化工学报 ›› 2025, Vol. 76 ›› Issue (8): 3915-3931.DOI: 10.11949/0438-1157.20250005

梁晓江( ), 陈薇薇, 罗佳南, 费浩天, 叶雪蕾, 李文豪, 聂勇(

), 陈薇薇, 罗佳南, 费浩天, 叶雪蕾, 李文豪, 聂勇( )

)

收稿日期:2025-01-02

修回日期:2025-03-04

出版日期:2025-08-25

发布日期:2025-09-17

通讯作者:

聂勇

作者简介:梁晓江(1988—),男,副教授,lxj0824@zjut.edu.cn

基金资助:

Xiaojiang LIANG( ), Weiwei CHEN, Jianan LUO, Haotian FEI, Xuelei YE, Wenhao LI, Yong NIE(

), Weiwei CHEN, Jianan LUO, Haotian FEI, Xuelei YE, Wenhao LI, Yong NIE( )

)

Received:2025-01-02

Revised:2025-03-04

Online:2025-08-25

Published:2025-09-17

Contact:

Yong NIE

摘要:

本文提出一种电场分散技术耦合管式填充床的新型气体分散方法,搭建了电分散器耦合管式填充床实验装置;并采用生物柴油-氮气上升流体系,通过高速摄像仪,开展气泡分散过程可视化研究,探究非均匀电场作用下荷电气泡的分散机制及其气泡群的分散特性。结果表明:在电场力作用下,气泡加速脱离,分散成多个粒径均一的荷电气泡;随着特征电场强度增加,气泡群的索特平均直径从1.80 mm减小到650 μm,呈现窄峰高斯分布。在此基础上,进一步将电分散器耦合管式填充床,考察特征电场强度、孔口气体流速、液体流速及填料类型对流经填充床前后荷电气泡群的二次分散影响规律。结果表明:电分散器的初始分散与填充床的二次分散具有较好的协同作用,填充床出口区的气泡单位体积数量密度基本稳定在(4.0 × 107)~(8.0 × 107)个/m3,气泡群的索特平均直径能够稳定在600~700 μm;此外,电分散管式填充床在不同工况下均具有良好的稳定性与适用性,在不改变气液比的条件下,通过改变特征电场强度可实现对荷电气泡的实时调控。研究结果为电分散耦合填充床技术在气液两相反应器中的应用与拓展提供了参考。

中图分类号:

梁晓江, 陈薇薇, 罗佳南, 费浩天, 叶雪蕾, 李文豪, 聂勇. 电分散管式填充床中荷电气泡的分散特性研究[J]. 化工学报, 2025, 76(8): 3915-3931.

Xiaojiang LIANG, Weiwei CHEN, Jianan LUO, Haotian FEI, Xuelei YE, Wenhao LI, Yong NIE. Dispersion characteristics of charged bubbles in an electric dispersion tubular packed bed[J]. CIESC Journal, 2025, 76(8): 3915-3931.

| 材料 | 密度/ (kg/m3) | 相对介电常数 | 表面张力/ (N/m) | 动力黏度/(mPa∙s) | 电导率/ (S/m) |

|---|---|---|---|---|---|

| 高纯氮气 | 1.18 | 1.00 | — | 1.79 × 10-2 | <10-15 |

| 生物柴油 | 879 | 1.98 | 3.20 × 10-2 | 5.21 | 2.00 × 10-8 |

表1 生物柴油和氮气的物理参数(25℃)

Table 1 Physical properties of biodiesel and nitrogen (25℃)

| 材料 | 密度/ (kg/m3) | 相对介电常数 | 表面张力/ (N/m) | 动力黏度/(mPa∙s) | 电导率/ (S/m) |

|---|---|---|---|---|---|

| 高纯氮气 | 1.18 | 1.00 | — | 1.79 × 10-2 | <10-15 |

| 生物柴油 | 879 | 1.98 | 3.20 × 10-2 | 5.21 | 2.00 × 10-8 |

| 填料 | 材料 | 比表面积/ (m2/m3) | 尺寸/mm | 空隙率/% |

|---|---|---|---|---|

| 金属西塔环 | 304丝网 | 1380 | ϕ3.0×3.0 | 94.9 |

| 陶瓷拉西环 | 陶瓷 | 900 | ϕ3.0×3.0×1.0 | 46.5 |

| 玻璃圆珠 | 玻璃 | 2000 | ϕ3.0 | 41.9 |

表2 填料物理参数

Table 2 Physical properties of packing

| 填料 | 材料 | 比表面积/ (m2/m3) | 尺寸/mm | 空隙率/% |

|---|---|---|---|---|

| 金属西塔环 | 304丝网 | 1380 | ϕ3.0×3.0 | 94.9 |

| 陶瓷拉西环 | 陶瓷 | 900 | ϕ3.0×3.0×1.0 | 46.5 |

| 玻璃圆珠 | 玻璃 | 2000 | ϕ3.0 | 41.9 |

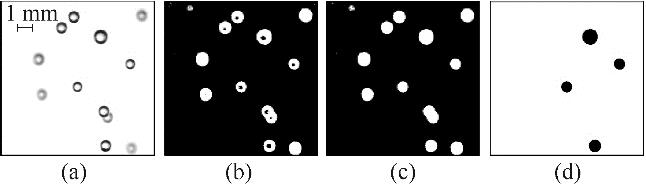

图2 图像处理流程图:(a)原始图片;(b)二值化;(c)填补空缺;(d)挑选气泡

Fig.2 Steps of image processing: (a) original image; (b) binarization; (c) fill the holes; (d) screen bubbles

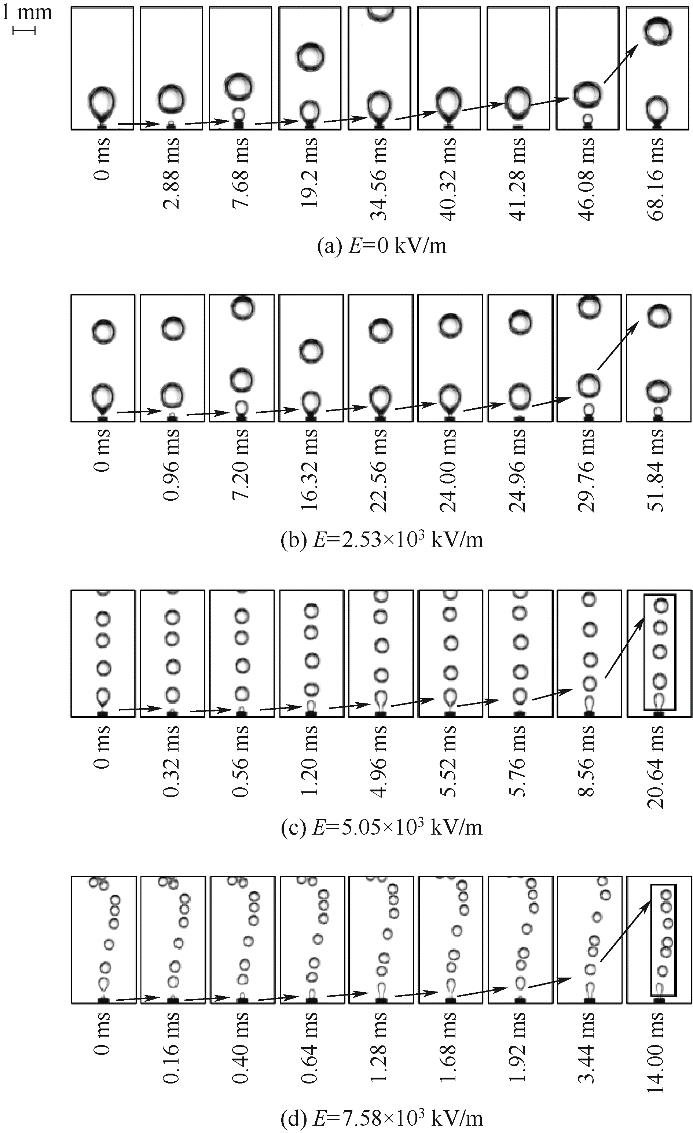

图4 电分散器中各特征电场强度下气泡演变时序图(uL=0.033 m/s,uG=1.062 m/s)

Fig.4 Bubble evolution sequence diagrams at varying electric field strength in an electro-disperser (uL=0.033 m/s, uG=1.062 m/s)

图6 电分散器出口处的荷电气泡群图片以及粒径分布(uL=0.033 m/s,uG=1.062 m/s)

Fig.6 Picture of the charged bubble cluster at the outlet of the electric dispersion and particle size distribution (uL=0.033 m/s, uG=1.062 m/s)

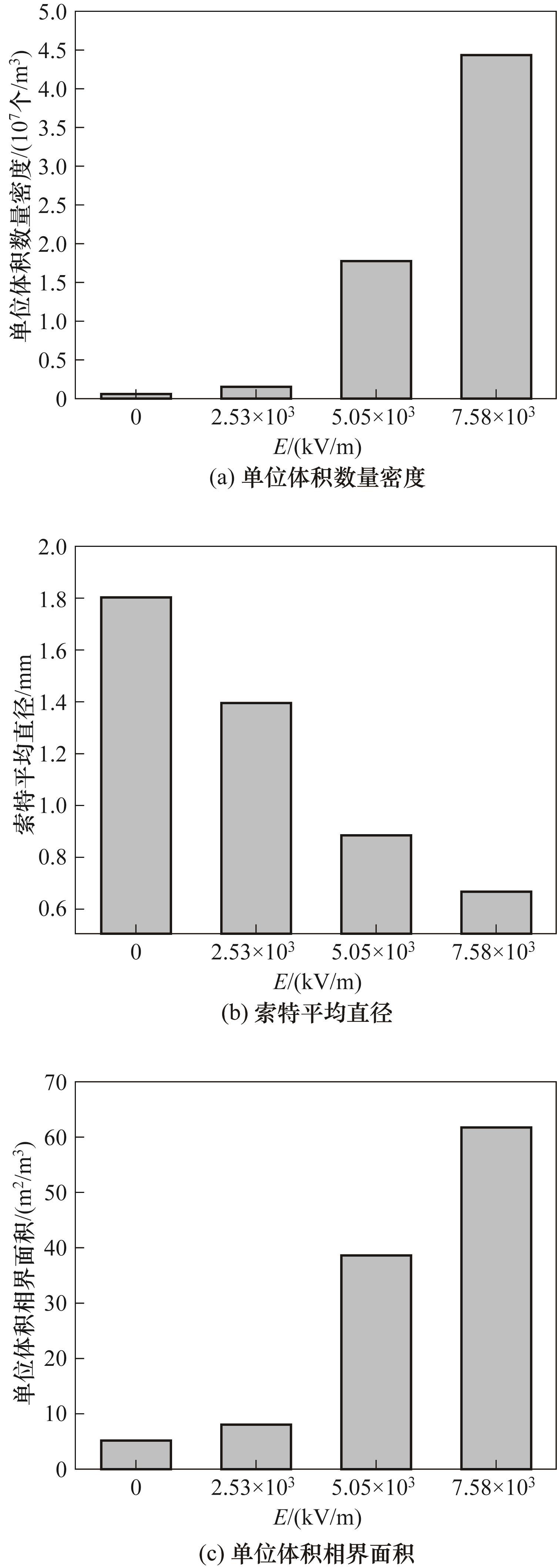

图7 电分散器出口处的荷电气泡群分散特性(uL=0.033 m/s,uG=1.062 m/s)

Fig.7 Charged microbubble population characteristics before entering the packing material (uL=0.033 m/s, uG=1.062 m/s)

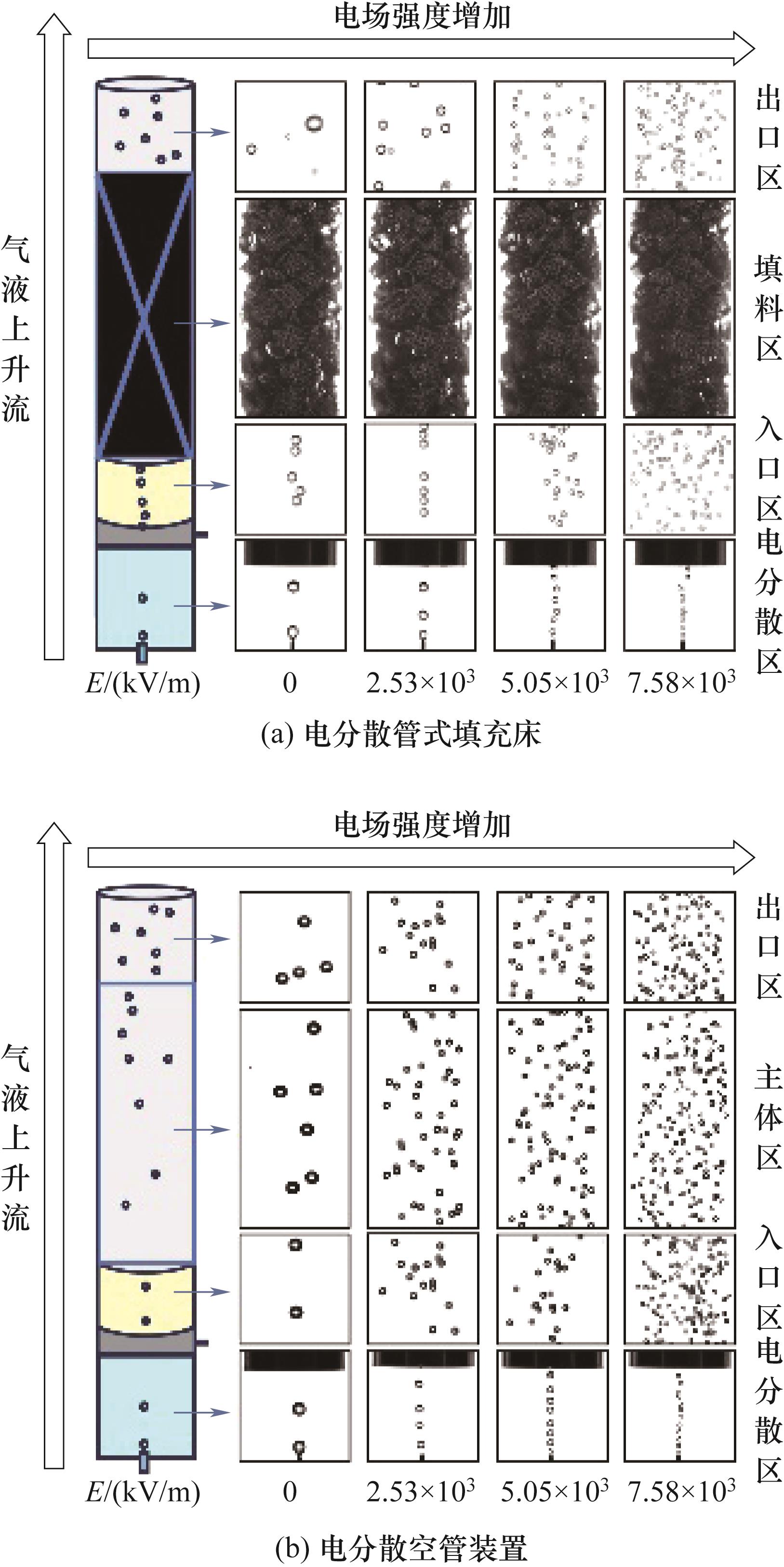

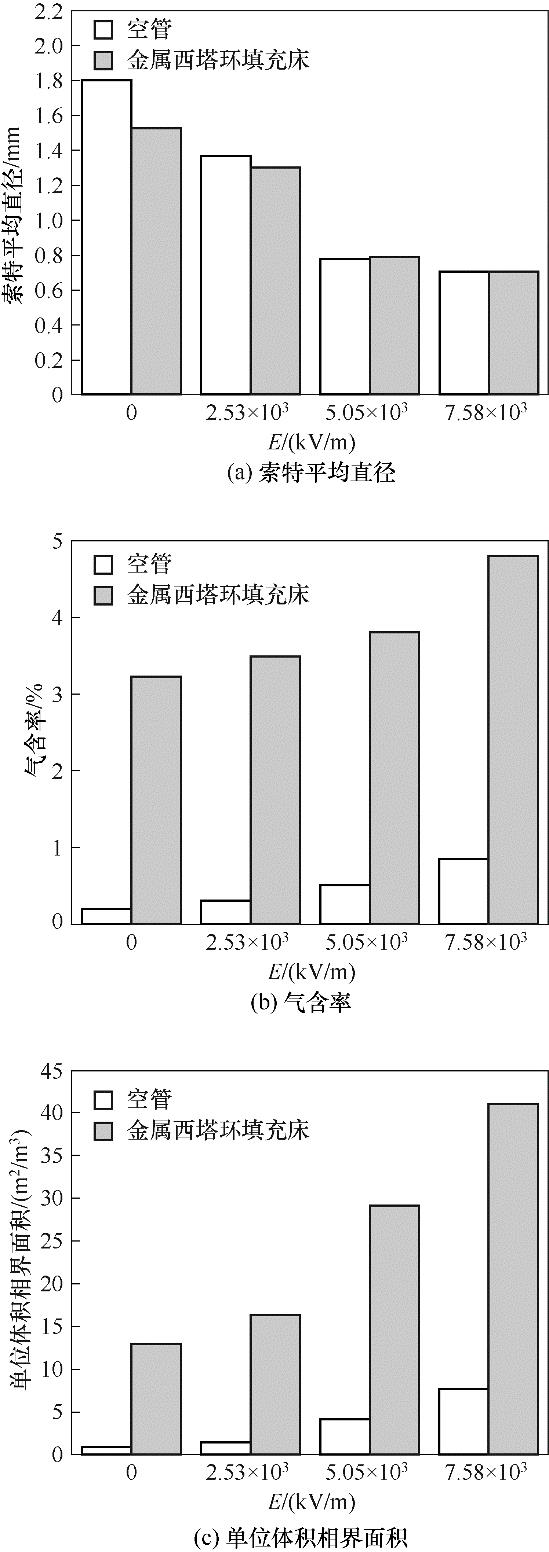

图8 不同特征电场强度下空管和电分散管式填充床中荷电气泡的分散特性对比(uL=0.033 m/s,uG=1.062 m/s)

Fig.8 Comparison of gas dispersion characteristics of electric dispersion empty tube device and electric dispersion tubular packed bed at different electric field strength (uL=0.033 m/s, uG=1.062 m/s)

图9 不同特征电场强度下电分散空管装置和电分散管式填充床装置的气体分散特性对比(uL=0.033 m/s,uG=1.062 m/s)

Fig.9 Comparison of gas dispersion characteristics of electric dispersion empty tubular packed bed and electric dispersion tubular packed bed at different electric field strength (uL=0.033 m/s, uG=1.062 m/s)

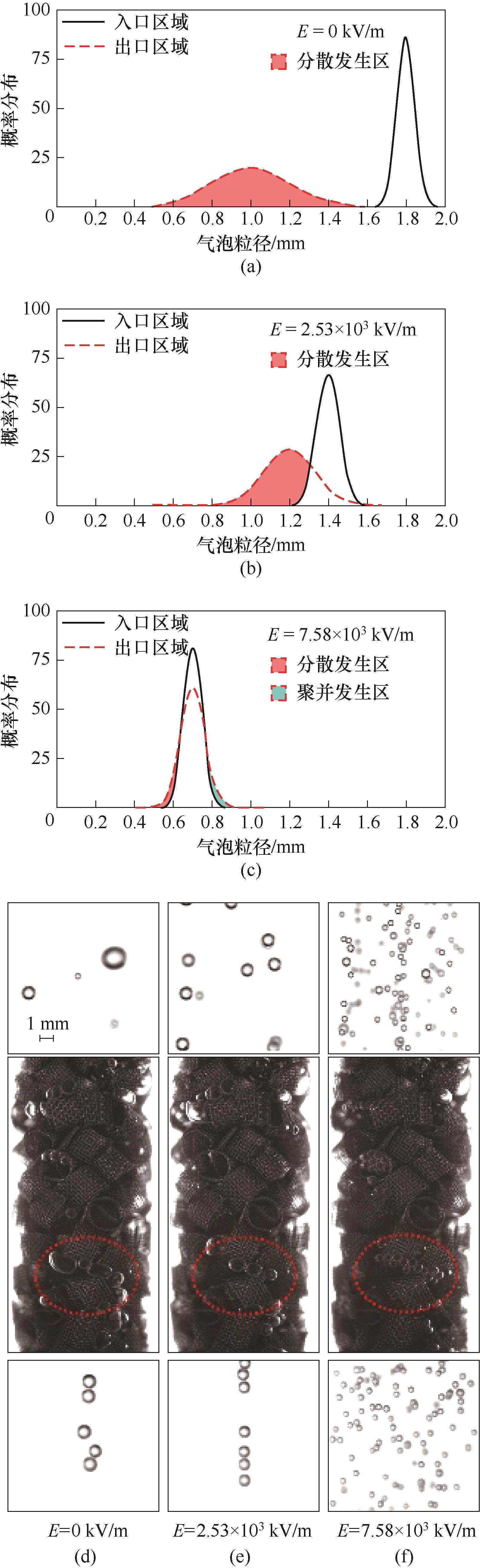

图10 不同特征电场强度下填料前后荷电气泡群粒径分布图及拍摄图(uL=0.033 m/s,uG=1.062 m/s)

Fig.10 Particle size distribution of charged bubble cluster before and after packing under three characteristic with and photographs with electric field strengths (uL=0.033 m/s, uG=1.062 m/s)

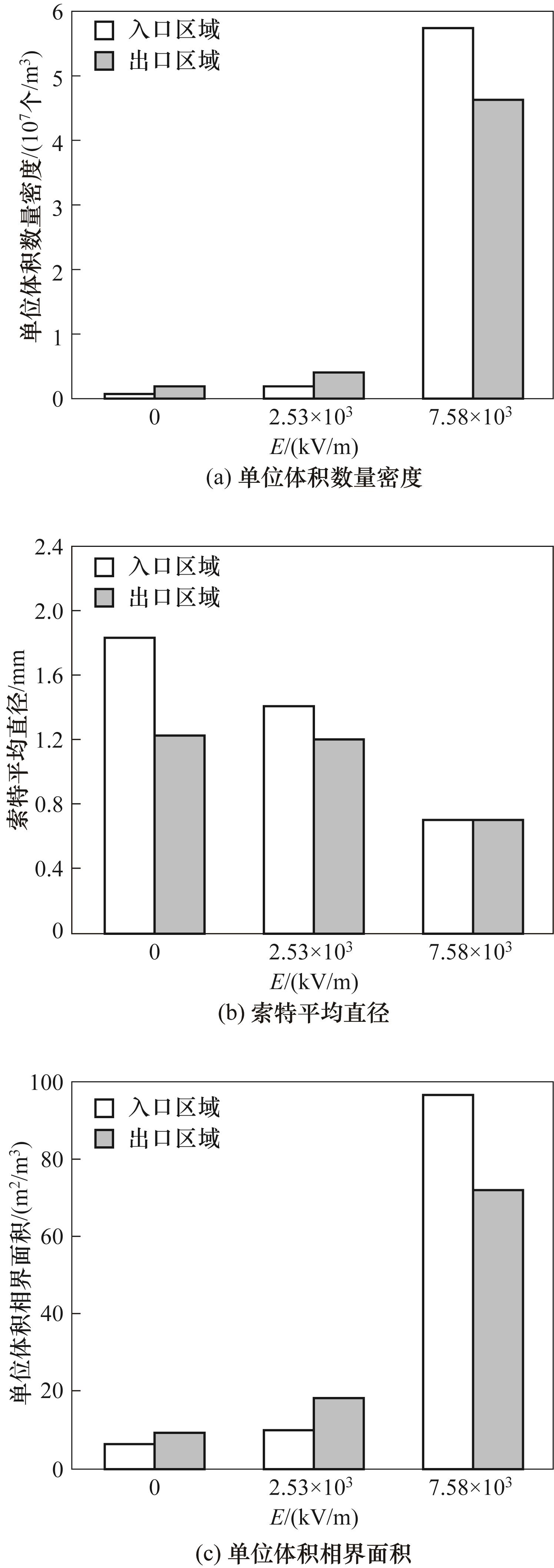

图11 不同特征电场强度下荷电气泡群经过填料前后分散特性变化(uL=0.033 m/s,uG=1.062 m/s)

Fig.11 Characteristic changes of charged microbubble populations before and after packing at various electric field strength (uL=0.033 m/s, uG=1.062 m/s)

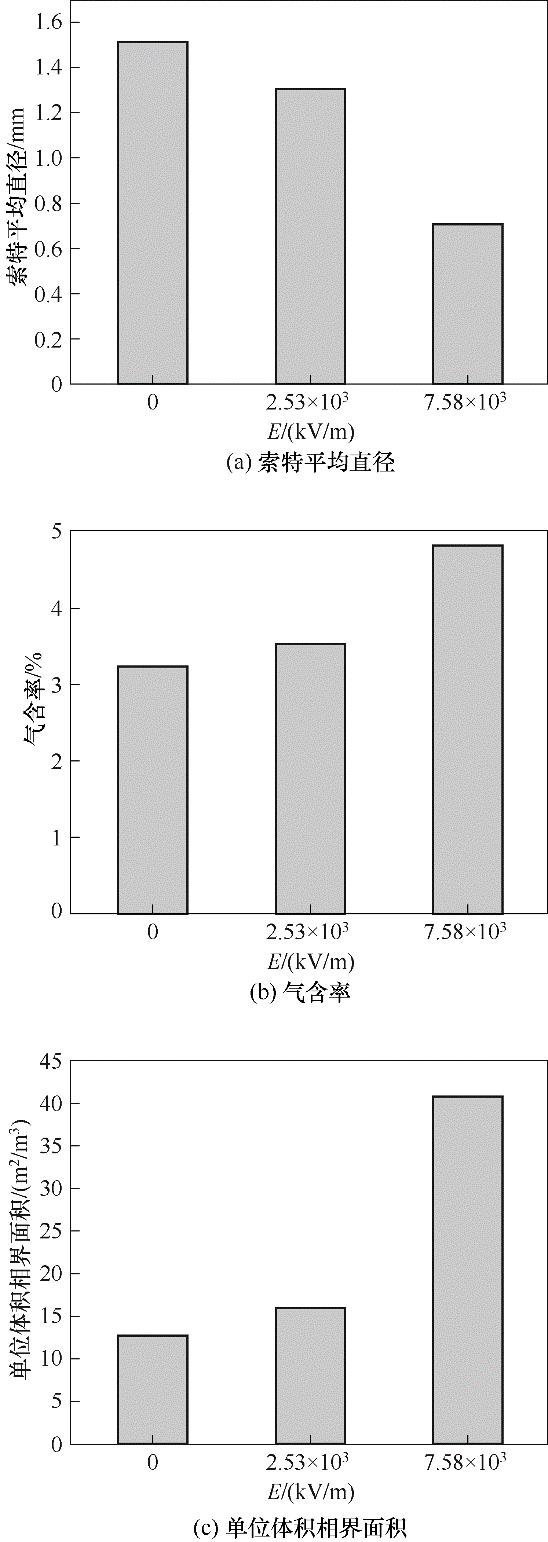

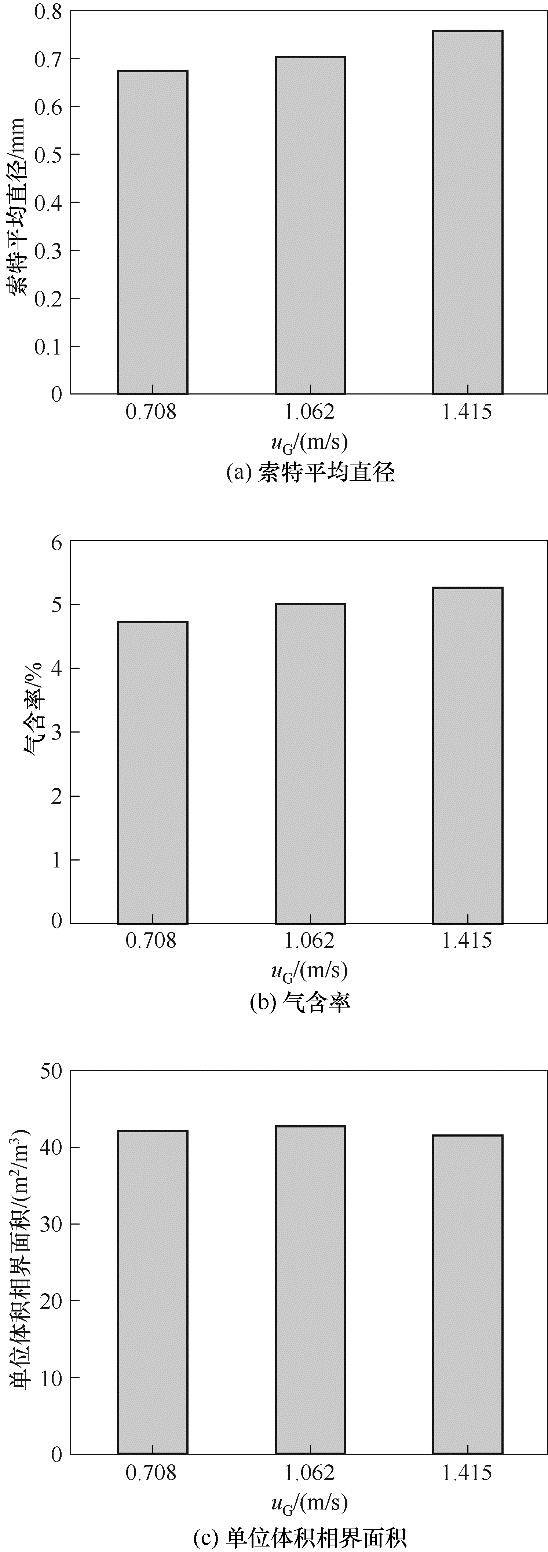

图12 不同特征电场强度下电分散管式填充床装置的气体分散特性(uL=0.033 m/s,uG=1.062 m/s)

Fig.12 Plot of gas dispersion characteristics of electric dispersion tubular packed bed with different characteristic electric field strengths (uL=0.033 m/s, uG=1.062 m/s)

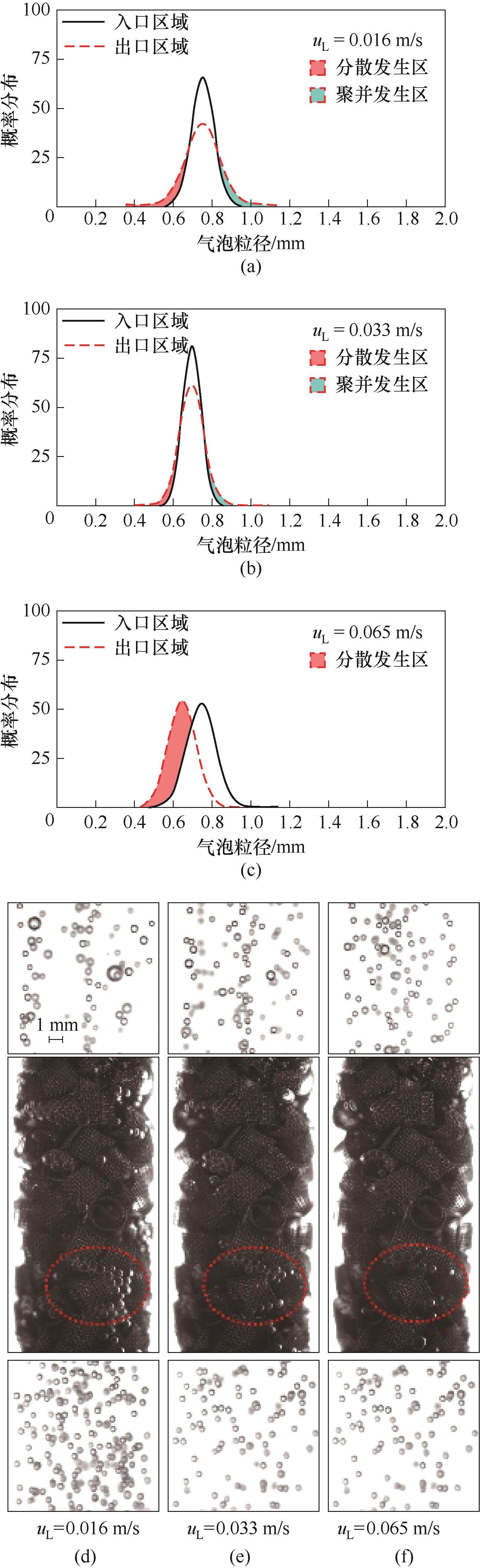

图13 三种液体流速时填料前后荷电气泡群粒径分布图及拍摄图(E=7.58 × 103 kV/m,uG=1.062 m/s)

Fig.13 Particle size distribution of charged bubble cluster before and after packing at three liquid flow rates and photographed (E=7.58 × 103 kV/m, uG=1.062 m/s)

图14 三种液体流速下荷电气泡群经过填料前后特性变化(uG=1.062 m/s,E=7.58 × 103 kV/m)

Fig.14 Characteristics of charged microbubble populations before and after packing at three liquid velocities (uG=1.062 m/s, E=7.58 × 103 kV/m)

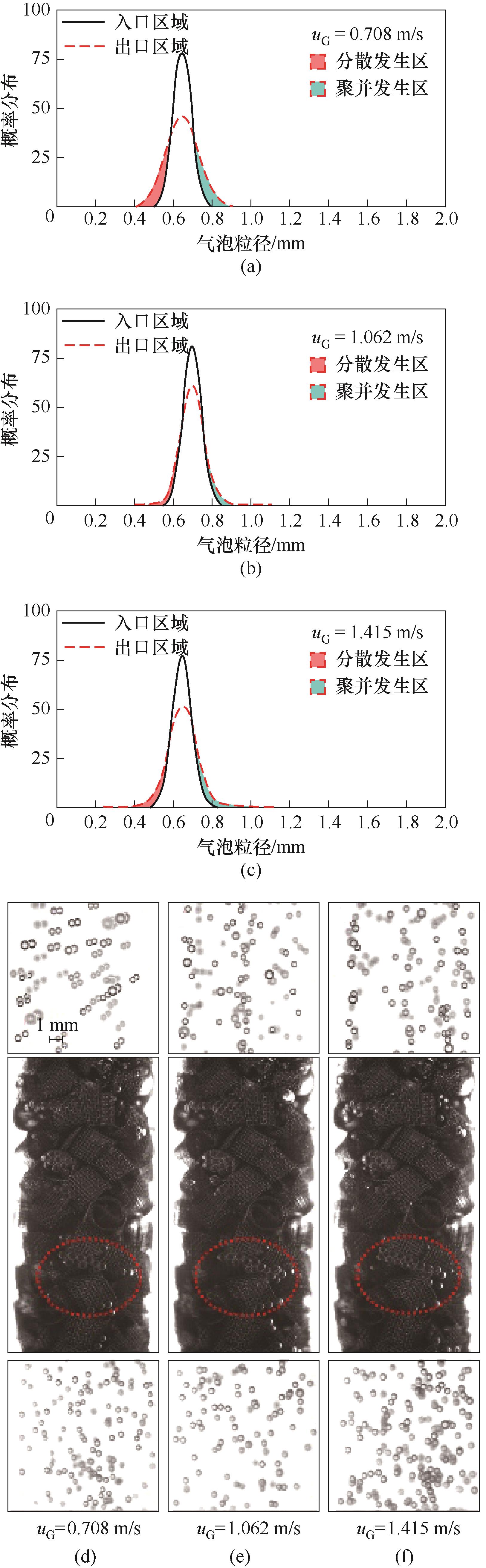

图15 三种液体流速下电分散管式填充床装置的气体分散特性 (uG=1.062 m/s,E=7.58 × 103 kV/m)

Fig.15 Plot of gas dispersion characteristics of electric dispersion tubular packed bed at three liquid flow rates (uG=1.062 m/s, E=7.58 × 103 kV/m)

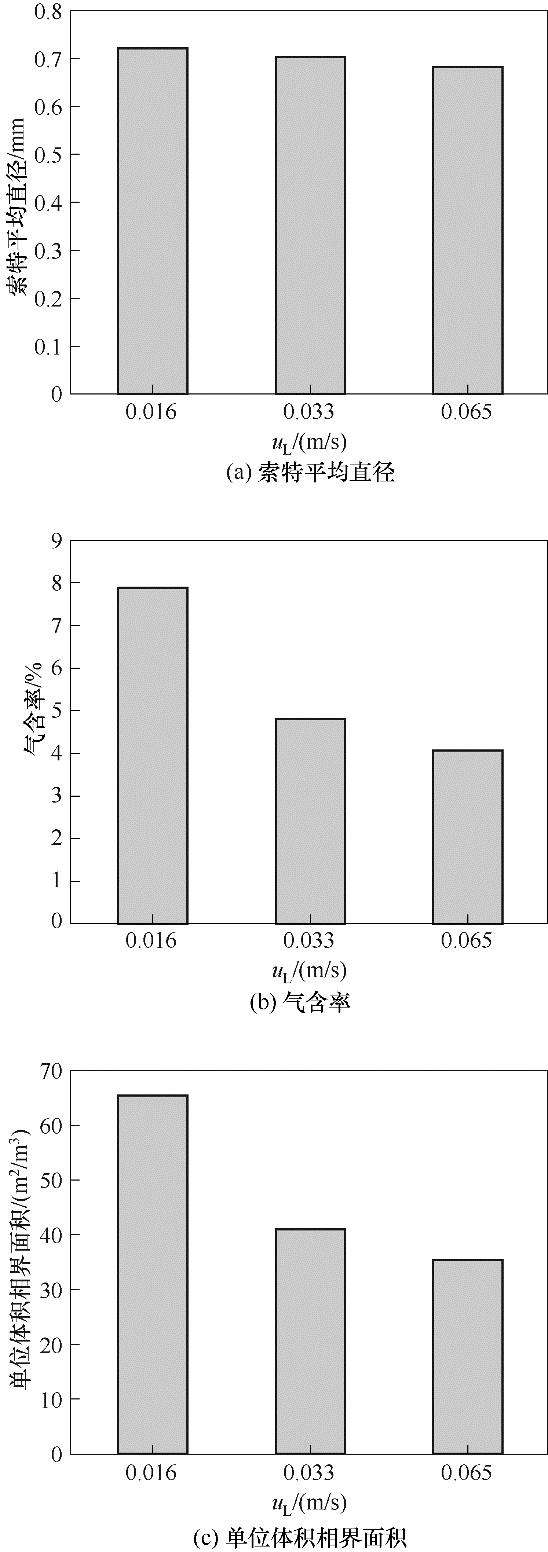

图16 三种孔口气体流速下填料前后荷电气泡群粒径分布图及拍摄图(E=7.58 × 103 kV/m,uL=0.033 m/s)

Fig.16 Particle size distribution of charged bubble groups before and after packing at three gas flow rates and photographed (E=7.58 × 103 kV/m, uL=0.033 m/s)

图17 三种孔口气体流速下荷电气泡群经过填料前后特性变化(uL=0.033 m/s,E=7.58 × 103 kV/m)

Fig.17 Characteristics of charged microbubble populations before and after packing at three gas velocities (uL=0.033 m/s,E=7.58 × 103 kV/m)

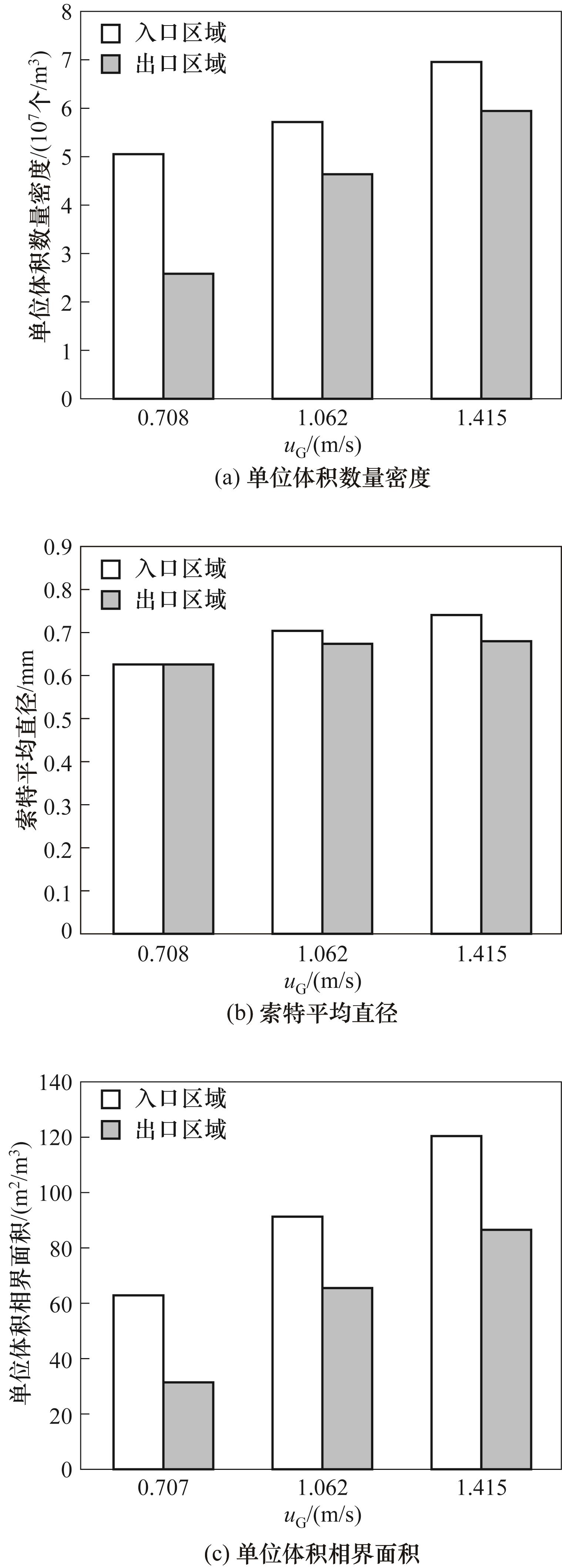

图18 三种孔口气体流速下电分散管式填充床装置的气体分散特性 (uL=0.033 m/s,E=7.58×103 kV/m)

Fig.18 Plot of gas dispersion characteristics of electric dispersion tubular packed bed for three orifice gas flow rates (uL=0.033 m/s, E=7.58 × 103 kV/m)

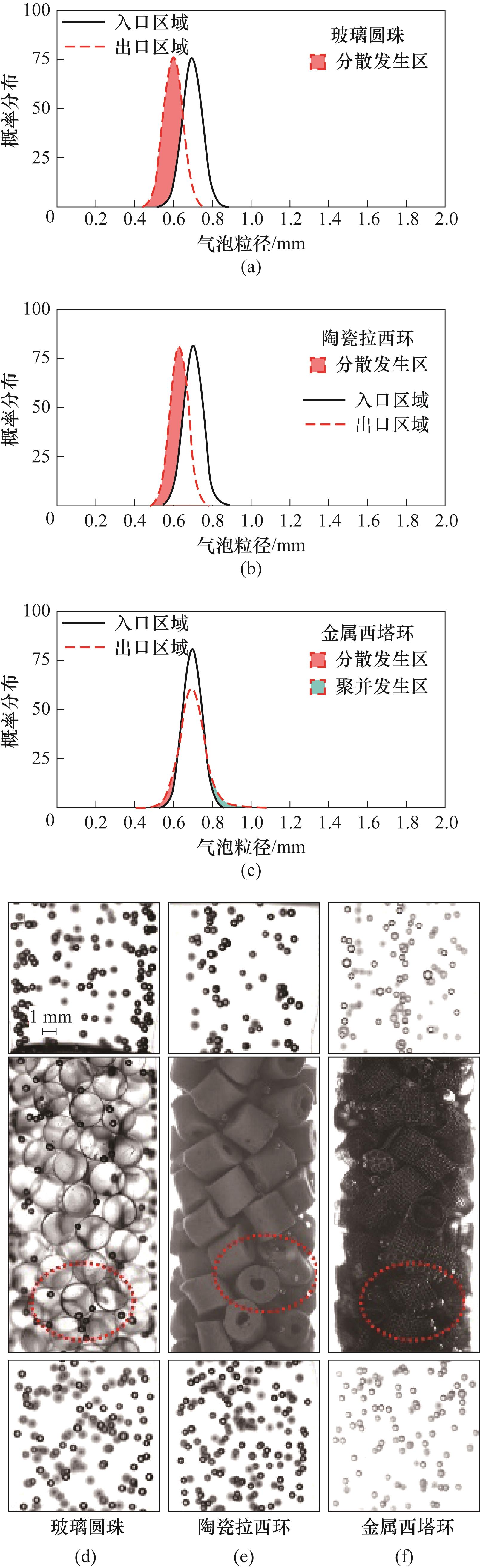

图19 荷电气泡群经过三种填料前后的气泡群粒径分布图及拍摄图(uG=1.062 m/s,uL=0.033 m/s,E=7.58 × 103 kV/m)

Fig.19 Particle size distribution of charged bubbles before and after passing through the three kinds of fillers and photographed images (uG=1.062 m/s, uL=0.033 m/s, E=7.58 × 103 kV/m)

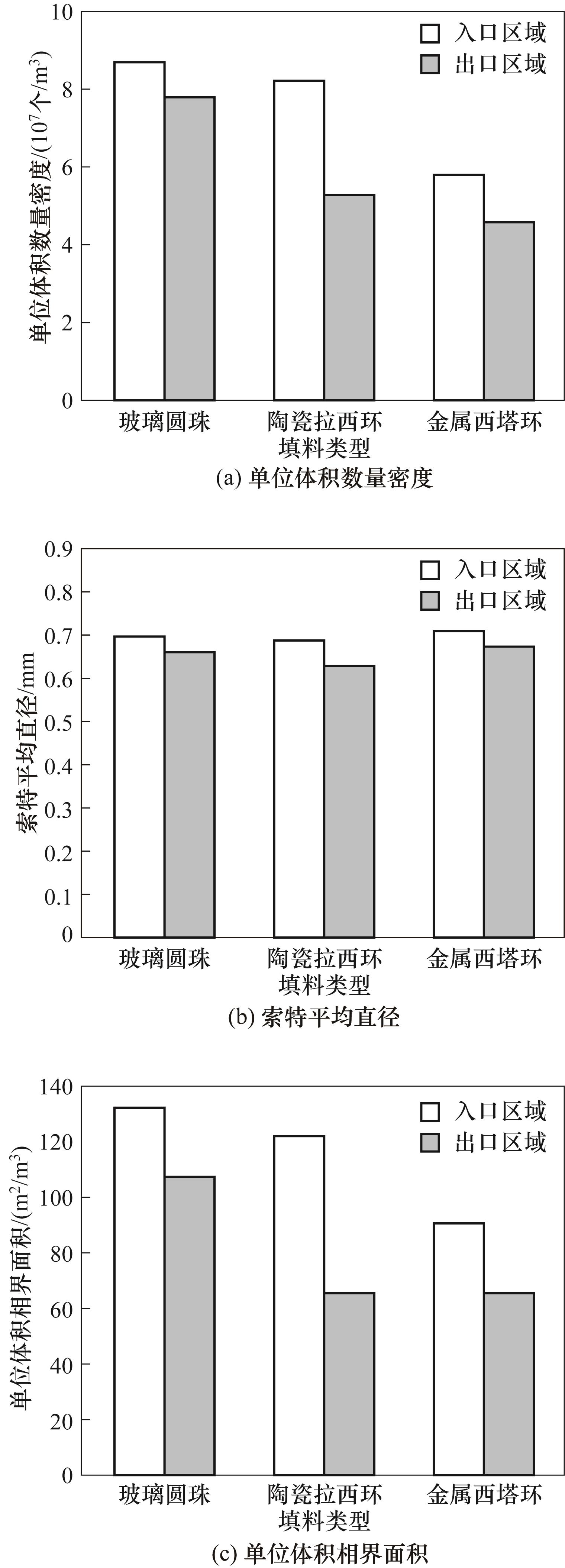

图20 三种填料前后荷电气泡群特性(uG=1.062 m/s,uL=0.033 m/s,E=7.58 × 103 kV/m)

Fig.20 Characteristics of charged microbubble populations before and after three kinds of packings (uG=1.062 m/s, uL=0.033 m/s, E=7.58 × 103 kV/m)

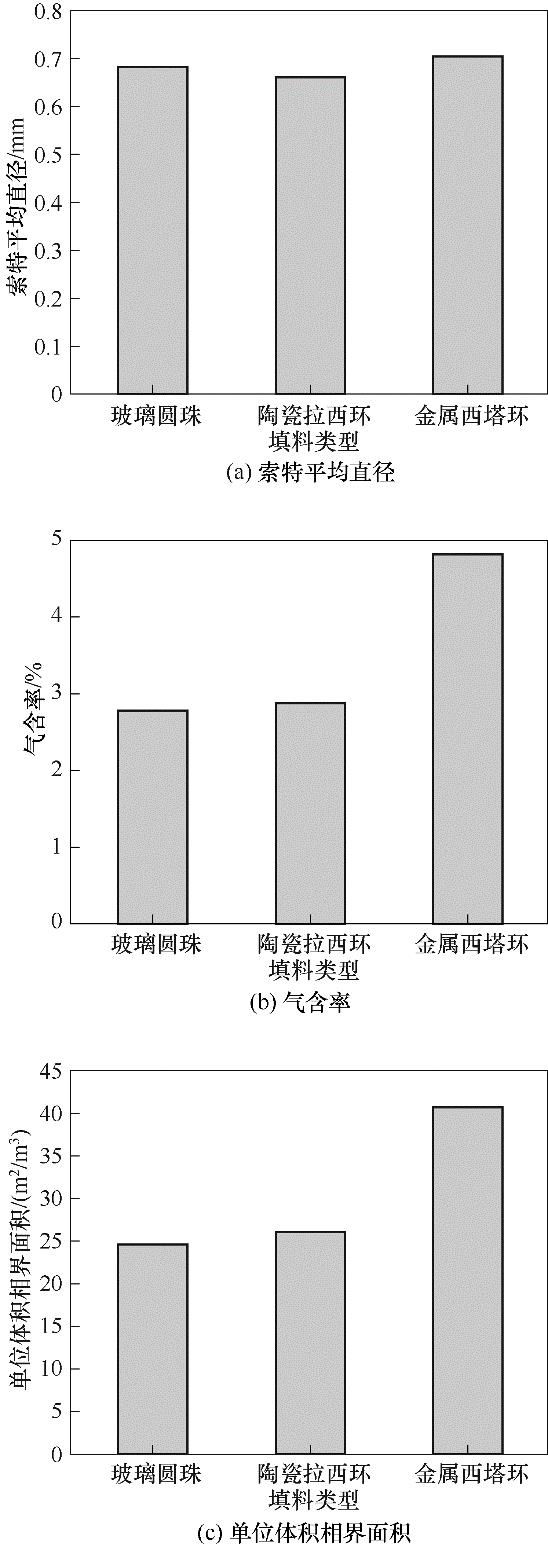

图21 三种填料类型下电分散管式填充床装置的气体分散特性(uG=1.062 m/s,uL=0.033 m/s,E=7.58 × 103 kV/m)

Fig.21 Plot of the overall gas dispersion characteristics of electric dispersion tubular packed bed with three types filler (uG=1.062 m/s, uL=0.033 m/s, E=7.58 × 103 kV/m)

| [1] | 于嘉朋, 徐娜, 张玮, 等. 微反应器内气液磺化反应收率和能耗建模及多目标优化[J]. 化工学报, 2024, 75(10): 3681-3690. |

| Yu J P, Xu N, Zhang W, et al. Modeling and multi-objective optimization of yield and energy consumption of gas-liquid sulfonation reaction in microreactor[J]. CIESC Journal, 2024, 75(10): 3681-3690. | |

| [2] | 田洪舟, 杨高东, 杨国强, 等. 微界面强化重油浆态床低压加氢的传质基础[J]. 化工学报, 2020, 71(11): 4927-4935. |

| Tian H Z, Yang G D, Yang G Q, et al. Mass transfer basis of low-pressure hydrogenation for heavy oil in microinterface-intensified slurry-bed reactor[J]. CIESC Journal, 2020, 71(11): 4927-4935. | |

| [3] | Leonard C, Ferrasse J H, Boutin O, et al. Bubble column reactors for high pressures and high temperatures operation[J]. Chemical Engineering Research and Design, 2015, 100: 391-421. |

| [4] | Kantarci N, Borak F, Ulgen K O. Bubble column reactors[J]. Process Biochemistry, 2005, 40(7): 2263-2283. |

| [5] | Hernandez-Alvarado F, Kalaga D V, Turney D, et al. Void fraction, bubble size and interfacial area measurements in co-current downflow bubble column reactor with microbubble dispersion[J]. Chemical Engineering Science, 2017, 168: 403-413. |

| [6] | Huang J, Sun L C, Liu H T, et al. A review on bubble generation and transportation in Venturi-type bubble generators[J]. Experimental and Computational Multiphase Flow, 2020, 2(3): 123-134. |

| [7] | Maluta F, Alberini F, Paglianti A, et al. Hydrodynamics, power consumption and bubble size distribution in gas-liquid stirred tanks[J]. Chemical Engineering Research and Design, 2023, 194: 582-596. |

| [8] | 崔怡洲, 李成祥, 翟霖晓, 等. 亚毫米气泡和常规尺寸气泡气液两相流流动与传质特性对比[J]. 化工学报, 2024, 75(1): 197-210. |

| Cui Y Z, Li C X, Zhai L X, et al. Comparative study on the flow and mass transfer characteristics of sub-millimeter bubbles and conventional bubbles in gas-liquid two-phase flow[J]. CIESC Journal, 2024, 75(1): 197-210. | |

| [9] | Kim Y B, Lee H S, Francis L, et al. Innovative swirling flow-type microbubble generator for multi-stage DCMD desalination system: focus on the two-phase flow pattern, bubble size distribution, and its effect on MD performance[J]. Journal of Membrane Science, 2019, 588: 117197. |

| [10] | 黄正梁, 郭晓云, 帅云, 等. 射流鼓泡反应器内气液分散状态检测[J]. 化工学报, 2019, 70(10): 3906-3913. |

| Huang Z L, Guo X Y, Shuai Y, et al. Detection of gas-liquid dispersion in jet bubbling reactor[J]. CIESC Journal, 2019, 70(10): 3906-3913. | |

| [11] | 张怡青, 陈家庆, 丁国栋, 等. 溶气释放式微细气泡发生技术的溶气机理与设备研究进展[J]. 北京石油化工学院学报, 2022, 30(1): 13-25, 30. |

| Zhang Y Q, Chen J Q, Ding G D, et al. Research progress on air-dissolving mechanism and device structure of pressurized dissolution type microbubble generator[J]. Journal of Beijing Institute of Petrochemical Technology, 2022, 30(1): 13-25, 30. | |

| [12] | 陈日志, 姜红, 范益群, 等. 膜分散技术及其强化反应过程的研究进展[J]. 化工进展, 2020, 39(12): 4812-4822. |

| Chen R Z, Jiang H, Fan Y Q, et al. Perspective on membrane dispersion technology and its enhanced reaction processes[J]. Chemical Industry and Engineering Progress, 2020, 39(12): 4812-4822. | |

| [13] | Bouaifi M, Hebrard G, Bastoul D, et al. A comparative study of gas hold-up, bubble size, interfacial area and mass transfer coefficients in stirred gas-liquid reactors and bubble columns[J]. Chemical Engineering and Processing: Process Intensification, 2001, 40(2): 97-111. |

| [14] | Zhao W D, Yao J W, Zhang X Y, et al. Review on the progress of the first-generation biodiesel hydrogenation and upgrading[J]. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2020, 42(21): 2704-2714. |

| [15] | Ball J C, Anderson J E, Sears V A, et al. Model reactions involving ester functional groups during thermo-oxidative degradation of biodiesel[J]. Journal of the American Oil Chemists' Society, 2019, 96(10): 1153-1161. |

| [16] | He Y, Zhang T, Lv L, et al. Application of microbubbles in chemistry, wastewater treatment, medicine, cosmetics, and agriculture: a review[J]. Environmental Chemistry Letters, 2023, 21(6): 3245-3271. |

| [17] | Babaeva N Y, Tereshonok D V, Naidis G V. Initiation of breakdown in bubbles immersed in liquids: pre-existed charges versus bubble size[J]. Journal of Physics D: Applied Physics, 2015, 48(35): 355201. |

| [18] | Ogata S, Tan K, Nishijima K, et al. Development of improved bubble disruption and dispersion technique by an applied electric field method[J]. AIChE Journal, 1985, 31(1): 62-69. |

| [19] | Rahmat A, Tofighi N, Yildiz M. Numerical simulation of the electrohydrodynamic effects on bubble rising using the SPH method[J]. International Journal of Heat and Fluid Flow, 2016, 62: 313-323. |

| [20] | Pandey V, Dalal A, Biswas G. Bubble formation in film boiling including electrohydrodynamic forces[J]. Procedia IUTAM, 2015, 15: 86-94. |

| [21] | Akira Y, Hiroshi M. Augmentation of convective and boiling heat transfer by applying an electro-hydrodynamical liquid jet[J]. International Journal of Heat and Mass Transfer, 1988, 31(2): 407-417. |

| [22] | Dong W, Li R Y, Yu H L, et al. An investigation of behaviours of a single bubble in a uniform electric field[J]. Experimental Thermal and Fluid Science, 2006, 30(6): 579-586. |

| [23] | Zu Y Q, Yan Y Y. A numerical investigation of electrohydrodynamic (EHD) effects on bubble deformation under pseudo-nucleate boiling conditions[J]. International Journal of Heat and Fluid Flow, 2009, 30(4): 761-767. |

| [24] | Liu Z, Herman C, Mewes D. Visualization of bubble detachment and coalescence under the influence of a nonuniform electric field[J]. Experimental Thermal and Fluid Science, 2006, 31(2): 151-163. |

| [25] | Zhang W, Wang J F, Li B, et al. Experimental investigation on bubble coalescence regimes under non-uniform electric field[J]. Chemical Engineering Journal, 2021, 417: 127982. |

| [26] | Wang J F, Han J F, Wu T Y, et al. Bubble deformation and breakup in a non-uniform electric field[J]. Chemical Engineering Science, 2024, 287: 119741. |

| [27] | Zuo L, Wang J F, Mei D Q, et al. Atomization and combustion characteristics of a biodiesel-ethanol fuel droplet in a uniform DC electric field[J]. Physics of Fluids, 2023, 35(1): 013303. |

| [28] | Zhang W, Wang J F, Wang Z T, et al. Review of bubble dynamics on charged liquid-gas flow[J]. Physics of Fluids, 2023, 35(2): 021302. |

| [29] | Li B, Wang Z T, Vivacqua V, et al. Drop-interface electrocoalescence mode transition under a direct current electric field[J]. Chemical Engineering Science, 2020, 213: 115360. |

| [30] | Wang D B, Wang J F, Yongphet P, et al. Experimental study on electric-field-induced droplet generation and breakup in an immiscible medium[J]. Experiments in Fluids, 2020, 61(3): 78. |

| [31] | Liang X J, Luo J N, Chen W W, et al. Characteristics of bubble dispersion under nonuniform electric field in an up-flow bubbling system: from charged bubble to charged bubble cluster[J]. Industrial & Engineering Chemistry Research, 2024, 63(44): 19289-19299. |

| [32] | Hijano A J, Loscertales I G, Ibáñez S E, et al. Periodic emission of droplets from an oscillating electrified meniscus of a low-viscosity, highly conductive liquid[J]. Physical Review. E, Statistical, Nonlinear, and Soft Matter Physics, 2015, 91(1): 013011. |

| [33] | Landau L D, Lifshitz E M, Sykes J B, et al. Electrodynamics of continuous media[J]. Physics Today, 1961, 14(10): 48-50. |

| [34] | Di Marco P, Grassi W, Memoli G, et al. Influence of electric field on single gas-bubble growth and detachment in microgravity[J]. International Journal of Multiphase Flow, 2003, 29(4): 559-578. |

| [35] | Zaghdoudi M C, Lallemand M. Study of the behaviour of a bubble in an electric field: steady shape and local fluid motion[J]. International Journal of Thermal Sciences, 2000, 39(1): 39-52. |

| [36] | Zhou Y T, Li B, Zhang M Y, et al. Effect of dielectrophoresis on the coalescence of binary droplets under a non-uniform electric field[J]. Chemical Engineering Science, 2020, 224: 115739. |

| [37] | Di Marco P, Kurimoto R, Saccone G, et al. Bubble shape under the action of electric forces[J]. Experimental Thermal and Fluid Science, 2013, 49: 160-168. |

| [38] | Zhang W, Wang J F, Li B, et al. EHD effects on periodic bubble formation and coalescence in ethanol under non-uniform electric field[J]. Chemical Engineering Science, 2020, 215: 115451. |

| [39] | Parmar R, Majumder S K. Microbubble generation and microbubble-aided transport process intensification: a state-of-the-art report[J]. Chemical Engineering and Processing: Process Intensification, 2013, 64: 79-97. |

| [40] | Muilwijk C, Van den Akker H E A. Experimental investigation on the bubble formation from needles with and without liquid co-flow[J]. Chemical Engineering Science, 2019, 202: 318-335. |

| [41] | Baltussen M W, Kuipers J A M, Deen N G. A numerical study of cutting bubbles with a wire mesh[J]. Chemical Engineering Science, 2017, 165: 25-32. |

| [42] | Jain D, Lau Y M, Kuipers J A M, et al. Discrete bubble modeling for a micro-structured bubble column[J]. Chemical Engineering Science, 2013, 100: 496-505. |

| [43] | Chen G H, Zhang Z C, Gao F, et al. Experimental studies of bubble cutting in a lab-scale micro-structured bubble column with different liquid viscosity[J]. Korean Journal of Chemical Engineering, 2022, 39(8): 2044-2054. |

| [1] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [2] | 曹庆泰, 郭松源, 李建强, 蒋赞, 汪彬, 耑锐, 吴静怡, 杨光. 负过载下多孔隔板对液氧贮箱蓄液性能的影响研究[J]. 化工学报, 2025, 76(S1): 217-229. |

| [3] | 燕子腾, 詹飞龙, 丁国良. 空调用套管式分流器结构设计及分流效果验证[J]. 化工学报, 2025, 76(S1): 152-159. |

| [4] | 段浩磊, 陈浩远, 梁坤峰, 王林, 陈彬, 曹勇, 张晨光, 李硕鹏, 朱登宇, 何亚茹, 杨大鹏. 纯电动车热管理系统低GWP工质替代方案性能分析与综合评价[J]. 化工学报, 2025, 76(S1): 54-61. |

| [5] | 王俊鹏, 冯佳琪, 张恩搏, 白博峰. 曲折式与阵列式迷宫阀芯结构内流动与空化特性研究[J]. 化工学报, 2025, 76(S1): 93-105. |

| [6] | 王御风, 罗小雪, 范鸿亮, 吴白婧, 李存璞, 魏子栋. 耦合电解水制氢的绿色有机电合成——电极界面调控策略综述[J]. 化工学报, 2025, 76(8): 3753-3771. |

| [7] | 张淇栋, 艾立强, 马原, 吴胜宝, 王磊, 厉彦忠. 基于一维漂移流模型的低温管路预冷过程两相流动与换热特性研究[J]. 化工学报, 2025, 76(8): 3842-3852. |

| [8] | 朱紫橙, 焦云鹏, 刘梦溪, 陈建华. 三相流化床内分布器与挡板效应的模拟分析[J]. 化工学报, 2025, 76(8): 3873-3884. |

| [9] | 巢欣旖, 陈文尧, 张晶, 钱刚, 周兴贵, 段学志. 甲醇和乙酸甲酯一步法制丙酸甲酯催化剂的可控制备与性能调控[J]. 化工学报, 2025, 76(8): 4030-4041. |

| [10] | 徐鹏国, 孟子衡, 朱干宇, 李会泉, 王晨晔, 孙振华, 田国才. 粗碳酸锂CO2微气泡深度碳化工艺与动力学研究[J]. 化工学报, 2025, 76(7): 3325-3338. |

| [11] | 米晓天, 刘宏臣, 王克军, 唐文娜, 徐永伟, 杨梅. 微通道内两相吸收剂TETA/DEEA吸收CO2过程的传质研究[J]. 化工学报, 2025, 76(6): 2667-2677. |

| [12] | 何昌秋, 田加猛, 陈义齐, 朱宇琛, 刘鑫, 王海, 王贞涛, 王军锋, 周致富, 陈斌. 电场-宏观结构表面协同强化薄液膜沸腾传热特性[J]. 化工学报, 2025, 76(6): 2589-2602. |

| [13] | 李艳, 雷美丽, 李鑫钢. 基于分离性能的顺序式模拟移动床结构调控策略[J]. 化工学报, 2025, 76(5): 2219-2229. |

| [14] | 赵浩帆, 任豪杰, 刘宗凯, 董冠英, 张亚涛. MOFs玻璃膜在气体分离领域的研究进展[J]. 化工学报, 2025, 76(5): 2042-2054. |

| [15] | 张翼辰, 张文彪, 李浩洋, 宁晓阳. 基于双差压模型的文丘里管气液两相CO2流量测量[J]. 化工学报, 2025, 76(4): 1493-1503. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号