化工学报 ›› 2025, Vol. 76 ›› Issue (5): 2119-2135.DOI: 10.11949/0438-1157.20241214

高冰冰1( ), 许诺1, 白云翔1, 张春芳1, 杨永强2, 董亮亮1(

), 许诺1, 白云翔1, 张春芳1, 杨永强2, 董亮亮1( )

)

收稿日期:2024-10-31

修回日期:2024-12-07

出版日期:2025-05-25

发布日期:2025-06-13

通讯作者:

董亮亮

作者简介:高冰冰(1999—),女,博士研究生,19855681148@163.com

基金资助:

Bingbing GAO1( ), Nuo XU1, Yunxiang BAI1, Chunfang ZHANG1, Yongqiang YANG2, Liangliang DONG1(

), Nuo XU1, Yunxiang BAI1, Chunfang ZHANG1, Yongqiang YANG2, Liangliang DONG1( )

)

Received:2024-10-31

Revised:2024-12-07

Online:2025-05-25

Published:2025-06-13

Contact:

Liangliang DONG

摘要:

氦气作为一种不可再生的稀有气体,在科学研究、工业生产等领域发挥着至关重要的作用,高效、经济地分离纯化氦气具有重要的科研和应用价值。膜分离技术以其能耗低、操作简便等优势,成为氦气分离领域的研究热点。聚合物膜因其优异的柔韧性、成膜性以及良好的气体分离性能而备受关注。介绍了近年来聚酰亚胺、自聚微孔聚合物和含氟聚合物等氦气分离膜材料的最新研究进展,重点综述氦气分离膜材料的可加工性、放大生产以及长期稳定性(如塑化和物理老化)等问题,并对未来氦气分离聚合物膜材料的开发及未来发展趋势进行了展望。

中图分类号:

高冰冰, 许诺, 白云翔, 张春芳, 杨永强, 董亮亮. 氦气分离聚合物膜[J]. 化工学报, 2025, 76(5): 2119-2135.

Bingbing GAO, Nuo XU, Yunxiang BAI, Chunfang ZHANG, Yongqiang YANG, Liangliang DONG. Polymeric membranes for helium separation[J]. CIESC Journal, 2025, 76(5): 2119-2135.

| 天然气田 | 含量/%(摩尔) | ||||

|---|---|---|---|---|---|

| He | CH4 | N2 | CO2 | C2+ | |

| 美国新墨西哥州 | 4.05 | 49 | 45 | 0.9 | 1.05 |

| 美国阿拉斯加州 | 2.54 | 90.2 | 6.8 | 0.3 | — |

| 美国得克萨斯州 | 1.17 | 66.2 | 31.1 | 0.1 | 1.43 |

| 加拿大艾伯塔省 | 0.53 | 93 | 6 | 0.5 | — |

| 波兰奥斯特罗 | 0.4 | 56 | 46 | 0.3 | 0.3 |

| 卡塔尔北场 | 0.03 | 79.5 | 5.19 | 3.68 | 8.85 |

| 澳大利亚棕榈谷 | 0.21 | 97.5 | 2.3 | 0.1 | — |

表1 富He天然气田列表及成分[9]

Table 1 List of He-rich natural gas fields and composition[9]

| 天然气田 | 含量/%(摩尔) | ||||

|---|---|---|---|---|---|

| He | CH4 | N2 | CO2 | C2+ | |

| 美国新墨西哥州 | 4.05 | 49 | 45 | 0.9 | 1.05 |

| 美国阿拉斯加州 | 2.54 | 90.2 | 6.8 | 0.3 | — |

| 美国得克萨斯州 | 1.17 | 66.2 | 31.1 | 0.1 | 1.43 |

| 加拿大艾伯塔省 | 0.53 | 93 | 6 | 0.5 | — |

| 波兰奥斯特罗 | 0.4 | 56 | 46 | 0.3 | 0.3 |

| 卡塔尔北场 | 0.03 | 79.5 | 5.19 | 3.68 | 8.85 |

| 澳大利亚棕榈谷 | 0.21 | 97.5 | 2.3 | 0.1 | — |

| 膜名称 | 厚度/nm | He渗透系数/GPU① | 选择性 | 文献 | |

|---|---|---|---|---|---|

| He/N2 | He/CH4 | ||||

| 醋酸纤维素 | 130 | 106 | 34 | 31 | [ |

| Udel® P1700 (聚砜) | 50~100 | 200 | 100 | 100 | [ |

| BPDA-TMPD (聚酰亚胺) | 约1000 | 360 | 12 | 11 | [ |

| Matrimid 5218 (聚酰亚胺) | 约300 | 87 | — | 197 | [ |

| P84® (聚酰亚胺) | 500 | 33 | 6.3 | 5 | [ |

表2 典型的He分离聚合物膜及性能

Table 2 Typical polymeric membranes for He separation and performances

| 膜名称 | 厚度/nm | He渗透系数/GPU① | 选择性 | 文献 | |

|---|---|---|---|---|---|

| He/N2 | He/CH4 | ||||

| 醋酸纤维素 | 130 | 106 | 34 | 31 | [ |

| Udel® P1700 (聚砜) | 50~100 | 200 | 100 | 100 | [ |

| BPDA-TMPD (聚酰亚胺) | 约1000 | 360 | 12 | 11 | [ |

| Matrimid 5218 (聚酰亚胺) | 约300 | 87 | — | 197 | [ |

| P84® (聚酰亚胺) | 500 | 33 | 6.3 | 5 | [ |

| 膜名称 | 温度/℃ | 压力/atm① | He渗透系数/Barrer② | 选择性 | 文献 | |

|---|---|---|---|---|---|---|

| He/N2 | He/CH4 | |||||

| P84® | 35 | 1 | 9 | 120 | 106 | [ |

| Matrimid® 5218 | 35 | 5 | 23.1 | 98.6 | 131.1 | [ |

| 6FDA-mPDA | 35 | 7 | 80.46 | 92.3 | 229.4 | [ |

| 6FDA-DAM:DABA | 35 | 7 | 195.91 | 27.8 | 30.1 | [ |

| 6FDA-DAM | 35 | 7 | 533.21 | 9.7 | 11.4 | [ |

| 6FDA-TFMB | 35 | 4 | 73 | 247 | — | [ |

| PI-TB | 35 | 1 | 376 | 19 | 13.92 | [ |

| MPAP-6FDA | 35 | 4 | 26.03 | 11.31 | — | [ |

| TC-EBPA-TB | 35 | 1 | 61.14 | 72.78 | — | [ |

| Ac-CoPI-TBs | 35 | 1 | 540 | 16.36 | 16.36 | [ |

| PI-TB-N | 35 | 1 | 531 | 13.61 | 13.97 | [ |

| 6FDA-terphenyl | 35 | 10 | 43.01 | 42.16 | 57.58 | [ |

| 6FDA-biphenyl | 35 | 10 | 37.59 | 61.02 | 105 | [ |

| 6FDA-phenyl | 35 | 10 | 36.45 | 59.17 | 103.25 | [ |

| 6FDA-BAPB | 36 | 6 | 38.2 | 81.27 | 82.3 | [ |

| 6FDA-durene | 35 | 4 | 358.4 | 9.46 | 11.06 | [ |

| 6FDA-Durene/CARDO(OH) | 25 | 35 | 285 | 13.7 | 21.4 | [ |

| 6FDA-DAM | 22 | 7 | 332 | 9.48 | 13.66 | [ |

| 6FDA-DAM/6FDA-CARDO | 22 | 7 | 139 | 14.04 | 21.82 | [ |

| 6FDA-6FpDA | 35 | 1 | 114 | 45.6 | 88.37 | [ |

| 6FDA-OFB | 35 | 1 | 220 | 22.68 | 42.31 | [ |

| 6FD-PP | 30 | 4 | 31.8 | 53.99 | 219.31 | [ |

| 40%-PI | 35 | 7 | 76.2 | 50.46 | 89.4 | [ |

| TBDA1-6FDA-PI | 35 | 1 | 199 | 30.62 | 60.3 | [ |

| TB-PIMPIs | 35 | 1 | 198 | 21.75 | 34.74 | [ |

表3 常见聚酰亚胺膜的He气体分离性能

Table 3 He separation properties of common polyimide membranes

| 膜名称 | 温度/℃ | 压力/atm① | He渗透系数/Barrer② | 选择性 | 文献 | |

|---|---|---|---|---|---|---|

| He/N2 | He/CH4 | |||||

| P84® | 35 | 1 | 9 | 120 | 106 | [ |

| Matrimid® 5218 | 35 | 5 | 23.1 | 98.6 | 131.1 | [ |

| 6FDA-mPDA | 35 | 7 | 80.46 | 92.3 | 229.4 | [ |

| 6FDA-DAM:DABA | 35 | 7 | 195.91 | 27.8 | 30.1 | [ |

| 6FDA-DAM | 35 | 7 | 533.21 | 9.7 | 11.4 | [ |

| 6FDA-TFMB | 35 | 4 | 73 | 247 | — | [ |

| PI-TB | 35 | 1 | 376 | 19 | 13.92 | [ |

| MPAP-6FDA | 35 | 4 | 26.03 | 11.31 | — | [ |

| TC-EBPA-TB | 35 | 1 | 61.14 | 72.78 | — | [ |

| Ac-CoPI-TBs | 35 | 1 | 540 | 16.36 | 16.36 | [ |

| PI-TB-N | 35 | 1 | 531 | 13.61 | 13.97 | [ |

| 6FDA-terphenyl | 35 | 10 | 43.01 | 42.16 | 57.58 | [ |

| 6FDA-biphenyl | 35 | 10 | 37.59 | 61.02 | 105 | [ |

| 6FDA-phenyl | 35 | 10 | 36.45 | 59.17 | 103.25 | [ |

| 6FDA-BAPB | 36 | 6 | 38.2 | 81.27 | 82.3 | [ |

| 6FDA-durene | 35 | 4 | 358.4 | 9.46 | 11.06 | [ |

| 6FDA-Durene/CARDO(OH) | 25 | 35 | 285 | 13.7 | 21.4 | [ |

| 6FDA-DAM | 22 | 7 | 332 | 9.48 | 13.66 | [ |

| 6FDA-DAM/6FDA-CARDO | 22 | 7 | 139 | 14.04 | 21.82 | [ |

| 6FDA-6FpDA | 35 | 1 | 114 | 45.6 | 88.37 | [ |

| 6FDA-OFB | 35 | 1 | 220 | 22.68 | 42.31 | [ |

| 6FD-PP | 30 | 4 | 31.8 | 53.99 | 219.31 | [ |

| 40%-PI | 35 | 7 | 76.2 | 50.46 | 89.4 | [ |

| TBDA1-6FDA-PI | 35 | 1 | 199 | 30.62 | 60.3 | [ |

| TB-PIMPIs | 35 | 1 | 198 | 21.75 | 34.74 | [ |

| 膜名称 | 温度/℃ | 压力/atm | He渗透系数/Barrer | 选择性 | 文献 | |

|---|---|---|---|---|---|---|

| He/N2 | He/CH4 | |||||

| CPIM | 35 | 3 | 153 | 6.3 | — | [ |

| FPIM-1 | 35 | 1 | 824 | 420 | 1004.87 | [ |

| PIM-F-30 | 22 | 1 | 710 | 229.03 | 443.75 | [ |

| ITB-DM | 35 | 2 | 32 | 229 | 246 | [ |

| ITB-OT | 35 | 2 | 83 | 184 | 198 | [ |

| ITB-Trip | 35 | 2 | 3698 | 4.8 | 4.9 | [ |

| PIM-PI-TB-2 | 35 | 1 | 300 | 7.14 | 6.82 | [ |

| PIM-Trip-TB | 35 | 2 | 2500 | 3.97 | 2.76 | [ |

| CCS-PIM | 25 | 2 | 745.5 | 26.3 | 21.67 | [ |

表4 常见自聚微孔聚合物膜的He气体分离性能

Table 4 He separation properties of common polymers of intrinsic microporosity membranes

| 膜名称 | 温度/℃ | 压力/atm | He渗透系数/Barrer | 选择性 | 文献 | |

|---|---|---|---|---|---|---|

| He/N2 | He/CH4 | |||||

| CPIM | 35 | 3 | 153 | 6.3 | — | [ |

| FPIM-1 | 35 | 1 | 824 | 420 | 1004.87 | [ |

| PIM-F-30 | 22 | 1 | 710 | 229.03 | 443.75 | [ |

| ITB-DM | 35 | 2 | 32 | 229 | 246 | [ |

| ITB-OT | 35 | 2 | 83 | 184 | 198 | [ |

| ITB-Trip | 35 | 2 | 3698 | 4.8 | 4.9 | [ |

| PIM-PI-TB-2 | 35 | 1 | 300 | 7.14 | 6.82 | [ |

| PIM-Trip-TB | 35 | 2 | 2500 | 3.97 | 2.76 | [ |

| CCS-PIM | 25 | 2 | 745.5 | 26.3 | 21.67 | [ |

| 膜名称 | 温度/℃ | 压力/atm | He渗透系数/Barrer | 选择性 | 文献 | |

|---|---|---|---|---|---|---|

| He/N2 | He/CH4 | |||||

| Teflon AF2400 | 22 | 1 | 2740 | 5.71 | 7.03 | [ |

| Teflon AF1600 | 22 | 1 | 830 | 15.09 | 20.24 | [ |

| Cytop | 22 | 1 | 170 | 34 | 85 | [ |

| Nafion | 35 | 1 | 40.9 | 227.22 | 511.25 | [ |

| Aquivion | 35 | 1 | 27.5 | 161.76 | 316.09 | [ |

| Poly(PFMMD) | 35 | 10 | 560 | 72 | 280 | [ |

| Poly(PFMD) | 35 | 10 | 210 | 295.77 | 1615.38 | [ |

| Homo AF | 22 | 3 | 3600 | 4.34 | 5.22 | [ |

| Hyflon AD | 25 | 1 | 340 | 8.95 | 17 | [ |

| Polyperfluoropropylene | 22 | 1 | 597 | 12.44 | 24.88 | [ |

| Poly(perfluropropyl vinyl ether) | 22 | 1 | 357 | 17.5 | 31.59 | [ |

| Copoly(HFP-TFE) | 22 | 1 | 533 | 19.89 | 46.75 | [ |

| Polyperfluoro(2-methyl-2- ethyl-1,3-dioxole) | 35 | 1 | 2180 | 6.81 | 9.08 | [ |

表5 常见全氟聚合物膜的He气体分离性能

Table 5 He separation properties of common perfluorinated polymeric membranes

| 膜名称 | 温度/℃ | 压力/atm | He渗透系数/Barrer | 选择性 | 文献 | |

|---|---|---|---|---|---|---|

| He/N2 | He/CH4 | |||||

| Teflon AF2400 | 22 | 1 | 2740 | 5.71 | 7.03 | [ |

| Teflon AF1600 | 22 | 1 | 830 | 15.09 | 20.24 | [ |

| Cytop | 22 | 1 | 170 | 34 | 85 | [ |

| Nafion | 35 | 1 | 40.9 | 227.22 | 511.25 | [ |

| Aquivion | 35 | 1 | 27.5 | 161.76 | 316.09 | [ |

| Poly(PFMMD) | 35 | 10 | 560 | 72 | 280 | [ |

| Poly(PFMD) | 35 | 10 | 210 | 295.77 | 1615.38 | [ |

| Homo AF | 22 | 3 | 3600 | 4.34 | 5.22 | [ |

| Hyflon AD | 25 | 1 | 340 | 8.95 | 17 | [ |

| Polyperfluoropropylene | 22 | 1 | 597 | 12.44 | 24.88 | [ |

| Poly(perfluropropyl vinyl ether) | 22 | 1 | 357 | 17.5 | 31.59 | [ |

| Copoly(HFP-TFE) | 22 | 1 | 533 | 19.89 | 46.75 | [ |

| Polyperfluoro(2-methyl-2- ethyl-1,3-dioxole) | 35 | 1 | 2180 | 6.81 | 9.08 | [ |

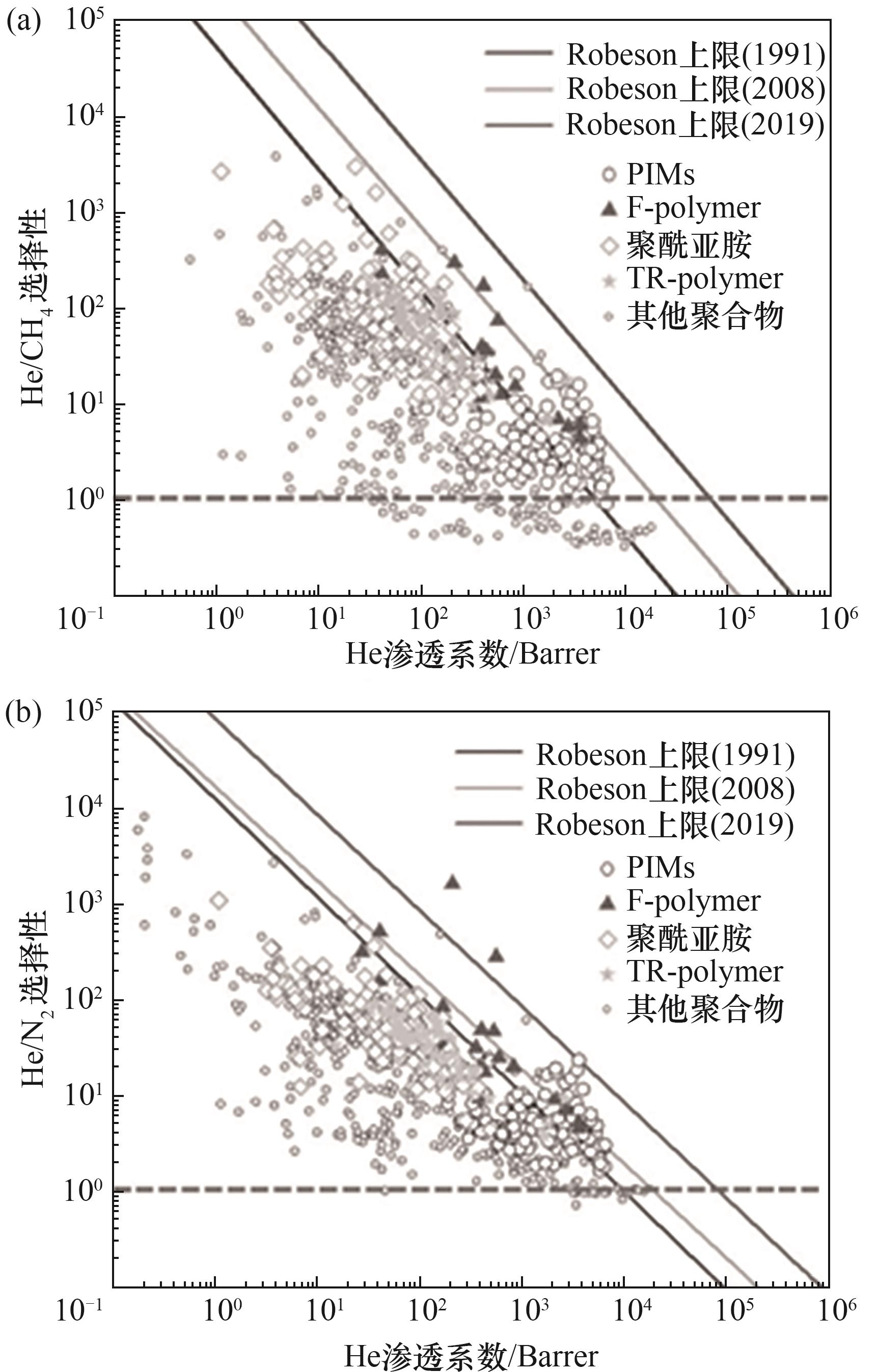

图3 聚合物膜对He/N2和He/CH4的分离性能与Robeson上限(1991年[75]、2008年[76]、2019年[77])的比较

Fig. 3 Comparison of separation performance of polymeric membranes for He/N2 and He/CH4 with the Robeson upper bounds (1991[75], 2008[76], 2019[77])

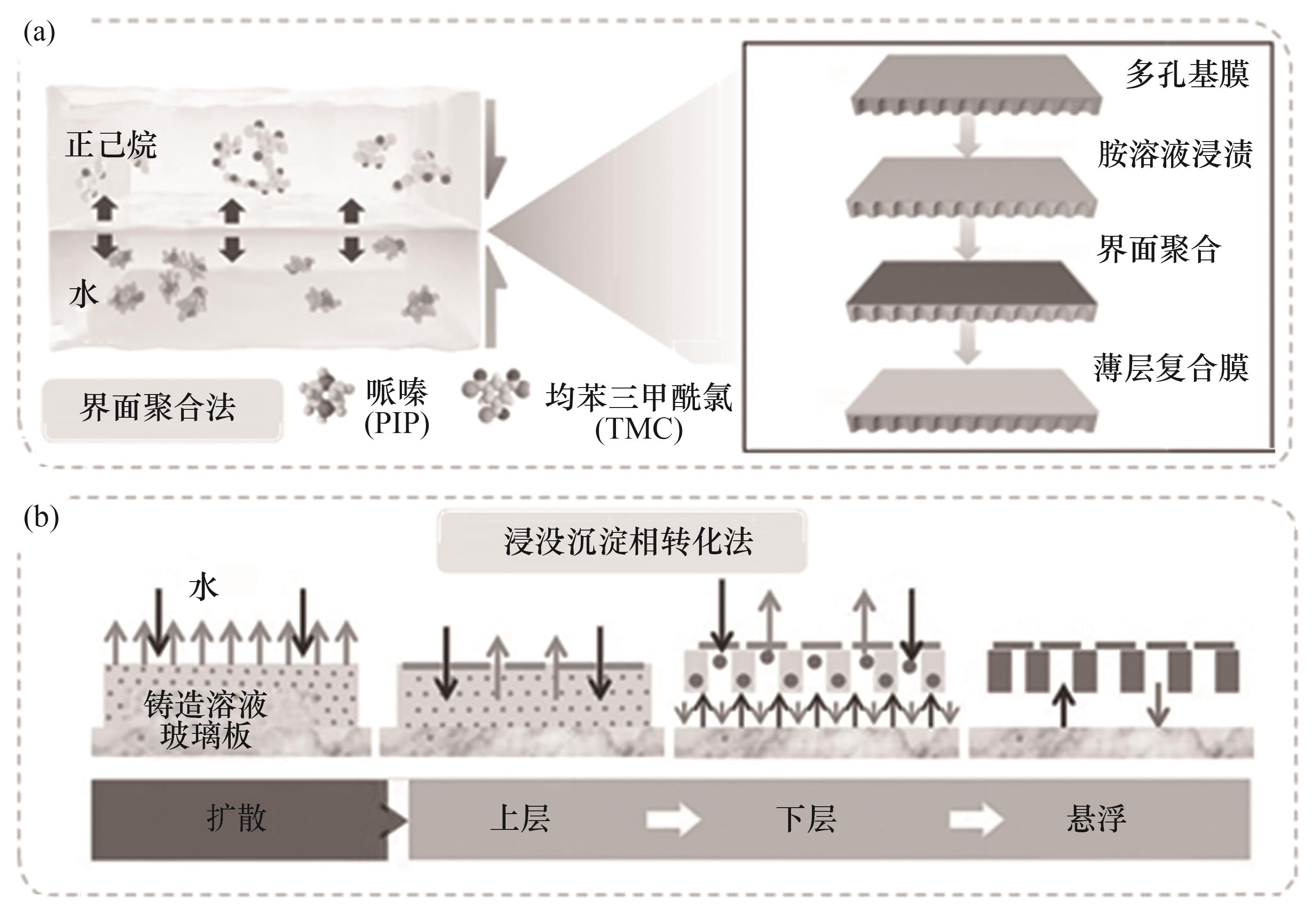

图4 非对称膜的制备方法:(a)界面聚合;(b)浸没沉淀相转化[98,101]

Fig.4 Preparation methods for asymmetric membranes: (a) interfacial polymerization; (b) immersion-precipitation phase inversion [98,101]

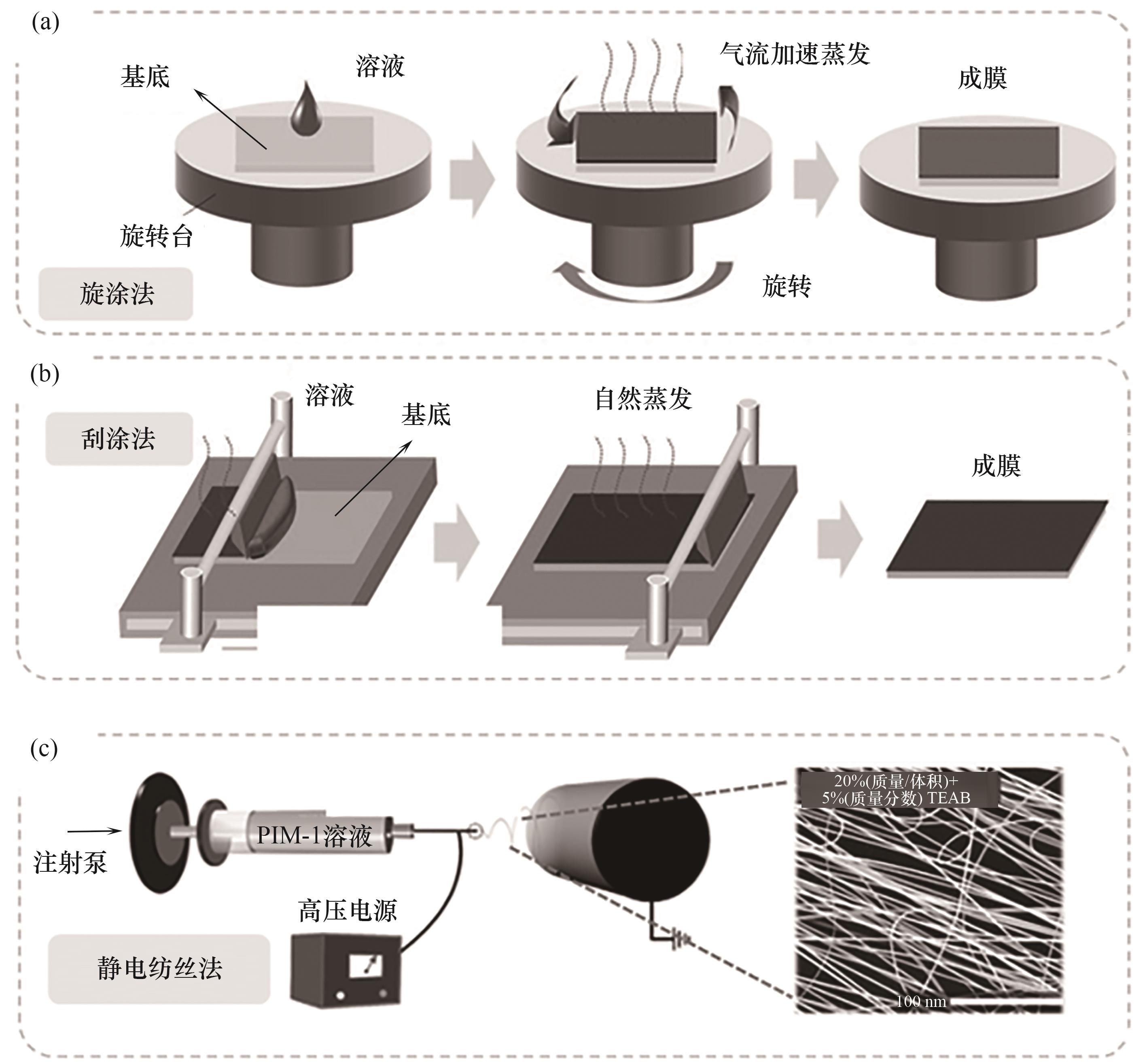

图5 对称膜的制备方法:(a)在玻璃板上旋涂;(b)刮涂;(c)静电纺丝[104-105]

Fig.5 Preparation method of symmetric membrane: (a) spin coating; (b) blade coating; (c) electrospinning[104-105]

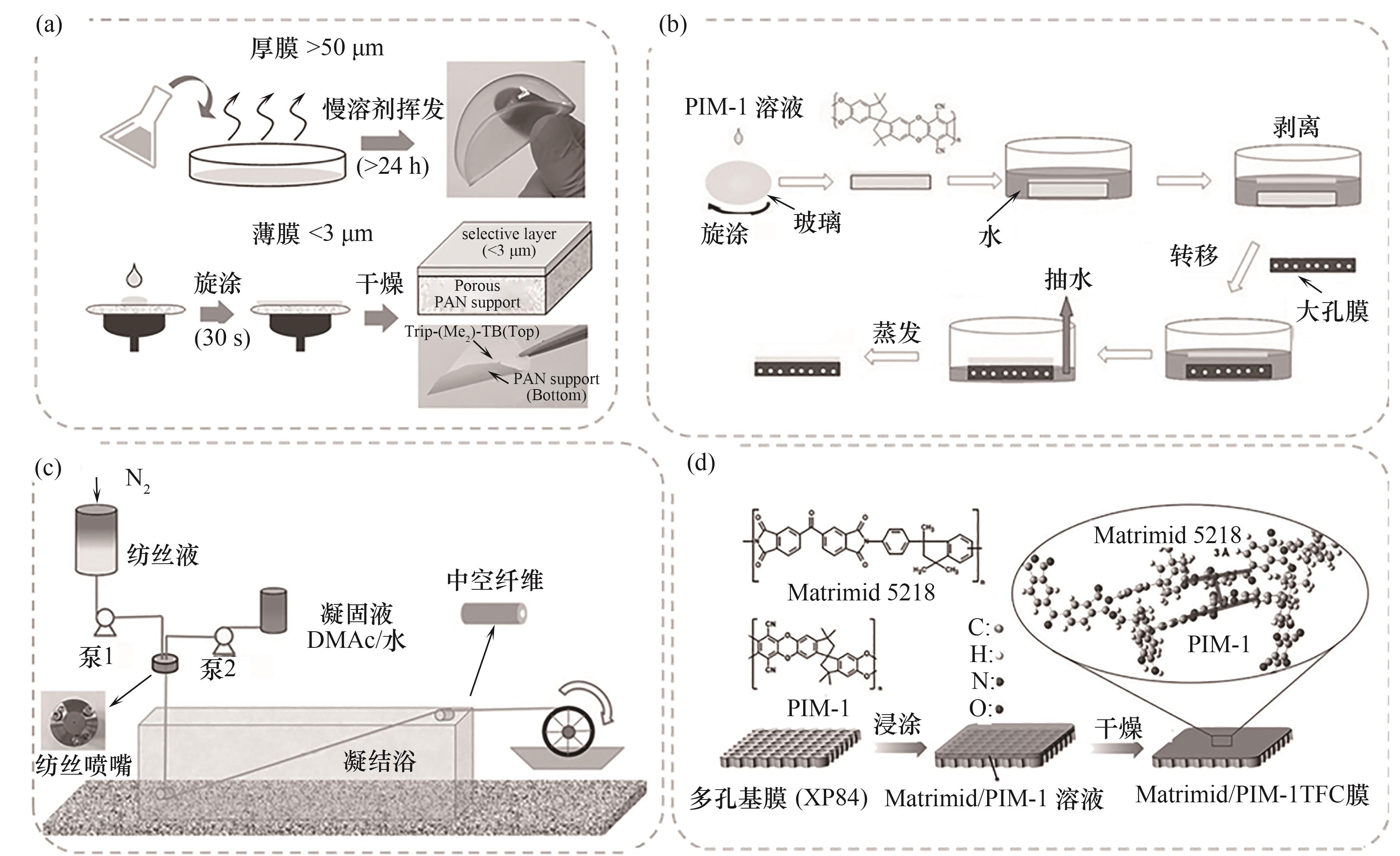

图6 (a)PIM-1膜和TFC膜的制备工艺;(b)旋涂法制备TFC PIM-1膜的工艺示意图;(c)中空纤维纺丝装置原理图;(d)引入Matrimid 5218的PIM-1 TFC膜的制备工艺[114-117]

Fig.6 (a) Process of PIM-based bulk membrane and TFC membrane preparation; (b) Schematic illustration of preparation process for TFC PIM-1 membranes via spin coating; (c) Schematic diagram of spinning device; (d)PIMs-based TFC membrane with introduction of Matrimid 5218[114-117]

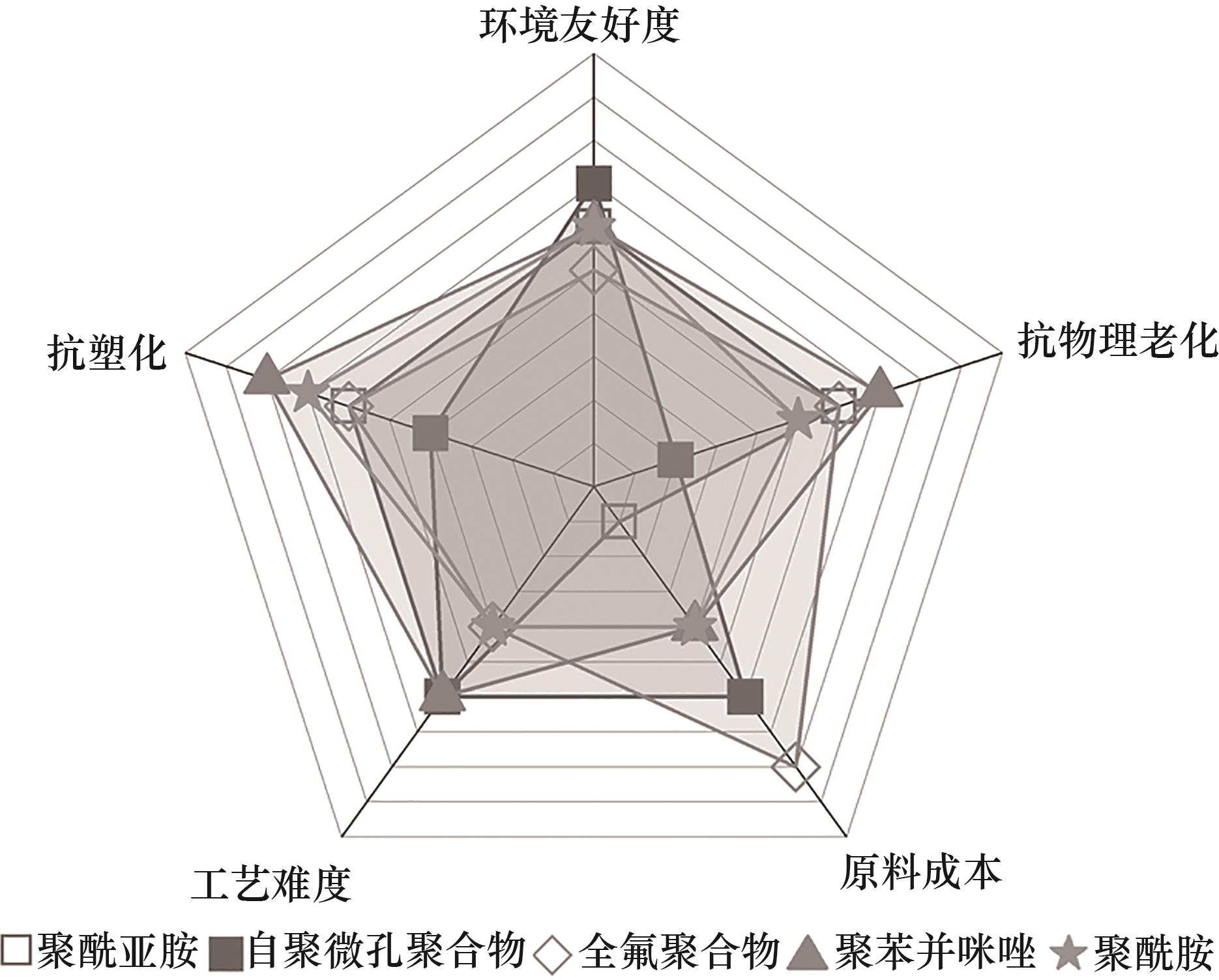

图7 几种常见He分离聚合物材料多维度工业分析的五边形雷达图

Fig.7 A pentagonal radar chart for a multi-dimensional industrial analysis of several common He-selective polymer materials

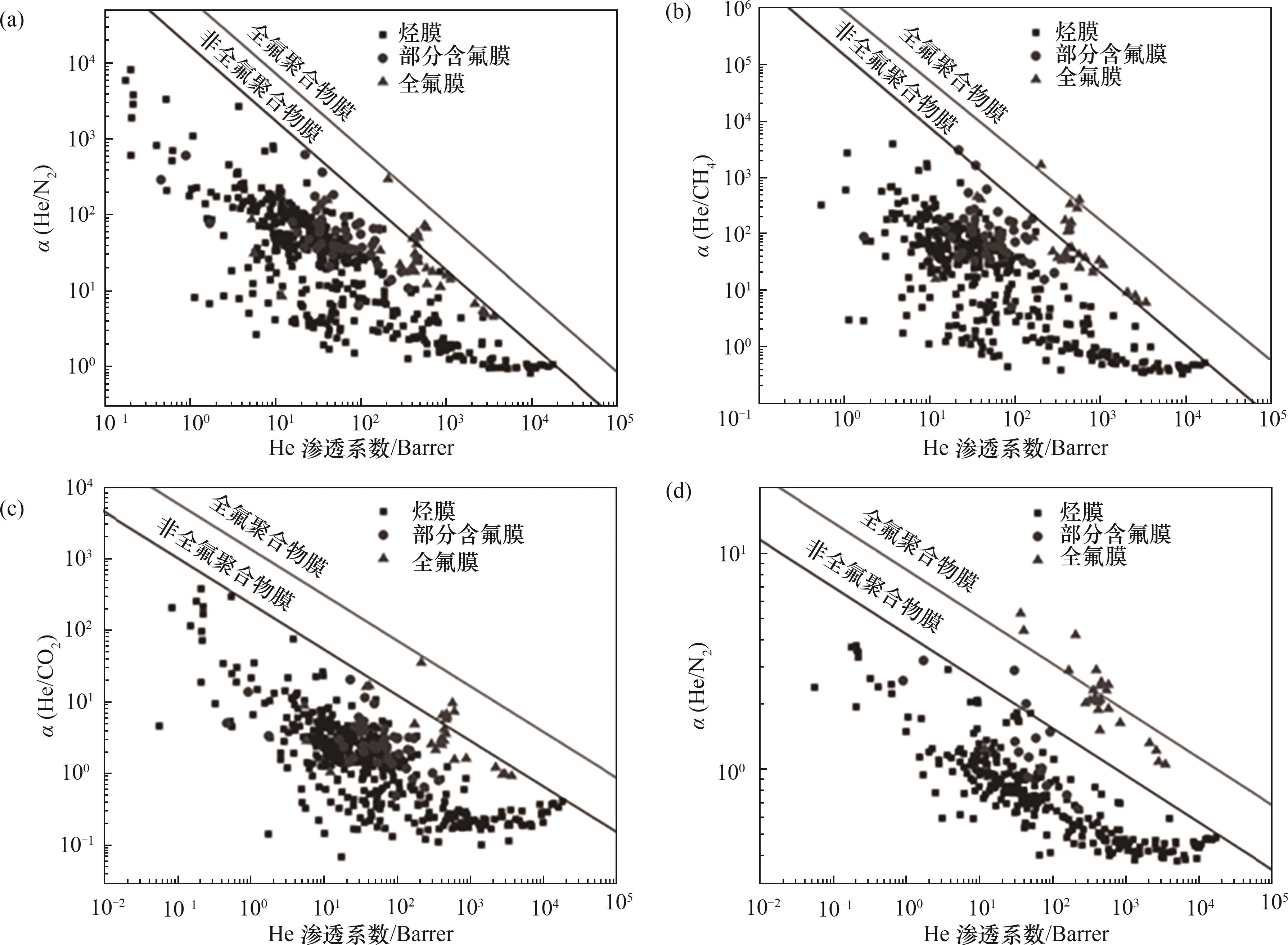

图9 非全氟聚合物膜和全氟聚合物膜用于He与其他气体分离的上限:(a) He/N2;(b) He/CH4;(c) He/CO2;(d) He/H2[125]

Fig. 9 Upper bounds of nonperfluoropolymer and perfluoropolymer membranes for He separation from other gases: (a) He/N2;(b) He/CH4; (c) He/CO2; (d) He/H2[125]

| 68 | Belov N, Nikiforov R, Polunin E, et al. Gas permeation, diffusion, sorption and free volume of poly(2-trifluoromethyl-2-pentafluoroethyl-1,3-perfluorodioxole)[J]. Journal of Membrane Science, 2018, 565: 112-118. |

| 69 | Ali Shah A, Heo H J, Park S, et al. Origin of fluoropolymer affinity toward water and its impact on membrane performance[J]. ACS Applied Polymer Materials, 2020, 2(11): 5249-5258. |

| 70 | Díez B, Cuadrado P, Marcos-Fernández Á, et al. Helium recovery by membrane gas separation using poly(o-acyloxyamide)s[J]. Industrial & Engineering Chemistry Research, 2014, 53(32): 12809-12818. |

| 71 | Jiao Y, Wu Q, Lai W, et al. Enhancement of molecular sieving and plasticization resistance of polybenzimidazole membranes through chemical crosslinking for helium recovery from multi-component natural gas[J]. Separation and Purification Technology, 2024, 331: 125560. |

| 72 | Wang X R, Shan M X, Liu X L, et al. High-performance polybenzimidazole membranes for helium extraction from natural gas[J]. ACS Applied Materials & Interfaces, 2019, 11(22): 20098-20103. |

| 73 | Choi S H, Ben Sultan M M, Alsuwailem A A, et al. Preparation and characterization of multilayer thin-film composite hollow fiber membranes for helium extraction from its mixtures[J]. Separation and Purification Technology, 2019, 222: 152-161. |

| 74 | Sun Y, Bai J, Zheng P J, et al. Interfacially polymerized nanofilms with triptycene moieties and enhanced micropore interconnectivity for highly permselective gas separations[J]. Chemical Engineering Journal, 2023, 471: 144414. |

| 75 | Robeson L M. Correlation of separation factor versus permeability for polymeric membranes[J]. Journal of Membrane Science, 1991, 62(2): 165-185. |

| 76 | Robeson L. The upper bound revisited[J]. Journal of Membrane Science, 2008, 320: 390-400. |

| 77 | Wu A X, Drayton J A, Smith Z P. The perfluoropolymer upper bound[J]. AIChE Journal, 2019, 65(12): e16700. |

| 78 | Roozitalab A, Hamidavi F, Kargari A. A review of membrane material for biogas and natural gas upgrading[J]. Gas Science and Engineering, 2023, 114: 204969. |

| 79 | Sridhar S, Smitha B, Aminabhavi T M. Separation of carbon dioxide from natural gas mixtures through polymeric membranes-a review[J]. Separation & Purification Reviews, 2007, 36(2): 113-174. |

| 80 | Maab H, Touheed A. Polyazole polymers membranes for high pressure gas separation technology[J]. Journal of Membrane Science, 2022, 642: 119980. |

| 81 | Li K H, Li Q X, Cai Z X, et al. Microporosity effect of intrinsic microporous polyimide membranes on their helium enrichment performance after direct fluorination[J]. Journal of Membrane Science, 2022, 660: 120868. |

| 82 | Wu Q, Liu L, Jiao Y, et al. Precise helium sieving from hydrogen using fluorine-decorated carbon hollow fiber membranes[J]. Angewandte Chemie, 2024, 136(33): e202400688. |

| 83 | Wang C, Li Z Y, Bai J, et al. Dual thermally crosslinked hollow fiber membranes for plasticization-resistant helium recovery from natural gas[J]. Separation and Purification Technology, 2025, 354: 129019. |

| 84 | Li Z Y, Han T L, Lai W, et al. Enhanced plasticization resistance of hollow fiber membranes for helium recovery from natural gas based on a novel thermally crosslinkable polyimide[J]. Journal of Membrane Science, 2023, 688: 122126. |

| 85 | Bakhtin D S, Sokolov S E, Borisov I L, et al. Mitigation of physical aging of polymeric membrane materials for gas separation: a review[J]. Membranes, 2023, 13(5): 519. |

| 86 | Bezzu C G, Carta M, Ferrari M C, et al. The synthesis, chain-packing simulation and long-term gas permeability of highly selective spirobifluorene-based polymers of intrinsic microporosity[J]. Journal of Materials Chemistry A, 2018, 6(22): 10507-10514. |

| 87 | Abdulhamid M A. Tröger's base-derived dianhydride as a promising contorted building block for polyimide-based membranes for gas separation[J]. Separation and Purification Technology, 2023, 310: 123208. |

| 88 | Alghunaimi F, Ghanem B, Alaslai N, et al. Gas permeation and physical aging properties of iptycene diamine-based microporous polyimides[J]. Journal of Membrane Science, 2015, 490: 321-327. |

| 89 | Yao J F, Wang H T. Zeolitic imidazolate framework composite membranes and thin films: synthesis and applications[J]. Chemical Society Reviews, 2014, 43(13): 4470-4493. |

| 90 | Chen L, Liu L F, Xue J, et al. Asymmetric membrane structure: an efficient approach to enhance hydrogen separation performance[J]. Separation and Purification Technology, 2018, 207: 363-369. |

| 91 | Wang Z Y, Liang S M, Kang Y, et al. Manipulating interfacial polymerization for polymeric nanofilms of composite separation membranes[J]. Progress in Polymer Science, 2021, 122: 101450. |

| 1 | Yu L, Mayne B, Nobandegani M S, et al. Recovery of helium from natural gas using MFI membranes[J]. Journal of Membrane Science, 2022, 644: 120113. |

| 2 | Simonenko Y M, Bondarenko A V, Chigrin A A, et al. Does helium have a cryogenic future?[J]. Chemical and Petroleum Engineering, 2016, 51(9): 707-713. |

| 3 | Eldrup M, Lightbody D, Sherwood J N. The temperature dependence of positron lifetimes in solid pivalic acid[J]. Chemical Physics, 1981, 63(1/2): 51-58. |

| 4 | Nuttall W J, Clarke R H, Glowacki B A. Stop squandering helium[J]. Nature, 2012, 485(7400): 573-575. |

| 5 | Rufford T E, Chan K I, Huang S H, et al. A review of conventional and emerging process technologies for the recovery of helium from natural gas[J]. Adsorption Science & Technology, 2014, 32(1): 49-72. |

| 6 | Berganza C J, Zhang J H. The role of helium gas in medicine[J]. Medical Gas Research, 2013, 3(1): 18. |

| 7 | Dai Z D, Deng J, He X Z, et al. Helium separation using membrane technology: recent advances and perspectives[J]. Separation and Purification Technology, 2021, 274: 119044. |

| 8 | Hofmann A W, Farnetani C G, Spiegelman M, et al. Displaced helium and carbon in the Hawaiian plume[J]. Earth and Planetary Science Letters, 2011, 312(1/2): 226-236. |

| 9 | Scholes C A, Ghosh U K. Review of membranes for helium separation and purification[J]. Membranes, 2017, 7(1): 9. |

| 10 | Baker R W, Low B T. Gas separation membrane materials: a perspective[J]. Macromolecules, 2014, 47(20): 6999-7013. |

| 11 | Scholes C A, Gosh U K, Ho M T. The economics of helium separation and purification by gas separation membranes[J]. Industrial & Engineering Chemistry Research, 2017, 56(17): 5014-5020. |

| 12 | Hamedi H, Karimi I A, Gundersen T. Optimization of helium extraction processes integrated with nitrogen removal units: a comparative study[J]. Computers & Chemical Engineering, 2019, 121: 354-366. |

| 92 | Zhao G J, Li L L, Gao H Q, et al. Polyamide nanofilms through a non-isothermal-controlled interfacial polymerization[J]. Advanced Functional Materials, 2024, 34(18): 2313026. |

| 93 | Lee T H, Balcik M, Wu W N, et al. Dual-phase microporous polymer nanofilms by interfacial polymerization for ultrafast molecular separation[J]. Science Advances, 2024, 10(33): eadp6666. |

| 94 | Cao R, Zhang E Y, Liu Y, et al. Block copolymer nanoparticles doping polyacrylonitrile membranes for efficient adsorption of water-soluble dyes from water[J]. Chemical Engineering Journal, 2024, 501: 157712. |

| 95 | Wang D M, Lai J Y. Recent advances in preparation and morphology control of polymeric membranes formed by nonsolvent induced phase separation[J]. Current Opinion in Chemical Engineering, 2013, 2(2): 229-237. |

| 96 | 邓麦村, 金万勤. 膜技术手册[M]. 2版. 北京: 化学工业出版社, 2020. |

| Deng M C, Jin W Q. Handbook of Membrane Technology[M]. 2nd ed. Beijing: Chemical Industry Press, 2020. | |

| 97 | Huang X, Wang W P, Zheng Z, et al. Surface monofunctionalized polymethyl pentene hollow fiber membranes by plasma treatment and hemocompatibility modification for membrane oxygenators[J]. Applied Surface Science, 2016, 362: 355-363. |

| 98 | Guillen G R, Pan Y J, Li M H, et al. Preparation and characterization of membranes formed by nonsolvent induced phase separation: a review[J]. Industrial & Engineering Chemistry Research, 2011, 50(7): 3798-3817. |

| 99 | Zhang T Q, Jia Z Q, Peng W J, et al. Preparation of 4-methyl-1-pentene membranes via non-solvent induced phase separation (NIPS)[J]. European Polymer Journal, 2022, 178: 111480. |

| 100 | Dibrov G, Ivanov M, Semyashkin M, et al. High-pressure aging of asymmetric Torlon® hollow fibers for helium separation from natural gas[J]. Fibers, 2018, 6(4): 83. |

| 101 | 李田田, 刘富. 基于相转化全过程的聚合物微孔膜功能化研究进展[J]. 功能高分子学报, 2020, 33(3): 210-225. |

| Li T T, Liu F. Functionalization of polymeric microporous membranes based on phase inversion[J]. Journal of Functional Polymers, 2020, 33(3): 210-225. | |

| 13 | Hamedi H, Karimi I A, Gundersen T. Optimal cryogenic processes for nitrogen rejection from natural gas[J]. Computers & Chemical Engineering, 2018, 112: 101-111. |

| 14 | Ye P C, Grahn M, Korelskiy D, et al. Efficient separation of N2 and He at low temperature using MFI membranes[J]. AIChE Journal, 2016, 62(8): 2833-2842. |

| 15 | Liu L, Wu Q, Wang S L, et al. Highly selective and hydrocarbon-resistant polyimide hollow fiber membranes for helium recovery from natural gas[J]. Industrial & Engineering Chemistry Research, 2023, 62(1): 708-716. |

| 16 | Kleines L, Wilski S, Alizadeh P, et al. Structure and gas separation properties of ultra-smooth PE-CVD silicon organic coated composite membranes[J]. Surface and Coatings Technology, 2021, 421: 127338. |

| 17 | Scholes C A, Stevens G W, Kentish S E. Membrane gas separation applications in natural gas processing[J]. Fuel, 2012, 96: 15-28. |

| 18 | Gantzel P K, Merten U. Gas separations with high-flux cellulose acetate membranes[J]. Industrial & Engineering Chemistry Process Design and Development, 1970, 9(2): 331-332. |

| 19 | Seong J G, Lee W H, Lee J, et al. Microporous polymers with cascaded cavities for controlled transport of small gas molecules[J]. Science Advances, 2021, 7(40): eabi9062. |

| 20 | Mohamed M A, Sazali N. Polyimide-based carbon membrane: effect of coating times on helium separations[J]. Journal of Advanced Research in Applied Mechanics, 2019, 64(1): 1-6. |

| 21 | Mangindaan D W, Shi G M, Chung T S. Pervaporation dehydration of acetone using P84 co-polyimide flat sheet membranes modified by vapor phase crosslinking[J]. Journal of Membrane Science, 2014, 458: 76-85. |

| 22 | Akbari A, Karimi-Sabet J, Ghoreishi S M. Matrimid® 5218 based mixed matrix membranes containing metal organic frameworks (MOFs) for helium separation[J]. Chemical Engineering and Processing - Process Intensification, 2020, 148: 107804. |

| 23 | Ahmadizadegan H, Tahriri M, Tahriri M, et al. Polyimide-TiO2 nanocomposites and their corresponding membranes: synthesis, characterization, and gas separation applications[J]. Solid State Sciences, 2019, 89: 25-36. |

| 24 | Qiu W L, Xu L R, Chen C C, et al. Gas separation performance of 6FDA-based polyimides with different chemical structures[J]. Polymer, 2013, 54(22): 6226-6235. |

| 102 | Shi Y S, Liang J C, Babu Shrestha B, et al. Enhancing the CO2 plasticization resistance of thin polymeric membranes by designing metal-polymer complexes[J]. Separation and Purification Technology, 2022, 289: 120699. |

| 103 | Topuz F, Satilmis B, Uyar T. Electrospinning of uniform nanofibers of polymers of intrinsic microporosity (PIM-1): the influence of solution conductivity and relative humidity[J]. Polymer, 2019, 178: 121610. |

| 104 | Chen Y Z, Peng P, Guo Z X, et al. Effect of hyperbranched poly(ester amine) additive on electrospinning of low concentration poly(methyl methacrylate) solutions[J]. Journal of Applied Polymer Science, 2010, 115(6): 3687-3696. |

| 105 | Vatanpour V, Kose-Mutlu B, Koyuncu I. Electrospraying technique in fabrication of separation membranes: a review[J]. Desalination, 2022, 533: 115765. |

| 106 | Wang D L, Teo W K, Li K. Preparation and characterization of high-flux polysulfone hollow fibre gas separation membranes[J]. Journal of Membrane Science, 2002, 204(1/2): 247-256. |

| 107 | Arundhathi B, Pabba M, Raj S S, et al. Advancements in mixed-matrix membranes for various separation applications: state of the art and future prospects[J]. Membranes, 2024, 14(11): 224. |

| 108 | Syrtsova D A, Shalygin M G, Teplyakov V V. Fluorinated hollow fiber membranes based on Matrimid 5218 and their application in the process of helium recovery from natural gas[J]. Petroleum Chemistry, 2018, 58(9): 760-769. |

| 109 | Nie J, Li H B. Hollow fiber carbon molecular sieve membranes for gas separation: a mini review[J]. Current Nanoscience, 2024, 20(2): 174-187. |

| 110 | Yong W F, Li F Y, Xiao Y C, et al. High performance PIM-1/Matrimid hollow fiber membranes for CO2/CH4, O2/N2 and CO2/N2 separation[J]. Journal of Membrane Science, 2013, 443: 156-169. |

| 111 | Jue M L, Breedveld V, Lively R P. Defect-free PIM-1 hollow fiber membranes[J]. Journal of Membrane Science, 2017, 530: 33-41. |

| 112 | Jansen J C, Tasselli F, Tocci E, et al. High-flux composite perfluorinated gas separation membranes of Hyflon® AD on a hollow fibre ultrafiltration membrane support[J]. Desalination, 2006, 192(1/2/3): 207-213. |

| 113 | Choi S H, Tasselli F, Jansen J C, et al. Effect of the preparation conditions on the formation of asymmetric poly(vinylidene fluoride) hollow fibre membranes with a dense skin[J]. European Polymer Journal, 2010, 46(8): 1713-1725. |

| 25 | Xing L X, Qin J L, Wang J M, et al. Polyimide membrane materials with multiple trifluoromethyl groups for helium enrichment from natural gases[J]. Industrial & Engineering Chemistry Research, 2023, 62(39): 16081-16092. |

| 26 | Hou Q H, Guo W T, Liu Z Y, et al. Breaking the trade-off of permeability-selectivity: strain-assisted T-C3N2 membranes for high-efficient helium separation and purification from gas mixture[J]. Journal of Membrane Science, 2024, 708: 123051. |

| 27 | Joo T, Lee T H, Kaser S J, et al. Free volume manipulation and in situ oxidative crosslinking of amine-functionalized microporous polymer membranes[J]. Chemistry Materials, 2024, 36(9): 4275-4290. |

| 28 | Zhuang Y B, Seong J G, Do Y S, et al. Intrinsically microporous soluble polyimides incorporating Tröger's base for membrane gas separation[J]. Macromolecules, 2014, 47(10): 3254-3262. |

| 29 | Ni J, Li J L, Wei B W, et al. Synthesis and characterization of novel homopolyimides containing pyridine and morpholine groups for gas separation by molecular design and simulation[J]. Fibers and Polymers, 2023, 24(12): 4155-4167. |

| 30 | Wang C, Cai Z L, Xie W, et al. Finely tuning the microporosity in dual thermally crosslinked polyimide membranes for plasticization resistance gas separations[J]. Journal of Membrane Science, 2022, 659: 120769. |

| 31 | Wang L, Li Y, Zhang P, et al. Thermally rearranged poly(benzoxazole-co-imide) composite membranes on α-Al2O3 support for helium extraction from natural gas[J]. Journal of Membrane Science, 2022, 657: 120614. |

| 32 | Ma H, Liu H H, Tian F, et al. Thermally cross-linked alkynyl-based polyimide membranes for efficient helium separation and physical aging control[J]. Chemical Engineering Science, 2024, 290: 119907. |

| 33 | Zhang Y, Lee W H, Seong J G, et al. Alicyclic segments upgrade hydrogen separation performance of intrinsically microporous polyimide membranes[J]. Journal of Membrane Science, 2020, 611: 118363. |

| 34 | Xu J W, Chng M L, Chung T S, et al. Permeability of polyimides derived from non-coplanar diamines and 4,4'-(hexafluoroisopropylidene) diphthalic anhydride[J]. Polymer, 2003, 44(16): 4715-4721. |

| 35 | Zhang B B, Qiao J, Dong C X, et al. Dibenzo-21-crown-7-ether contained 6FDA-based polyimide membrane with improved gas selectivity[J]. Separation and Purification Technology, 2021, 264: 118454. |

| 36 | Lin W H, Chung T S. Gas permeability, diffusivity, solubility, and aging characteristics of 6FDA-durene polyimide membranes[J]. Journal of Membrane Science, 2001, 186(2): 183-193. |

| 37 | Hayek A, Alsamah A, Saleem Q, et al. Enhanced high-pressure mixed-gas sieving properties of thermally cross-linked polyimide membranes[J]. ACS Applied Polymer Materials, 2024, 6(10): 6108-6120. |

| 38 | Yahaya G O, Hayek A, Alsamah A, et al. Copolyimide membranes with improved H2S/CH4 selectivity for high-pressure sour mixed-gas separation[J]. Separation and Purification Technology, 2021, 272: 118897. |

| 39 | Wu A X, Drayton J A, Rodriguez K M, et al. Influence of aliphatic and aromatic fluorine groups on gas permeability and morphology of fluorinated polyimide films[J]. Macromolecules, 2020, 53(13): 5085-5095. |

| 40 | Huang F, Largier T D, Khan W, et al. 6FDA-DABA polyimide, polyphenylene, and polyimide-polyphenylene multiblock synthesis, characterization, and membrane gas separation performance and modeled transport[J]. Journal of Membrane Science, 2023, 683: 121864. |

| 41 | Huo G L, Guo Z Y, Zhang Z G, et al. Effect of uniaxial stretching on gas separation performance of polyimide membranes[J]. Journal of Membrane Science, 2023, 687: 122046. |

| 42 | Wang Z G, Wang D, Zhang F, et al. Tröger's base-based microporous polyimide membranes for high-performance gas separation[J]. ACS Macro Letters, 2014, 3(7): 597-601. |

| 43 | Hu X F, He Y B, Wang Z, et al. Intrinsically microporous co-polyimides derived from ortho-substituted Tröger's base diamine with a pendant tert-butyl-phenyl group and their gas separation performance[J]. Polymer, 2018, 153: 173-182. |

| 44 | Astorino C, De Nardo E, Lettieri S, et al. Advancements in gas separation for energy applications: exploring the potential of polymer membranes with intrinsic microporosity (PIM)[J]. Membranes, 2023, 13(12): 903. |

| 45 | Li P, Chung T S, Paul D R. Gas sorption and permeation in PIM-1[J]. Journal of Membrane Science, 2013, 432: 50-57. |

| 46 | Thomas S, Pinnau I, Du N Y, et al. Hydrocarbon/hydrogen mixed-gas permeation properties of PIM-1, an amorphous microporous spirobisindane polymer[J]. Journal of Membrane Science, 2009, 338(1/2): 1-4. |

| 47 | Li F Y, Xiao Y C, Ong Y K, et al. UV-rearranged PIM-1 polymeric membranes for advanced hydrogen purification and production[J]. Advanced Energy Materials, 2012, 2(12): 1456-1466. |

| 48 | Ahn J, Chung W J, Pinnau I, et al. Gas transport behavior of mixed-matrix membranes composed of silica nanoparticles in a polymer of intrinsic microporosity (PIM-1)[J]. Journal of Membrane Science, 2010, 346(2): 280-287. |

| 114 | Lee T H, Balçık M, Lee B K, et al. Hyperaging-induced H2-selective thin-film composite membranes with enhanced submicroporosity toward green hydrogen supply[J]. Journal of Membrane Science, 2023, 672: 121438. |

| 115 | Gorgojo P, Karan S, Wong H C, et al. Ultrathin polymer films with intrinsic microporosity: anomalous solvent permeation and high flux membranes[J]. Advanced Functional Materials, 2014, 24(30): 4729-4737. |

| 116 | Xiao M F, Li J H, Lei H Y, et al. Preparation and microstructure control of PMDA/ODA polyimide hollow fibers[J]. Fibers and Polymers, 2020, 21(5): 944-953. |

| 117 | Li J Q, Feng W L, Zhang M X, et al. Microporous matrimid/PIM-1 thin film composite membranes with narrow pore size distribution used for molecular separation in organic solvents[J]. Macromolecular Rapid Communications, 2023, 44(6): e2200826. |

| 118 | Zhao T Q, Tan J K, Zhou W L, et al. Engineering robust porous/dense composite hollow fiber membranes for highly efficient hydrogen separation[J]. Journal of Membrane Science, 2024, 705: 122872. |

| 119 | Shen J, Wang Z Z, Yang H W, et al. A new technology for producing hydrogen and adjustable ratio syngas from coke oven gas[J]. Energy & Fuels, 2007, 21(6): 3588-3592. |

| 120 | Bernardo G, Araújo T, da Silva Lopes T, et al. Recent advances in membrane technologies for hydrogen purification[J]. International Journal of Hydrogen Energy, 2020, 45(12): 7313-7338. |

| 121 | Freeman B D. Basis of permeability/selectivity tradeoff relations in polymeric gas separation membranes[J]. Macromolecules, 1999, 32(2): 375-380. |

| 122 | Jana A, Modi A. Recent progress on functional polymeric membranes for CO2 separation from flue gases: a review[J]. Carbon Capture Science & Technology, 2024, 11: 100204. |

| 123 | Meloni E, Martino M, Palma V. A short review on Ni based catalysts and related engineering issues for methane steam reforming[J]. Catalysts, 2020, 10(3): 352. |

| 124 | Dong L L, Zhang W H, Qu Z, et al. Cardo-type porous organic nanospheres: tailoring interfacial compatibility in thermally rearranged mixed matrix membranes for improved hydrogen purification[J]. Journal of Membrane Science, 2020, 612: 118414. |

| 125 | Deng M, Wei J, Ma Y L, et al. Next-generation carbon molecule sieve membranes derived from polyimides and polymers of intrinsic microporosity for key energy intensive gas separations and carbon capture[J]. Journal of Materials Chemistry A, 2024, 12(31): 19806-19838. |

| 126 | Bandehali S, Kargari A, Moghadassi A, et al. Acrylonitrile-butadiene-styrene/poly(vinyl acetate)/nanosilica mixed matrix membrane for He/CH4 separation[J]. Asia-Pacific Journal of Chemical Engineering, 2014, 9(5): 638-644. |

| 49 | Du N Y, Robertson G P, Song J S, et al. High-performance carboxylated polymers of intrinsic microporosity (PIMs) with tunable gas transport properties[J]. Macromolecules, 2009, 42(16): 6038-6043. |

| 50 | Ma X H, Li K H, Zhu Z Y, et al. High-performance polymer molecular sieve membranes prepared by direct fluorination for efficient helium enrichment[J]. Journal of Materials Chemistry A, 2021, 9(34): 18313-18322. |

| 51 | Belov N A, Alentiev A Y, Nikiforov R Y, et al. Gas separation properties of PIM-1 films treated by elemental fluorine in liquid perfluorodecalin[J]. Polymer, 2023, 280: 126033. |

| 52 | Zheng P J, Xie W, Cai Z L, et al. Ionization of Tröger's base polymer of intrinsic microporosity for high-performance membrane-mediated helium recovery[J]. Journal of Membrane Science, 2023, 672: 121425. |

| 53 | Ghanem B, Alaslai N, Miao X H, et al. Novel 6FDA-based polyimides derived from sterically hindered Tröger's base diamines: synthesis and gas permeation properties[J]. Polymer, 2016, 96: 13-19. |

| 54 | Wang Y G, Alaslai N, Ghanem B, et al. Hydroxyl-functionalized polymers of intrinsic microporosity and dual-functionalized blends for high-performance membrane-based gas separations[J]. Advanced Materials, 2024: e2406076. |

| 55 | Yu C, Wang Y, Xia Y F, et al. Polymers of intrinsic microporosity with internal dihedral lock for efficient gas separation[J]. Advanced Membranes, 2024, 4: 100097. |

| 56 | Son T Y, Jeong M A, Nam S Y. Amorphous fluoropolymer membrane for gas separation applications[J]. Journal of Nanoscience and Nanotechnology, 2018, 18(9): 6206-6212. |

| 57 | Li K, Wang Y L, Wang C L, et al. Fluorine domains induced ultrahigh nitrogen solubility in ionic liquids[J]. Journal of the American Chemical Society, 2024, 146(37): 25569-25577. |

| 58 | Yavari M, Fang M F, Nguyen H, et al. Dioxolane-based perfluoropolymers with superior membrane gas separation properties[J]. Macromolecules, 2018, 51(7): 2489-2497. |

| 59 | Chiou J S, Paul D R. Gas permeation in a dry Nafion membrane[J]. Industrial & Engineering Chemistry Research, 1988, 27(11): 2161-2164. |

| 60 | Catalano J, Myezwa T, De Angelis M G, et al. The effect of relative humidity on the gas permeability and swelling in PFSI membranes[J]. International Journal of Hydrogen Energy, 2012, 37(7): 6308-6316. |

| 61 | Deng J, Box W J, Condes L C, et al. Effect of halogen substituents on polymer membrane hydrophobicity, swelling and transport mechanism: chlorine versus fluorine[J]. Journal of Membrane Science, 2022, 662: 120964. |

| 62 | Murali R S, Sankarshana T, Sridhar S, et al. Fluorinated polymer membranes for separation of industrial gas mixtures[J]. Journal of Polymer Materials, 2012, 29(3): 317-330. |

| 63 | Fang M F, He Z J, Merkel T C, et al. High-performance perfluorodioxolane copolymer membranes for gas separation with tailored selectivity enhancement[J]. Journal of Materials Chemistry A, 2018, 6(2): 652-658. |

| 64 | Macchione M, Jansen J C, De Luca G, et al. Experimental analysis and simulation of the gas transport in dense Hyflon® AD60X membranes: influence of residual solvent[J]. Polymer, 2007, 48(9): 2619-2635. |

| 65 | Belov N A, Zharov A A, Shashkin A V, et al. Gas transport and free volume in hexafluoropropylene polymers[J]. Journal of Membrane Science, 2011, 383(1/2): 70-77. |

| 66 | Belov N, Nizhegorodova Y, Zharov A, et al. A new polymer, poly(perfluoropropylvinyl ether) and its comparison with other perfluorinated membrane materials[J]. Journal of Membrane Science, 2015, 495: 431-438. |

| 67 | Nikiforov R, Belov N, Zharov A, et al. Gas permeation and diffusion in copolymers of tetrafluoroethylene and hexafluoropropylene: effect of annealing[J]. Journal of Membrane Science, 2017, 540: 129-135. |

| 127 | Cai F F, Jin F K, Hao J, et al. Selective hydrogenolysis of glycerol to 1,2-propanediol on Nb-modified Pd-Zr-Al catalysts[J]. Catalysis Communications, 2019, 131: 105801. |

| 128 | Sunarso J, Hashim S S, Lin Y S, et al. Membranes for helium recovery: an overview on the context, materials and future directions[J]. Separation and Purification Technology, 2017, 176: 335-383. |

| 129 | Lu H T, Kanehashi S, Scholes C A, et al. The potential for use of cellulose triacetate membranes in post combustion capture[J]. International Journal of Greenhouse Gas Control, 2016, 55: 97-104. |

| 130 | Budd P M, Makhseed S M, Ghanem B S, et al. Microporous polymeric materials[J]. Materials Today, 2004, 7(4): 40-46. |

| 131 | Hu Y M, Shiotsuki M, Sanda F, et al. Synthesis and properties of indan-based polyacetylenes that feature the highest gas permeability among all the existing polymers[J]. Macromolecules, 2008, 41(22): 8525-8532. |

| 132 | Choi S H, Qahtani M S, Qasem E A. Multilayer thin-film composite membranes for helium enrichment[J]. Journal of Membrane Science, 2018, 553: 180-188. |

| 133 | Itoh Y, Chen S, Hirahara R, et al. Ultrafast water permeation through nanochannels with a densely fluorous interior surface[J]. Science, 2022, 376(6594): 738-743. |

| 134 | Toy L G, Nagai K, Freeman B D, et al. Pure-gas and vapor permeation and sorption properties of poly[1-phenyl-2-[p-(trimethylsilyl)phenyl]acetylene](PTMSDPA)[J]. Macromolecules, 2000, 33(7): 2516-2524. |

| 135 | Zhou S N, Wang Z J, Wang M H, et al. Nanoporous boron nitride membranes for helium separation[J]. ACS Applied Nano Materials, 2019, 2(7): 4471-4479. |

| 136 | Atlaskin A A, Kryuchkov S S, Stepakova A N, et al. Experimental determination of the gas transport characteristics of polysulfone and poly(phenylene oxide) hollow fiber membranes in relation to noble gases[J]. Membranes and Membrane Technologies, 2023, 5(5): 352-359. |

| 137 | Alentiev A Y, Nikiforov R Y, Levin I S, et al. Gas transport properties of vinylidene fluoride-tetrafluoroethylene copolymers[J]. Membranes and Membrane Technologies, 2023, 5(6): 430-439. |

| [1] | 茅雨洁, 路晓飞, 锁显, 杨立峰, 崔希利, 邢华斌. 工业气体中微量氧深度脱除催化剂研究进展[J]. 化工学报, 2025, 76(5): 1997-2010. |

| [2] | 时任泽, 丁秋燕, 袁振军, 那健, 刘见华, 郭树虎, 赵雄, 李洪, 高鑫. 4N电子级二乙氧基甲基硅烷的纯化技术研究[J]. 化工学报, 2025, 76(5): 2186-2197. |

| [3] | 郭明钢, 杨晓航, 代岩, 米盼盼, 马世鑫, 贺高红, 肖武, 崔福军. 贫氦管输天然气提氦多元化产品耦合工艺优化设计[J]. 化工学报, 2025, 76(5): 2251-2261. |

| [4] | 李家顺, 李旺, 秦祖赠, 苏通明, 谢新玲, 纪红兵. 聚酰亚胺增强木质纤维素纳米纤丝气凝胶制备及其油水分离性能研究[J]. 化工学报, 2025, 76(5): 2169-2185. |

| [5] | 胡嘉朗, 姜明源, 金律铭, 张永刚, 胡鹏, 纪红兵. 机器学习辅助MOFs高通量计算筛选及气体分离研究进展[J]. 化工学报, 2025, 76(5): 1973-1996. |

| [6] | 何燎, 李俊, 高梦舒, 刘东阳, 张宇豪, 赵亮, 高金森, 徐春明. 石油烃中芳烃分离技术研究进展[J]. 化工学报, 2025, 76(5): 1909-1926. |

| [7] | 徐泽海, 刘超, 张国亮. 聚合物基疏水渗透汽化膜及其溶剂回收应用[J]. 化工学报, 2025, 76(5): 2055-2069. |

| [8] | 王金月, 谢恩泽, 马翰泽, 袁晟, 何光伟, 姜忠义. 单原子层分离膜:进展与展望[J]. 化工学报, 2025, 76(5): 1943-1959. |

| [9] | 陆艳秋, 狄扬, 石文博, 殷聪聪, 汪勇. 基于新型有机多孔聚合物的智能响应膜研究进展[J]. 化工学报, 2025, 76(5): 2101-2118. |

| [10] | 陶春珲, 李印辉, 傅钰, 段然, 赵泽一, 唐羽丰, 张罡, 马和平. 不同吸附剂对低浓度Kr气的选择性吸附与纯化[J]. 化工学报, 2025, 76(5): 2358-2366. |

| [11] | 赵浩帆, 任豪杰, 刘宗凯, 董冠英, 张亚涛. MOFs玻璃膜在气体分离领域的研究进展[J]. 化工学报, 2025, 76(5): 2042-2054. |

| [12] | 张越, 刘佳鑫, 马敬, 刘毅. 金属有机骨架膜应用于海水提铀研究进展[J]. 化工学报, 2025, 76(5): 2087-2100. |

| [13] | 郭彭涛, 王婷, 薛波, 应允攀, 刘大欢. 用于CH4/N2分离的多吸附位点超微孔MOF[J]. 化工学报, 2025, 76(5): 2304-2312. |

| [14] | 李紫鹃, 谭晓艳, 吴永盛, 杨陈怡, 陈红, 毕小刚, 刘捷, 喻发全. 分子模拟研究三维扭曲催化芳烃-降冰片烯环化聚合物膜的CO2/N2分离机理[J]. 化工学报, 2025, 76(5): 2348-2357. |

| [15] | 花敬贤, 罗宇荣, 顾亚伟, 吴婷婷, 潘宜昌, 邢卫红. 超薄取向ZIF-8膜的制备及乙烯/乙烷高效分离[J]. 化工学报, 2025, 76(5): 2209-2218. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号