化工学报 ›› 2024, Vol. 75 ›› Issue (4): 1270-1283.DOI: 10.11949/0438-1157.20231274

吴希1( ), 孙博1, 刘银东2, 齐传磊2, 陈凯毅1, 王路海2, 许崇1(

), 孙博1, 刘银东2, 齐传磊2, 陈凯毅1, 王路海2, 许崇1( ), 李永峰1(

), 李永峰1( )

)

收稿日期:2023-12-04

修回日期:2024-02-15

出版日期:2024-04-25

发布日期:2024-06-06

通讯作者:

许崇,李永峰

作者简介:吴希(1992—),女,博士研究生,wuxicup@163.com

基金资助:

Xi WU1( ), Bo SUN1, Yindong LIU2, Chuanlei QI2, Kaiyi CHEN1, Luhai WANG2, Chong XU1(

), Bo SUN1, Yindong LIU2, Chuanlei QI2, Kaiyi CHEN1, Luhai WANG2, Chong XU1( ), Yongfeng LI1(

), Yongfeng LI1( )

)

Received:2023-12-04

Revised:2024-02-15

Online:2024-04-25

Published:2024-06-06

Contact:

Chong XU, Yongfeng LI

摘要:

当前钠离子电池作为新型储能技术在新能源领域被寄予厚望,其中碳负极作为钠离子电池关键组成之一,其材料制备、储钠机制研究和综合性能提升颇具挑战。沥青基前体具有低成本、高碳含量、高碳收率等优势,被认为是合成碳负极的潜在碳源。然而沥青基碳源直接高温热解碳化将产生高石墨化的碳,碳层间距小,致使其储钠容量相对较低。近年来,陆续提出了沥青改性、结构设计、表面修饰、碳复合等策略来解决碳化过程中易石墨化和重排的难题,所得碳负极储钠性能得到显著提升。本综述详细归纳总结了当前以沥青为碳源制备碳负极材料的相关技术研究进展,讨论了沥青衍生钠电碳负极未来面临的问题和研究重点,期望为高性能碳负极材料的制备提供参考。

中图分类号:

吴希, 孙博, 刘银东, 齐传磊, 陈凯毅, 王路海, 许崇, 李永峰. 钠离子电池沥青基碳负极材料制备技术研究进展[J]. 化工学报, 2024, 75(4): 1270-1283.

Xi WU, Bo SUN, Yindong LIU, Chuanlei QI, Kaiyi CHEN, Luhai WANG, Chong XU, Yongfeng LI. Research progress in preparation technology of pitch-based carbon anode materials for sodium-ion batteries[J]. CIESC Journal, 2024, 75(4): 1270-1283.

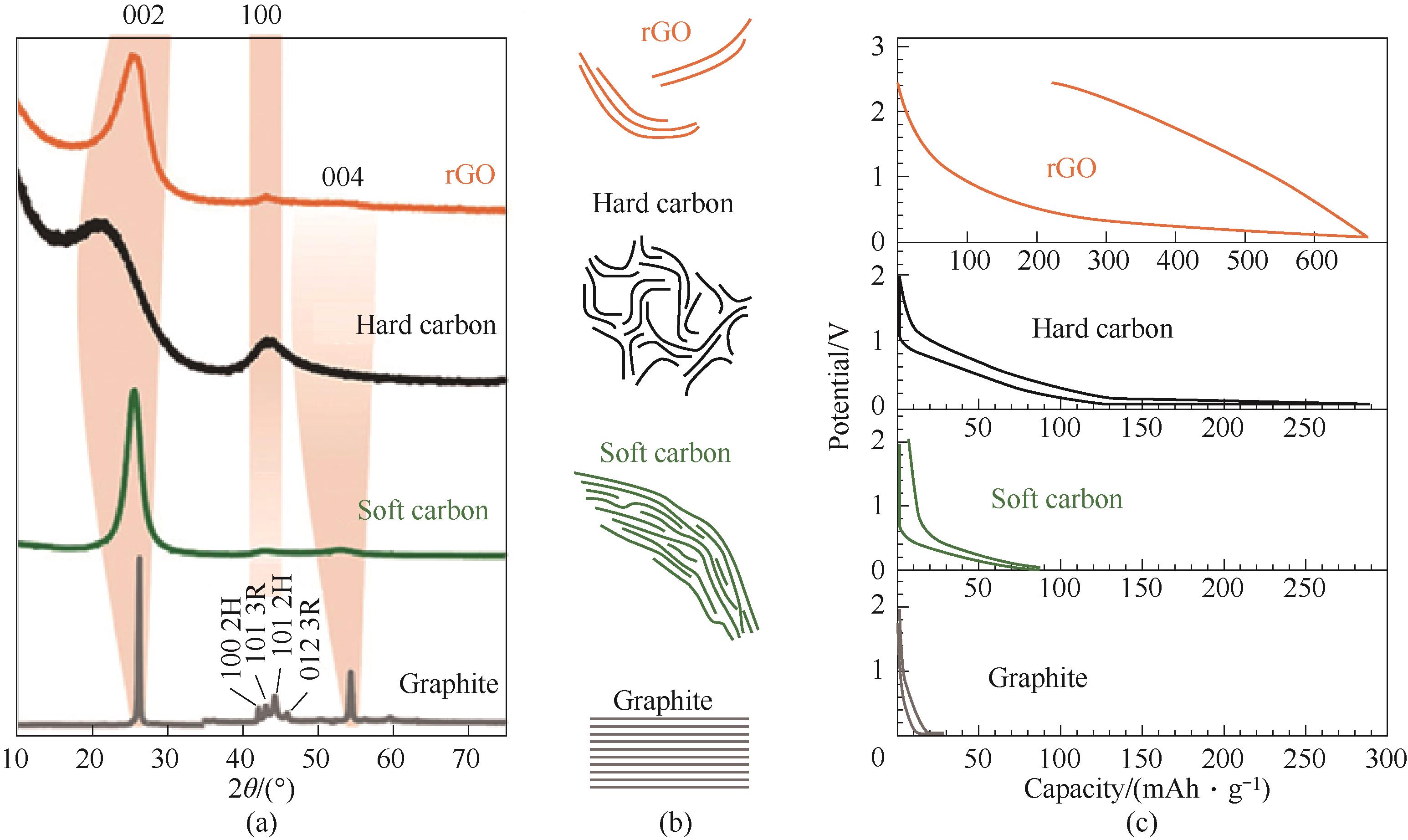

图1 典型碳材料的XRD衍射谱图(a)、微观结构示意图(b)以及储钠容量-电压曲线对比(c)[17]

Fig.1 XRD patterns (a), microstructure diagram (b), and comparisons of the capacity-voltage profiles for sodium storage (c) of typical carbon materials[17]

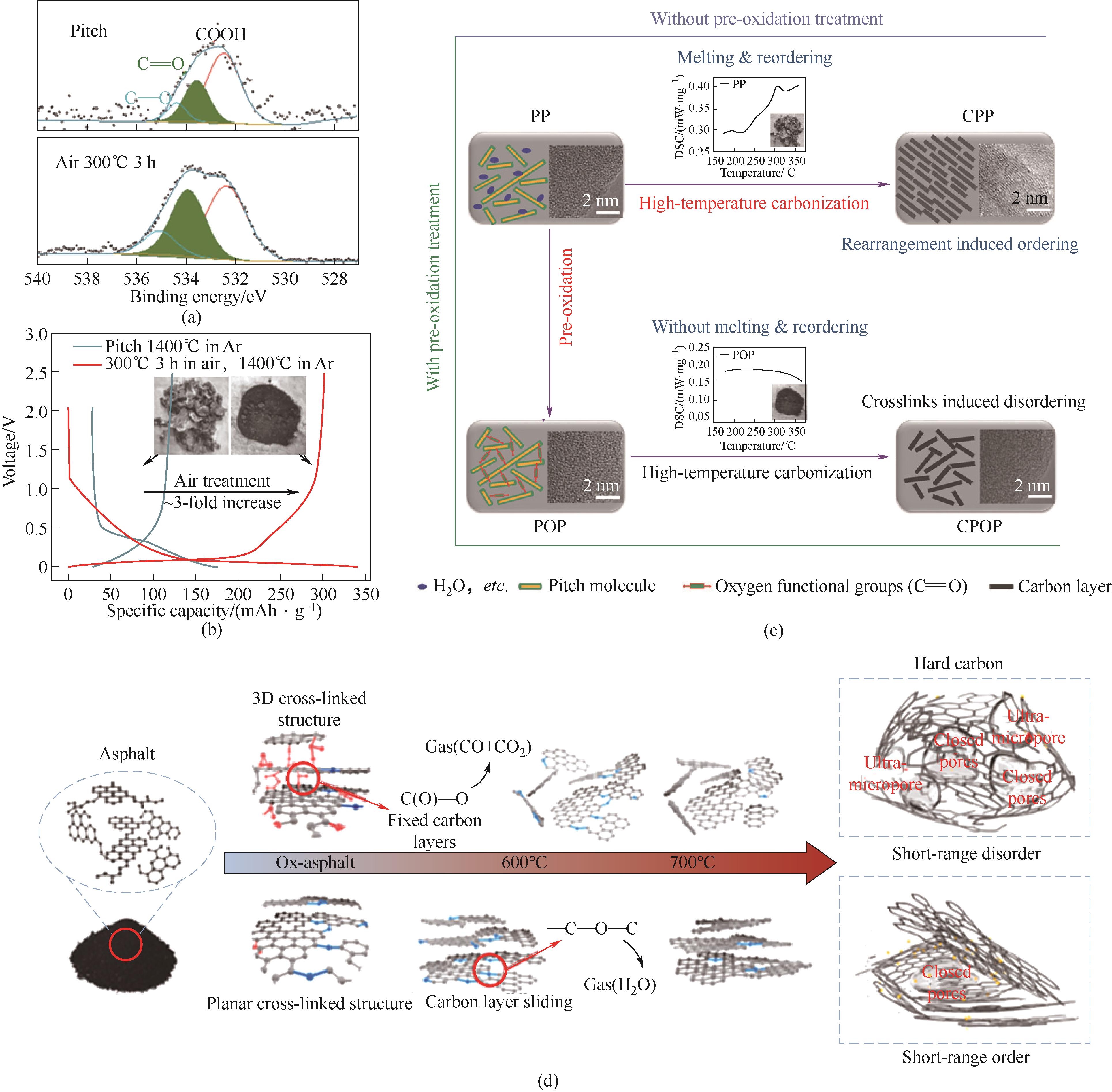

图2 未氧化和氧化石油沥青衍生碳材料的O 1s高分辨谱图(a)、钠电充放电曲线(b)、反应机理(c)[29];氧官能团对炭化过程中碳结构演化的机制(d)[32]

Fig.2 Deconvoluted O 1s spectra (a), charge/discharge curves in SIBs (b), and schematic illustration of the synthesis process (c) for carbon materials derived from unoxidized and oxidized petroleum asphalt[29]; The mechanism of oxygen functionalities on the evolution of carbon structure during carbonization (d) [32]

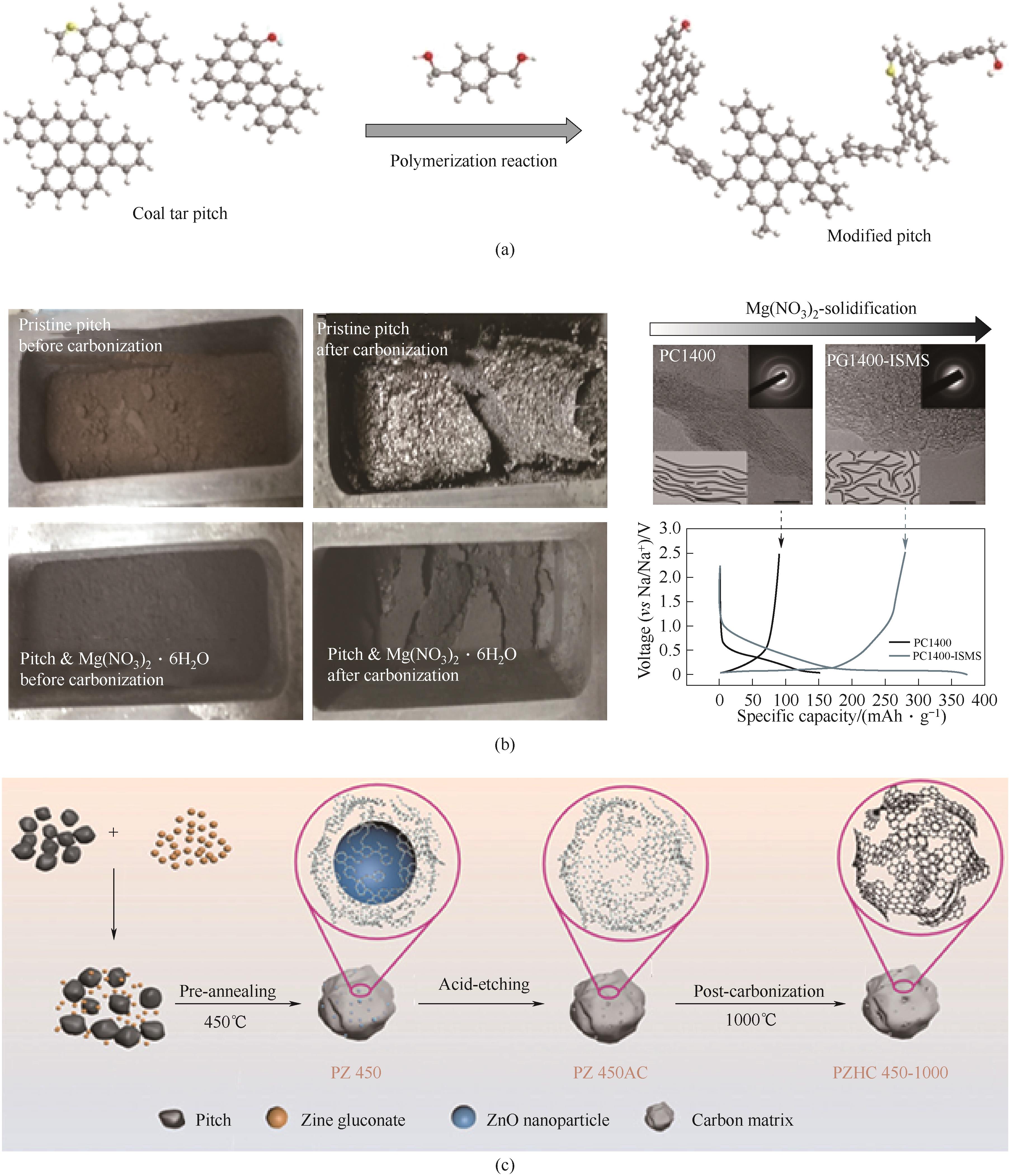

图3 对苯二醇改性煤沥青分子结构示意图(a)[39];添加Mg(NO3)2改性沥青碳化前后的照片及相应的微观结构和储钠充放电曲线(b)[42];葡萄糖酸锌改性石油沥青制备硬炭材料示意图(c)[43]

Fig.3 Schematic diagram of the molecular structure of coal tar pitch modified by benzene glycol (a)[39]; Images of pitch modified by Mg(NO3)2 before and after carbonization, and comparisons of microstructure and charge/discharge curves for Na-storage (b)[42]; Schematic illustration for the preparation of hard carbon derived from petroleum asphalt modified by zinc gluconate (c)[43]

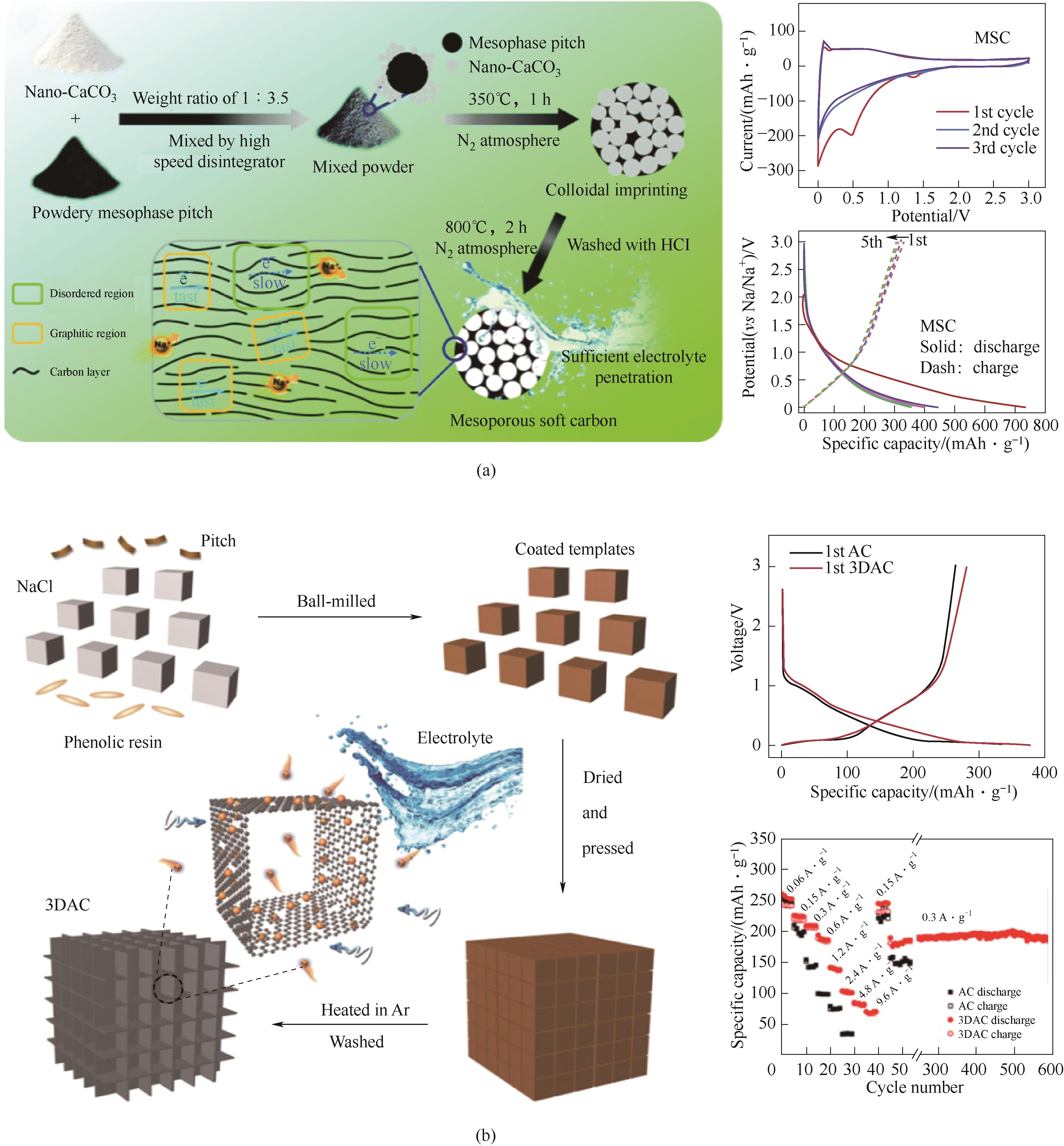

图4 以碳酸钙为模板合成介孔型软炭示意图以及相应CV曲线和充放电曲线(a)[47];3D无定形多孔碳的制备过程示意图以及相应充放电曲线和倍率图(b)[54]

Fig.4 Schematic illustration for the preparation of mesoporous soft carbon by using calcium carbonate as a template, and its CV curves and charge-discharge profiles (a)[47]; Schematic illustration of the fabrication process of 3D porous amorphous carbon, and its charge-discharge profiles and rate capability (b)[54]

图5 DFT计算不同氮类型与Na+的配位能(a)[58];不同P掺杂构型和层间距计算结果以及稳定结构Na+吸附能(b)[59]

Fig.5 DFT calculations of the coordinated energy of different nitrogen types with Na+ (a)[58]; Different configurations of P-doping and results of interlayer distances and the related stable adsorption energy for Na+ (b)[59]

图6 石油沥青/酚醛树脂制备碳复合负极材料原理示意图(a)[71];石油沥青/g-C3N4碳复合材料制备过程示意图及相应材料的储钠电化学性能(b)[74]

Fig.6 Schematic diagram of the synthesis procedure for the carbon composite anode by using petroleum asphalt and phenolic resin (a)[71]; Illustration for the preparation of the carbon composite material by using petroleum asphalt and g-C3N4 and the corresponding curves of electrochemical performance for sodium storage (b)[74]

| 1 | Sun Y K. Future of electrochemical energy storage[J]. ACS Energy Letters, 2017, 2(3): 716. |

| 2 | Feng Y, Zhou L M, Ma H, et al. Challenges and advances in wide-temperature rechargeable lithium batteries[J]. Energy & Environmental Science, 2022, 15(5): 1711-1759. |

| 3 | Sang J W, Tang B, Pan K C, et al. Current status and enhancement strategies for all-solid-state lithium batteries[J]. Accounts of Materials Research, 2023, 4(6): 472-483. |

| 4 | Ma M, Chong S K, Yao K, et al. Advanced anode materials for potassium batteries: sorting out opportunities and challenges by potassium storage mechanisms[J]. Matter, 2023, 6(10): 3220-3273. |

| 5 | Wang J R, Xi L, Peng C X, et al. Recent progress in hard carbon anodes for sodium-ion batteries[J]. Advanced Engineering Materials, 2024, 26(8): 2302063. |

| 6 | Hwang J Y, Myung S T, Sun Y K. Sodium-ion batteries: present and future[J]. Chemical Society Reviews, 2017, 46(12): 3529-3614. |

| 7 | Zhao Y, Kang Y Q, Wozny J, et al. Recycling of sodium-ion batteries[J]. Nature Reviews Materials, 2023, 8: 623-634. |

| 8 | Sada K, Darga J, Manthiram A. Challenges and prospects of sodium-ion and potassium-ion batteries for mass production[J]. Advanced Energy Materials, 2023, 13(39): 2302321. |

| 9 | Ong S P, Chevrier V L, Hautier G, et al. Voltage, stability and diffusion barrier differences between sodium-ion and lithium-ion intercalation materials[J]. Energy & Environmental Science, 2011, 4(9): 3680-3688. |

| 10 | Yabuuchi N, Kubota K, Dahbi M, et al. Research development on sodium-ion batteries[J]. Chemical Reviews, 2014, 114(23): 11636-11682. |

| 11 | Yang X M, Rogach A L. Anodes and sodium-free cathodes in sodium ion batteries[J]. Advanced Energy Materials, 2020, 10(22): 2000288. |

| 12 | Fang L B, Bahlawane N, Sun W P, et al. Conversion-alloying anode materials for sodium ion batteries[J]. Small, 2021, 17(37): e2101137. |

| 13 | Wang K F, Sun F, Wang H, et al. Altering thermal transformation pathway to create closed pores in coal-derived hard carbon and boosting of Na+ plateau storage for high-performance sodium-ion battery and sodium-ion capacitor[J]. Advanced Functional Materials, 2022, 32(34): 2203725. |

| 14 | Guo Z Y, Xu Z, Xie F, et al. Investigating the superior performance of hard carbon anodes in sodium-ion compared with lithium- and potassium-ion batteries[J]. Advanced Materials, 2023, 35(42): e2304091. |

| 15 | Yuan M, Cao B, Liu H, et al. Sodium storage mechanism of nongraphitic carbons: a general model and the function of accessible closed pores[J]. Chemistry of Materials, 2022, 34(7): 3489-3500. |

| 16 | Tan S C, Yang H, Zhang Z, et al. The progress of hard carbon as an anode material in sodium-ion batteries[J]. Molecules, 2023, 28(7): 3134. |

| 17 | Saurel D, Orayech B, Xiao B W, et al. From charge storage mechanism to performance: a roadmap toward high specific energy sodium-ion batteries through carbon anode optimization[J]. Advanced Energy Materials, 2018, 8(17): 1703268. |

| 18 | Hu H Y, Xiao Y, Ling W, et al. A stable biomass-derived hard carbon anode for high-performance sodium-ion full battery[J]. Energy Technology, 2021, 9(1): 2000730. |

| 19 | Kamiyama A, Kubota K, Nakano T, et al. High-capacity hard carbon synthesized from macroporous phenolic resin for sodium-ion and potassium-ion battery[J]. ACS Applied Energy Materials, 2020, 3(1): 135-140. |

| 20 | Jiang M C, Sun N, Ali Soomro R, et al. The recent progress of pitch-based carbon anodes in sodium-ion batteries[J]. Journal of Energy Chemistry, 2021, 55(4): 34-47. |

| 21 | Zhang Y, Fang H Q, Guan L, et al. Effect of asphalt component distribution characteristics in layered porous carbon on performance of supercapacitors[J]. Journal of Power Sources, 2024, 593: 233966. |

| 22 | Song X Y, Jiang R Y, Zhang L. In-situ growth of CNTs-porous carbon from asphalt with superior double-layer capacitive performance[J]. Applied Surface Science, 2022, 583: 152549. |

| 23 | 宁汇, 赵青山, 张浩然, 等. 石油沥青基碳材料在电化学储能中的应用[J]. 中国科学: 化学, 2018, 48(4): 329-341. |

| Ning H, Zhao Q S, Zhang H R, et al. Application of petroleum asphalt-based carbon materials in electrochemical energy storage[J]. Scientia Sinica (Chimica), 2018, 48(4): 329-341. | |

| 24 | Thomas P, Ghanbaja J, Billaud D. Electrochemical insertion of sodium in pitch-based carbon fibres in comparison with graphite in NaClO4-ethylene carbonate electrolyte[J]. Electrochimica Acta, 1999, 45(3): 423-430. |

| 25 | Du W S, Sun C, Sun Q. The recent progress of pitch nanoengineering to obtain the carbon anode for high-performance sodium ion batteries[J]. Materials, 2023, 16(13): 4871. |

| 26 | 董伟, 杨绍斌, 沈丁, 等. 石油沥青和葡萄糖热解炭的可逆储钠性能研究[J]. 新型炭材料, 2017, 32(3): 227-233. |

| Dong W, Yang S B, Shen D, et al. Performance of pitch and glucose pyrocarbons for reversible sodium storage[J]. New Carbon Materials, 2017, 32(3): 227-233. | |

| 27 | Song L J, Liu S S, Yu B J, et al. Anode performance of mesocarbon microbeads for sodium-ion batteries[J]. Carbon, 2015, 95: 972-977. |

| 28 | Yuan C, Zhu Y Y, Zhao P Y, et al. Enhanced electrochemical performance of mesocarbon-microbeads-based anodes through air oxidation for sodium-ion batteries[J]. ChemElectroChem, 2017, 4(10): 2583-2592. |

| 29 | Lu Y X, Zhao C L, Qi X G, et al. Pre-oxidation-tuned microstructures of carbon anodes derived from pitch for enhancing Na storage performance[J]. Advanced Energy Materials, 2018, 8(27): 1800108. |

| 30 | Guo H Y, Li Y Y, Wang C L, et al. Effect of the air oxidation stabilization of pitch on the microstructure and sodium storage of hard carbons[J]. New Carbon Materials, 2021, 36(6): 1073-1078. |

| 31 | Daher N, Huo D, Davoisne C, et al. Impact of preoxidation treatments on performances of pitch-based hard carbons for sodium-ion batteries[J]. ACS Applied Energy Materials, 2020, 3(7): 6501-6510. |

| 32 | Xu R, Yi Z L, Song M X, et al. Boosting sodium storage performance of hard carbons by regulating oxygen functionalities of the cross-linked asphalt precursor[J]. Carbon, 2023, 206: 94-104. |

| 33 | Li F Y, Tao H C, Yang X L. Adjusting the state of pitch anode for effective oxidation with suppressed graphitization and enhanced Na storage performances[J]. Ionics, 2022, 28(11): 5141-5151. |

| 34 | Liu X, Zhu Y Y, Liu N, et al. Catalytic synthesis of hard/soft carbon hybrids with heteroatom doping for enhanced sodium storage[J]. ChemistrySelect, 2019, 4(12): 3551-3558. |

| 35 | Kim M I, Bai B C. Effect of nitric acid treatment on the pitch properties and preparation of activated carbon[J]. Carbon Letters, 2022, 32(1): 99-107. |

| 36 | Wang J, Yan L, Liu B H, et al. A solvothermal pre-oxidation strategy converting pitch from soft carbon to hard carbon for enhanced sodium storage[J]. Chinese Chemical Letters, 2023, 34(4): 107526. |

| 37 | 陈涛, 吴吉昊, 车晓刚, 等. 改性沥青基硬炭材料的可控制备及其储钠性能[J]. 洁净煤技术, 2023, 29(2): 92-98. |

| Chen T, Wu J H, Che X G, et al. Fabrication of modified pitch-based hard carbon materials for high-performance sodium-ion storage[J]. Clean Coal Technology, 2023, 29(2): 92-98. | |

| 38 | Chen H, Sun N, Wang Y X, et al. One stone two birds: pitch assisted microcrystalline regulation and defect engineering in coal-based carbon anodes for sodium-ion batteries[J]. Energy Storage Materials, 2023, 56: 532-541. |

| 39 | Wang Y W, Xiao N, Wang Z Y, et al. Rational design of high-performance sodium-ion battery anode by molecular engineering of coal tar pitch[J]. Chemical Engineering Journal, 2018, 342: 52-60. |

| 40 | 郭永强, 李晨, 黄鲜安, 等. 钠离子电池用负极材料煤沥青基硬炭制备[J]. 炭素技术, 2021, 40(2): 36-41. |

| Guo Y Q, Li C, Huang X A, et al. Preparation of hard carbon from coal tar pitch for sodium ion battery[J]. Carbon Techniques, 2021, 40(2): 36-41. | |

| 41 | Li Y M, Hu Y S, Li H, et al. A superior low-cost amorphous carbon anode made from pitch and lignin for sodium-ion batteries[J]. Journal of Materials Chemistry A, 2016, 4(1): 96-104. |

| 42 | Qi Y R, Lu Y X, Liu L L, et al. Retarding graphitization of soft carbon precursor: from fusion-state to solid-state carbonization[J]. Energy Storage Materials, 2020, 26: 577-584. |

| 43 | He H N, He J, Yu H B, et al. Dual-interfering chemistry for soft-hard carbon translation toward fast and durable sodium storage[J]. Advanced Energy Materials, 2023, 13(16): 2300357. |

| 44 | Zhang S H, Sun N, Li X, et al. Closed pore engineering of activated carbon enabled by waste mask for superior sodium storage[J]. Energy Storage Materials, 2024, 66: 103183. |

| 45 | Igarashi D, Tanaka Y, Kubota K, et al. New template synthesis of anomalously large capacity hard carbon for Na- and K-ion batteries[J]. Advanced Energy Materials, 2023, 13(47): 2302647. |

| 46 | Wenzel S, Hara T, Janek J, et al. Room-temperature sodium-ion batteries: improving the rate capability of carbon anode materials by templating strategies[J]. Energy & Environmental Science, 2011, 4(9): 3342-3345. |

| 47 | Cao B, Liu H, Xu B, et al. Mesoporous soft carbon as an anode material for sodium ion batteries with superior rate and cycling performance[J]. Journal of Materials Chemistry A, 2016, 4(17): 6472-6478. |

| 48 | Xie M M, Zhu X B, Li D Q, et al. Spent asphalt-derived mesoporous carbon for high-performance Li/Na/K-ion storage[J]. Journal of Power Sources, 2021, 514: 230593. |

| 49 | Han L, Li Z M, Yang F, et al. Enhancing capacitive storage of carbonaceous anode by surface doping and structural modulation for high-performance sodium-ion battery[J]. Powder Technology, 2021, 382: 541-549. |

| 50 | Li Z, Cao Y J, Li G Y, et al. High rate capability of S-doped ordered mesoporous carbon materials with directional arrangement of carbon layers and large d-spacing for sodium-ion battery[J]. Electrochimica Acta, 2021, 366: 137466. |

| 51 | Díez N, Fuertes A B, Sevilla M. Molten salt strategies towards carbon materials for energy storage and conversion[J]. Energy Storage Materials, 2021, 38: 50-69. |

| 52 | Qiu D, Cao T F, Zhang J, et al. Precise carbon structure control by salt template for high performance sodium-ion storage[J]. Journal of Energy Chemistry, 2019, 31: 101-106. |

| 53 | Wang Y X, Wang Y W, Liu J L, et al. Preparation of carbon nanosheets from petroleum asphalt via recyclable molten-salt method for superior lithium and sodium storage[J]. Carbon, 2017, 122: 344-351. |

| 54 | Lu P, Sun Y, Xiang H F, et al. 3D amorphous carbon with controlled porous and disordered structures as a high-rate anode material for sodium-ion batteries[J]. Advanced Energy Materials, 2018, 8(8): 1702434. |

| 55 | Liu C, Zheng H J, Wang Y W, et al. Microstructure regulation of pitch-based soft carbon anodes by iodine treatment towards high-performance potassium-ion batteries[J]. Journal of Colloid and Interface Science, 2022, 615: 485-493. |

| 56 | Wang G, Yu M H, Feng X L. Carbon materials for ion-intercalation involved rechargeable battery technologies[J]. Chemical Society Reviews, 2021, 50(4): 2388-2443. |

| 57 | Lu B, Zhang C, Deng D R, et al. Synthesis of low-cost and high-performance dual-atom doped carbon-based materials with a simple green route as anodes for sodium-ion batteries[J]. Molecules, 2023, 28(21): 7314-7326. |

| 58 | Liu Z, Zhang L H, Sheng L Z, et al. Edge-nitrogen-rich carbon dots pillared graphene blocks with ultrahigh volumetric/gravimetric capacities and ultralong life for sodium-ion storage[J]. Advanced Energy Materials, 2018, 8(30): 1802042. |

| 59 | Qiao Y, Han R M, Pang Y D, et al. 3D well-ordered porous phosphorus doped carbon as an anode for sodium storage: structure design, experimental and computational insights[J]. Journal of Materials Chemistry A, 2019, 7(18): 11400-11407. |

| 60 | Hong Z S, Zhen Y C, Ruan Y R, et al. Rational design and general synthesis of S-doped hard carbon with tunable doping sites toward excellent Na-ion storage performance[J]. Advanced Materials, 2018, 30(29): 1802035. |

| 61 | Hao M Y, Xiao N, Wang Y W, et al. Pitch-derived N-doped porous carbon nanosheets with expanded interlayer distance as high-performance sodium-ion battery anodes[J]. Fuel Processing Technology, 2018, 177: 328-335. |

| 62 | Sun L, Song X Y, Liu Y X, et al. Spongy-like N, S-codoped ultrathin layered carbon assembly for realizing high performance sodium-ion batteries[J]. FlatChem, 2021, 28: 100258. |

| 63 | Sun W, Sun Q, Lu R F, et al. Sodium hypophosphite-assist pyrolysis of coal pitch to synthesis P-doped carbon nanosheet anode for ultrafast and long-term cycling sodium-ion batteries[J]. Journal of Alloys and Compounds, 2021, 889: 161678. |

| 64 | Miao Y L, Zong J, Liu X J. Phosphorus-doped pitch-derived soft carbon as an anode material for sodium ion batteries[J]. Materials Letters, 2017, 188: 355-358. |

| 65 | He L, Sun Y R, Wang C L, et al. High performance sulphur-doped pitch-based carbon materials as anode materials for sodium-ion batteries[J]. New Carbon Materials, 2020, 35(4): 420-427. |

| 66 | Shao Y, Cui Y H, Wang C D, et al. Initiating fluorine chemistry in polycyclic aromatic hydrocarbon-derived carbon for new cluster-mode Na storage with superhigh capacity[J]. Small, 2023, 19(22): e2300107. |

| 67 | Zhao Y, Cong Y, Ning H, et al. N, P co-doped pitch derived soft carbon nanoboxes as high-performance anodes for sodium-ion batteries[J]. Journal of Alloys and Compounds, 2022, 918: 165691. |

| 68 | Xu R, Sun N, Zhou H Y, et al. Hard carbon anodes derived from phenolic resin/sucrose cross-linking network for high-performance sodium-ion batteries[J]. Battery Energy, 2023, 2(2): 20220054. |

| 69 | Fan C L, Zhang R S, Luo X H, et al. Epoxy phenol novolac resin: a novel precursor to construct high performance hard carbon anode toward enhanced sodium-ion batteries[J]. Carbon, 2023, 205: 353-364. |

| 70 | Li Y M, Mu L Q, Hu Y S, et al. Pitch-derived amorphous carbon as high performance anode for sodium-ion batteries[J]. Energy Storage Materials, 2016, 2: 139-145. |

| 71 | Yin X P, Zhao Y F, Wang X, et al. Modulating the graphitic domains of hard carbons derived from mixed pitch and resin to achieve high rate and stable sodium storage[J]. Small, 2022, 18(5): e2105568. |

| 72 | Wang Y W, Xiao N, Wang Z Y, et al. Ultrastable and high-capacity carbon nanofiber anodes derived from pitch/polyacrylonitrile for flexible sodium-ion batteries[J]. Carbon, 2018, 135: 187-194. |

| 73 | Yang S B, Dong W, Shen D, et al. Composite of nonexpansion reduced graphite oxide and carbon derived from pitch as anodes of Na-ion batteries with high coulombic efficiency[J]. Chemical Engineering Journal, 2017, 309: 674-681. |

| 74 | Weng G M, Xie Y, Wang H, et al. A promising carbon/g-C3N4 composite negative electrode for a long-life sodium-ion battery[J]. Angewandte Chemie International Edition, 2019, 58(39): 13727-13733. |

| [1] | 李云璇, 刘新悦, 陈熙, 刘文, 周明月, 蓝兴英. 基于固液氧化还原靶向反应的能量存储技术:材料、器件及动力学[J]. 化工学报, 2024, 75(4): 1222-1240. |

| [2] | 贾旭东, 杨博龙, 程前, 李雪丽, 向中华. 分步负载金属法制备铁钴双金属位点高效氧还原电催化剂[J]. 化工学报, 2024, 75(4): 1578-1593. |

| [3] | 严孝清, 赵瑛, 张宇哲, 欧鸿辉, 黄起中, 胡华贵, 杨贵东. 五重孪晶铜纳米线@聚吡咯制备及其电催化硝酸盐还原制氨[J]. 化工学报, 2024, 75(4): 1519-1532. |

| [4] | 常蕊, 邢蕊蕊, 闫学海. 基于非共价化学的绿色生物可循环肽材料[J]. 化工学报, 2024, 75(4): 1317-1332. |

| [5] | 刘恺轩, 姜沁源, 汪菲, 李润, 朱平, 王康康, 臧永路, 赵彦龙, 张如范. 高密度超长碳纳米管的可控制备:进展与展望[J]. 化工学报, 2024, 75(4): 1355-1369. |

| [6] | 李昂, 赵振宇, 李洪, 高鑫. 微波诱导高分散Pd/FeP催化剂构筑及其电催化性能研究[J]. 化工学报, 2024, 75(4): 1594-1606. |

| [7] | 孙铭泽, 黄鹤来, 牛志强. 铂基氧还原催化剂:从单晶电极到拓展表面纳米材料[J]. 化工学报, 2024, 75(4): 1256-1269. |

| [8] | 潘娜, 田昌, 怀兰坤, 刘玉玉, 张芬芬, 高晓梅, 刘伟, 闫良国, 赵艳侠. 聚合铝钛基絮凝剂的合成与应用[J]. 化工学报, 2024, 75(3): 1009-1018. |

| [9] | 吴吉昊, 陈涛, 刘思宇, 刘梦柯, 杨卷. 双功能活化制备沥青基硬炭用于钠离子电池负极[J]. 化工学报, 2024, 75(3): 1019-1027. |

| [10] | 李浩文, 兰昊, 郑幼丹, 孙勇辉, 杨子昕, 宋谦石, 汪小憨. 热通道内典型碳氢燃料的热解结焦行为[J]. 化工学报, 2024, 75(2): 626-636. |

| [11] | 尹玉华, 方灿, 易清风, 李广. 不同碳导电剂对铁-空气电池性能的影响[J]. 化工学报, 2024, 75(2): 685-694. |

| [12] | 孟祥军, 花莹曦, 张长金, 张弛, 杨林睿, 杨若昔, 刘鉴漪, 许春建. 6N电子级氘气的制备与纯化技术研究[J]. 化工学报, 2024, 75(1): 377-390. |

| [13] | 闻文, 王慧艳, 周静红, 曹约强, 周兴贵. 石墨负极颗粒对锂离子电池容量衰减及SEI膜生长影响的模拟研究[J]. 化工学报, 2024, 75(1): 366-376. |

| [14] | 齐元帅, 彭文朝, 李阳, 张凤宝, 范晓彬. 电化学脱盐机理及相关研究进展[J]. 化工学报, 2024, 75(1): 171-189. |

| [15] | 程业品, 胡达清, 徐奕莎, 刘华彦, 卢晗锋, 崔国凯. 离子液体基低共熔溶剂在转化CO2中的应用[J]. 化工学报, 2023, 74(9): 3640-3653. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号