化工学报 ›› 2025, Vol. 76 ›› Issue (5): 2186-2197.DOI: 10.11949/0438-1157.20240994

时任泽1,2( ), 丁秋燕1,2, 袁振军3,4, 那健1,2, 刘见华3,4, 郭树虎1,3,4, 赵雄1,3,4(

), 丁秋燕1,2, 袁振军3,4, 那健1,2, 刘见华3,4, 郭树虎1,3,4, 赵雄1,3,4( ), 李洪1,2, 高鑫1,2(

), 李洪1,2, 高鑫1,2( )

)

收稿日期:2024-09-03

修回日期:2024-09-20

出版日期:2025-05-25

发布日期:2025-06-13

通讯作者:

赵雄,高鑫

作者简介:时任泽(1998—),男,硕士研究生,a1120305060@163.com

基金资助:

Renze SHI1,2( ), Qiuyan DING1,2, Zhenjun YUAN3,4, Jian NA1,2, Jianhua LIU3,4, Shuhu GUO1,3,4, Xiong ZHAO1,3,4(

), Qiuyan DING1,2, Zhenjun YUAN3,4, Jian NA1,2, Jianhua LIU3,4, Shuhu GUO1,3,4, Xiong ZHAO1,3,4( ), Hong LI1,2, Xin GAO1,2(

), Hong LI1,2, Xin GAO1,2( )

)

Received:2024-09-03

Revised:2024-09-20

Online:2025-05-25

Published:2025-06-13

Contact:

Xiong ZHAO, Xin GAO

摘要:

在集成电路的薄膜沉积工艺中,电子级二乙氧基甲基硅烷(DEMS)是制造低介电常数硅基半导体薄膜的关键前体,要求其有机纯度达到99.990%(质量分数,4N),总金属离子杂质含量≤5.000 μg/L,单个金属杂质含量≤0.500 μg/L。目前工艺难以达到纯度要求,因此提出了完整的电子级DEMS纯化的减压共沸精馏工艺技术路线,主要工作包括:(1)通过常规精馏实验分析了DEMS的纯化难点,进行减压共沸精馏实验,将关键组分杂质乙醇提纯至0.010%(质量分数)以下,降低了DEMS的纯化难度,有机纯度达到4N;(2)通过常规减压精馏实验探究,实现总金属离子杂质含量≤5.000 μg/L和单个杂质含量≤0.500 μg/L的目标;(3)建立了减压共沸精馏模型,利用实验结果进行模型验证,进一步建立了减压共沸精馏工艺,利用模型对新工艺进行优化设计。研究结果得到的DEMS产品指标达到了电子级标准,满足集成电路制造工艺要求,为规模化、低成本生产电子级DEMS奠定了理论基础。

中图分类号:

时任泽, 丁秋燕, 袁振军, 那健, 刘见华, 郭树虎, 赵雄, 李洪, 高鑫. 4N电子级二乙氧基甲基硅烷的纯化技术研究[J]. 化工学报, 2025, 76(5): 2186-2197.

Renze SHI, Qiuyan DING, Zhenjun YUAN, Jian NA, Jianhua LIU, Shuhu GUO, Xiong ZHAO, Hong LI, Xin GAO. Study on the purification technology of 4N electronic-grade diethoxymethylsilane[J]. CIESC Journal, 2025, 76(5): 2186-2197.

| 名称 | 组分纯度/% | 乙醇含量/% | 氯离子含量/(mg/L) | 单个杂质含量/(μg/L) | 总金属离子杂质含量/(μg/L) |

|---|---|---|---|---|---|

| 电子级DEMS | ≥99.990 | ≤0.010 | ≤1.000 | ≤0.500 | ≤5.000 |

表1 电子级DEMS有机纯度和杂质含量的控制标准

Table 1 Control standards for organic purity and impurity content of electronic grade DEMS

| 名称 | 组分纯度/% | 乙醇含量/% | 氯离子含量/(mg/L) | 单个杂质含量/(μg/L) | 总金属离子杂质含量/(μg/L) |

|---|---|---|---|---|---|

| 电子级DEMS | ≥99.990 | ≤0.010 | ≤1.000 | ≤0.500 | ≤5.000 |

| 序号 | 组分 | 沸点/℃ | 序号 | 组分 | 沸点/℃ |

|---|---|---|---|---|---|

| 1 | FeCl2 | 1023 | 8 | AlCl3 | 182 |

| 2 | FeCl3 | 316 | 9 | TiCl4 | 135 |

| 3 | CaCl2 | 1600 | 10 | PCl3 | 75 |

| 4 | NaCl | 1465 | 11 | POCl3 | 105 |

| 5 | KCl | 1420 | 12 | PCl5 | 160 |

| 6 | MgCl2 | 1412 | 13 | BCl3 | 12 |

| 7 | ZnCl2 | 732 | 14 | B2Cl4 | 55 |

表2 工业级DEMS中杂质的组成和沸点统计

Table 2 The composition and boiling point statistics of impurities in industrial DEMS

| 序号 | 组分 | 沸点/℃ | 序号 | 组分 | 沸点/℃ |

|---|---|---|---|---|---|

| 1 | FeCl2 | 1023 | 8 | AlCl3 | 182 |

| 2 | FeCl3 | 316 | 9 | TiCl4 | 135 |

| 3 | CaCl2 | 1600 | 10 | PCl3 | 75 |

| 4 | NaCl | 1465 | 11 | POCl3 | 105 |

| 5 | KCl | 1420 | 12 | PCl5 | 160 |

| 6 | MgCl2 | 1412 | 13 | BCl3 | 12 |

| 7 | ZnCl2 | 732 | 14 | B2Cl4 | 55 |

| 化合物 | 分子式 | CAS号 | 分子量 | 沸点/℃ |

|---|---|---|---|---|

| 二乙氧基甲基硅烷 | C5H14O2Si | 2031-62-1 | 134.25 | 98 |

| 甲基三乙氧基硅烷 | C7H18O3Si | 2031-67-6 | 178.30 | 141 |

| 四乙氧基硅烷 | C8H20O4Si | 78-10-4 | 208.33 | 168 |

| 乙醇 | C2H6O | 64-17-5 | 46.07 | 78 |

| 正己烷 | C6H14 | 110-54-3 | 86.18 | 69 |

表3 精馏体系各物质的沸点

Table 3 Boiling points of distillation system substances

| 化合物 | 分子式 | CAS号 | 分子量 | 沸点/℃ |

|---|---|---|---|---|

| 二乙氧基甲基硅烷 | C5H14O2Si | 2031-62-1 | 134.25 | 98 |

| 甲基三乙氧基硅烷 | C7H18O3Si | 2031-67-6 | 178.30 | 141 |

| 四乙氧基硅烷 | C8H20O4Si | 78-10-4 | 208.33 | 168 |

| 乙醇 | C2H6O | 64-17-5 | 46.07 | 78 |

| 正己烷 | C6H14 | 110-54-3 | 86.18 | 69 |

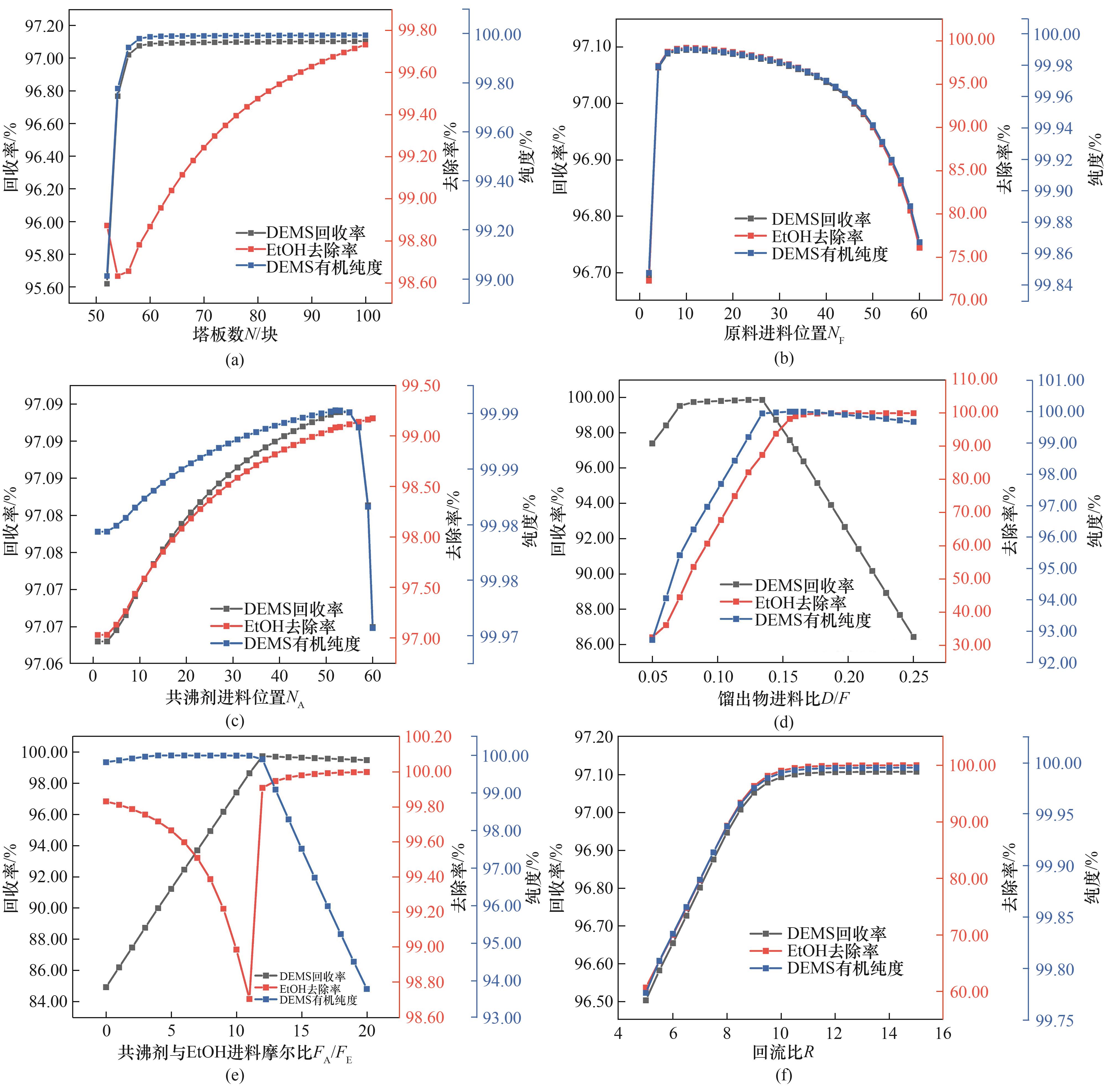

图12 N、NF、NA、D/F、FA/FE和R对DEMS回收率、EtOH去除率和DEMS有机纯度的影响

Fig.12 Plots of the effect of N, NF, NA, D/F, FA/FE and R on DEMS recovery, EtOH removal and DEMS organic purity

| 模型名称 | 1#塔参数 | 2#塔参数 | DEMS回收率/% | DEMS有机纯度/% | ||

|---|---|---|---|---|---|---|

| 塔板数 | 回流比 | 塔板数 | 回流比 | |||

| AD | 33 | 0.40 | 20 | 15.85 | 95 | 99.968 |

| VD* | 29 | 0.25 | 90 | 8.00 | 84 | 99.990 |

| VAD | 37 | 2.34 | 25 | 0.25 | 89 | 99.568 |

| VAD* | 65 | 10.00 | 13 | 1.10 | 91 | 99.993 |

表4 四种模型参数对比

Table 4 Comparison of four model parameters

| 模型名称 | 1#塔参数 | 2#塔参数 | DEMS回收率/% | DEMS有机纯度/% | ||

|---|---|---|---|---|---|---|

| 塔板数 | 回流比 | 塔板数 | 回流比 | |||

| AD | 33 | 0.40 | 20 | 15.85 | 95 | 99.968 |

| VD* | 29 | 0.25 | 90 | 8.00 | 84 | 99.990 |

| VAD | 37 | 2.34 | 25 | 0.25 | 89 | 99.568 |

| VAD* | 65 | 10.00 | 13 | 1.10 | 91 | 99.993 |

| 技术指标 | 要求 | 实验结果 | 模拟结果 |

|---|---|---|---|

| 有机纯度/% | ≥99.990 | 99.993 | 99.993 |

| 乙醇含量/% | ≤0.010 | 0.007 | 0.002 |

| 氯离子含量/(mg/L) | ≤1.000 | 未检出 | — |

| 单个杂质含量/(μg/L) | ≤0.500 | 0.322 | — |

| 总金属离子杂质含量/(μg/L) | ≤5.000 | 1.240 | — |

表5 本文工艺所得4N级DEMS技术指标

Table 5 Technical specifications for 4N DEMS prepared by the as-proposed process

| 技术指标 | 要求 | 实验结果 | 模拟结果 |

|---|---|---|---|

| 有机纯度/% | ≥99.990 | 99.993 | 99.993 |

| 乙醇含量/% | ≤0.010 | 0.007 | 0.002 |

| 氯离子含量/(mg/L) | ≤1.000 | 未检出 | — |

| 单个杂质含量/(μg/L) | ≤0.500 | 0.322 | — |

| 总金属离子杂质含量/(μg/L) | ≤5.000 | 1.240 | — |

| 1 | 常欣, 万烨, 赵雄, 等. 先进硅基前驱体的应用研究与技术进展[J]. 半导体技术, 2020, 45(6): 409-418. |

| Chang X, Wan Y, Zhao X, et al. Application research and technology progress on advanced silicon-based precursors[J]. Semiconductor Technology, 2020, 45(6): 409-418. | |

| 2 | Cheng Y L, We B J, O’Neil M L, et al. The effect of deposition temperature on the structure and electrical properties of low-k film using diethoxymethylsilane (DEMS) prepared by plasma enhanced chemical vapor deposition[J]. Thin Solid Films, 2007, 516(2/3/4): 438-443. |

| 3 | Cheng Y, Wang Y, Hwang G, et al. Effect of deposition temperature and oxygen flow rate on properties of low dielectric constant SiCOH film prepared by plasma enhanced chemical vapor deposition using diethoxymethylsilane[J]. Surface and Coatings Technology, 2006, 200(10): 3134-3139. |

| 4 | Cheng L Y, Lu S Y, Chiu J T. Comparative study of low dielectric constant material deposited using different precursors[J]. Advanced Materials Research, 2011, 1266(233/234/235): 2480-2485. |

| 5 | Thanh N B. Process for the preparation of hydrido organooxysilanes: EP93305178[P]. 1994-01-12. |

| 6 | Peter F, Reiner G, Hans-joachim V. Method for the continuous preparation of alkoxysilanes: US53858983A[P]. 1985-03-19. |

| 7 | Hans-Joachim K, Hans-Joachim V. Prcess for the continuous esterification of chlorosilanes: US19750584271[P]. 1977-08-02. |

| 8 | Marvin B H. Prcess for preparation of organooxysilanes: US05374761A[P]. 1994-04-29. |

| 9 | Makoto N, Hiraki H. Process for producing alkoxysilanes: US4851558A[P]. 1989-07-25. |

| 10 | 钱浩. 液体氯硅烷中硼磷杂质高效分离工艺[D]. 天津: 天津大学, 2016. |

| Qian H. Efficient separation process of boron and phosphorus impurities in liquid chlorosilane[D]. Tianjin: Tianjin University, 2016. | |

| 11 | 李闻笛, 李鑫钢, 廉景燕, 等. 二氯二氢硅精馏提纯方案的研究与优化[J]. 化工进展, 2011, 30(S1): 777-779. |

| Li W D, Li X G, Lian J Y, et al. Study and optimization of rectification and purification scheme of dichlorosilane[J]. Chemical Industry and Engineering Progress, 2011, 30(S1): 777-779. | |

| 12 | 曹军. 反应精馏技术用于硅烷生产工艺的研究[J]. 云南化工, 2020, 47(3): 65-67. |

| Cao J. Study on the application of reactive distillation technology in silane production process[J]. Yunnan Chemical Technology, 2020, 47(3): 65-67. | |

| 13 | Zhao X, Hou Z K, Guo S H, et al. Photocatalytic reactive distillation—a novel process intensification approach for purification of electronic-grade silicon tetrachloride[J]. Chemical Engineering Journal, 2023, 475: 145947. |

| 14 | Wan Y, Guo W H, Xiao J, et al. Integrated UV-based photo microreactor-distillation technology toward process intensification of continuous ultra-high-purity electronic-grade silicon tetrachloride manufacture[J]. Chinese Journal of Chemical Engineering, 2020, 28(9): 2248-2255. |

| 15 | Sugimura S, Matsuoto K, Matsuoto Y, et al. Method for purifying chlorosilane: US20120148471[P]. 2012-06-14. |

| 16 | 陈刚, 凌礼照, 朱学锋, 等. 一种电子级硝酸的制备方法: 117566700A[P]. 2024-02-20. |

| Chen G, Ling L Z, Zhu X F, et al. Preparation method of electronic grade nitric acid: 117566700A[P]. 2024-02-20. | |

| 17 | 王佳佳, 陈润泽, 李欣, 等. 一种电子级六氟丁二烯的纯化方法: 117384009A[P]. 2024-01-12. |

| Wang J J, Chen R Z, Li X, et al. Purification method of electronic grade hexafluorobutadiene: 117384009A[P]. 2024-01-12. | |

| 18 | 梅厄加, 钱德勒. 用作化学气相沉积的前体的有机硅组合物的纯化方法: 101250690[P]. 2008-08-27. |

| Mejia S G, Chandler K A. Method for purifying organosilicon compositions used as precursors for chemical vapor deposition: 101250690[P]. 2008-08-27. | |

| 19 | Ritscher J S, Turner S M. Acidic halide neutralization in alkoxysilanes: US5210254[P]. 1993-05-11. |

| 20 | Wassmann-Wilken S, Werner C, Wilken J, et al. Methods of refining silane compounds: US20040938809[P]. 2005-03-17. |

| 21 | 杨敏, 陈德义, 宛志文, 等. 有机硅组合物及其应用: 115572307A[P]. 2023-01-06. |

| Yang M, Chen D Y, Wan Z W, et al. Silicone composition and use thereof: 115572307A[P]. 2023-01-06. | |

| 22 | Guo W H, Guo S H, Zhao X, et al. Simultaneous distillation-extraction for manufacturing ultra-high-purity electronic-grade octamethylcyclotetrasiloxane (D4)[J]. Journal of Industrial and Engineering Chemistry, 2022, 109: 275-286. |

| 23 | 余淑娴, 应水良. 甲基二乙氧基硅烷的合成[J]. 南昌大学学报(理科版), 2005, 29(2): 146-150. |

| Yu S X, Ying S L. Synthesizing methods of methyldiethoxysilane[J]. Journal of Nanchang University (Natural Science), 2005, 29(2): 146-150. | |

| 24 | 李瑶, 汪瑜华, 佘慧玲. 甲基二乙氧基硅烷的合成研究[J]. 杭州化工, 2006, 36(1): 12-13. |

| Li Y, Wang Y H, She H L. A study of methyldiethoxysilane synthesis[J]. Hangzhou Chemical Industry, 2006, 36(1): 12-13. | |

| 25 | 钟伟. 萃取精馏分离纯化二甲基二氯硅烷的研究[D]. 青岛: 青岛科技大学, 2012. |

| Zhong W. Study on separation and purification of dimethyldichlorosilane by extractive distillation[D]. Qingdao: Qingdao University of Science & Technology, 2012. | |

| 26 | Li H, Sun G L, Li D Y, et al. Molecular interaction mechanism in the separation of a binary azeotropic system by extractive distillation with ionic liquid[J]. Green Energy & Environment, 2021, 6(3): 329-338. |

| 27 | 宋高鹏. 共沸精馏分离乙二醇-丙二醇-丁二醇物系的研究[D]. 天津: 天津大学, 2007. |

| Song G P. Study on separation of ethylene glycol-propylene glycol-butanediol system by azeotropic distillation[D]. Tianjin: Tianjin University, 2007. | |

| 28 | Han Z W, Ren Y Y, Li H, et al. Simultaneous extractive and azeotropic distillation separation process for production of PODEn from formaldehyde and methylal[J]. Industrial & Engineering Chemistry Research, 2019, 58(13): 5252-5260. |

| 29 | 廖永忠, 鲍坚斌, 韩世钧. 共沸点的测定[J]. 石油化工, 1991, 20(3): 171-175. |

| Liao Y Z, Bao J B, Han S J. Measurement of azeotropesic point[J]. Petrochemical Technology, 1991, 20(3): 171-175. | |

| 30 | 隋振英, 邹东雷. 共沸精馏中共沸剂的选择[J]. 化学工程师, 1996, 10(3): 27-29. |

| Sui Z Y, Zou D L. Selection of azeotropic agent in azeotropic distillation[J]. Chemical Engineer, 1996, 10(3): 27-29. | |

| 31 | 刘光永. 化工开发实验技术[M]. 天津: 天津大学出版社, 1994: 232-235. |

| Liu G Y. Experimental Technology of Chemical Development[M]. Tianjin: Tianjin University Press, 1994: 232-235. | |

| 32 | 姜标, 张黎明, 陈君, 等. 一种电子级八甲基环四硅氧烷的提纯方法: 103788124A[P]. 2014-05-14. |

| Jiang B, Zhang L M, Chen J, et al. Purification method of electronic grade octamethylcyclotetrasiloxan: 103788124A[P]. 2014-05-14. | |

| 33 | 毕明洋. 基于络合吸附法除四氯化硅中痕量磷杂质的研究[D]. 天津: 天津大学, 2020. |

| Bi M Y. Study on removal of trace phosphorus impurities from silicon tetrachloride based on complex adsorption method[D]. Tianjin: Tianjin University, 2020. |

| [1] | 茅雨洁, 路晓飞, 锁显, 杨立峰, 崔希利, 邢华斌. 工业气体中微量氧深度脱除催化剂研究进展[J]. 化工学报, 2025, 76(5): 1997-2010. |

| [2] | 高冰冰, 许诺, 白云翔, 张春芳, 杨永强, 董亮亮. 氦气分离聚合物膜[J]. 化工学报, 2025, 76(5): 2119-2135. |

| [3] | 李家顺, 李旺, 秦祖赠, 苏通明, 谢新玲, 纪红兵. 聚酰亚胺增强木质纤维素纳米纤丝气凝胶制备及其油水分离性能研究[J]. 化工学报, 2025, 76(5): 2169-2185. |

| [4] | 胡嘉朗, 姜明源, 金律铭, 张永刚, 胡鹏, 纪红兵. 机器学习辅助MOFs高通量计算筛选及气体分离研究进展[J]. 化工学报, 2025, 76(5): 1973-1996. |

| [5] | 王金月, 谢恩泽, 马翰泽, 袁晟, 何光伟, 姜忠义. 单原子层分离膜:进展与展望[J]. 化工学报, 2025, 76(5): 1943-1959. |

| [6] | 陆艳秋, 狄扬, 石文博, 殷聪聪, 汪勇. 基于新型有机多孔聚合物的智能响应膜研究进展[J]. 化工学报, 2025, 76(5): 2101-2118. |

| [7] | 齐昊, 王玉杰, 李申辉, 邹琦, 刘轶群, 赵之平. 双金属Co/Zn-ZIFs中C3H6和C3H8吸附和扩散行为分子模拟研究[J]. 化工学报, 2025, 76(5): 2313-2326. |

| [8] | 陶春珲, 李印辉, 傅钰, 段然, 赵泽一, 唐羽丰, 张罡, 马和平. 不同吸附剂对低浓度Kr气的选择性吸附与纯化[J]. 化工学报, 2025, 76(5): 2358-2366. |

| [9] | 陈建兵, 常昊, 高明, 邢兵, 张磊, 刘奇磊. 基于反应模板与分子动力学的胺基相变吸收剂分相预测方法[J]. 化工学报, 2025, 76(5): 2387-2396. |

| [10] | 赵浩帆, 任豪杰, 刘宗凯, 董冠英, 张亚涛. MOFs玻璃膜在气体分离领域的研究进展[J]. 化工学报, 2025, 76(5): 2042-2054. |

| [11] | 张越, 刘佳鑫, 马敬, 刘毅. 金属有机骨架膜应用于海水提铀研究进展[J]. 化工学报, 2025, 76(5): 2087-2100. |

| [12] | 何燎, 李俊, 高梦舒, 刘东阳, 张宇豪, 赵亮, 高金森, 徐春明. 石油烃中芳烃分离技术研究进展[J]. 化工学报, 2025, 76(5): 1909-1926. |

| [13] | 徐泽海, 刘超, 张国亮. 聚合物基疏水渗透汽化膜及其溶剂回收应用[J]. 化工学报, 2025, 76(5): 2055-2069. |

| [14] | 顾栋, 皮行健, 张叠, 张瑛. 不同粒径CAU-1/PI混合基质膜的构建与H2/CO2分离性能研究[J]. 化工学报, 2025, 76(5): 2410-2418. |

| [15] | 郭彭涛, 王婷, 薛波, 应允攀, 刘大欢. 用于CH4/N2分离的多吸附位点超微孔MOF[J]. 化工学报, 2025, 76(5): 2304-2312. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号