化工学报 ›› 2024, Vol. 75 ›› Issue (9): 3094-3102.DOI: 10.11949/0438-1157.20240072

黄正梁1,2( ), 冯铭瑞2, 宋琦2, 任聪静3(

), 冯铭瑞2, 宋琦2, 任聪静3( ), 杨遥1,2, 孙婧元1,2, 王靖岱1,2, 阳永荣1,2

), 杨遥1,2, 孙婧元1,2, 王靖岱1,2, 阳永荣1,2

收稿日期:2024-01-15

修回日期:2024-04-02

出版日期:2024-09-25

发布日期:2024-10-10

通讯作者:

任聪静

作者简介:黄正梁(1982—),男,博士,高级实验师,huangzhengl@zju.edu.cn

基金资助:

Zhengliang HUANG1,2( ), Mingrui FENG2, Qi SONG2, Congjing REN3(

), Mingrui FENG2, Qi SONG2, Congjing REN3( ), Yao YANG1,2, Jingyuan SUN1,2, Jingdai WANG1,2, Yongrong YANG1,2

), Yao YANG1,2, Jingyuan SUN1,2, Jingdai WANG1,2, Yongrong YANG1,2

Received:2024-01-15

Revised:2024-04-02

Online:2024-09-25

Published:2024-10-10

Contact:

Congjing REN

摘要:

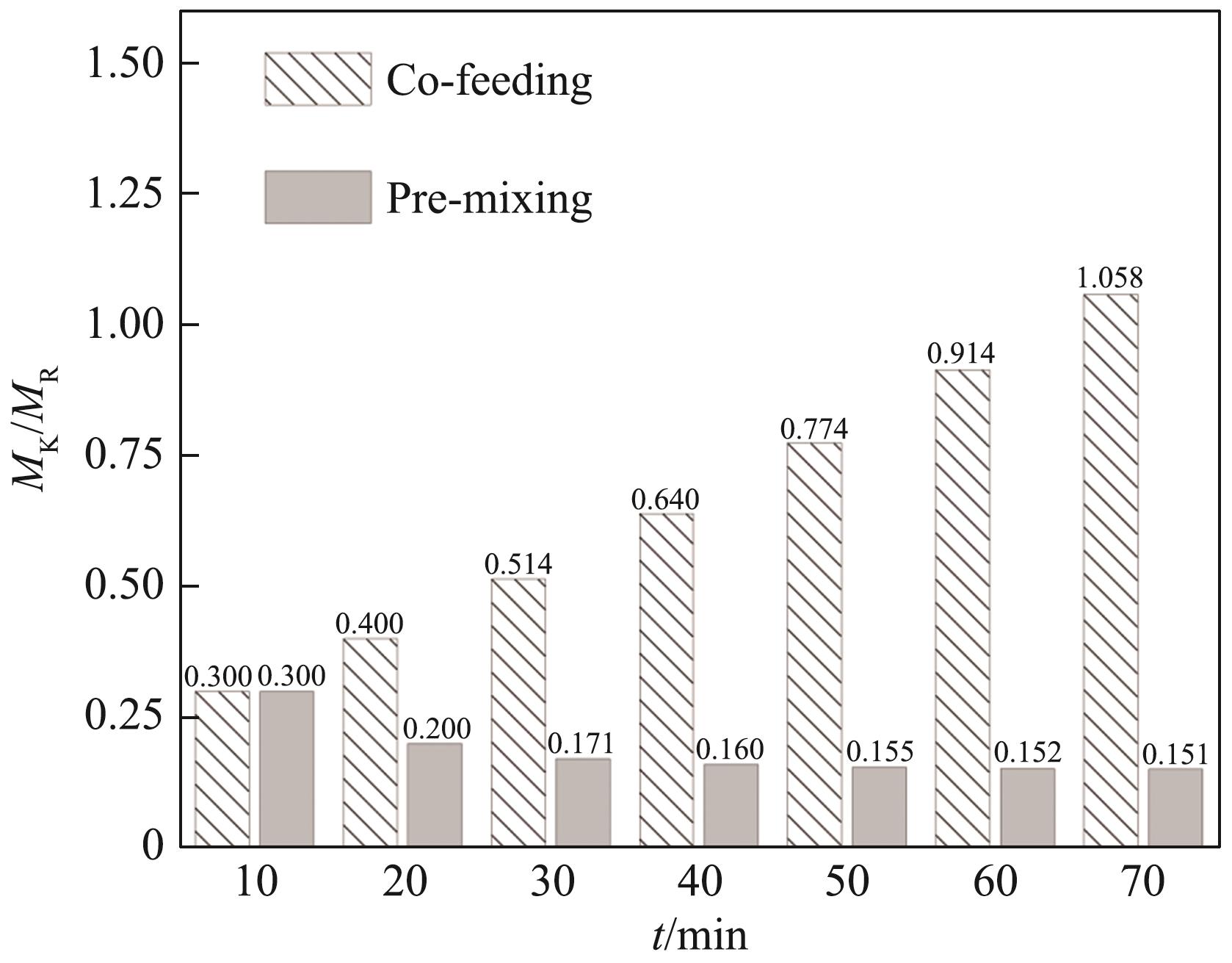

针对放射性废树脂流化裂解反应过程中颗粒团聚问题,提出了高岭土和陶瓷颗粒预混进料抑制颗粒团聚的新思路,在流化裂解实验装置中通过测量床层压降和对产物的XRD、SEM以及元素分析,考察预混时高岭土添加量对流化特性和颗粒团聚的影响规律。研究结果表明,高岭土与陶瓷球预混后可在陶瓷球颗粒表面形成均匀的涂覆层,当高岭土添加量≥0.20%(质量分数)时具有显著的抑制废树脂流化裂解反应中颗粒团聚的作用,但存在一定的作用时长,应定期补加预混高岭土的陶瓷球颗粒以维持陶瓷球表面的高岭土覆层,当高岭土预混添加量为0.20%(质量分数)时高岭土预混进料抑制团聚的作用时长约为70 min。与高岭土和废树脂共混进料相比,预混进料可在更低的高岭土添加量条件下达到颗粒团聚抑制效果,有利于放射性废树脂的减量化处理。

中图分类号:

黄正梁, 冯铭瑞, 宋琦, 任聪静, 杨遥, 孙婧元, 王靖岱, 阳永荣. 预混进料对废树脂流化裂解反应中颗粒团聚的抑制作用[J]. 化工学报, 2024, 75(9): 3094-3102.

Zhengliang HUANG, Mingrui FENG, Qi SONG, Congjing REN, Yao YANG, Jingyuan SUN, Jingdai WANG, Yongrong YANG. Inhibitory effect of premixed feedstock on particle agglomeration in fluidized pyrolysis reaction of waste resin[J]. CIESC Journal, 2024, 75(9): 3094-3102.

| 流化颗粒 | Geldart分类[ | 颗粒密度ρp/ (kg/m3) | 平均粒径dp/mm |

|---|---|---|---|

| 阳离子交换树脂 | B | 1475 | 0.5 |

| 氧化铝陶瓷球 | B/D | 3925 | 0.5 |

| 高岭土 | C | 2481 | 0.01 |

表1 流化颗粒的物性参数

Table 1 Physical properties of fluidized particles

| 流化颗粒 | Geldart分类[ | 颗粒密度ρp/ (kg/m3) | 平均粒径dp/mm |

|---|---|---|---|

| 阳离子交换树脂 | B | 1475 | 0.5 |

| 氧化铝陶瓷球 | B/D | 3925 | 0.5 |

| 高岭土 | C | 2481 | 0.01 |

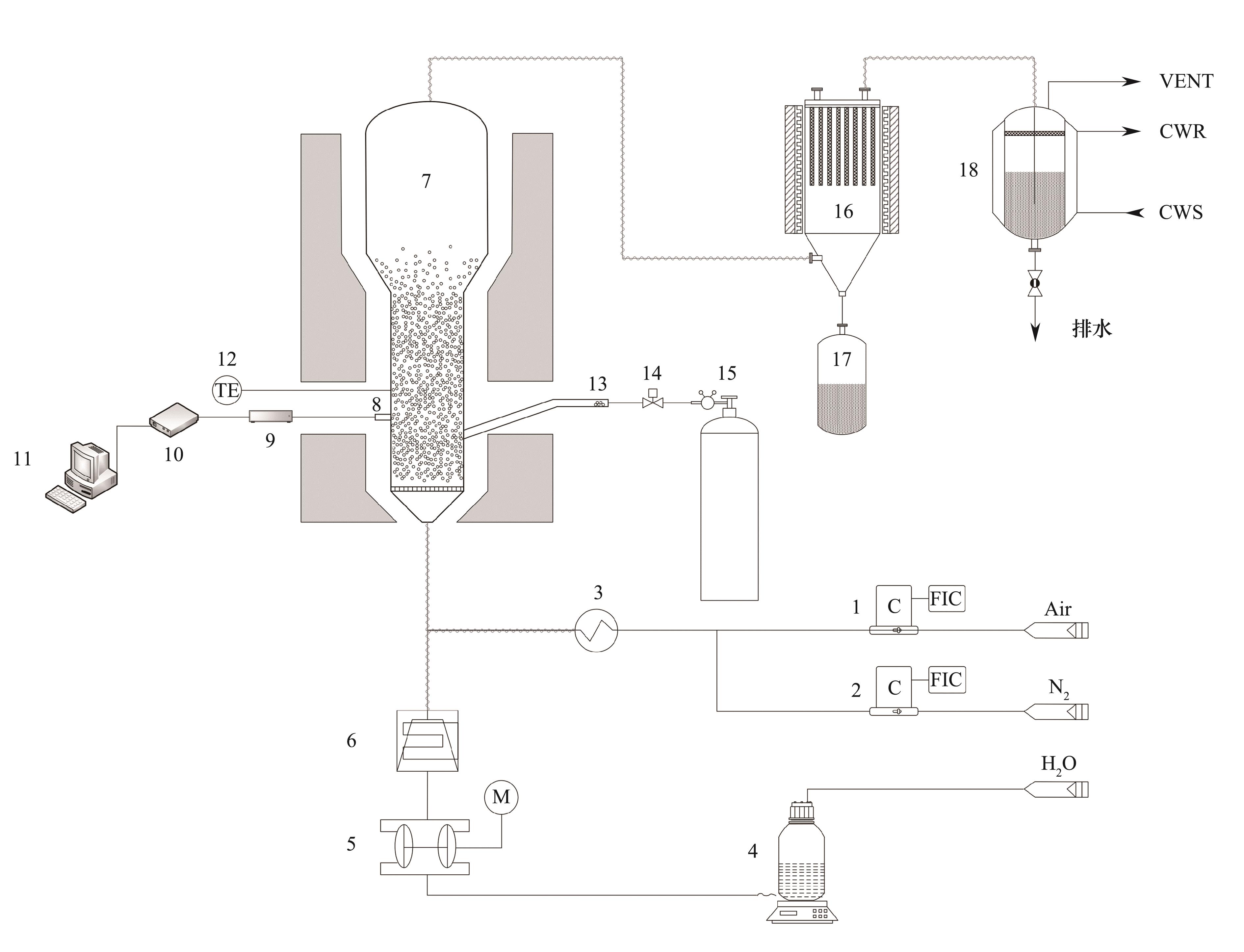

图1 流化裂解实验装置1—空气质量流量计;2—氮气质量流量计;3—气体预热器;4—水储罐;5—隔膜泵;6—蒸发器;7—流化床;8—压差探头;9—压力传感器;10—数据采集卡;11—计算机;12—热电偶;13—进料管;14—电磁阀;15—氮气瓶;16—气固分离器;17—固体收集罐;18—气体洗涤罐

Fig.1 Fluidized pyrolysis experimental device

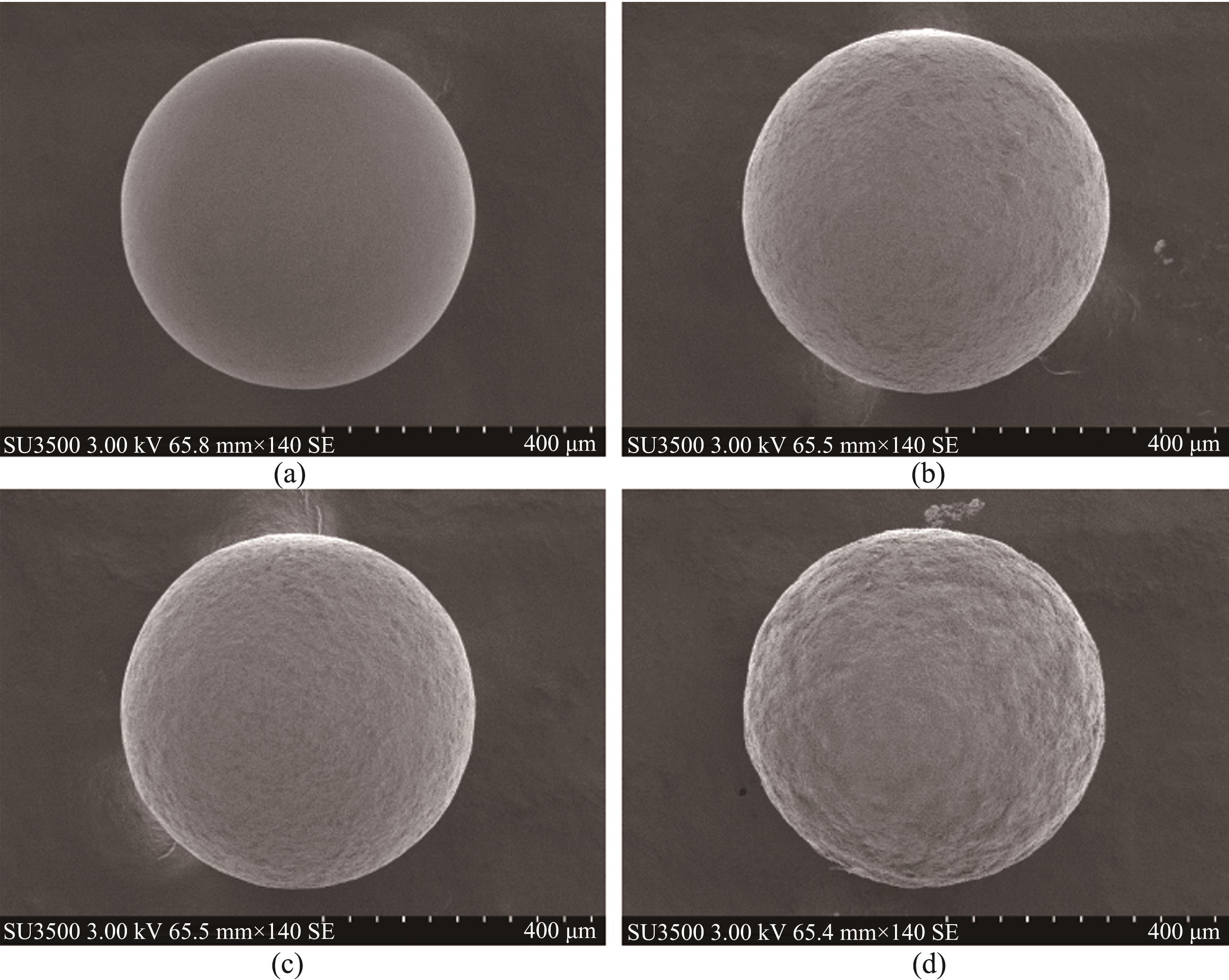

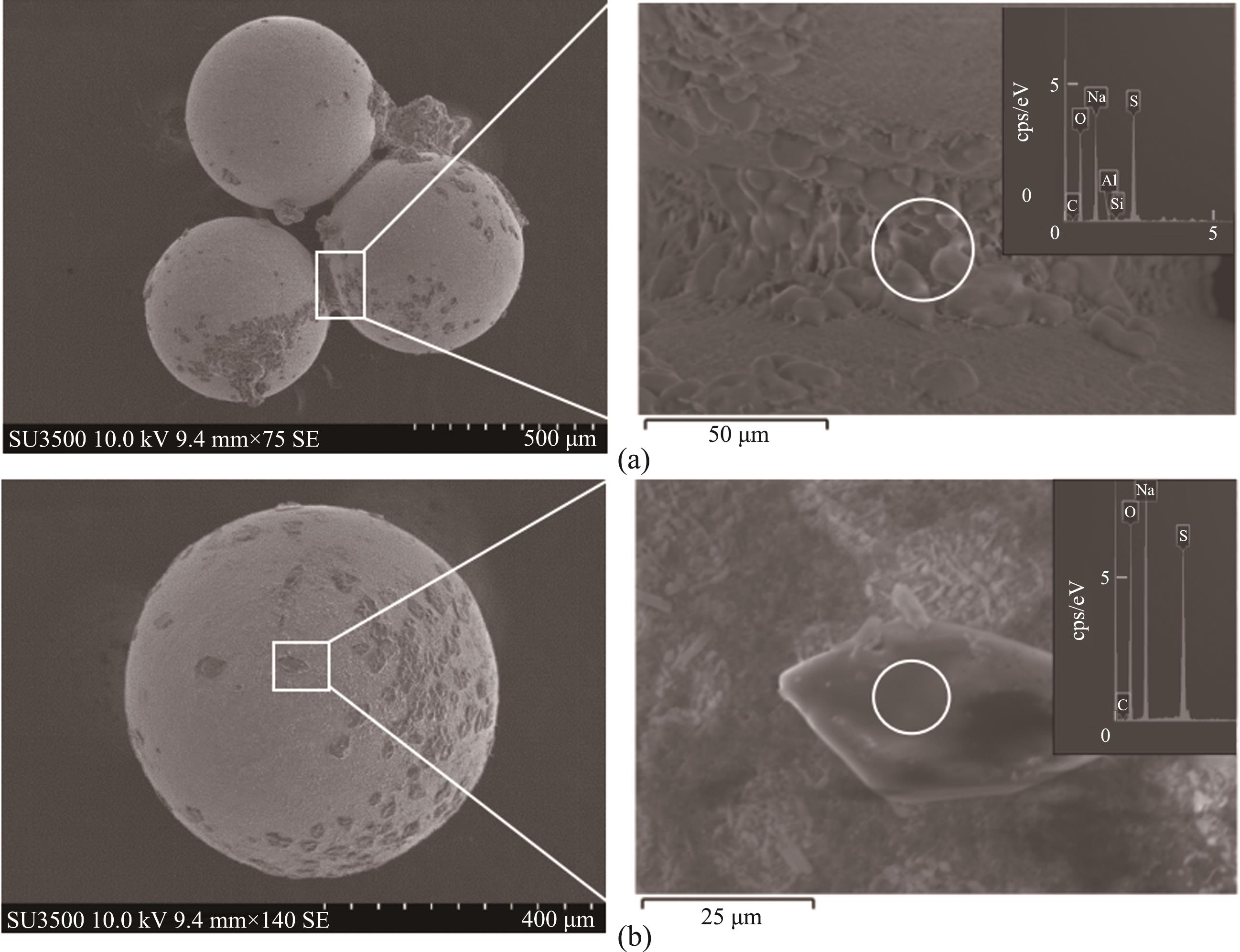

图2 初始陶瓷球颗粒 (a) 及其与0.04%(质量分数) (b)、0.20%(质量分数) (c)和0.40%(质量分数) (d)高岭土预混后的表面形貌

Fig.2 Morphologies of original Al2O3 particle (a) and particles after premixed with 0.04% (b), 0.20% (c) and 0.40% (d) kaolin

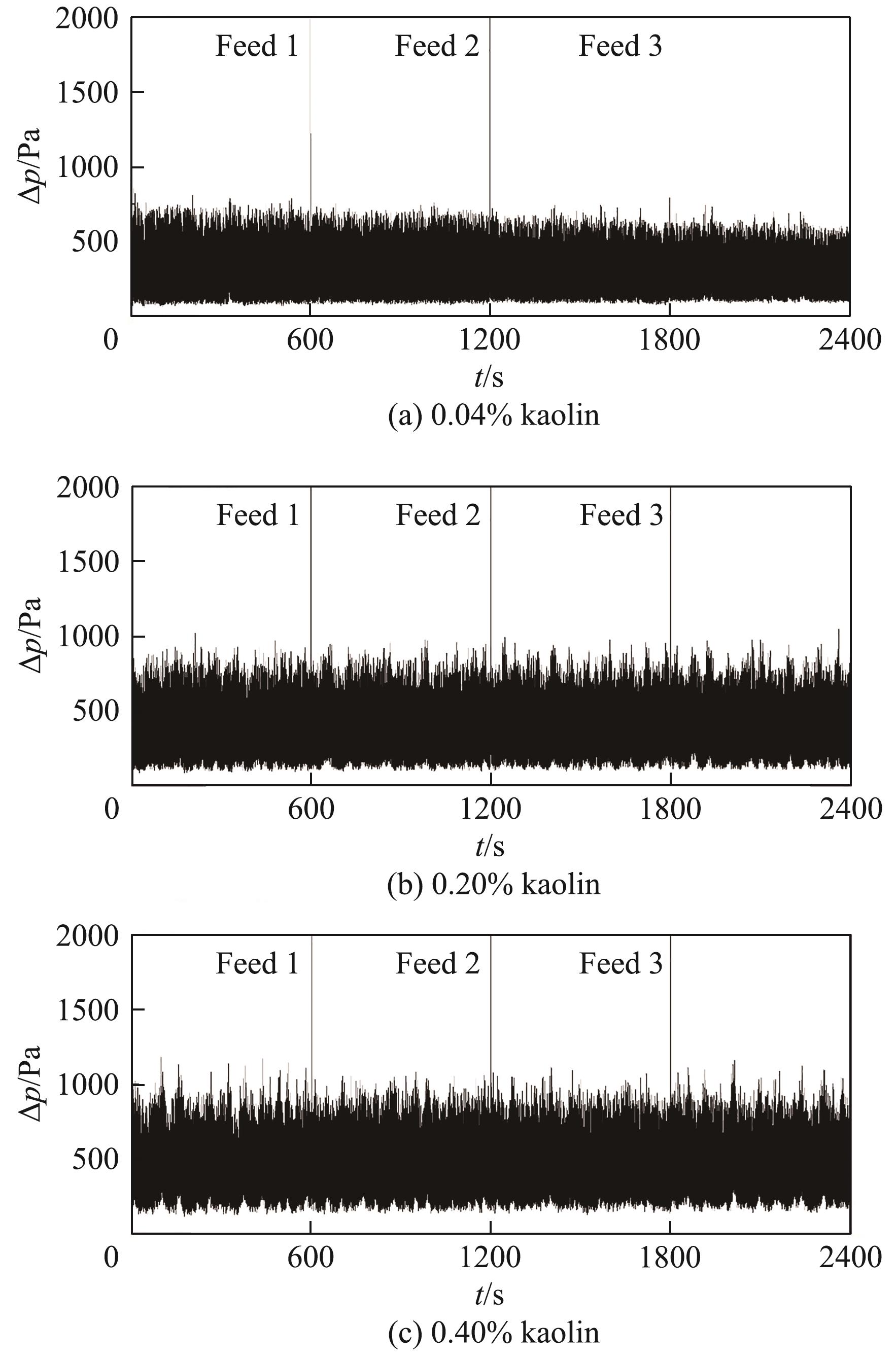

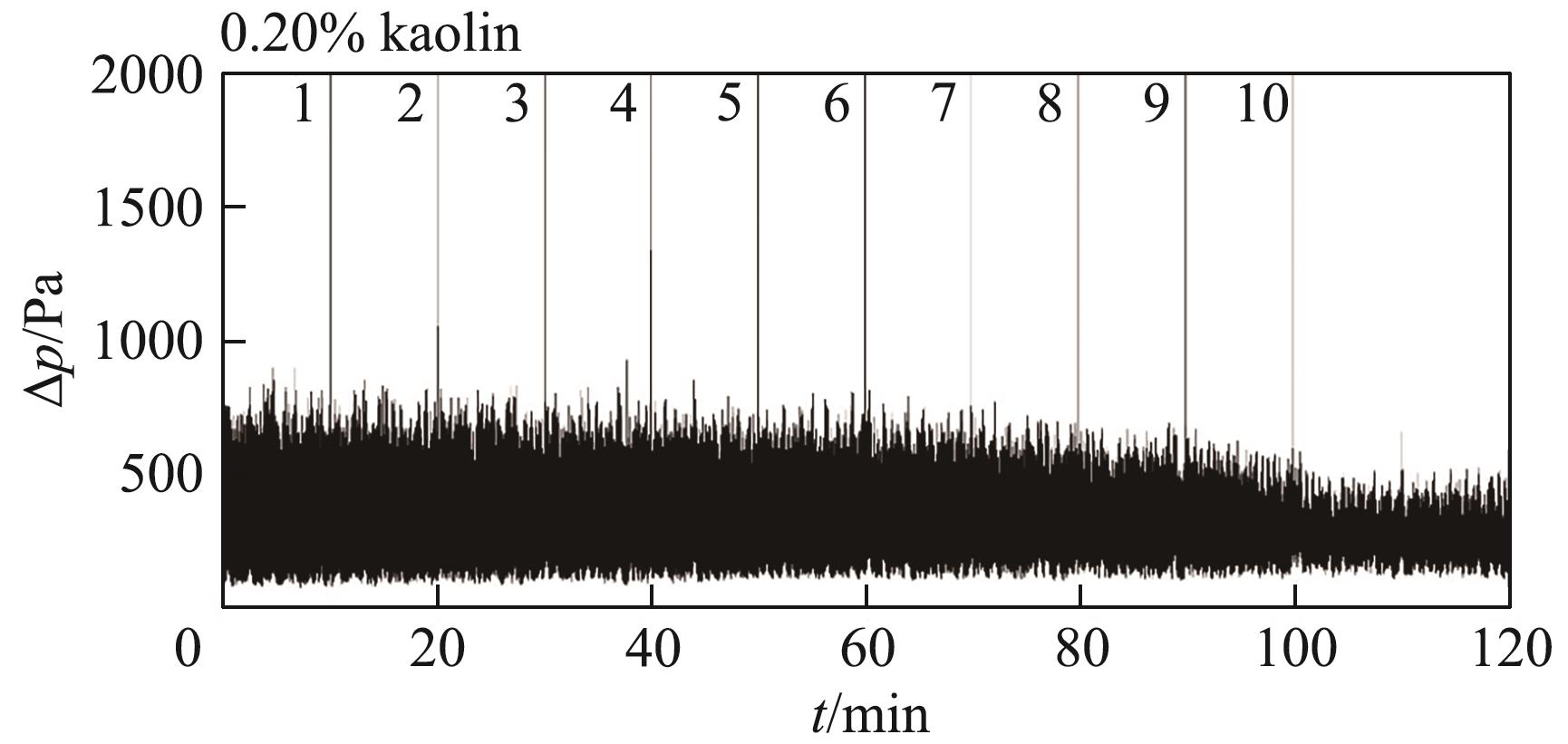

图3 高岭土预混量对树脂进料前后床层压降的影响(T=700℃, ug=0.8 m/s, H=45 mm)

Fig.3 Effect of kaolin premixed amount on pressure drop before and after resin feeding (T=700℃, ug=0.8 m/s, H=45 mm)

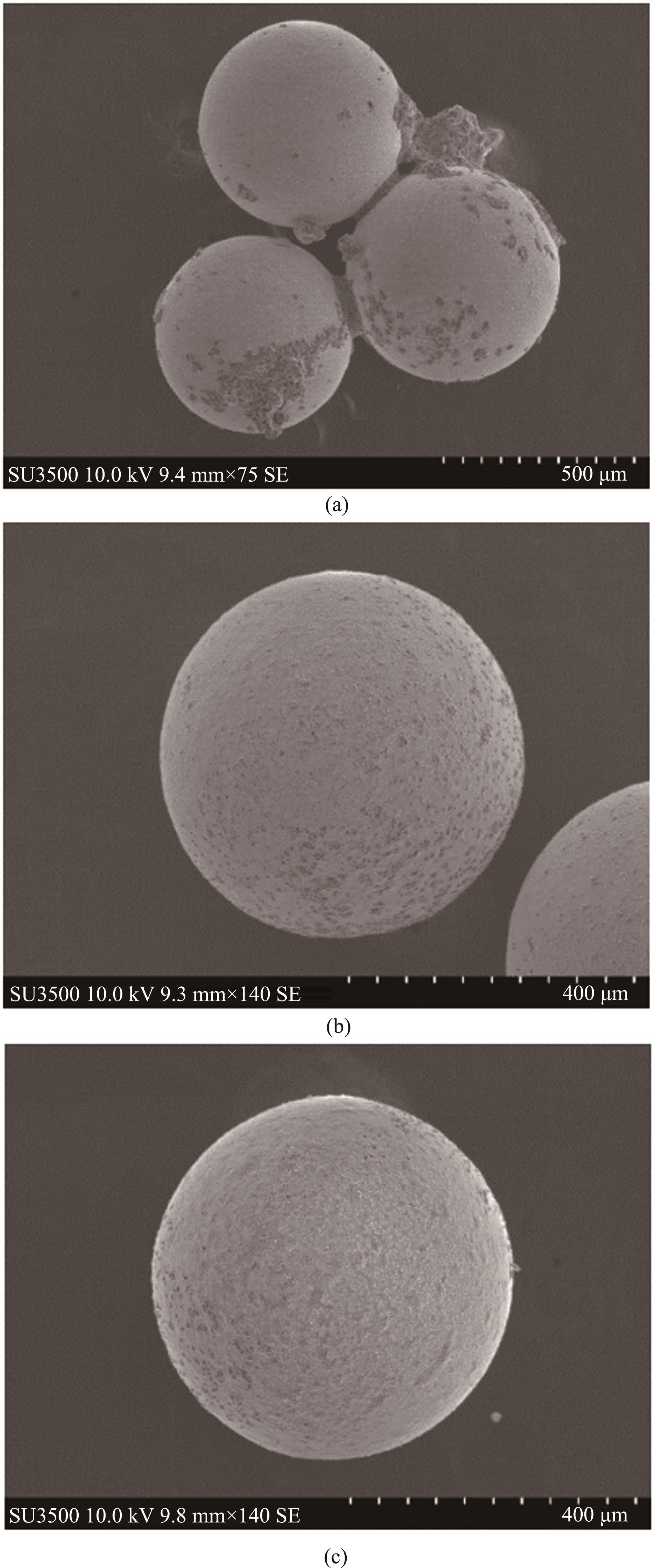

图4 0.04%(质量分数)(a)、0.2%(质量分数)(b)和0.4%(质量分数)(c)高岭土预混颗粒反应后的表面形貌

Fig.4 Morphologies of particles premixed with 0.04% (mass) (a), 0.2% (b) and 0.4% (c) kaolin after reaction

图5 0.04%(质量分数)高岭土预混陶瓷球颗粒:(a) 聚团中固桥的元素分布;(b) 分散颗粒表面元素分布

Fig.5 Elements distribution in ceramic sphere particles premixed with 0.04% (mass) kaolinite: (a) within solid bridges of agglomerates; (b) on surface of dispersed particles

| 灰分组成元素 | 聚团中固桥的元素 组成/%(质量分数) | 分散颗粒表面元素 分布/%(质量分数) |

|---|---|---|

| O | 49.56 | 50.12 |

| Na | 31.64 | 27.17 |

| S | 18.80 | 22.19 |

| Si | 0 | 0.51 |

| C | 0 | 0 |

表2 0.04%(质量分数)高岭土预混陶瓷球颗粒不同位置灰分组成和元素含量

Table 2 Ash composition element contents at different locations in ceramic sphere particles premixed with 0.04% (mass) kaolin

| 灰分组成元素 | 聚团中固桥的元素 组成/%(质量分数) | 分散颗粒表面元素 分布/%(质量分数) |

|---|---|---|

| O | 49.56 | 50.12 |

| Na | 31.64 | 27.17 |

| S | 18.80 | 22.19 |

| Si | 0 | 0.51 |

| C | 0 | 0 |

图7 高岭土预混颗粒流化床层H=45 mm处压降随树脂进料的变化(700℃,0.8 m/s)

Fig.7 Variation of pressure drop at H=45 mm from fluidization of particles premixed with kaolin before and after resin feeding at 0.8 m/s in 700℃

图10 不同高岭土进料方式下流化床中高岭土和废树脂质量比与反应时间的关系

Fig.10 Relationship between kaolin to waste resin mass ratio and reaction time in reactor under different kaolin feeding methods

| 1 | Deng D Y, Zhang L F, Dong M, et al. Radioactive waste: a review[J]. Water Environment Research, 2020, 92(10): 1818-1825. |

| 2 | 张立东, 李永红. 放射性废树脂处理技术调研及路线选择探讨[J]. 科学时代, 2015(14): 73-74. |

| Zhang L D, Li Y H. Investigation on treatment technology of radioactive spent resin and discussion on route selection [J]. Scientific Time, 2015(14): 73-74. | |

| 3 | Li J F, Chen L, Wang J L. Solidification of radioactive wastes by cement-based materials[J]. Progress in Nuclear Energy, 2021, 141: 103957. |

| 4 | 李洪辉, 王刚, 付杰, 等. 高整体性能容器介绍与检测方法[J]. 辐射防护, 2013, 33(3): 179-184, 192. |

| Li H H, Wang G, Fu J, et al. An introduction to high integrity container and its testing methods[J]. Radiation Protection, 2013, 33(3): 179-184, 192. | |

| 5 | 马小强. 废树脂热态超压技术在田湾核电站的应用[J]. 中国核电, 2019, 12(6): 695-700. |

| Ma X Q. Application of spent resin hot super-compression technology at tianwan NPP[J]. China Nuclear Power, 2019, 12(6): 695-700. | |

| 6 | Dubois M A, Dozol J F, Nicotra C, et al. Pyrolysis and incineration of cationic and anionic ion-exchange resins—identification of volatile degradation compounds[J]. Journal of Analytical and Applied Pyrolysis, 1995, 31: 129-140. |

| 7 | Castro H A, Luca V, Bianchi H L. Study of plasma off-gas treatment from spent ion exchange resin pyrolysis[J]. Environmental Science and Pollution Research International, 2018, 25(22): 21403-21410. |

| 8 | Hafeez M A, Singh B K, Yang S H, et al. Recent advances in Fenton-like treatment of radioactive ion exchange resins[J]. Chemical Engineering Journal Advances, 2023, 14: 100461. |

| 9 | Cowen M, Mason J, Ryan K, et al. Steam reforming technology for denitration and immobilization of DOE tank wastes[J]. Ceramic Transactions, 2003, 176: 97-110. |

| 10 | 国家核安全局. 核设施放射性废物最小化: HAD 401/08—2016 [S]. 2016. |

| National Nuclear Safety Administration. Minimizing radioactive waste in nuclear facilities: HAD 401/08—2016 [S]. 2016. | |

| 11 | Mason J B, Foster A L. THOR® steam reforming technology for the treatment of complex and problematic wastes[C]//ASME 2011 14th International Conference on Environmental Remediation and Radioactive Waste Management. Reims, France, 2012: 755-763. |

| 12 | Zhong W Q, Yu A B, Zhou G W, et al. CFD simulation of dense particulate reaction system: approaches, recent advances and applications[J]. Chemical Engineering Science, 2016, 140: 16-43. |

| 13 | Wang S, Shen Y S. Particle-scale study of heat and mass transfer in a bubbling fluidised bed[J]. Chemical Engineering Science, 2021, 240: 116655. |

| 14 | Lee W J, Bera S, Kim C M, et al. Synthesis of highly dispersed Pt nanoparticles into carbon supports by fluidized bed reactor atomic layer deposition to boost PEMFC performance[J]. NPG Asia Materials, 2020, 12: 40. |

| 15 | Ren C J, Zhang P, Song Q, et al. Particle agglomeration and inhibition method in the fluidized pyrolysis reaction of waste resin[J]. Chinese Journal of Chemical Engineering, 2024, 67: 135-147. |

| 16 | Van Der Drift A, Olsen A. Conversion of biomass, prediction and solution methods for ash agglomeration and related problems[R]. Netherlands, 1999. |

| 17 | Yates J G, Lettieri P. Fluidized-bed Reactors: Processes and Operating Conditions[M]. Cham: Springer International Publishing, 2016. |

| 18 | Salour D, Jenkins B M, Vafaei M, et al. Control of in-bed agglomeration by fuel blending in a pilot scale straw and wood fueled AFBC[J]. Biomass and Bioenergy, 1993, 4(2): 117-133. |

| 19 | Knutsson P, Schwebel G L, Steenari B, et al. Effect of bed materials mixing on the observed bed sintering[C]//11th International Conference on Fluidized Bed Technology. Beijing, China, 2014: 655-660. |

| 20 | Steenari B M, Lindqvist O. High-temperature reactions of straw ash and the anti-sintering additives kaolin and dolomite[J]. Biomass and Bioenergy, 1998, 14(1): 67-76. |

| 21 | Olofsson G, Ye Z C, Bjerle I, et al. Bed agglomeration problems in fluidized-bed biomass combustion[J]. Industrial & Engineering Chemistry Research, 2002, 41(12): 2888-2894. |

| 22 | Morris J D, Daood S S, Chilton S, et al. Mechanisms and mitigation of agglomeration during fluidized bed combustion of biomass: a review[J]. Fuel, 2018, 230: 452-473. |

| 23 | Zhao Z D, Liu D Y, Ma J L, et al. Fluidization of nanoparticle agglomerates assisted by combining vibration and stirring methods[J]. Chemical Engineering Journal, 2020, 388: 124213. |

| 24 | 陈其国. 用于制备粒状多晶硅的流化床反应器: 202007139U[P]. 2011-10-12. |

| Chen Q G.Fluidized bed reactor for preparing granular polysilicon: 202007139U[P]. 2011-10-12. | |

| 25 | Li J, Kong J, He S Y, et al. Self-agglomeration mechanism of iron nanoparticles in a fluidized bed[J]. Chemical Engineering Science, 2018, 177: 455-463. |

| 26 | Geldart D. Types of gas fluidization[J]. Powder Technology, 1973, 7(5): 285-292. |

| 27 | Yu C J, Qin J G, Nie H, et al. Experimental research on agglomeration in straw-fired fluidized beds[J]. Applied Energy, 2011, 88(12): 4534-4543. |

| 28 | Rogers W A. The prediction of wear in fluidized beds[J]. Journal of Pressure Vessel Technology, 1995, 117(2): 142-149. |

| 29 | 宁丽景, 陈惠超, 梁财. 粉煤灰改性钙基吸收剂颗粒在流化床中的磨损特性研究[J]. 锅炉技术, 2016, 47(1): 74-79. |

| Ning L J, Chen H C, Liang C. The study of attrition performance of calcium-based sorbent modified by fly-ash in a fluidized bed[J]. Boiler Technology, 2016, 47(1): 74-79. | |

| 30 | 陶中东, 顾正东, 吴东方. 颗粒流化磨损研究进展[J]. 化工进展, 2014, 33(10): 2535-2539, 2564. |

| Tao Z D, Gu Z D, Wu D F. Research progress on fluidized particle attrition[J]. Chemical Industry and Engineering Progress, 2014, 33(10): 2535-2539, 2564. | |

| 31 | Huang Z L, Yu Y B, Song Q, et al. Hole-growth phenomenon during pyrolysis of a cation-exchange resin particle[J]. Journal of Zhejiang University-Science A (Applied Physics & Engineering), 2022, 23(12): 974-988. |

| [1] | 王舒英, 左涛, 石志伟, 范小明, 张卫新. 阳离子交换树脂基介孔石墨化碳合成与储钠性能[J]. 化工学报, 2024, 75(9): 3338-3347. |

| [2] | 吴学红, 韦新, 侯加文, 吕财, 刘勇, 刘鹤, 常志娟. 热解法制备碳纳米管及其在散热涂层中的应用研究[J]. 化工学报, 2024, 75(9): 3360-3368. |

| [3] | 祝赫, 张仪, 齐娜娜, 张锴. 欧拉-欧拉双流体模型中颗粒黏性对液固散式流态化的影响[J]. 化工学报, 2024, 75(9): 3103-3112. |

| [4] | 丁湧, 李文建, 陈昭宇, 曹立辉, 刘轩铭, 任强强, 胡松, 向军. 废旧晶体硅光伏组件EVA有氧热解动力学与产物特性[J]. 化工学报, 2024, 75(9): 3310-3319. |

| [5] | 姚宏哲, 黄飞宇, 杨松, 钟梅, 代正华. 重质油高温快速热解自动反应网络的动力学建模[J]. 化工学报, 2024, 75(7): 2644-2655. |

| [6] | 晁惠雨, 白振敏, 侯汉青, 田立志, 李洪, 房晓权, 石晓华. 液相法合成三聚氰酸体系热力学分析[J]. 化工学报, 2024, 75(6): 2157-2165. |

| [7] | 吴希, 孙博, 刘银东, 齐传磊, 陈凯毅, 王路海, 许崇, 李永峰. 钠离子电池沥青基碳负极材料制备技术研究进展[J]. 化工学报, 2024, 75(4): 1270-1283. |

| [8] | 李浩文, 兰昊, 郑幼丹, 孙勇辉, 杨子昕, 宋谦石, 汪小憨. 热通道内典型碳氢燃料的热解结焦行为[J]. 化工学报, 2024, 75(2): 626-636. |

| [9] | 陶明清, 慕明昊, 程滕, 王博. 喷雾耦合降温强化旋风分离器脱除细颗粒物的研究[J]. 化工学报, 2024, 75(2): 584-592. |

| [10] | 吴雷, 刘姣, 李长聪, 周军, 叶干, 刘田田, 朱瑞玉, 张秋利, 宋永辉. 低阶粉煤催化微波热解制备含碳纳米管的高附加值改性兰炭末[J]. 化工学报, 2023, 74(9): 3956-3967. |

| [11] | 杨峥豪, 何臻, 常玉龙, 靳紫恒, 江霞. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| [12] | 张浩, 徐惠斌, 高健, 刘帝宏, 周泽华. Geldart-D类湿颗粒倾斜落料行为及其强化[J]. 化工学报, 2023, 74(4): 1519-1527. |

| [13] | 衣思敏, 马亚丽, 刘伟强, 张金帅, 岳岩, 郑强, 贾松岩, 李雪. 微晶菱镁矿蒸氨及水化动力学研究[J]. 化工学报, 2023, 74(4): 1578-1586. |

| [14] | 任金胜, 刘克润, 焦志伟, 刘家祥, 于源. 涡流空气分级机近导叶处团聚体解团机理研究[J]. 化工学报, 2023, 74(4): 1528-1538. |

| [15] | 陈瑞哲, 程磊磊, 顾菁, 袁浩然, 陈勇. 纤维增强树脂复合材料化学回收技术研究进展[J]. 化工学报, 2023, 74(3): 981-994. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号