化工学报 ›› 2024, Vol. 75 ›› Issue (9): 3056-3073.DOI: 10.11949/0438-1157.20240101

高文芳1( ), 崔晗1,2,3, 孙一冉1, 彭佳晴1, 朱睿1, 夏然1, 张馨予1, 李佳奇1, 王学良4, 孙峙5(

), 崔晗1,2,3, 孙一冉1, 彭佳晴1, 朱睿1, 夏然1, 张馨予1, 李佳奇1, 王学良4, 孙峙5( ), 吕龙义1(

), 吕龙义1( )

)

收稿日期:2024-01-23

修回日期:2024-05-29

出版日期:2024-09-25

发布日期:2024-10-10

通讯作者:

孙峙,吕龙义

作者简介:高文芳(1990—),女,博士,副教授,wfgao@hebut.edu.cn

基金资助:

Wenfang GAO1( ), Han CUI1,2,3, Yiran SUN1, Jiaqing PENG1, Rui ZHU1, Ran XIA1, Xinyu ZHANG1, Jiaqi LI1, Xueliang WANG4, Zhi SUN5(

), Han CUI1,2,3, Yiran SUN1, Jiaqing PENG1, Rui ZHU1, Ran XIA1, Xinyu ZHANG1, Jiaqi LI1, Xueliang WANG4, Zhi SUN5( ), Longyi LYU1(

), Longyi LYU1( )

)

Received:2024-01-23

Revised:2024-05-29

Online:2024-09-25

Published:2024-10-10

Contact:

Zhi SUN, Longyi LYU

摘要:

随着工业化进程加快,金属资源的关键性已成为我国乃至全球关注的问题,金属资源的大范围应用使其在生产时造成的环境影响越来越严重。为选择对环境影响较小的金属种类及生产方式,针对62种典型金属工业生产过程,对其相关的环境影响评价研究进展进行总结,重点关注黑色金属和有色轻、重金属生产过程的环境影响,并对与碳足迹分析相关的研究进行重点总结评述。重金属在生态毒性、人类健康等毒性影响方面均有较大影响;稀有金属和准金属的相关评价主要集中在Li和V上,且是未来的主要研究方向;贵金属相比其他金属造成的碳排放较为显著。金属生产行业未来需重点考虑金属元素自身性质,依据其不同阶段的污染程度优化生产方式,且聚焦金属生产行业的温室气体排放问题。

中图分类号:

高文芳, 崔晗, 孙一冉, 彭佳晴, 朱睿, 夏然, 张馨予, 李佳奇, 王学良, 孙峙, 吕龙义. 典型金属生产过程的环境影响评价研究进展[J]. 化工学报, 2024, 75(9): 3056-3073.

Wenfang GAO, Han CUI, Yiran SUN, Jiaqing PENG, Rui ZHU, Ran XIA, Xinyu ZHANG, Jiaqi LI, Xueliang WANG, Zhi SUN, Longyi LYU. A critical review on environmental impact assessment of typical metal production processes[J]. CIESC Journal, 2024, 75(9): 3056-3073.

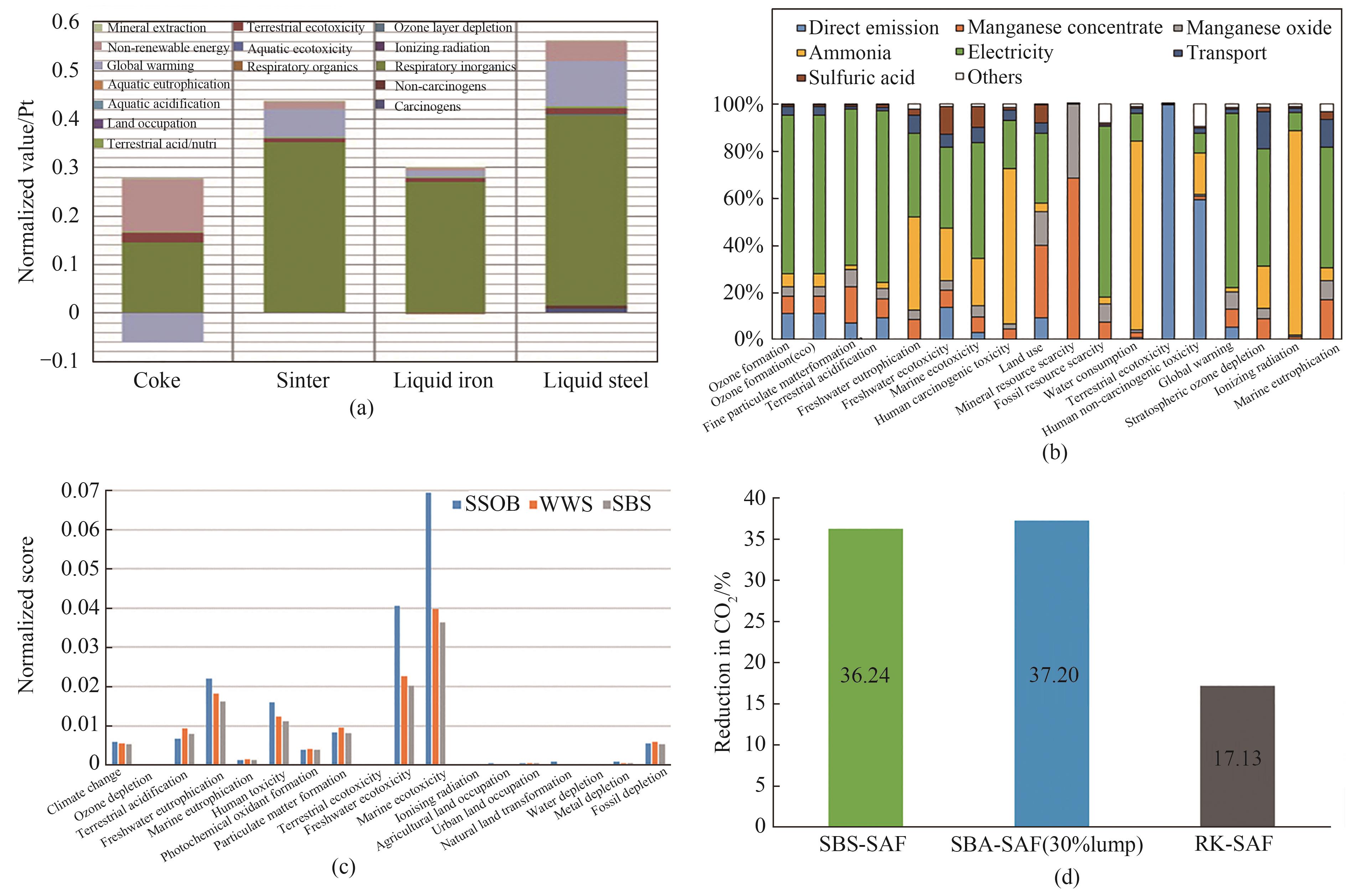

图2 (a) 每吨产品的单项评分结果比较[14];(b) 电解锰的主要环境影响因素[42];(c) 三种烧结烟气超低排放处理技术的标准化效果[41];(d) 非化石能源工艺节省的CO2占比[58]

Fig.2 (a) Comparison of single score results for each ton product[14]; (b) the main factors affecting the production environment of electrolytic Mn[42]; (c) standardization effects of three technologies for ultra-low emission treatment of sintering flue gas[41]; (d) the proportion of CO2 saved by nonfossil energy processes[58]

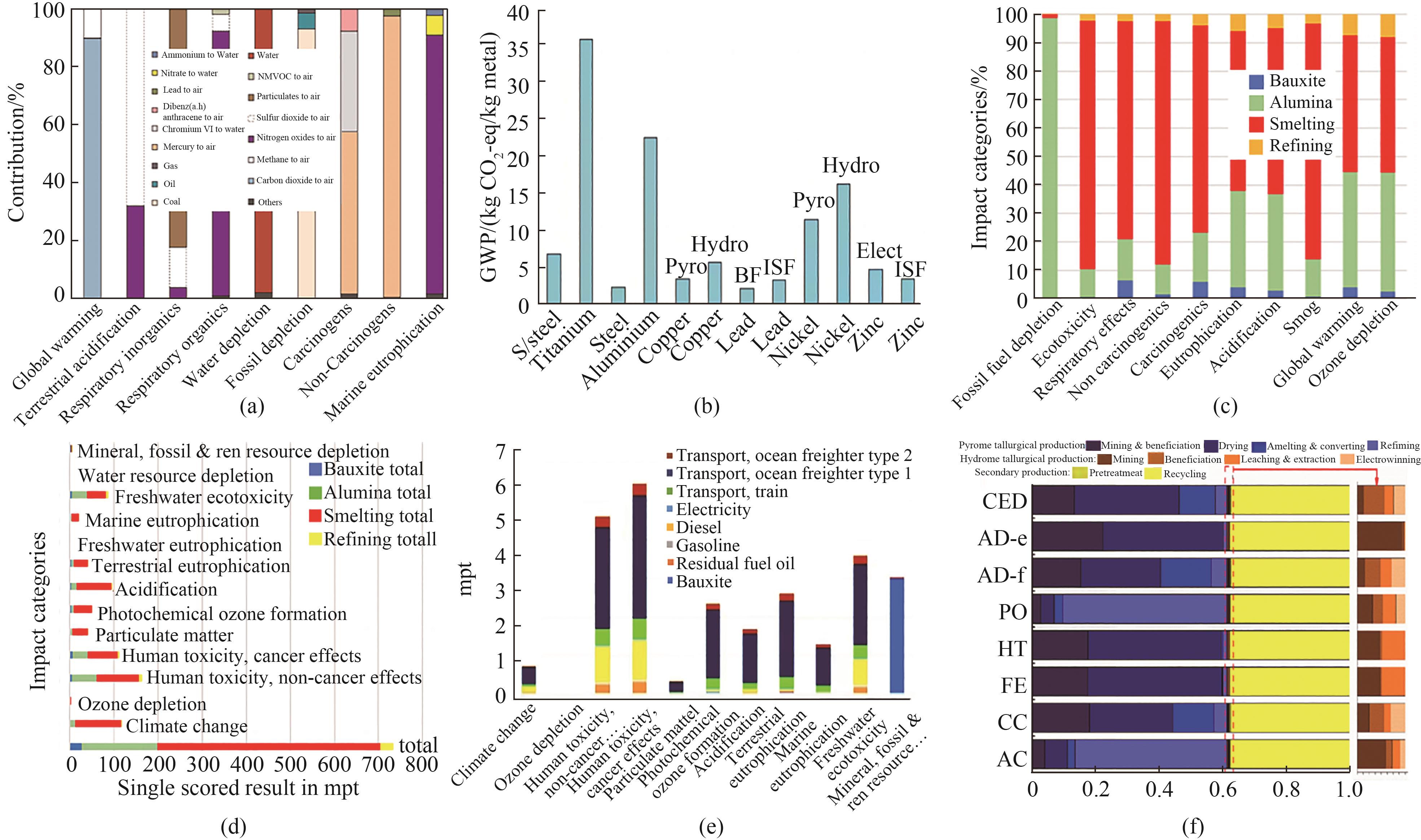

图3 (a) 钾肥生产的环境影响[62];(b) 金属生产的GWP[13];(c) TRACI法分析Al生产过程的结果[68];(d) Al生产过程的环境影响[68];(e) 不同Al开采工艺的环境影响[70];(f) 不同Cu生产路线的环境贡献[74]

Fig.3 (a) Environmental impact of K fertilizer production[62]; (b) production of GWP for various metals[13]; (c) analysis results from TRACI method for Al production processes[68]; (d) environmental impact of Al production process[68]; (e) environmental impact of different Al mining processes[70]; (f) environmental contribution of different Cu production routes[74]

图4 (a) Au-Ag耦合生产和 (b) Au-Ag-Pb-Zn-Cu联合生产的LCA结果[97];(c) Au-Ag精炼工艺的归一化结果[97];(d) GWP相关结果[100];(e) 生产Nb2O5的环境影响[109];(f) 生命周期影响评价(LCIA)对WC-Co的评估结果[110]

Fig.4 (a) LCA results of Au-Ag coupled production and (b) Au-Ag-Pb-Zn-Cu combined production[97]; (c) normalized results of Au-Ag refining process[97]; (d) GWP related results[100]; (e) environmental impact of Nb2O5 production[109]; (f) LCIA’s assessment of WC-Co[110]

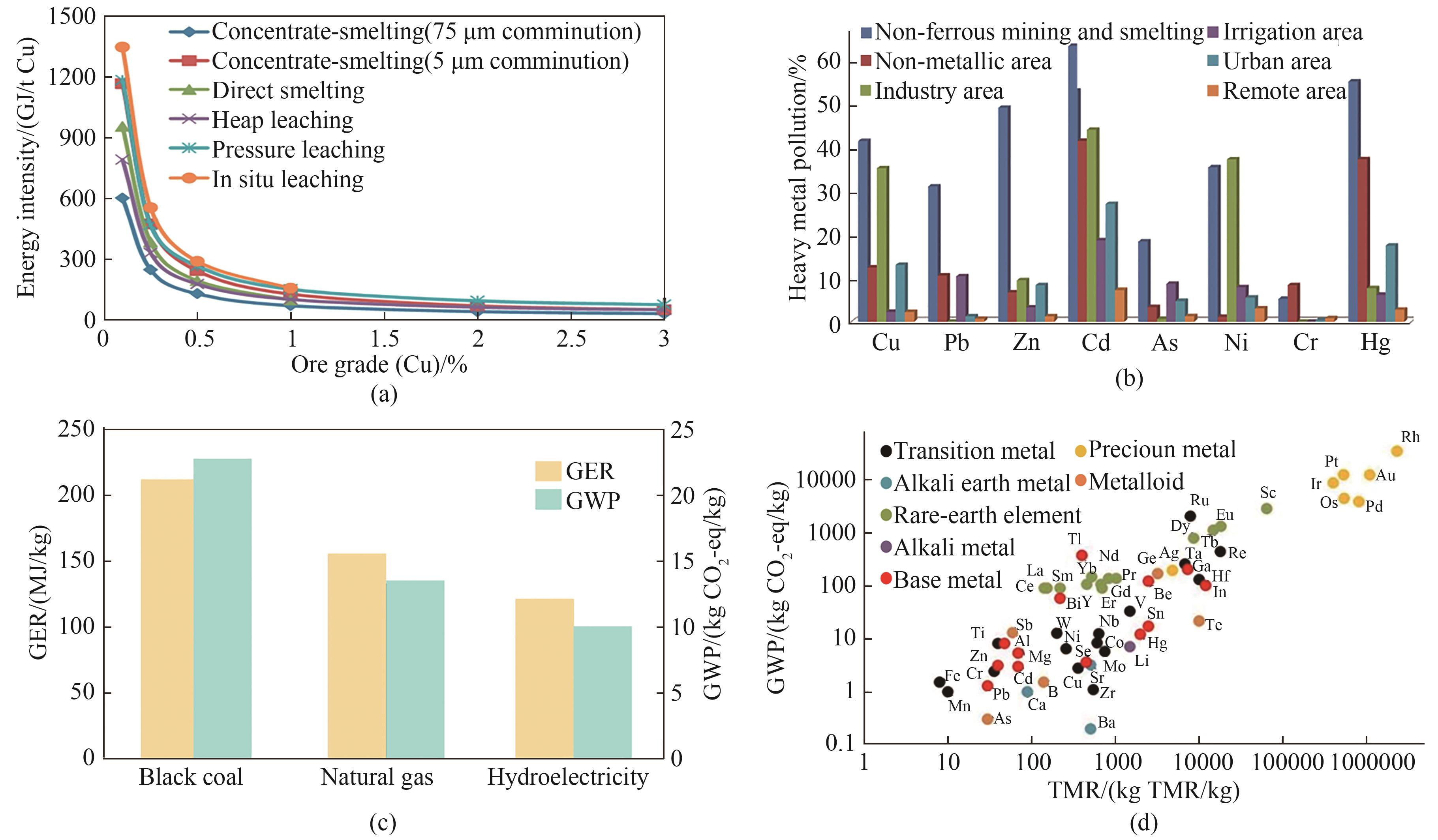

图5 (a) 矿石品位对Cu生产的影响[120];(b) 潜在来源的重金属污染率[126];(c) 电能来源对Al的GER和GWP的影响[13];(d) GWP和总材料需求之间的关系[119]

Fig.5 (a) Effect of ore grade on Cu production[120]; (d) heavy metal pollution rates from potential sources[126]; (c) effect of electricity energy source on GER and GWP for Al[13]; (d) relations between GWP and total material requirement[119]

| 1 | 傅一珂, 陈定江, 刘伯民, 等. 2005—2015年间中国省域物质资源消耗的解耦状态分析[J]. 中国环境科学, 2019, 39(12): 5333-5341. |

| Fu Y K, Chen D J, Liu B M, et al. Decoupling analysis of provincial material consumption in China during 2005—2015[J]. China Environmental Science, 2019, 39(12): 5333-5341. | |

| 2 | Ali H, Khan E, Ilahi I. Environmental chemistry and ecotoxicology of hazardous heavy metals: environmental persistence, toxicity, and bioaccumulation[J]. Journal of Chemistry, 2019, 2019: 6730305. |

| 3 | Brough D, Jouhara H. The aluminium industry: a review on state-of-the-art technologies, environmental impacts and possibilities for waste heat recovery[J]. International Journal of Thermofluids, 2020, 1: 100007. |

| 4 | Watari T, Nansai K, Nakajima K. Review of critical metal dynamics to 2050 for 48 elements[J]. Resources, Conservation and Recycling, 2020, 155: 104669. |

| 5 | Antony L V M, Reddy R G. Processes for production of high-purity metal powders[J]. JOM, 2003, 55(3): 14-18. |

| 6 | Jowitt S M, Mudd G M, Thompson J F H. Future availability of non-renewable metal resources and the influence of environmental, social, and governance conflicts on metal production[J]. Communications Earth & Environment, 2020, 1: 13. |

| 7 | Ming W Y, Guo X D, Xu Y J, et al. Progress in non-traditional machining of amorphous alloys[J]. Ceramics International, 2023, 49(2): 1585-1604. |

| 8 | Dudka S, Adriano D C. Environmental impacts of metal ore mining and processing: a review[J]. Journal of Environmental Quality, 1997, 26(3): 590-602. |

| 9 | Izatt R M, Izatt S R, Bruening R L, et al. Challenges to achievement of metal sustainability in our high-tech society[J]. Chemical Society Reviews, 2014, 43(8): 2451-2475. |

| 10 | Moors E H M, Mulder K F, Vergragt P J. Towards cleaner production: barriers and strategies in the base metals producing industry[J]. Journal of Cleaner Production, 2005, 13(7): 657-668. |

| 11 | Sun Q, Zhang W M. Carbon footprint analysis in metal cutting process[C]//Proceedings of the 1st International Conference on Mechanical Engineering and Material Science. Paris, France: Atlantis Press, 2012: 717-720. |

| 12 | Jia W T, Wen J W, Yan W Y, et al. Evaluation of ionic species contribution in critical metal extraction: a case study of high-purity vanadium production[J]. Journal of Cleaner Production, 2022, 343: 130967. |

| 13 | Norgate T E, Jahanshahi S, Rankin W J. Assessing the environmental impact of metal production processes[J]. Journal of Cleaner Production, 2007, 15(8/9): 838-848. |

| 14 | Olmez G M, Dilek F B, Karanfil T, et al. The environmental impacts of iron and steel industry: a life cycle assessment study[J]. Journal of Cleaner Production, 2016, 130: 195-201. |

| 15 | Yang Y, Guo Y Q, Zhu W S, et al. Environmental impact assessment of China’s primary aluminum based on life cycle assessment[J]. Transactions of Nonferrous Metals Society of China, 2019, 29(8): 1784-1792. |

| 16 | Cacciuttolo C, Cano D. Environmental impact assessment of mine tailings spill considering metallurgical processes of gold and copper mining: case studies in the Andean countries of Chile and Peru[J]. Water, 2022, 14(19): 3057. |

| 17 | Zhang G M, Wang Y T, Meng X H, et al. Life cycle assessment on the vanadium production process: a multi-objective assessment under environmental and economic perspectives[J]. Resources, Conservation and Recycling, 2023, 192: 106926. |

| 18 | 胡超, 董玉明, 张伟, 等. 浓硫酸活化五氧化二钒制备高浓度全钒液流电池正极电解液[J]. 化工学报, 2023, 74(S1): 338-345. |

| Hu C, Dong Y M, Zhang W, et al. Preparation of high-concentration positive electrolyte of vanadium redox flow battery by activating vanadium pentoxide with highly concentrated sulfuric acid[J]. CIESC Journal, 2023, 74(S1): 338-345. | |

| 19 | Fthenakis V, Wang W M, Kim H C. Life cycle inventory analysis of the production of metals used in photovoltaics[J]. Renewable and Sustainable Energy Reviews, 2009, 13(3): 493-517. |

| 20 | Nuss P, Eckelman M J. Life cycle assessment of metals: a scientific synthesis[J]. PLoS One, 2014, 9(7): e101298. |

| 21 | Rachid S, Taha Y, Benzaazoua M. Environmental evaluation of metals and minerals production based on a life cycle assessment approach: a systematic review[J]. Minerals Engineering, 2023, 198: 108076. |

| 22 | Tillman A M. The Hitch Hiker’S Guide to LCA: An Orientation in Life Cycle Assessment Methodology and Application[M]. Sweden: Studentlitteratur, 2009. |

| 23 | Giurco D P, Stewart M, Petrie J G. The role of LCA in performance assessment in minerals processing—a copper case study[C]∥ 6th International Conference on Environmental Issues and Management of Waste in Energy and Mineral Production, Calgary, Canada, 2000. |

| 24 | 田亚峻, 邓业林, 张岳玲, 等. 生命周期评价的发展新方向: 基于GIS的生命周期评价[J]. 化工学报, 2016, 67(6): 2195-2201. |

| Tian Y J, Deng Y L, Zhang Y L, et al. New direction of life cycle assessment: GIS-based life cycle assessment[J]. CIESC Journal, 2016, 67(6): 2195-2201. | |

| 25 | 崔晗, 王玉亭, 李华杰, 等. 城镇污水处理过程的多角度综合评价研究进展[J]. 过程工程学报, 2024, 24(1): 1-16. |

| Cui H, Wang Y T, Li H J, et al. Research progress on multi-objective comprehensive evaluation of urban wastewater treatment processes[J]. The Chinese Journal of Process Engineering, 2024, 24(1): 1-16. | |

| 26 | Hauschild M Z, Rosenbaum R K, Olsen S I. Life Cycle Assessment[M]. Cham: Springer International Publishing, 2018: 13, 61-62. |

| 27 | 高峰, 阳丹品, 聂祚仁, 等. 基于MFA/LCA的典型有色金属生产环境负荷评价与优化[J]. 中国材料进展, 2016, 35(3): 179-186, 204. |

| Gao F, Yang D P, Nie Z R, et al. The environment load evaluation and optimization for the typical non-ferrous metals production based on the MFA/LCA method[J]. Materials China, 2016, 35(3): 179-186, 204. | |

| 28 | Finnveden G, Hauschild M Z, Ekvall T, et al. Recent developments in life cycle assessment[J]. Journal of Environmental Management, 2009, 91(1): 1-21. |

| 29 | Wackernagel M, Onisto L, Bello P, et al. National natural capital accounting with the ecological footprint concept[J]. Ecological Economics, 1999, 29(3): 375-390. |

| 30 | Matthews H S, Hendrickson C T, Weber C L. The importance of carbon footprint estimation boundaries[J]. Environmental Science & Technology, 2008, 42(16): 5839-5842. |

| 31 | Liang Y H, Su J, Xi B D, et al. Life cycle assessment of lithium-ion batteries for greenhouse gas emissions[J]. Resources, Conservation and Recycling, 2017, 117: 285-293. |

| 32 | Wiedmann T, Minx J. A definition of ‘carbon footprint’[J]. Ecological Economics Research Trends, 2008, 1: 1-11. |

| 33 | Wiedmann T. Editorial: carbon footprint and input-output analysis—an introduction[J]. Economic Systems Research, 2009, 21(3): 175-186. |

| 34 | 什么叫“有色金属”?[J]. 新疆有色金属, 2012, 35(6): 90. |

| What is “non-ferrous metal”?[J]. Xinjiang Nonferrous Metals, 2012, 35(6): 90. | |

| 35 | Ferreira H, Leite M G P. A life cycle assessment study of iron ore mining[J]. Journal of Cleaner Production, 2015, 108: 1081-1091. |

| 36 | Liu Y X, Li H J, Huang S P, et al. Environmental and economic-related impact assessment of iron and steel production. A call for shared responsibility in global trade[J]. Journal of Cleaner Production, 2020, 269: 122239. |

| 37 | 倪文翔, 赵京, 李博, 等. 转炉煤气全干法显热回收工艺中余热锅炉积灰特性研究[J]. 化工学报, 2023, 74(8): 3485-3493. |

| Ni W X, Zhao J, Li B, et al. Study on waste heat boiler ash deposition characteristics in sensible heat recovery process of converter gas[J]. CIESC Journal, 2023, 74(8): 3485-3493. | |

| 38 | Li X L, Sun W Q, Zhao L, et al. Material metabolism and environmental emissions of BF-BOF and EAF steel production routes[J]. Mineral Processing and Extractive Metallurgy Review, 2018, 39(1): 50-58. |

| 39 | Suer J L, Traverso M, Jäger N. Review of life cycle assessments for steel and environmental analysis of future steel production scenarios[J]. Sustainability, 2022, 14(21): 14131. |

| 40 | Fick G, Mirgaux O, Neau P, et al. Using biomass for pig iron production: a technical, environmental and economical assessment[J]. Waste and Biomass Valorization, 2014, 5(1): 43-55. |

| 41 | Cui L, Liu M Y, Yuan X L, et al. Environmental and economic impact assessment of three sintering flue gas treatment technologies in the iron and steel industry[J]. Journal of Cleaner Production, 2021, 311: 127703. |

| 42 | Zhang R R, Ma X T, Shen X X, et al. Life cycle assessment of electrolytic manganese metal production[J]. Journal of Cleaner Production, 2020, 253: 119951. |

| 43 | Farjana S H, Huda N, Parvez Mahmud M A, et al. A global life cycle assessment of manganese mining processes based on EcoInvent database[J]. Science of the Total Environment, 2019, 688: 1102-1111. |

| 44 | Santamaria A B, Sulsky S I. Risk assessment of an essential element: manganese[J]. Journal of Toxicology and Environmental Health. Part A, 2010, 73(2): 128-155. |

| 45 | Marks B, Peters A, McGough D. Aquatic environmental risk assessment of manganese processing industries[J]. NeuroToxicology, 2017, 58: 187-193. |

| 46 | Rodrigues J L G, Araújo C F S, dos Santos N R, et al. Airborne manganese exposure and neurobehavior in school-aged children living near a ferro-manganese alloy plant[J]. Environmental Research, 2018, 167: 66-77. |

| 47 | Westfall L A, Davourie J, Ali M, et al. Cradle-to-gate life cycle assessment of global manganese alloy production[J]. The International Journal of Life Cycle Assessment, 2016, 21(11): 1573-1579. |

| 48 | He S C, Jiang D Y, Hong M H, et al. Hazard-free treatment and resource utilisation of electrolytic manganese residue: a review[J]. Journal of Cleaner Production, 2021, 306: 127224. |

| 49 | Davourie J, Westfall L, Ali M, et al. Evaluation of particulate matter emissions from manganese alloy production using life-cycle assessment[J]. NeuroToxicology, 2017, 58: 180-186. |

| 50 | Zhang Y J, Zhou X, Ma W B, et al. Distribution of mercury and methylmercury in farmland soils affected by manganese mining and smelting activities[J]. International Journal of Environmental Research and Public Health, 2022, 19(16): 10288. |

| 51 | Panda R C, Selvasekhar S, Murugan D, et al. Cleaner production of basic chromium sulfate—with a review of sustainable green production options[J]. Journal of Cleaner Production, 2016, 112: 4854-4862. |

| 52 | 李萱萱. 高级氧化技术在处理染料废水中的应用[J]. 化工进展, 2012, 31(S2): 219-222. |

| Li X X. Application of advanced oxidation in dye wastewater treatment[J]. Chemical Industry and Engineering Progress, 2012, 31(S2): 219-222. | |

| 53 | Das P K, Das B P, Dash P. Chromite mining pollution, environmental impact, toxicity and phytoremediation: a review[J]. Environmental Chemistry Letters, 2021, 19(2): 1369-1381. |

| 54 | Nakkeeran E, Patra C, Shahnaz T, et al. Continuous biosorption assessment for the removal of hexavalent chromium from aqueous solutions using Strychnos nux vomica fruit shell[J]. Bioresource Technology Reports, 2018, 3: 256-260. |

| 55 | Tumolo M, Ancona V, de Paola D, et al. Chromium pollution in European water, sources, health risk, and remediation strategies: an overview[J]. International Journal of Environmental Research and Public Health, 2020, 17(15): 5438. |

| 56 | Susaj E, Kucaj E, Laçi E, et al. Environmental impacts assessment of chromium minings in bulqiza area, Albania[J]. European Journal of Interdisciplinary Studies, 2017, 3(4): 35. |

| 57 | Walawska B, Kowalski Z. Environmental evaluation of the effects of using chromic waste in the production of chromium compounds[J]. Journal of Cleaner Production, 2001, 9(3): 219-226. |

| 58 | Hamuyuni J, Johto H, Bunjaku A, et al. Simulation-based life cycle assessment of ferrochrome smelting technologies to determine environmental impacts[J]. Journal of Cleaner Production, 2021, 295: 126503. |

| 59 | 郎建平, 唐晓艳, 陶建清. 无机化学. [M]. 2版. 南京: 南京大学出版社, 2020. |

| Lang J P, Tang X Y, Tao J Q. Inorganic Chemistry [M]. 2nd ed. Nanjing: Nanjing University Press, 2020. | |

| 60 | 江瑜, 袁小武, 胡蕴成. 金属钠的制备研究[J]. 东方电气评论, 2013, 27(1): 1-3, 11. |

| Jiang Y, Yuan X W, Hu Y C. Research on preparation of metal sodium[J]. Dongfang Electric Review, 2013, 27(1): 1-3, 11. | |

| 61 | Peters J, Buchholz D, Passerini S, et al. Life cycle assessment of sodium-ion batteries[J]. Energy & Environmental Science, 2016, 9(5): 1744-1751. |

| 62 | Chen W, Geng Y, Hong J L, et al. Life cycle assessment of potash fertilizer production in China[J]. Resources, Conservation and Recycling, 2018, 138: 238-245. |

| 63 | 王世栋, 高晓雷, 李权, 等. 金属钙、钙合金的制备与应用研究进展[J]. 材料导报, 2012, 26(7): 1-5, 14. |

| Wang S D, Gao X L, Li Q, et al. Research progress in the preparation and applications of metal calcium and its alloys[J]. Materials Review, 2012, 26(7): 1-5, 14. | |

| 64 | Dahlawi S M, Siddiqui S. Calcium polysulphide, its applications and emerging risk of environmental pollution—a review article[J]. Environmental Science and Pollution Research International, 2017, 24(1): 92-102. |

| 65 | Wang T, Tao Q L, Xie Z X. Performance and environmental evaluation of stabilized base material with strontium slag in low-volume road in China[J]. Advances in Civil Engineering, 2019, 2019: 6958926. |

| 66 | 丁绍兰, 刘云, 汪雁, 等. 基于LCA方法对氯化钡生产过程的环境影响评价[J]. 应用化工, 2022, 51(8): 2386-2389, 2395. |

| Ding S L, Liu Y, Wang Y, et al. Environmental impact assessment of barium chloride production process based on LCA method[J]. Applied Chemical Industry, 2022, 51(8): 2386-2389, 2395. | |

| 67 | Fatollahi-Fard F. Production of titanium metal by an electrochemical molten salt process[D]. Pennsylvania: Carnegie Mellon University, 2017. |

| 68 | Farjana S H, Huda N, Parvez Mahmud M A. Impacts of aluminum production: a cradle to gate investigation using life-cycle assessment[J]. Science of the Total Environment, 2019, 663: 958-970. |

| 69 | Zhang Y L, Sun M X, Hong J L, et al. Environmental footprint of aluminum production in China[J]. Journal of Cleaner Production, 2016, 133: 1242-1251. |

| 70 | Farjana S H, Huda N, Parvez Mahmud M A. Life cycle assessment of cobalt extraction process[J]. Journal of Sustainable Mining, 2019, 18(3): 150-161. |

| 71 | Zhang T Z, Bai Y Y, Shen X X, et al. Cradle-to-gate life cycle assessment of cobalt sulfate production derived from a nickel-copper-cobalt mine in China[J]. The International Journal of Life Cycle Assessment, 2021, 26(6): 1198-1210. |

| 72 | 白月阳. 我国电解镍生产的生命周期评价[D]. 济南: 山东大学, 2022. |

| Bai Y Y. Life cycle assessment of China’s electrolytic nickel production[D]. Jinan: Shandong University, 2022. | |

| 73 | Wei W J, Samuelsson P B, Tilliander A, et al. Energy consumption and greenhouse gas emissions of nickel products[J]. Energies, 2020, 13(21): 5664. |

| 74 | Dong D, van Oers L, Tukker A, et al. Assessing the future environmental impacts of copper production in China: implications of the energy transition[J]. Journal of Cleaner Production, 2020, 274: 122825. |

| 75 | Wang H T, Liu Y, Gong X Z, et al. Life cycle assessment of metallic copper produced by the pyrometallurgical technology of China[J]. Materials Science Forum, 2015, 814: 559-563. |

| 76 | Hong J L, Chen Y L, Liu J, et al. Life cycle assessment of copper production: a case study in China[J]. The International Journal of Life Cycle Assessment, 2018, 23(9): 1814-1824. |

| 77 | 王湘月, 周晓君, 阳春华. 不确定条件下的湿法炼锌除铜过程机会约束优化控制[J]. 化工学报, 2020, 71(3): 1226-1233. |

| Wang X Y, Zhou X J, Yang C H. Chance constrained optimization for copper removal process under uncertainty in zinc hydrometallurgy[J]. CIESC Journal, 2020, 71(3): 1226-1233. | |

| 78 | Qi C C, Ye L P, Ma X T, et al. Life cycle assessment of the hydrometallurgical zinc production chain in China[J]. Journal of Cleaner Production, 2017, 156: 451-458. |

| 79 | Van Genderen E, Wildnauer M, Santero N, et al. A global life cycle assessment for primary zinc production[J]. The International Journal of Life Cycle Assessment, 2016, 21(11): 1580-1593. |

| 80 | Hu Y Y, Li M, Wu W G, et al. Life cycle assessment for waste acid treatment in zinc smelting[J]. Transactions of Nonferrous Metals Society of China, 2022, 32(11): 3822-3834. |

| 81 | 成应向, 刘喜珍, 漆燕, 等. 有色冶炼铜镉渣中镉的提取工艺研究[J]. 环境工程, 2012, 30(S2): 331-334, 345. |

| Cheng Y X, Liu X Z, Qi Y, et al. Process research of extracting cadmium from non-ferrous copper and cadmium slag[J]. Environmental Engineering, 2012, 30(S2): 331-334, 345. | |

| 82 | Kwonpongsagoon S, Waite T D, Moore S J. Use of information from substance flux analysis for human health risk assessment at regional scales: cadmium as a case study in Australia[M]∥ Integrative Modeling of Biophysical, Social and Economic Systems for Resource Management Solutions. Townsville QLD Australia, 2003. |

| 83 | Marshall B G, Camacho A A, Jimenez G, et al. Mercury challenges in Mexico: regulatory, trade and environmental impacts[J]. Atmosphere, 2020, 12(1): 57. |

| 84 | 周瑞, 林青, 于跃, 等. 我国原生汞生产行业典型企业Hg的污染排放特征[J]. 环境科学研究, 2016, 29(5): 664-671. |

| Zhou R, Lin Q, Yu Y, et al. Mercury pollution characteristics of industrial companies in primary production industry of China[J]. Research of Environmental Sciences, 2016, 29(5): 664-671. | |

| 85 | Wang J, Dai H X, Luo L. Tin in the comprehensive utilization of mineral processing engineering and its research progress[J]. Advanced Materials Research, 2013, 734/735/736/737: 1010-1013. |

| 86 | Su Z J, Zhang Y B, Liu B B, et al. Extraction and separation of tin from tin-bearing secondary resources: a review[J]. JOM, 2017, 69(11): 2364-2372. |

| 87 | Singh N, Li J H. Environmental impacts of lead ore mining and smelting[J]. Advanced Materials Research, 2014, 878: 338-347. |

| 88 | Sun W Y, Gong X Z, Sun B X, et al. Life cycle assessment of lead production in China[J]. Materials Science Forum, 2019, 944: 1123-1129. |

| 89 | Hong J M, Yu Z H, Shi W X, et al. Life cycle environmental and economic assessment of lead refining in China[J]. The International Journal of Life Cycle Assessment, 2017, 22(6): 909-918. |

| 90 | Yukhin Y M, Daminov A S, Logutenko O A, et al. Processing of metallic bismuth for the production of bismuth compounds[J]. Separation Science and Technology, 2021, 56(6): 1168-1176. |

| 91 | Liu W F, Yang T Z, Chen L, et al. Development of antimony smelting technology in China[C]∥ 4th International Symposium on High-Temperature Metallurgical Processing. Wiley Online Library, 2013: 341-351. |

| 92 | Qi Y T, Wei X D, Zhao M J, et al. Heavy metal pollution characteristics and potential ecological risk assessment of soils around three typical antimony mining areas and watersheds in China[J]. Frontiers in Environmental Science, 2022, 10: 913293. |

| 93 | 宁增平, 肖唐付. 锑的表生地球化学行为与环境危害效应[J]. 地球与环境, 2007, 35(2): 176-182. |

| Ning Z P, Xiao T F. Supergene geochemical behavior and environmental risk of antimony[J]. Earth and Environment, 2007, 35(2): 176-182. | |

| 94 | Al-Teay S, Al-Jumaily H. Environmental impact assessment of heavy metals pollution in the surface soil surrounding the shwan private oil refinery, northeastern Kirkuk[J]. Iraqi Geological Journal, 2023, 56(1D): 67-80. |

| 95 | 江新德, 王振希, 江桂仙, 等. 植物还原法制备Au-Ag合金纳米材料及其拉曼应用[J]. 化工学报, 2016, 67(11): 4906-4911. |

| Jiang X D, Wang Z X, Jiang G X, et al. Raman enhancement of biosynthesized Au-Ag bimetallic nanomaterials[J]. CIESC Journal, 2016, 67(11): 4906-4911. | |

| 96 | Norgate T, Haque N. Using life cycle assessment to evaluate some environmental impacts of gold production[J]. Journal of Cleaner Production, 2012, 29: 53-63. |

| 97 | Farjana S H, Huda N, Parvez Mahmud M A, et al. Impact analysis of goldsilver refining processes through life-cycle assessment[J]. Journal of Cleaner Production, 2019, 228: 867-881. |

| 98 | Mudd G M, Jowitt S M, Werner T T. Global platinum group element resources, reserves and mining—a critical assessment[J]. Science of the Total Environment, 2018, 622: 614-625. |

| 99 | Bossi T, Gediga J. The environmental profile of platinum group metals[J]. Johnson Matthey Technology Review, 2017, 61(2): 111-121. |

| 100 | Stamp A, Althaus H J, Wäger P A. Limitations of applying life cycle assessment to complex co-product systems: the case of an integrated precious metals smelter-refinery[J]. Resources, Conservation and Recycling, 2013, 80: 85-96. |

| 101 | 张正, 何永平, 孙海东, 等. 蛇形流场电控离子交换装置用于选择性提锂[J]. 化工学报, 2023, 74(5): 2022-2033. |

| Zhang Z, He Y P, Sun H D, et al. Electrochemically switched ion exchange device with serpentine flow field for selective extraction of lithium[J]. CIESC Journal, 2023, 74(5): 2022-2033. | |

| 102 | Kaunda R B. Potential environmental impacts of lithium mining[J]. Journal of Energy & Natural Resources Law, 2020, 38(3): 237-244. |

| 103 | Jiang S Y, Zhang L, Li F Y, et al. Environmental impacts of lithium production showing the importance of primary data of upstream process in life-cycle assessment[J]. Journal of Environmental Management, 2020, 262: 110253. |

| 104 | Chordia M, Wickerts S, Nordelöf A, et al. Life cycle environmental impacts of current and future battery-grade lithium supply from brine and spodumene[J]. Resources, Conservation and Recycling, 2022, 187: 106634. |

| 105 | Ambrose H, Kendall A. Understanding the future of lithium(part 2): Temporally and spatially resolved life-cycle assessment modeling[J]. Journal of Industrial Ecology, 2020, 24(1): 90-100. |

| 106 | Kelly J C, Wang M, Dai Q, et al. Energy, greenhouse gas, and water life cycle analysis of lithium carbonate and lithium hydroxide monohydrate from brine and ore resources and their use in lithium ion battery cathodes and lithium ion batteries[J]. Resources, Conservation and Recycling, 2021, 174: 105762. |

| 107 | Gao W F, Sun Z, Cao H B, et al. Economic evaluation of typical metal production process: a case study of vanadium oxide production in China[J]. Journal of Cleaner Production, 2020, 256: 120217. |

| 108 | 肖金花. 基于生命周期评价的五氧化二钒的环境影响评价及成本分析[D]. 昆明: 昆明理工大学, 2021. |

| Xiao J H. Environmental impact assessment and cost analysis of vanadium pentoxide based on life cycle assessment[D]. Kunming: Kunming University of Science and Technology, 2021. | |

| 109 | da Silva Lima L, Alvarenga R A F, de Souza Amaral T, et al. Life cycle assessment of ferroniobium and niobium oxides: quantifying the reduction of environmental impacts as a result of production process improvements[J]. Journal of Cleaner Production, 2022, 348: 131327. |

| 110 | Furberg A, Arvidsson R, Molander S. Environmental life cycle assessment of cemented carbide (WC-Co) production[J]. Journal of Cleaner Production, 2019, 209: 1126-1138. |

| 111 | Lee J C K, Wen Z G. Rare earths from mines to metals: comparing environmental impacts from China’s main production pathways[J]. Journal of Industrial Ecology, 2017, 21(5): 1277-1290. |

| 112 | Bailey G, Joyce P J, Schrijvers D, et al. Review and new life cycle assessment for rare earth production from bastnäsite, ion adsorption clays and lateritic monazite[J]. Resources, Conservation and Recycling, 2020, 155: 104675. |

| 113 | Weng Z H, Haque N, Mudd G M, et al. Assessing the energy requirements and global warming potential of the production of rare earth elements[J]. Journal of Cleaner Production, 2016, 139: 1282-1297. |

| 114 | Vahidi E, Zhao F. Environmental life cycle assessment on the separation of rare earth oxides through solvent extraction[J]. Journal of Environmental Management, 2017, 203: 255-263. |

| 115 | Zaimes G G, Hubler B J, Wang S, et al. Environmental life cycle perspective on rare earth oxide production[J]. ACS Sustainable Chemistry & Engineering, 2015, 3(2): 237-244. |

| 116 | Türkbay T, Laratte B, Çolak A, et al. Life cycle assessment of boron industry from mining to refined products[J]. Sustainability, 2022, 14(3): 1787. |

| 117 | 谢明辉, 阮久莉, 白璐, 等. 太阳能级多晶硅生命周期环境影响评价[J]. 环境科学研究, 2015, 28(2): 291-296. |

| Xie M H, Ruan J L, Bai L, et al. Environmental impacts of solar grade polysilicon based on life cycle assessment[J]. Research of Environmental Sciences, 2015, 28(2): 291-296. | |

| 118 | 闫可欣, 姜洪涛, 高维群, 等. 电子级多晶硅原料中痕量硼磷杂质的脱除研究进展[J]. 化工学报, 2024, 75(1): 83-94. |

| Yan K X, Jiang H T, Gao W Q, et al. Recent advances in the removal of trace boron and phosphorus impurities from electronic grade silicon raw materials[J]. CIESC Journal, 2024, 75(1): 83-94. | |

| 119 | Kosai S, Yamasue E. Global warming potential and total material requirement in metal production: identification of changes in environmental impact through metal substitution[J]. Science of the Total Environment, 2019, 651: 1764-1775. |

| 120 | Northey S, Mohr S, Mudd G M, et al. Modelling future copper ore grade decline based on a detailed assessment of copper resources and mining[J]. Resources, Conservation and Recycling, 2014, 83: 190-201. |

| 121 | Valderrama C V, Santibanez-González E, Pimentel B, et al. Designing an environmental supply chain network in the mining industry to reduce carbon emissions[J]. Journal of Cleaner Production, 2020, 254: 119688. |

| 122 | van der Voet E, van Oers L, Verboon M, et al. Environmental implications of future demand scenarios for metals: methodology and application to the case of seven major metals[J]. Journal of Industrial Ecology, 2019, 23(1): 141-155. |

| 123 | Plekhanova I O, Zolotareva O A, Tarasenko I D, et al. Assessment of ecotoxicity of soils contaminated by heavy metals[J]. Eurasian Soil Science, 2019, 52(10): 1274-1288. |

| 124 | Kandeler F, Kampichler C, Horak O. Influence of heavy metals on the functional diversity of soil microbial communities[J]. Biology and Fertility of Soils, 1996, 23(3): 299-306. |

| 125 | Plyaskina O V, Ladonin D V. Heavy metal pollution of urban soils[J]. Eurasian Soil Science, 2009, 42(7): 816-823. |

| 126 | Zhang X Y, Zhong T Y, Liu L, et al. Impact of soil heavy metal pollution on food safety in China[J]. PLoS One, 2015, 10(8): e0135182. |

| 127 | Okereafor U, Makhatha M, Mekuto L, et al. Toxic metal implications on agricultural soils, plants, animals, aquatic life and human health[J]. International Journal of Environmental Research and Public Health, 2020, 17(7): 2204. |

| 128 | Huang Y Y, Zhou B H, Li N, et al. Spatial-temporal analysis of selected industrial aquatic heavy metal pollution in China[J]. Journal of Cleaner Production, 2019, 238: 117944. |

| 129 | Mehmood A, Aslam Mirza M, Aziz Choudhary M, et al. Spatial distribution of heavy metals in crops in a wastewater irrigated zone and health risk assessment[J]. Environmental Research, 2019, 168: 382-388. |

| 130 | Li Z Y, Ma Z W, van der Kuijp T J, et al. A review of soil heavy metal pollution from mines in China: pollution and health risk assessment[J]. Science of the Total Environment, 2014, 468: 843-853. |

| 131 | Sengul A B, Asmatulu E. Toxicity of metal and metal oxide nanoparticles: a review[J]. Environmental Chemistry Letters, 2020, 18(5): 1659-1683. |

| 132 | Norgate T, Haque N. Energy and greenhouse gas impacts of mining and mineral processing operations[J]. Journal of Cleaner Production, 2010, 18(3): 266-274. |

| 133 | 张琦峰, 方恺, 徐明, 等. 基于投入产出分析的碳足迹研究进展[J]. 自然资源学报, 2018, 33(4): 696-708. |

| Zhang Q F, Fang K, Xu M, et al. Review of carbon footprint research based on input-output analysis[J]. Journal of Natural Resources, 2018, 33(4): 696-708. | |

| 134 | 王微, 林剑艺, 崔胜辉, 等. 碳足迹分析方法研究综述[J]. 环境科学与技术, 2010, 33(7): 71-78. |

| Wang W, Lin J Y, Cui S H, et al. An overview of carbon footprint analysis[J]. Environmental Science & Technology, 2010, 33(7): 71-78. | |

| 135 | Feng C, Zhu R, Wei G S, et al. Typical case of carbon capture and utilization in Chinese iron and steel enterprises: CO2 emission analysis[J]. Journal of Cleaner Production, 2022, 363: 132528. |

| 136 | Na H M, Yuan Y X, Du T, et al. Multi-process production occurs in the iron and steel industry, supporting ‘dual carbon’ target: an in-depth study of CO2 emissions from different processes[J]. Journal of Environmental Sciences, 2024, 140: 46-58. |

| 137 | Zhu T Y, Liu X L, Wang X D, et al. Technical development and prospect for collaborative reduction of pollution and carbon emissions from iron and steel industry in China[J]. Engineering, 2023, 31: 37-49. |

| 138 | Cherubini F, Raugei M, Ulgiati S. LCA of magnesium production: technological overview and worldwide estimation of environmental burdens[J]. Resources, Conservation and Recycling, 2008, 52(8/9): 1093-1100. |

| 139 | Ekman Nilsson A, Macias Aragonés M, Arroyo Torralvo F, et al. A review of the carbon footprint of Cu and Zn production from primary and secondary sources[J]. Minerals, 2017, 7(9): 168. |

| 140 | Boesch M E, Vadenbo C, Saner D, et al. An LCA model for waste incineration enhanced with new technologies for metal recovery and application to the case of Switzerland[J]. Waste Management, 2014, 34(2): 378-389. |

| 141 | Hu A H, Kuo C H, Huang L H, et al. Carbon footprint assessment of recycling technologies for rare earth elements: a case study of recycling yttrium and europium from phosphor[J]. Waste Management, 2017, 60: 765-774. |

| 142 | Farjana S H, Huda N, Parvez Mahmud M A. Life cycle analysis of copper-gold-lead-silver-zinc beneficiation process[J]. Science of the Total Environment, 2019, 659: 41-52. |

| 143 | Zhang C, Chen F, Huang S Y, et al. Resource nationalism and platinum group metals: chinese strategies in a hydrogen-powered future[J]. The Extractive Industries and Society, 2023, 15: 101317. |

| 144 | Xia J S, Ghahreman A. Platinum group metals recycling from spent automotive catalysts: metallurgical extraction and recovery technologies[J]. Separation and Purification Technology, 2023, 311: 123357. |

| 145 | Yang S Q, Yu Z Q, Ma W H, et al. Coupling the digital twin technology and life cycle assessment: carbon dioxide emissions from polysilicon production[J]. Sustainable Production and Consumption, 2023, 41: 156-166. |

| [1] | 胡术刚, 田国庆, 刘文娟, 徐广飞, 刘华清, 张建, 王艳龙. 纳米零价铁的制备及氧化还原技术的应用进展[J]. 化工学报, 2024, 75(9): 3041-3055. |

| [2] | 郑晓园, 蔡炎嶙, 应芝, 王波, 豆斌林. 污水污泥磷形态亚临界水热转化研究[J]. 化工学报, 2024, 75(8): 2970-2982. |

| [3] | 高磊, 戴闻, 杨忠莲, 李淑萍, 闫刚印, 孙琪, 陆勇泽, 朱光灿. 汞对低气压条件下污水处理系统脱氮性能的影响研究[J]. 化工学报, 2024, 75(5): 2036-2046. |

| [4] | 王灵洁, 高海龙, 靳继鹏, 王志浩, 李见波. 海水中的污染物对逆电渗析电堆性能的影响[J]. 化工学报, 2024, 75(2): 695-705. |

| [5] | 王宝凤, 王术高, 程芳琴. 固废基硫掺杂多孔炭材料制备及其对CO2吸附性能研究进展[J]. 化工学报, 2024, 75(2): 395-411. |

| [6] | 杨百玉, 寇悦, 姜峻韬, 詹亚力, 王庆宏, 陈春茂. 炼化碱渣湿式氧化预处理过程DOM的化学转化特征[J]. 化工学报, 2023, 74(9): 3912-3920. |

| [7] | 张曼铮, 肖猛, 闫沛伟, 苗政, 徐进良, 纪献兵. 危废焚烧处理耦合有机朗肯循环系统工质筛选与热力学优化[J]. 化工学报, 2023, 74(8): 3502-3512. |

| [8] | 段重达, 姚小伟, 朱家华, 孙静, 胡南, 李广悦. 环境因素对克雷白氏杆菌诱导碳酸钙沉淀的影响[J]. 化工学报, 2023, 74(8): 3543-3553. |

| [9] | 吕龙义, 及文博, 韩沐达, 李伟光, 高文芳, 刘晓阳, 孙丽, 王鹏飞, 任芝军, 张光明. 铁基导电材料强化厌氧去除卤代有机污染物:研究进展及未来展望[J]. 化工学报, 2023, 74(8): 3193-3202. |

| [10] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [11] | 屈园浩, 邓文义, 谢晓丹, 苏亚欣. 活性炭/石墨辅助污泥电渗脱水研究[J]. 化工学报, 2023, 74(7): 3038-3050. |

| [12] | 陈朝光, 贾玉香, 汪锰. 以低浓度废酸驱动中和渗析脱盐的模拟与验证[J]. 化工学报, 2023, 74(6): 2486-2494. |

| [13] | 朱理想, 罗默也, 张晓东, 龙涛, 余冉. 醌指纹法指示三氯乙烯污染土功能微生物活性应用研究[J]. 化工学报, 2023, 74(6): 2647-2654. |

| [14] | 张建华, 陈萌萌, 孙雅雯, 彭永臻. 部分短程硝化同步除磷耦合Anammox实现生活污水高效脱氮除磷[J]. 化工学报, 2023, 74(5): 2147-2156. |

| [15] | 胡香凝, 尹渊博, 袁辰, 是赟, 刘翠伟, 胡其会, 杨文, 李玉星. 成品油在土壤中运移可视化的实验研究[J]. 化工学报, 2023, 74(4): 1827-1835. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号