化工学报 ›› 2024, Vol. 75 ›› Issue (3): 914-923.DOI: 10.11949/0438-1157.20231370

陈宇翔1( ), 刘传磊1, 龚子君2, 赵起越1, 郭冠初1, 姜豪1, 孙辉1,3,4(

), 刘传磊1, 龚子君2, 赵起越1, 郭冠初1, 姜豪1, 孙辉1,3,4( ), 沈本贤1

), 沈本贤1

收稿日期:2023-12-25

修回日期:2024-02-06

出版日期:2024-03-25

发布日期:2024-05-11

通讯作者:

孙辉

作者简介:陈宇翔(1996—),男,博士研究生,chenyuxiang0425@gmail.com

基金资助:

Yuxiang CHEN1( ), Chuanlei LIU1, Zijun GONG2, Qiyue ZHAO1, Guanchu GUO1, Hao JIANG1, Hui SUN1,3,4(

), Chuanlei LIU1, Zijun GONG2, Qiyue ZHAO1, Guanchu GUO1, Hao JIANG1, Hui SUN1,3,4( ), Benxian SHEN1

), Benxian SHEN1

Received:2023-12-25

Revised:2024-02-06

Online:2024-03-25

Published:2024-05-11

Contact:

Hui SUN

摘要:

针对传统胺洗脱硫工艺中有机硫脱除效率低,溶剂开发周期长、成本高等问题,利用7种机器学习算法建立了乙硫醇溶解度的定量构效关系模型,运用SHAP方法阐释了乙硫醇的吸收机理,对备选分子库进行了虚拟筛选,识别出高效吸收脱除乙硫醇的溶剂。基于COSMO-RS模型计算了14732种溶剂的乙硫醇溶解度,这些分子覆盖了广泛的化学空间;XGBoost算法在预测乙硫醇溶解度方面表现最佳,该算法的

中图分类号:

陈宇翔, 刘传磊, 龚子君, 赵起越, 郭冠初, 姜豪, 孙辉, 沈本贤. 机器学习辅助乙硫醇高效吸收溶剂分子设计[J]. 化工学报, 2024, 75(3): 914-923.

Yuxiang CHEN, Chuanlei LIU, Zijun GONG, Qiyue ZHAO, Guanchu GUO, Hao JIANG, Hui SUN, Benxian SHEN. Machine learning-assisted solvent molecule design for efficient absorption of ethanethiol[J]. CIESC Journal, 2024, 75(3): 914-923.

| 原料 | 含量 | 生产厂家 |

|---|---|---|

| 3-乙氧基丙胺 | 99.0% | 北京华威锐科化工有限公司 |

| 3-丁氧基丙胺 | 98.0% | 上海恩拿马生物科技有限公司 |

| 3-二乙胺基丙胺 | 99.0% | 上海迈瑞尔生化科技有限公司 |

| 1,4-二甲基哌嗪 | 98.0% | 上海迈瑞尔生化科技有限公司 |

| 环丁砜 | 99.7% | 上海新铂化学技术有限公司 |

| 混合气 | 上海伟创标准气体有限公司 | |

| 乙硫醇 | 5578.2 mg/m3(标准工况) | |

| 氮气 | 余量 |

表1 平衡溶解度测定实验所用原料

Table 1 Raw materials used for equilibrium solubility determination experiment

| 原料 | 含量 | 生产厂家 |

|---|---|---|

| 3-乙氧基丙胺 | 99.0% | 北京华威锐科化工有限公司 |

| 3-丁氧基丙胺 | 98.0% | 上海恩拿马生物科技有限公司 |

| 3-二乙胺基丙胺 | 99.0% | 上海迈瑞尔生化科技有限公司 |

| 1,4-二甲基哌嗪 | 98.0% | 上海迈瑞尔生化科技有限公司 |

| 环丁砜 | 99.7% | 上海新铂化学技术有限公司 |

| 混合气 | 上海伟创标准气体有限公司 | |

| 乙硫醇 | 5578.2 mg/m3(标准工况) | |

| 氮气 | 余量 |

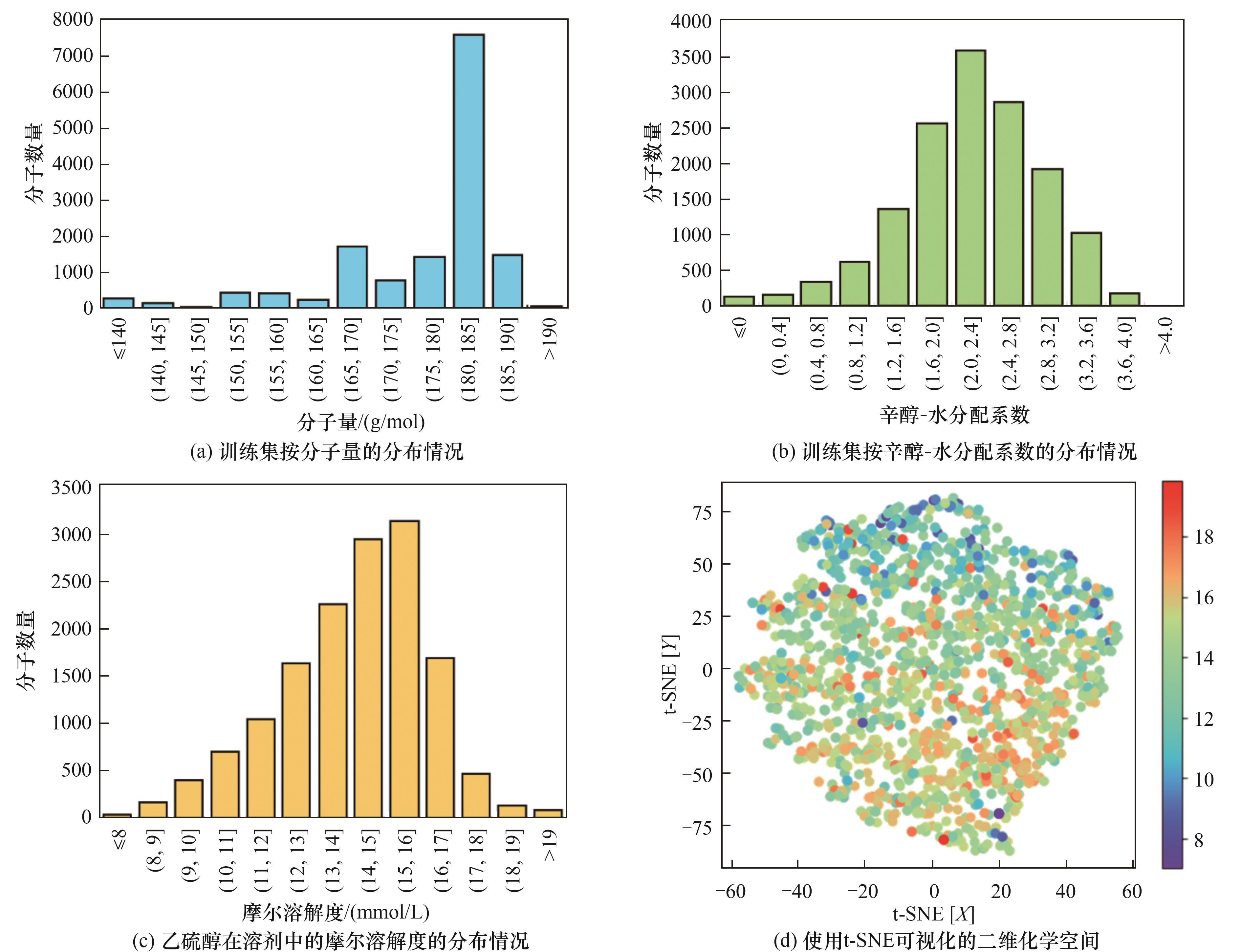

图2 初始训练集中分子量、辛醇-水分配系数、乙硫醇摩尔溶解度的分布情况和初始训练集的二维化学空间

Fig.2 Distribution of molecular weight, octanol-water partition coefficient, and molar solubility of ethanethiol in the initial training set, and the two-dimensional chemical space of the initial training set

| 算法 | 超参数 | 搜索空间 | 优化后的参数 |

|---|---|---|---|

| MLR | default | — | default |

| RR | alpha | logspace(-5,3,20) | 0.16 |

| LR | alpha | logspace(-5,3,20) | 0.12 |

| KNN | n_neighbors | [ | 8 |

| DT | max_depth | [ | 100 |

| RF | max_depth | [ | 100 |

| max_features | [sqrt, log2, none] | sqrt | |

| n_estimators | [ | 10000 | |

| XGBoost | learning_rate | [0.001,0.01,0.1,1,10] | 0.01 |

| max_depth | [ | 100 | |

| n_estimators | [ | 10000 |

表 2 不同算法的超参数

Table 2 Hyperparameter of different algorithms

| 算法 | 超参数 | 搜索空间 | 优化后的参数 |

|---|---|---|---|

| MLR | default | — | default |

| RR | alpha | logspace(-5,3,20) | 0.16 |

| LR | alpha | logspace(-5,3,20) | 0.12 |

| KNN | n_neighbors | [ | 8 |

| DT | max_depth | [ | 100 |

| RF | max_depth | [ | 100 |

| max_features | [sqrt, log2, none] | sqrt | |

| n_estimators | [ | 10000 | |

| XGBoost | learning_rate | [0.001,0.01,0.1,1,10] | 0.01 |

| max_depth | [ | 100 | |

| n_estimators | [ | 10000 |

| 算法 | RMSE | MAE | ||

|---|---|---|---|---|

| MLR | 0.66 | 0.65 | 1.23 | 0.87 |

| RR | 0.66 | 0.65 | 1.24 | 0.87 |

| LR | 0.64 | 0.63 | 1.27 | 0.90 |

| KNN | 0.57 | 0.36 | 1.67 | 1.25 |

| DT | 0.75 | 0.48 | 1.50 | 1.04 |

| RF | 0.95 | 0.65 | 1.23 | 0.86 |

| XGBoost | 0.98 | 0.66 | 1.22 | 0.84 |

表3 不同算法得到的乙硫醇溶解度预测模型的指标

Table 3 Metrics of ethanethiol solubility prediction model using different algorithms

| 算法 | RMSE | MAE | ||

|---|---|---|---|---|

| MLR | 0.66 | 0.65 | 1.23 | 0.87 |

| RR | 0.66 | 0.65 | 1.24 | 0.87 |

| LR | 0.64 | 0.63 | 1.27 | 0.90 |

| KNN | 0.57 | 0.36 | 1.67 | 1.25 |

| DT | 0.75 | 0.48 | 1.50 | 1.04 |

| RF | 0.95 | 0.65 | 1.23 | 0.86 |

| XGBoost | 0.98 | 0.66 | 1.22 | 0.84 |

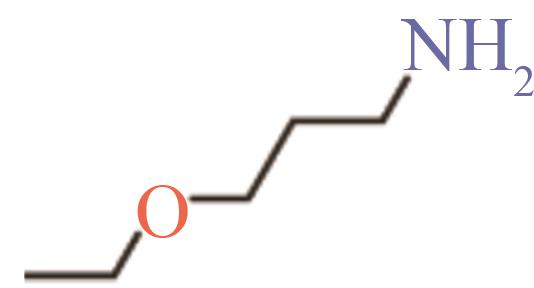

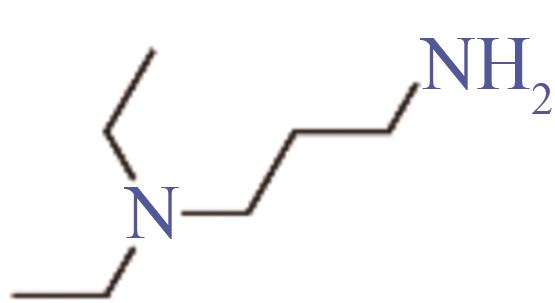

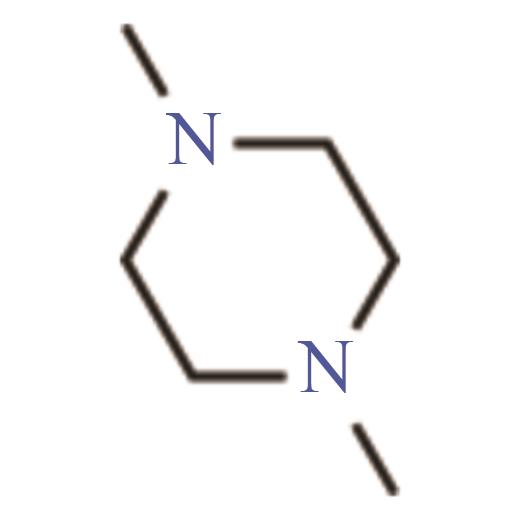

| 分子结构 | 分子名称 | CAS号 | 沸点/℃ | 熔点/℃ | 水溶性 |

|---|---|---|---|---|---|

| 3-乙氧基丙胺 | 6291-85-6 | 136~138 | -24 | 可溶 |

| 3-二乙胺基丙胺 | 104-78-9 | 168~171 | -60 | 可溶 |

| 1,4-二甲基哌嗪 | 106-58-1 | 131~132 | -1 | 可溶 |

| 3-丁氧基丙胺 | 16499-88-0 | 169~170 | -65 | 可溶 |

表4 选出的4个分子的性质

Table 4 Properties of the four selected molecules

| 分子结构 | 分子名称 | CAS号 | 沸点/℃ | 熔点/℃ | 水溶性 |

|---|---|---|---|---|---|

| 3-乙氧基丙胺 | 6291-85-6 | 136~138 | -24 | 可溶 |

| 3-二乙胺基丙胺 | 104-78-9 | 168~171 | -60 | 可溶 |

| 1,4-二甲基哌嗪 | 106-58-1 | 131~132 | -1 | 可溶 |

| 3-丁氧基丙胺 | 16499-88-0 | 169~170 | -65 | 可溶 |

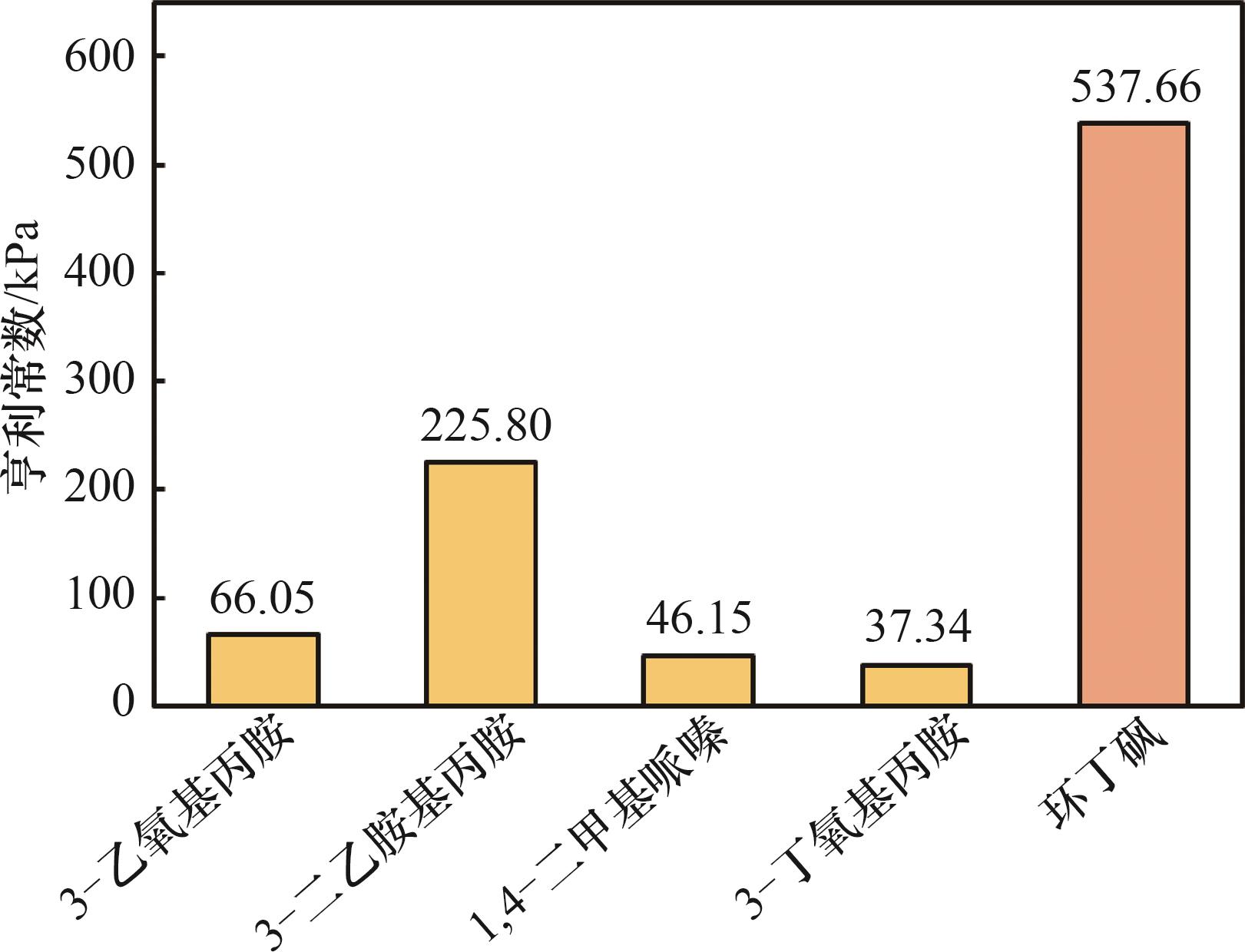

图6 实验测定40℃下乙硫醇在3-乙氧基丙胺、3-二乙胺基丙胺、1,4-二甲基哌嗪、3-丁氧基丙胺和环丁砜中溶解的亨利常数

Fig. 6 The experimental Henry’s constants of ethanethiol in 3-ethoxypropylamine, 3-diethylaminopropylamine, 1,4-dimethylpiperazine, 3-butoxypropylamine and sulfolane at 40℃

| 1 | 中国石油国家高端智库研究中心. 中国天然气发展报告(2023) [M]. 北京: 石油工业出版社, 2023. |

| PetroChina National Research Center for High-End Think Tank. China Natural Gas Development Report (2023) [M]. Beijing: Petroleum Industry Press, 2023. | |

| 2 | de Angelis A. Natural gas removal of hydrogen sulphide and mercaptans[J]. Applied Catalysis B: Environmental, 2012, 113/114: 37-42. |

| 3 | Iliuta M C, Larachi F. Solubility of total reduced sulfurs (hydrogen sulfide, methyl mercaptan, dimethyl sulfide, and dimethyl disulfide) in liquids[J]. Journal of Chemical & Engineering Data, 2007, 52(1): 2-19. |

| 4 | Petit C, Mendoza B, Bandosz T J. Hydrogen sulfide adsorption on MOFs and MOF/graphite oxide composites[J]. Chemphyschem: a European Journal of Chemical Physics and Physical Chemistry, 2010, 11(17): 3678-3684. |

| 5 | Nemestóthy N, Bakonyi P, Lajtai-Szabó P, et al. The impact of various natural gas contaminant exposures on CO2/CH4 separation by a polyimide membrane[J]. Membranes, 2020, 10(11): 324. |

| 6 | Gągol M, Soltani R D C, Przyjazny A, et al. Effective degradation of sulfide ions and organic sulfides in cavitation-based advanced oxidation processes (AOPs)[J]. Ultrasonics Sonochemistry, 2019, 58: 104610. |

| 7 | Aghel B, Janati S, Wongwises S, et al. Review on CO2 capture by blended amine solutions[J]. International Journal of Greenhouse Gas Control, 2022, 119: 103715. |

| 8 | 陈颖, 杨鹤, 梁宏宝, 等. 天然气脱硫脱碳方法的研究进展[J]. 石油化工, 2011, 40: 565-570. |

| Chen Y, Yang H, Liang H B, et al. Advances in research of decarbonization and desulfurization for natural gas[J]. Petrochemical Technology, 2011, 40: 565-570. | |

| 9 | Al-Baghli N A, Pruess S A, Yesavage V F, et al. A rate-based model for the design of gas absorbers for the removal of CO2 and H2S using aqueous solutions of MEA and DEA[J]. Fluid Phase Equilibria, 2001, 185(1/2): 31-43. |

| 10 | 王开岳. 天然气脱硫脱碳工艺发展进程的回顾: 甲基二乙醇胺现居一支独秀地位[J]. 天然气与石油, 2011, 29(1): 15-21. |

| Wang K Y. Review on development process of gas desulfurization and decarburization technique—methyldiethanolamine (MDEA for short) outshines others[J]. Natural Gas and Oil, 2011, 29(1): 15-21. | |

| 11 | 王开岳. 天然气净化工艺: 脱硫脱碳、脱水、硫黄回收及尾气处理[M]. 2版. 北京: 石油工业出版社, 2015. |

| Wang K Y. Natural Gas Purification Process: Desulfurization and Decarbonization, Dehydration, Sulfur Recovery and Tail Gas Treatment[M]. 2nd ed. Beijing: Petroleum Industry Press, 2015. | |

| 12 | Hochgesand G. Rectisol and purisol[J]. Industrial & Engineering Chemistry, 1970, 62(7): 37-43. |

| 13 | Murrieta-Guevara F, Rebolledo-Libreros E, Trejo A. Gas solubility of hydrogen sulfide and carbon dioxide in mixtures of sulfolane with diethanolamine at different temperatures[J]. Fluid Phase Equilibria, 1994, 95: 163-174. |

| 14 | Bucklin R W, Schendel R. Comparison of fluor solvent and selexol processes[J]. Energy Progress, 1984, 4: 137-142. |

| 15 | Luo Q L, Feng B, Liu Z H, et al. Experimental study on simultaneous absorption and desorption of CO2, SO2, and NO x using aqueous N-methyldiethanolamine and dimethyl sulfoxide solutions[J]. Energy & Fuels, 2018, 32(3): 3647-3659. |

| 16 | Orlov A A, Marcou G, Horvath D, et al. Computer-aided design of new physical solvents for hydrogen sulfide absorption[J]. Industrial & Engineering Chemistry Research, 2021, 60(23): 8588-8596. |

| 17 | Shokouhi M, Farahani H, Vahidi M, et al. Experimental solubility of carbonyl sulfide in sulfolane and γ-butyrolactone[J]. Journal of Chemical & Engineering Data, 2017, 62(10): 3401-3408. |

| 18 | Abduesslam M, Kayi H K. Capture of carbonyl sulfide by organic liquid mixtures: a systematic DFT investigation[J]. Industrial & Engineering Chemistry Research, 2021, 60(3): 1366-1374. |

| 19 | Rivera-Tinoco R, Bouallou C. Reaction kinetics of carbonyl sulfide (COS) with diethanolamine in methanolic solutions[J]. Industrial & Engineering Chemistry Research, 2008, 47(19): 7375-7380. |

| 20 | Fisher R A. Design of experiments[J]. BMJ, 1936, 1(3923): 554. |

| 21 | 于惠波, 沈本贤, 孙辉, 等. 改性UDS溶剂提高天然气中甲硫醇脱除效率的研究[J]. 石油炼制与化工, 2017, 48: 28-33. |

| Yu H B, Shen B X, Sun H, et al. Study of improving MeSH removal efficiency by modified UDS solvent from natural gas[J]. Petroleum Processing and Petrochemicals, 2017, 48: 28-33. | |

| 22 | 段思慧. 脱硫醇吸收剂的量化计算及溶解机理研究[D]. 北京: 北京化工大学, 2020. |

| Duan S H. Study on quantitative calculation and dissolution mechanism of desulfurized alcohol absorbent[D]. Beijing: Beijing University of Chemical Technology, 2020. | |

| 23 | Francoeur P G, Koes D R. SolTranNet—a machine learning tool for fast aqueous solubility prediction[J]. Journal of Chemical Information and Modeling, 2021, 61(6): 2530-2536. |

| 24 | Chen Y X, Liu C L, Guo G C, et al. Machine-learning-guided reaction kinetics prediction towards solvent identification for chemical absorption of carbonyl sulfide[J]. Chemical Engineering Journal, 2022, 444: 136662. |

| 25 | Boobier S, Liu Y F, Sharma K, et al. Predicting solvent-dependent nucleophilicity parameter with a causal structure property relationship[J]. Journal of Chemical Information and Modeling, 2021, 61(10): 4890-4899. |

| 26 | Maskeri M A, Fernandes A J, Di Mauro G, et al. Taming keteniminium reactivity by steering reaction pathways: computational predictions and experimental validations[J]. Journal of the American Chemical Society, 2022, 144(51): 23358-23367. |

| 27 | LeCun Y, Bengio Y, Hinton G. Deep learning[J]. Nature, 2015, 521: 436-444. |

| 28 | 王彦旭. 基于机器学习的低共熔溶剂的物性预测及其在CO2吸收中的应用研究[D]. 杭州: 浙江大学, 2023. |

| Wang Y X. Physical property prediction of deep eutectic solvents based on machine learning and its application in CO2 absorption[D]. Hangzhou: Zhejiang University, 2023. | |

| 29 | Blum L C, Reymond J L. 970 million druglike small molecules for virtual screening in the chemical universe database GDB-13[J]. Journal of the American Chemical Society, 2009, 131(25): 8732-8733. |

| 30 | Tropsha A. Best practices for QSAR model development, validation, and exploitation[J]. Molecular Informatics, 2010, 29(6/7): 476-488. |

| 31 | Boobier S, Hose D R J, Blacker A J, et al. Machine learning with physicochemical relationships: solubility prediction in organic solvents and water[J]. Nature Communications, 2020, 11: 5753. |

| 32 | Sorkun M C, Khetan A, Er S. AqSolDB, a curated reference set of aqueous solubility and 2D descriptors for a diverse set of compounds[J]. Scientific Data, 2019, 6: 143. |

| 33 | Moriwaki H, Tian Y S, Kawashita N, et al. Mordred: a molecular descriptor calculator[J]. Journal of Cheminformatics, 2018, 10(1): 4. |

| 34 | Liu C L, Chen Y X, Jiang H, et al. Revealing the structure-interaction-dissolubility relationships through computational investigation coupled with solubility measurement: toward solvent design for organosulfide capture[J]. Industrial & Engineering Chemistry Research, 2022, 61(20): 7183-7192. |

| 35 | Tomasulo P. ChemIDplus—super source for chemical and drug information[J]. Medical Reference Services Quarterly, 2002, 21(1): 53-59. |

| 36 | Wang J M, Krudy G, Hou T J, et al. Development of reliable aqueous solubility models and their application in druglike analysis[J]. Journal of Chemical Information and Modeling, 2007, 47(4): 1395-1404. |

| 37 | Sayers E W, Bolton E E, Brister J R, et al. Database resources of the national center for biotechnology information[J]. Nucleic Acids Research, 2022, 50(D1): D20-D26. |

| [1] | 曾玉娇, 肖炘, 杨刚, 张意博, 郑光明, 李防, 汪凤玲. 基于机理与数据混合驱动的湿法磷酸生产过程代理建模与优化[J]. 化工学报, 2024, 75(3): 936-944. |

| [2] | 李文俊, 赵中阳, 倪震, 周灿, 郑成航, 高翔. 基于气-液传质强化的湿法烟气脱硫CFD模拟研究[J]. 化工学报, 2024, 75(2): 505-519. |

| [3] | 黄琮琪, 吴一梅, 陈建业, 邵双全. 碱性电解水制氢装置热管理系统仿真研究[J]. 化工学报, 2023, 74(S1): 320-328. |

| [4] | 胡超, 董玉明, 张伟, 张红玲, 周鹏, 徐红彬. 浓硫酸活化五氧化二钒制备高浓度全钒液流电池正极电解液[J]. 化工学报, 2023, 74(S1): 338-345. |

| [5] | 金正浩, 封立杰, 李舒宏. 氨水溶液交叉型再吸收式热泵的能量及 分析[J]. 化工学报, 2023, 74(S1): 53-63. 分析[J]. 化工学报, 2023, 74(S1): 53-63. |

| [6] | 米泽豪, 花儿. 基于DFT和COSMO-RS理论研究多元胺型离子液体吸收SO2气体[J]. 化工学报, 2023, 74(9): 3681-3696. |

| [7] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [8] | 胡兴枝, 张皓焱, 庄境坤, 范雨晴, 张开银, 向军. 嵌有超小CeO2纳米粒子的碳纳米纤维的制备及其吸波性能[J]. 化工学报, 2023, 74(8): 3584-3596. |

| [9] | 刘尚豪, 贾胜坤, 罗祎青, 袁希钢. 基于梯度提升决策树的三组元精馏流程结构最优化[J]. 化工学报, 2023, 74(5): 2075-2087. |

| [10] | 李木金, 胡松, 施德磐, 赵鹏, 高瑞, 李进龙. 环氧丁烷尾气溶剂吸收及精制工艺[J]. 化工学报, 2023, 74(4): 1607-1618. |

| [11] | 杨灿, 孙雪琦, 尚明华, 张建, 张香平, 曾少娟. 相变离子液体体系吸收分离CO2的研究现状及展望[J]. 化工学报, 2023, 74(4): 1419-1432. |

| [12] | 何万媛, 陈一宇, 朱春英, 付涛涛, 高习群, 马友光. 阵列凸起微通道内气液两相传质特性研究[J]. 化工学报, 2023, 74(2): 690-697. |

| [13] | 党青梅, 李强, 丁晖殿, 贾胜坤, 钱行, 苑杨, 黄克谨, 陈海胜. 基于动态模式分解的精馏吸收状态变量非设计条件下的重构与预测[J]. 化工学报, 2023, 74(10): 4229-4240. |

| [14] | 王煦清, 严圣林, 朱礼涛, 张希宝, 罗正鸿. 填料塔中有机胺吸收CO2气液传质的研究进展[J]. 化工学报, 2023, 74(1): 237-256. |

| [15] | 任嘉辉, 刘豫, 刘朝, 刘浪, 李莹. 基于分子指纹和拓扑指数的工质临界温度理论预测[J]. 化工学报, 2022, 73(4): 1493-1500. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号