | ≤A2 |

| R2 | 0.1/0.5/0.4 | ≤A2 | R14 | 0.2/0.2/0.6 | ≤A2 | ||

| R3 | 0.1/0.4/0.5 | ≤A2 | R15 | 0.1/0.2/0.7 | ≤A2 | ||

| R4 | 0.1/0.3/0.6 | ≤A2 | R16 | 0.1/0.1/0.8 | ≤A2 | ||

CO2/R290/ R1336mzz(Z) | R5 | 0.1/0.4/0.5 | ≤A2 | CO2/R290/ R1234ze(Z) | R17 | 0.1/0.2/0.7 | ≤A2 |

| R6 | 0.1/0.3/0.6 | ≤A2 | R18 | 0.1/0.1/0.8 | ≤A2 | ||

CO2/R1270/ R1336mzz(Z) | R7 | 0.1/0.4/0.5 | ≤A2 | CO2/R1270/ R1234ze(Z) | R19 | 0.1/0.2/0.7 | ≤A2 |

| R8 | 0.1/0.3/0.6 | ≤A2 | R20 | 0.1/0.1/0.8 | ≤A2 | ||

CO2/RE170/ R1336mzz(Z) | R9 | 0.2/0.5/0.3 | ≤A2 | CO2/RE170/ R1234ze(Z) | R21 | 0.2/0.3/0.5 | ≤A2 |

| R10 | 0.2/0.4/0.4 | ≤A2 | R22 | 0.2/0.2/0.6 | ≤A2 | ||

| R11 | 0.1/0.4/0.5 | ≤A2 | R23 | 0.2/0.1/0.7 | ≤A2 | ||

| R12 | 0.1/0.3/0.6 | ≤A2 | R24 | 0.1/0.1/0.8 | ≤A2 |

| 1 | Vannoni A, Sorce A, Traverso A, et al. Techno-economic optimization of high-temperature heat pumps for waste heat recovery[J]. Energy Conversion and Management, 2023, 290: 117194. |

| 2 | Jouhara H, Olabi A G. Editorial: industrial waste heat recovery[J]. Energy, 2018, 160: 1-2. |

| 3 | Hamid K, Sajjad U, Ulrich Ahrens M, et al. Potential evaluation of integrated high temperature heat pumps: a review of recent advances[J]. Applied Thermal Engineering, 2023, 230: 120720. |

| 4 | Adamson K M, Walmsley T G, Carson J K, et al. High-temperature and transcritical heat pump cycles and advancements: a review[J]. Renewable and Sustainable Energy Reviews, 2022, 167: 112798. |

| 5 | Abas N, Kalair A R, Khan N, et al. Natural and synthetic refrigerants, global warming: a review[J]. Renewable and Sustainable Energy Reviews, 2018, 90: 557-569. |

| 6 | Mateu-Royo C, Navarro-Esbrí J, Mota-Babiloni A, et al. Thermodynamic analysis of low GWP alternatives to HFC-245fa in high-temperature heat pumps: HCFO-1224yd(Z), HCFO-1233zd(E) and HFO-1336mzz(Z)[J]. Applied Thermal Engineering, 2019, 152: 762-777. |

| 7 | Bolaji B O, Huan Z. Ozone depletion and global warming: case for the use of natural refrigerant—a review[J]. Renewable and Sustainable Energy Reviews, 2013, 18: 49-54. |

| 8 | Harby K. Hydrocarbons and their mixtures as alternatives to environmental unfriendly halogenated refrigerants: an updated overview[J]. Renewable and Sustainable Energy Reviews, 2017, 73: 1247-1264. |

| 9 | Al-Sayyab A K S, Navarro-Esbrí J, Barragán-Cervera A, et al. Comprehensive experimental evaluation of R1234yf-based low GWP working fluids for refrigeration and heat pumps[J]. Energy Conversion and Management, 2022, 258: 115378. |

| 10 | Pabon J J G, Khosravi A, Belman-Flores J M, et al. Applications of refrigerant R1234yf in heating, air conditioning and refrigeration systems: a decade of researches[J]. International Journal of Refrigeration, 2020, 118: 104-113. |

| 11 | Sarkar J, Bhattacharyya S. Assessment of blends of CO2 with butane and isobutane as working fluids for heat pump applications[J]. International Journal of Thermal Sciences, 2009, 48(7): 1460-1465. |

| 12 | Niu B L, Zhang Y F. Experimental study of the refrigeration cycle performance for the R744/R290 mixtures[J]. International Journal of Refrigeration, 2007, 30(1): 37-42. |

| 13 | Yao X Y, Shen J, Kang H F, et al. Measurement of critical parameters for the binary mixture of R744 (carbon dioxide) + R1234yf (2,3,3,3-tetrafluoropro-1-ene)[J]. The Journal of Chemical Thermodynamics, 2023, 178: 106978. |

| 14 | Thu K, Takezato K, Takata N, et al. Drop-in experiments and exergy assessment of HFC-32/HFO-1234yf/R744 mixture with GWP below 150 for domestic heat pumps[J]. International Journal of Refrigeration, 2021, 121: 289-301. |

| 15 | Sánchez D, Cabello R, Llopis R, et al. Energy assessment and environmental impact analysis of an R134a/R744 cascade refrigeration plant upgraded with the low-GWP refrigerants R152a, R1234ze(E), propane (R290) and propylene (R1270)[J]. International Journal of Refrigeration, 2019, 104: 321-334. |

| 16 | Kim J H, Cho J M, Kim M S. Cooling performance of several CO2/propane mixtures and glide matching with secondary heat transfer fluid[J]. International Journal of Refrigeration, 2008, 31(5): 800-806. |

| 17 | Garimella S, Milkie J, MacDonald M. Condensation of zeotropic mixtures of low-pressure hydrocarbons and synthetic refrigerants[J]. International Journal of Heat and Mass Transfer, 2020, 162: 120301. |

| 18 | 梁坤峰, 冯长振, 王莫然, 等. 非共沸工质换热匹配特性影响热泵性能的高级㶲分析[J]. 化工学报, 2021, 72(4): 2038-2046. |

| Liang K F, Feng C Z, Wang M R, et al. Advanced exergy analysis of heat pump performance affected by heat transfer matching characteristics of non-azeotropic refrigerants[J]. CIESC Journal, 2021, 72(4): 2038-2046. | |

| 19 | Abedini H, Tomassetti S, Di Nicola G, et al. Zeotropic mixtures R1234ze(Z)/acetone and R1234ze(Z)/isohexane as refrigerants in high temperature heat pumps: influence of the accuracy in thermodynamic properties evaluations [J]. International Journal of Refrigeration, 2023, 152: 93-109. |

| 20 | Ganesan P, Eikevik T M. New zeotropic CO2-based refrigerant mixtures for cascade high-temperature heat pump to reach heat sink temperature up to 180℃[J]. Energy Conversion and Management: X, 2023, 20: 100407. |

| 21 | Dai B M, Feng Y N, Liu S C, et al. Dual pressure condensation heating high temperature heat pump using eco-friendly working fluid mixtures for industrial heating processes: 4E analysis[J]. Energy, 2023, 283: 128639. |

| 22 | Gómez-Hernández J, Grimes R, Briongos J V, et al. Carbon dioxide and acetone mixtures as refrigerants for industry heat pumps to supply temperature in the range 150—220℃[J]. Energy, 2023, 269: 126821. |

| 23 | Zhang H W, Geng X D, Shao S Q, et al. Performance analysis of a R134a/CO2 cascade heat pump in severe cold regions of China[J]. Energy, 2022, 239: 122651. |

| 24 | Xiao B, Chang H W, He L, et al. Annual performance analysis of an air source heat pump water heater using a new eco-friendly refrigerant mixture as an alternative to R134a[J]. Renewable Energy, 2020, 147: 2013-2023. |

| 25 | Guo H, Gong M Q, Qin X Y. Performance analysis of a modified subcritical zeotropic mixture recuperative high-temperature heat pump[J]. Applied Energy, 2019, 237: 338-352. |

| 26 | Zhang S J, Wang H X, Guo T. Experimental investigation of moderately high temperature water source heat pump with non-azeotropic refrigerant mixtures[J]. Applied Energy, 2010, 87(5): 1554-1561. |

| 27 | Ma X L, Zhang Y F, Fang L, et al. Performance analysis of a cascade high temperature heat pump using R245fa and BY-3 as working fluid[J]. Applied Thermal Engineering, 2018, 140: 466-475. |

| 28 | Fernández-Moreno A, Mota-Babiloni A, Giménez-Prades P, et al. Optimal refrigerant mixture in single-stage high-temperature heat pumps based on a multiparameter evaluation[J]. Sustainable Energy Technologies and Assessments, 2022, 52: 101989. |

| 29 | Abedini H, Vieren E, Demeester T, et al. A comprehensive analysis of binary mixtures as working fluid in high temperature heat pumps[J]. Energy Conversion and Management, 2023, 277: 116652. |

| 30 | 刘剑, 张小松. 基于大滑移温度非共沸工质的双温冷水机组[J]. 化工学报, 2016, 67(4): 1186-1192. |

| Liu J, Zhang X S. Double temperature chilled water unit based on large temperature glide zeotropic mixture[J]. CIESC Journal, 2016, 67(4): 1186-1192. | |

| 31 | Zühlsdorf B, Jensen J K, Cignitti S, et al. Analysis of temperature glide matching of heat pumps with zeotropic working fluid mixtures for different temperature glides[J]. Energy, 2018, 153: 650-660. |

| 32 | Ganesan P, Eikevik T M, Hamid K, et al. Thermodynamic analysis of cascade high-temperature heat pump using new natural zeotropic refrigerant mixtures: R744/R600 and R744/R601[J]. International Journal of Refrigeration, 2023, 154: 215-230. |

| 33 | Brunin O, Feidt M, Hivet B. Comparison of the working domains of some compression heat pumps and a compression-absorption heat pump[J]. International Journal of Refrigeration, 1997, 20(5): 308-318. |

| 34 | ASHRAE. Designation and safety classification of refrigerants: standard 34—2019 [S]. Atlanta, GA, USA: American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc., 2019. |

| 35 | Sobieraj M, Rosiński M. Experimental study of the heat transfer in R744/R600a mixtures below the R744 triple point temperature[J]. International Journal of Refrigeration, 2019, 103: 243-252. |

| 36 | Liu J, Zhou L, Lin Z, et al. Performance evaluation of low GWP large glide temperature zeotropic mixtures applied in air source heat pump for DHW production[J]. Energy Conversion and Management, 2022, 274: 116457. |

| 37 | Shu G Q, Long B, Tian H, et al. Flame temperature theory-based model for evaluation of the flammable zones of hydrocarbon-air-CO2 mixtures[J]. Journal of Hazardous Materials, 2015, 294: 137-144. |

| 38 | 巨福军. 热泵热水器用R744混合工质优选及其系统稳态与瞬态特性研究[D]. 南京: 东南大学, 2019. |

| Ju F J. Study on the quality selection of R744 mixer for heat pump water heater and the steady and transient characteristics of the system[D]. Nanjing: Southeast University, 2019. | |

| 39 | 田贯三. 可燃制冷剂爆炸理论与燃烧爆炸抑制机理的研究[D]. 天津: 天津大学, 2000. |

| Tian G S. Study on explosion theory of flammable refrigerant and suppression mechanism of combustion explosion[D].Tianjin: Tianjin University, 2000. | |

| 40 | Ma T G. A thermal theory for estimating the flammability limits of a mixture[J]. Fire Safety Journal, 2011, 46(8): 558-567. |

| 41 | Zhao Z, Luo J L, Yang K Y, et al. Experimental study on the influence of flame retardants on the flammability of R1234yf[J]. Journal of Loss Prevention in the Process Industries, 2023, 81: 104945. |

| 42 | Calleja-Anta D, Nebot-Andres L, Cabello R, et al. A3 and A2 refrigerants: border determination and hunt for A2 low-GWP blends[J]. International Journal of Refrigeration, 2022, 134: 86-94. |

| 43 | Fukuda S, Kojima H, Kondou C, et al. Experimental assessment on performance of a heat pump cycle using R32/R1234yf and R744/R32/R1234yf[C]//International Refrigeration and Air Conditioning Conference. 2016. |

| 44 | Tian H, Wu M Q, Shu G Q, et al. Experimental and theoretical study of flammability limits of hydrocarbon-CO2 mixture[J]. International Journal of Hydrogen Energy, 2017, 42(49): 29597-29605. |

| 45 | Chen Q, Yan J W, Chen G M, et al. Experimental studies on the flammability of mixtures of dimethyl ether[J]. Journal of Fluorine Chemistry, 2015, 176: 40-43. |

| [1] | 杨欣, 王文, 徐凯, 马凡华. 高压氢气加注过程中温度特征仿真分析[J]. 化工学报, 2023, 74(S1): 280-286. |

| [2] | 常明慧, 王林, 苑佳佳, 曹艺飞. 盐溶液蓄能型热泵循环特性研究[J]. 化工学报, 2023, 74(S1): 329-337. |

| [3] | 代宝民, 王启龙, 刘圣春, 张佳宁, 李鑫海, 宗凡迪. 非共沸工质辅助过冷CO2冷热联供系统的热力学性能分析[J]. 化工学报, 2023, 74(S1): 64-73. |

| [4] | 张化福, 童莉葛, 张振涛, 杨俊玲, 王立, 张俊浩. 机械蒸汽压缩蒸发技术研究现状与发展趋势[J]. 化工学报, 2023, 74(S1): 8-24. |

| [5] | 胡建波, 刘洪超, 胡齐, 黄美英, 宋先雨, 赵双良. 有机笼跨细胞膜易位行为的分子动力学模拟研究[J]. 化工学报, 2023, 74(9): 3756-3765. |

| [6] | 张曼铮, 肖猛, 闫沛伟, 苗政, 徐进良, 纪献兵. 危废焚烧处理耦合有机朗肯循环系统工质筛选与热力学优化[J]. 化工学报, 2023, 74(8): 3502-3512. |

| [7] | 卫雪岩, 钱勇. 微米级铁粉燃料中低温氧化反应特性及其动力学研究[J]. 化工学报, 2023, 74(6): 2624-2638. |

| [8] | 姚晓宇, 沈俊, 李健, 李振兴, 康慧芳, 唐博, 董学强, 公茂琼. 流体气液临界参数测量方法研究进展[J]. 化工学报, 2023, 74(5): 1847-1861. |

| [9] | 陈科, 杜理, 曾英, 任思颖, 于旭东. 四元体系LiCl+MgCl2+CaCl2+H2O 323.2 K相平衡研究及计算[J]. 化工学报, 2023, 74(5): 1896-1903. |

| [10] | 党玉荣, 莫春兰, 史科锐, 方颖聪, 张子杨, 李作顺. 综合评价模型联合遗传算法的混合工质ORC系统性能研究[J]. 化工学报, 2023, 74(5): 1884-1895. |

| [11] | 毛元敬, 杨智, 莫松平, 郭浩, 陈颖, 罗向龙, 陈健勇, 梁颖宗. C6~C10烷醇的SAFT-VR Mie状态方程参数回归及其热物性研究[J]. 化工学报, 2023, 74(3): 1033-1041. |

| [12] | 程文婷, 李杰, 徐丽, 程芳琴, 刘国际. AlCl3·6H2O在FeCl3、CaCl2、KCl及KCl–FeCl3溶液中溶解度的实验及预测[J]. 化工学报, 2023, 74(2): 642-652. |

| [13] | 邓均锐, 李泽宇, 陈嘉衍. 面向动力电池热安全的准被动式热移出系统[J]. 化工学报, 2023, 74(11): 4679-4687. |

| [14] | 洪小东, 董轩, 林美金, 廖祖维, 任聪静, 杨遥, 蒋斌波, 王靖岱, 阳永荣. 图神经网络预测烃类工质的热力学性质[J]. 化工学报, 2023, 74(11): 4466-4474. |

| [15] | 刘宗鹏, 胡少剑, 张宇宁, 马玲, 李磊, 武本成, 朱建华. 复合型多元醇酯合成反应的热力学分析及动力学研究[J]. 化工学报, 2023, 74(11): 4475-4486. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号