化工学报 ›› 2025, Vol. 76 ›› Issue (4): 1779-1787.DOI: 10.11949/0438-1157.20241133

收稿日期:2024-10-14

修回日期:2024-11-22

出版日期:2025-04-25

发布日期:2025-05-12

通讯作者:

卿梦霞

作者简介:刘亮(1967—),男,博士,教授,liuliang_hn@163.com

基金资助:

Liang LIU( ), Jiajun WU, Mengxia QING(

), Jiajun WU, Mengxia QING( ), Guangya ZHOU, Zihang HE

), Guangya ZHOU, Zihang HE

Received:2024-10-14

Revised:2024-11-22

Online:2025-04-25

Published:2025-05-12

Contact:

Mengxia QING

摘要:

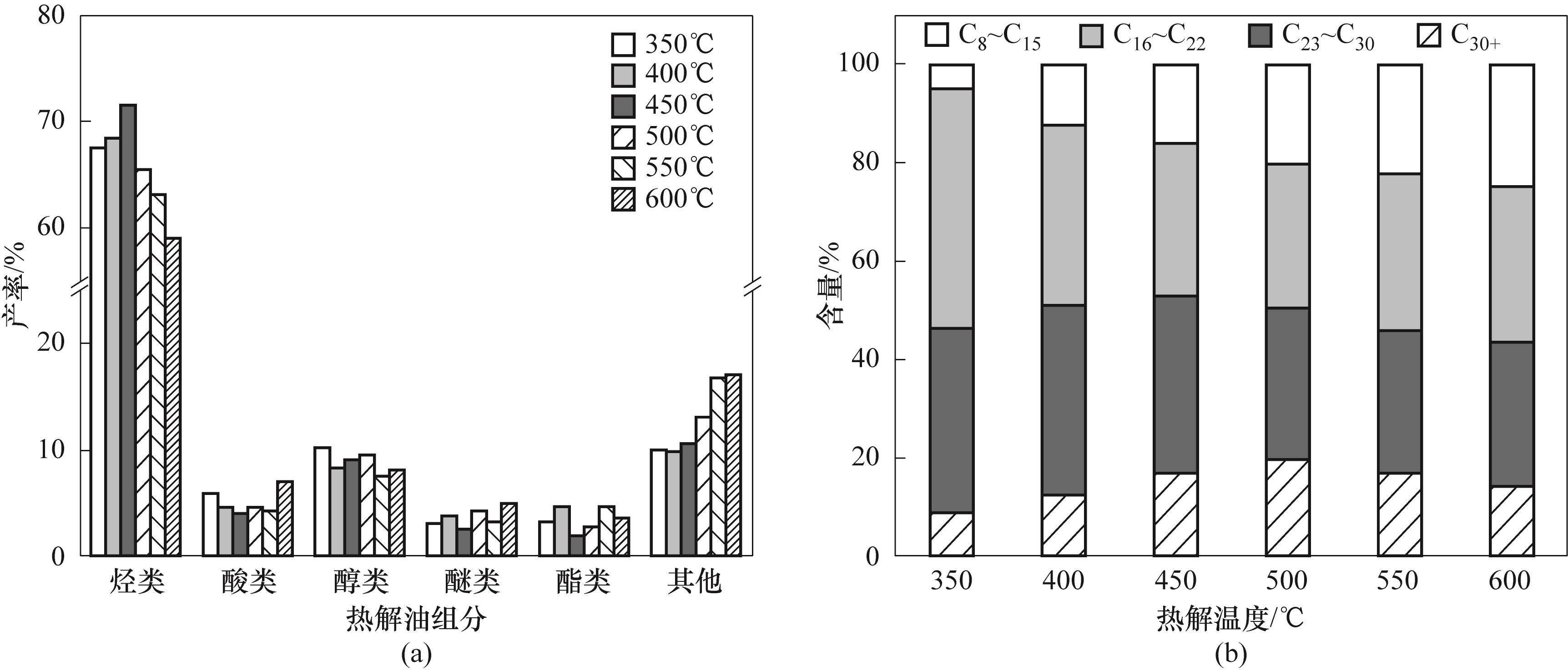

热解法可快速实现低含油量落地油泥的无害化处理与资源化利用,但其高含水量的特点会造成大量能量损耗,热解处理过程中的能量平衡问题不容忽视。对落地油泥开展了相关热解实验,利用Aspen Plus软件对热解工艺流程进行建模,通过改变初始含水率、热解温度、焦炭燃烧比等参数,分析工艺系统实现能量自平衡的可能性。结果表明:在450℃时,热解油中烃类物质含量高达71.6%,热解温度低于450℃时得到的热解油品质较高,C6~C30的占比超过90%。在不同热解温度下焦炭燃烧比均不超过100%,系统可以通过调节焦炭燃烧比实现对落地油泥干燥和热解处理过程的能量自平衡。降低油泥的初始含水率有利于减少系统的能耗,初始含水率越低系统能量自平衡越容易,如落地油泥经脱水处理后含水率仍然较高时,工艺系统可以通过适当提高热解温度来继续保持能量平衡。

中图分类号:

刘亮, 吴佳俊, 卿梦霞, 周光亚, 贺梓航. 落地油泥热解特性及工艺系统能量平衡分析[J]. 化工学报, 2025, 76(4): 1779-1787.

Liang LIU, Jiajun WU, Mengxia QING, Guangya ZHOU, Zihang HE. Characteristics of landed oil sludge pyrolysis and energy balance analysis of the process system[J]. CIESC Journal, 2025, 76(4): 1779-1787.

| Mar/% | Ad/% | Vd/% | FCd/% | Cd/% | Hd/% | Nd/% | Sd/% | |

|---|---|---|---|---|---|---|---|---|

| 10~40 | 73.58 | 20.95 | 5.47 | 15.13 | 2.23 | 0.43 | 1.06 | 7.57 |

表1 落地油泥的工业分析和元素分析

Table 1 Industrial analysis and elemental analysis of ground oil sludge

| Mar/% | Ad/% | Vd/% | FCd/% | Cd/% | Hd/% | Nd/% | Sd/% | |

|---|---|---|---|---|---|---|---|---|

| 10~40 | 73.58 | 20.95 | 5.47 | 15.13 | 2.23 | 0.43 | 1.06 | 7.57 |

| 操作单元 | 模块 | 功能 |

|---|---|---|

| 干燥单元 | RSTOIC | 干燥油泥 |

| FLASH | 气固分离 | |

| 粉碎单元 | CRUSHER | 粉碎油泥 |

| 热解单元 | RYIELD | 将干燥油泥分解成系统可识别的单质 |

| RYIELD | 生成热解产物 | |

| 分离单元 | SSPLIT | 气固分离 |

| 燃烧单元 | RGIBBS | 可燃气体燃烧 |

| 换热器 | HEAT1 | 热解过程提供热量 |

| HEAT2 | 干燥过程提供热量 | |

| 换热效率 | MULT | 调节换热效率 |

| 分配单元 | FSPLIT | 调节焦炭燃烧比 |

表2 Aspen Plus模拟流程单元操作模块及功能

Table 2 Aspen Plus simulates process unit operating modules and functions

| 操作单元 | 模块 | 功能 |

|---|---|---|

| 干燥单元 | RSTOIC | 干燥油泥 |

| FLASH | 气固分离 | |

| 粉碎单元 | CRUSHER | 粉碎油泥 |

| 热解单元 | RYIELD | 将干燥油泥分解成系统可识别的单质 |

| RYIELD | 生成热解产物 | |

| 分离单元 | SSPLIT | 气固分离 |

| 燃烧单元 | RGIBBS | 可燃气体燃烧 |

| 换热器 | HEAT1 | 热解过程提供热量 |

| HEAT2 | 干燥过程提供热量 | |

| 换热效率 | MULT | 调节换热效率 |

| 分配单元 | FSPLIT | 调节焦炭燃烧比 |

图7 不同温度下热解油的产物分布(a)和烃类的碳数分布(b)

Fig.7 Product distribution of pyrolysis oil (a) and carbon number distribution of hydrocarbons (b) at different temperatures

| 1 | 齐越. 落地油泥资源化回收工艺环境可行性研究[J]. 石油化工安全环保技术, 2020, 36(6): 63-68, 8. |

| Qi Y. Environmental feasibility study on the recycling process of oily sludge[J]. Petrochemical Safety and Environmental Protection Technology, 2020, 36(6): 63-68, 8. | |

| 2 | 陈忠喜. 含油污泥处理工艺技术现状及其展望[J]. 油气田地面工程, 2020, 39(10): 1-7. |

| Chen Z X. Present situation and prospect of oily sludge treatment technology[J]. Oil-Gas Field Surface Engineering, 2020, 39(10): 1-7. | |

| 3 | 齐加胜, 赵建平, 黄欣欣. 长庆油田落地油泥处理技术研究[J]. 当代化工, 2018, 47(11): 2326-2329, 2333. |

| Qi J S, Zhao J P, Huang X X. Research on treatment technology of ground oil sludge in Changqing oilfield[J]. Contemporary Chemical Industry, 2018, 47(11): 2326-2329, 2333. | |

| 4 | 屈撑囤, 李金灵, 朱世东, 等. 油气田含油污泥处理技术[M]. 北京: 石油工业出版社, 2017. |

| Qu C T, Li J L, Zhu S D. Treatment Technology of Oily Sludge in Oil and Gas Fields[M]. Beijing: Petroleum Industry Press, 2017. | |

| 5 | 黄静, 刘建坤, 蒋廷学, 等. 含油污泥热解技术研究进展[J]. 化工进展, 2019, 38(S1): 232-239. |

| Huang J, Liu J K, Jiang T X, et al. Research progress on pyrolysis technology of oily sludge[J]. Chemical Industry and Engineering Progress, 2019, 38(S1): 232-239. | |

| 6 | 白潇阳, 周玲, 倪虹果, 等. 含油污泥无害化处理技术原理和适用性分析[J]. 环境科学与技术, 2015, 38(S1): 285-289. |

| Bai X Y, Zhou L, Ni H G, et al. Principle and applicability analysis of harmless treatment technology for oil sludge[J]. Environmental Science and Technology, 2015, 38(S1): 285-289. | |

| 7 | 赵衡振, 陈德珍, 洪鎏, 等. 含油污泥热解工艺及目标产物定位[J]. 石油学报(石油加工), 2020, 36(3): 557-567. |

| Zhao H Z, Chen D Z, Hong L, et al. Target products of oily sludges pyrolysis disposal[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2020, 36(3): 557-567. | |

| 8 | 高怀. 化工过程模拟在工业生产中的应用[J]. 煤炭与化工, 2017, 40(3): 138-140. |

| Gao H. The application of chemical process simulation in industrial production[J]. Coal and Chemical Industry, 2017, 40(3): 138-140. | |

| 9 | 魏智宇, 杨晴, 周荷雯, 等. 基于Aspen Plus平台的生物质热解模型与应用研究综述[J]. 能源与环境, 2018(6): 94-96. |

| Wei Z Y, Yang Q, Zhou H W, et al. Review on biomass pyrolysis model and application based on Aspen Plus platform[J]. Energy and Environment, 2018(6): 94-96. | |

| 10 | Hasan M M, Rasul M G, Jahirul M I, et al. Modeling and process simulation of waste macadamia nutshell pyrolysis using Aspen Plus software[J]. Energy Reports, 2022, 8: 429-437. |

| 11 | 柏静儒, 吴海涛, 刘斌, 等. 基于Aspen Plus的油砂干馏过程模拟[J]. 东北电力大学学报, 2017, 37(6): 45-49. |

| Bai J R, Wu H T, Liu B, et al. Modeling of retortingprocess for oil sand using Aspen Plus[J]. Journal of Northeast Electric Power University, 2017, 37(6): 45-49. | |

| 12 | Gong Z Q, Du A X, Wang Z B, et al. Analysis on integrated thermal treatment of oil sludge by Aspen Plus[J]. Waste Management, 2019, 87: 512-524. |

| 13 | Sun H, Luo L, Wang D, et al. Carbon balance analysis of sewage sludge biochar-to-soil system[J]. Journal of Cleaner Production, 2022, 358: 132057. |

| 14 | 付建英, 余权, 马瀚程, 等. 基于Aspen Plus的非均质垃圾与秸秆的共热解气化模拟[J]. 能源与环境, 2020(5): 2-5. |

| Fu J Y, Yu Q, Ma H C, et al. Simulation of co-pyrolysis gasification of heterogeneous garbage and straw based on Aspen Plus[J]. Energy and Environment, 2020(5): 2-5. | |

| 15 | 杨儒浦, 胡松, 池寰瀛, 等. 基于Aspen Plus的污泥热解与混烧技术经济特性对比分析[J]. 可再生能源, 2017, 35(6): 798-804. |

| Yang R P, Hu S, Chi H Y, et al. Techno-economic comparison analysis of sewage sludge pyrolysis and co-combustion based on Aspen Plus[J]. Renewable Energy Resources, 2017, 35(6): 798-804. | |

| 16 | Zhang H L, Shu Y X, Yue S L, et al. Process design and optimization on self-sustaining pyrolysis and carbonization of ultra-low calorific value coal gangue[J]. Sustainable Energy Technologies and Assessments, 2023, 60: 103491. |

| 17 | 蔡杰. 基于ASPEN Plus的村镇垃圾热解气化燃烧模拟与试验[D]. 杭州: 浙江大学, 2021. |

| Cai J. Simulation and experiment of pyrolysis, gasification and combustion of village waste based on ASPEN Plus[D]. Hangzhou: Zhejiang University, 2021. | |

| 18 | 王伟, 商玉坤, 武建军. 基于Aspen Plus的褐煤热解过程模拟[J]. 化学工业与工程, 2011, 28(3): 49-53, 73. |

| Wang W, Shang Y K, Wu J J. The lignite coal pyrolysis process simulation based on Aspen Plus[J]. Chemical Industry and Engineering, 2011, 28(3): 49-53, 73. | |

| 19 | 王学斌, 周澳, 杨明辉, 等. 燃煤电厂200t/d生活垃圾无氧热解耦合协同处置优化[J]. 煤炭学报, 2022, 47(11): 3897-3905. |

| Wang X B, Zhou A, Yang M H, et al. Optimization on 200 t/d garbage co-utilization in a coal-fired power plant through air-free pyrolysis process[J]. Journal of China Coal Society, 2022, 47(11): 3897-3905. | |

| 20 | 林法伟, 郑发, 李建陶, 等. 大庆多源含油污泥热解特性的对比[J]. 化工进展, 2021, 40(S2): 421-433. |

| Lin F W, Zheng F, Li J T, et al. Comparing pyrolysis characteristics of Daqing multi-source oil sludge[J]. Chemical Industry and Engineering Progress, 2021, 40(S2): 421-433. | |

| 21 | Qu Y, Li A M, Wang D, et al. Kinetic study of the effect of in situ mineral solids on pyrolysis process of oil sludge[J]. Chemical Engineering Journal, 2019, 374: 338-346. |

| 22 | 詹咏, 张领军, 谢加才, 等. 热解终温对含油污泥三相产物特性的影响[J]. 环境工程学报, 2021, 15(7): 2409-2416. |

| Zhan Y, Zhang L J, Xie J C, et al. Effect of final pyrolysis temperature on characteristics of three-phase products of oily sludge[J]. Chinese Journal of Environmental Engineering, 2021, 15(7): 2409-2416. | |

| 23 | Wu S L, Shen D K, Hu J, et al. Cellulose-hemicellulose interactions during fast pyrolysis with different temperatures and mixing methods[J]. Biomass and Bioenergy, 2016, 95: 55-63. |

| 24 | Wan G, Bei L, Yu J, et al. Products distribution and hazardous elements migration during pyrolysis of oily sludge from the oil refining process[J]. Chemosphere, 2022, 288: 132524. |

| 25 | Quan C, Zhang G T, Xu L H, et al. Improvement of the pyrolysis products of oily sludge: catalysts and catalytic process[J]. Journal of the Energy Institute, 2022, 104: 67-79. |

| 26 | Wu S L, Kang D, Xiao R, et al. Autoignition characteristics of bio-based fuels, farnesane and TPGME, in comparison with fuels of similar cetane rating[J]. Proceedings of the Combustion Institute, 2021, 38(4): 5585-5595. |

| 27 | 杨慧芬, 李真, 付鹏, 等. 罐底油泥热解产物高附加值利用途径[J]. 环境工程学报, 2021, 15(2): 717-726. |

| Yang H F, Li Z, Fu P, et al. High value-added utilization approach of pyrolysis products generated by tank bottom oily sludge[J]. Chinese Journal of Environmental Engineering, 2021, 15(2): 717-726. | |

| 28 | Wu S L, Wang Z W, Yang H W, et al. The applicability of catalytic esterified biomass-pyrolysis-oil surrogates in diesel engine[J]. Fuel Processing Technology, 2020, 198: 106251. |

| 29 | Wu S L, Kang D, Liu Y, et al. The oxidation of C2—C4 diols and diol/TPGME blends in a motored engine[J]. Fuel, 2019, 257: 116093. |

| 30 | 彭涛. 含油污泥干化热解一体化技术及设备[D]. 常州: 常州大学, 2021. |

| Peng T. Integrated technology and equipment for drying and pyrolysis of oily sludge[D]. Changzhou: Changzhou University, 2021. | |

| 31 | Zhou A, Wang X B, Yu S L, et al. Process design and optimization on self-sustaining pyrolysis and carbonization of municipal sewage sludge[J]. Waste Management, 2023, 159: 125-133. |

| 32 | 冯东征, 何选明, 柯萍, 等. 稻杆与褐煤共热解转化效能研究[J]. 煤炭转化, 2019, 42(1): 15-21. |

| Feng D Z, He X M, Ke P, et al. Study on conversion efficiency of co-pyrolysis of straws and lignite[J]. Coal Conversion, 2019, 42(1): 15-21. |

| [1] | 徐东菱, 马跃, 龚露, 马桂丽, 王金可, 郭丰志, 王浩伦, 李思佳, 李术元, 岳长涛. 油页岩与烟煤混合流化热解实验研究[J]. 化工学报, 2025, 76(4): 1742-1753. |

| [2] | 李中青, 王志远, 栾小建, 梁四凯, 王凯. 电沉积-低氧分压法制备MnO涂层及其抑制石脑油热裂解结焦性能研究[J]. 化工学报, 2025, 76(3): 1050-1063. |

| [3] | 徐芳, 张锐, 崔达, 王擎. ReaxFF-MD揭示木质素热解反应机制的分子动力学研究[J]. 化工学报, 2025, 76(3): 1253-1263. |

| [4] | 姚国家, 王志, 苏昂, 冯东阁, 唐宏, 孙灵芳. 空气系数对煤粉预热解燃烧特性的影响分析[J]. 化工学报, 2025, 76(3): 1243-1252. |

| [5] | 丁湧, 李文建, 陈昭宇, 曹立辉, 刘轩铭, 任强强, 胡松, 向军. 废旧晶体硅光伏组件EVA有氧热解动力学与产物特性[J]. 化工学报, 2024, 75(9): 3310-3319. |

| [6] | 黄正梁, 冯铭瑞, 宋琦, 任聪静, 杨遥, 孙婧元, 王靖岱, 阳永荣. 预混进料对废树脂流化裂解反应中颗粒团聚的抑制作用[J]. 化工学报, 2024, 75(9): 3094-3102. |

| [7] | 王舒英, 左涛, 石志伟, 范小明, 张卫新. 阳离子交换树脂基介孔石墨化碳合成与储钠性能[J]. 化工学报, 2024, 75(9): 3338-3347. |

| [8] | 吴学红, 韦新, 侯加文, 吕财, 刘勇, 刘鹤, 常志娟. 热解法制备碳纳米管及其在散热涂层中的应用研究[J]. 化工学报, 2024, 75(9): 3360-3368. |

| [9] | 姚宏哲, 黄飞宇, 杨松, 钟梅, 代正华. 重质油高温快速热解自动反应网络的动力学建模[J]. 化工学报, 2024, 75(7): 2644-2655. |

| [10] | 晁惠雨, 白振敏, 侯汉青, 田立志, 李洪, 房晓权, 石晓华. 液相法合成三聚氰酸体系热力学分析[J]. 化工学报, 2024, 75(6): 2157-2165. |

| [11] | 吴希, 孙博, 刘银东, 齐传磊, 陈凯毅, 王路海, 许崇, 李永峰. 钠离子电池沥青基碳负极材料制备技术研究进展[J]. 化工学报, 2024, 75(4): 1270-1283. |

| [12] | 李浩文, 兰昊, 郑幼丹, 孙勇辉, 杨子昕, 宋谦石, 汪小憨. 热通道内典型碳氢燃料的热解结焦行为[J]. 化工学报, 2024, 75(2): 626-636. |

| [13] | 王茂先, 孙启典, 付哲, 华放, 纪晔, 程易. 分子水平动力学模型和机器学习方法相结合研究废弃塑料热解[J]. 化工学报, 2024, 75(11): 4320-4332. |

| [14] | 吴雷, 刘姣, 李长聪, 周军, 叶干, 刘田田, 朱瑞玉, 张秋利, 宋永辉. 低阶粉煤催化微波热解制备含碳纳米管的高附加值改性兰炭末[J]. 化工学报, 2023, 74(9): 3956-3967. |

| [15] | 杨峥豪, 何臻, 常玉龙, 靳紫恒, 江霞. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号