化工学报 ›› 2025, Vol. 76 ›› Issue (11): 5877-5889.DOI: 10.11949/0438-1157.20250570

收稿日期:2025-05-24

修回日期:2025-07-25

出版日期:2025-11-25

发布日期:2025-12-19

通讯作者:

罗小平

作者简介:罗小平(1967—),男,博士,教授,mmxpluo@scut.edu.cn

基金资助:

Xiaoping LUO( ), Lan XIAO, Jiayu ZHANG

), Lan XIAO, Jiayu ZHANG

Received:2025-05-24

Revised:2025-07-25

Online:2025-11-25

Published:2025-12-19

Contact:

Xiaoping LUO

摘要:

为了探究相分离结构对微细通道流动沸腾传热性能和均温性的影响,对三种相分离孔数(10孔N1型、20孔N2型、30孔N3型)和三种布置位置(中下游A型、上下游B型、上中下游C型)开展了研究。实验采用乙醇作为工质,在热通量15.05~124.89 kW/m²、工质入口温度40℃、质量流率102.50 kg/(m²·s)条件下,对2 mm×2 mm矩形逆流微细通道进行流动沸腾实验,通过脉动压力实现气相分离。引入强化传热因子、沿程壁温分布、壁面平均温度和温度标准差等参数分析相分离结构的影响。结果表明,跨膜压力一定时,相分离孔数为20时传热系数最大,孔数增加至30对传热提升有限。与无相分离工况相比,相分离结构使传热强化因子最大达1.92,沿程壁温标准差最大降低44%。这表明,相分离微细通道有效提升了传热效率和均温性。

中图分类号:

罗小平, 肖岚, 张嘉宇. 脉动压力作用下相分离结构微细通道流动沸腾传热[J]. 化工学报, 2025, 76(11): 5877-5889.

Xiaoping LUO, Lan XIAO, Jiayu ZHANG. Flow boiling heat transfer of phase separation structure microchannels under pulsating pressure[J]. CIESC Journal, 2025, 76(11): 5877-5889.

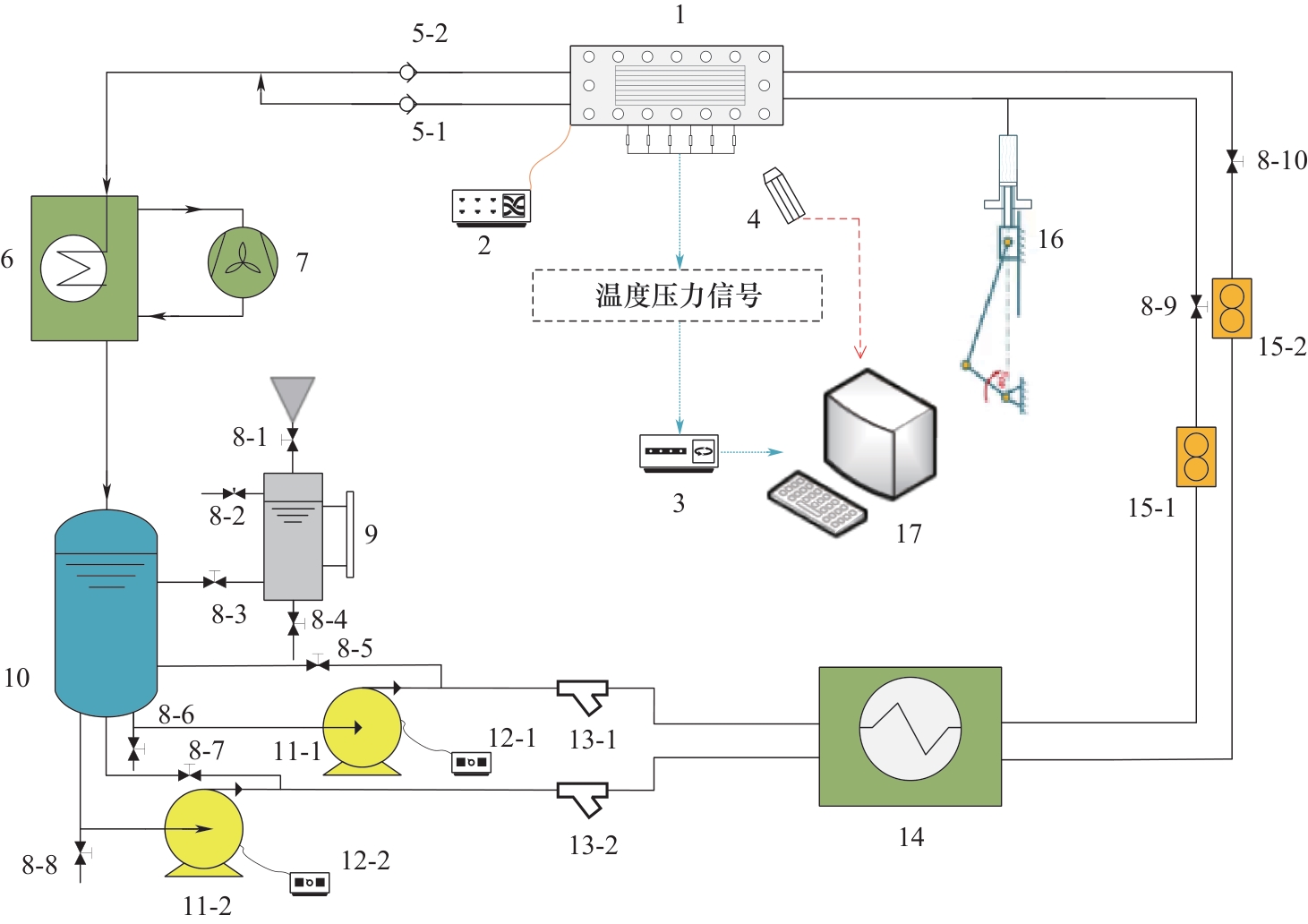

图1 实验装置示意图1—实验段; 2—直流高压静电发生器; 3—安捷伦数据采集仪; 4—高速摄像机; 5-1,5-2—单向阀; 6—冷水机组; 7—冷凝器; 8-1~8-10—针阀; 9—注液系统; 10—储液罐; 11-1,11-2—耐高温磁力泵; 12-1,12-2—调频器; 13-1,13-2—过滤器; 14—恒温水浴; 15-1,15-2—流量计; 16—脉动压力发生装置; 17—计算机

Fig.1 Schematic diagram of experimental system

饱和温度 Tsat/℃ | 液相密度 | 气相密度 | 液相黏度 | 液相热导率 | 液相比热容 cp,l /(J(kg·K)) | 汽化潜热 hf,g/(J/kg) | 表面张力 |

|---|---|---|---|---|---|---|---|

| 78.34 | 736.49 | 1.65 | 0.44 | 0.15 | 2.93 | 846.75 | 16.75 |

表1 乙醇物性参数

Table 1 Physical properties of ethanol

饱和温度 Tsat/℃ | 液相密度 | 气相密度 | 液相黏度 | 液相热导率 | 液相比热容 cp,l /(J(kg·K)) | 汽化潜热 hf,g/(J/kg) | 表面张力 |

|---|---|---|---|---|---|---|---|

| 78.34 | 736.49 | 1.65 | 0.44 | 0.15 | 2.93 | 846.75 | 16.75 |

| 测量仪器 | 测量值 | 设备型号 | 量程 | 精度 |

|---|---|---|---|---|

| 热电阻 | 温度/℃ | PT-100 | 0~200 | 0.1℃ |

| 转子流量计 | 流量/(L/h) | LZB-WS-10 | 6~60 | 2.5% |

| 压力传感器 | 压力/kPa | HY-131 | 0~100 | 0.2% |

| 直流高压静电发生器 | 电压/kV | DW-P503 | 0~50 | 0.5% |

表2 仪器精度

Table 2 Instrument accuracy

| 测量仪器 | 测量值 | 设备型号 | 量程 | 精度 |

|---|---|---|---|---|

| 热电阻 | 温度/℃ | PT-100 | 0~200 | 0.1℃ |

| 转子流量计 | 流量/(L/h) | LZB-WS-10 | 6~60 | 2.5% |

| 压力传感器 | 压力/kPa | HY-131 | 0~100 | 0.2% |

| 直流高压静电发生器 | 电压/kV | DW-P503 | 0~50 | 0.5% |

| 测量物理参数 | 最大不确定度/% |

|---|---|

| 热通量qeff | 3.31 |

| 单相段长度Lsp | 2.76 |

| 质量流率G | 2.50 |

| 局部饱和传热系数h | 6.29 |

表3 间接物理量最大相对误差

Table 3 Maximum relative error of indirect physical quantities

| 测量物理参数 | 最大不确定度/% |

|---|---|

| 热通量qeff | 3.31 |

| 单相段长度Lsp | 2.76 |

| 质量流率G | 2.50 |

| 局部饱和传热系数h | 6.29 |

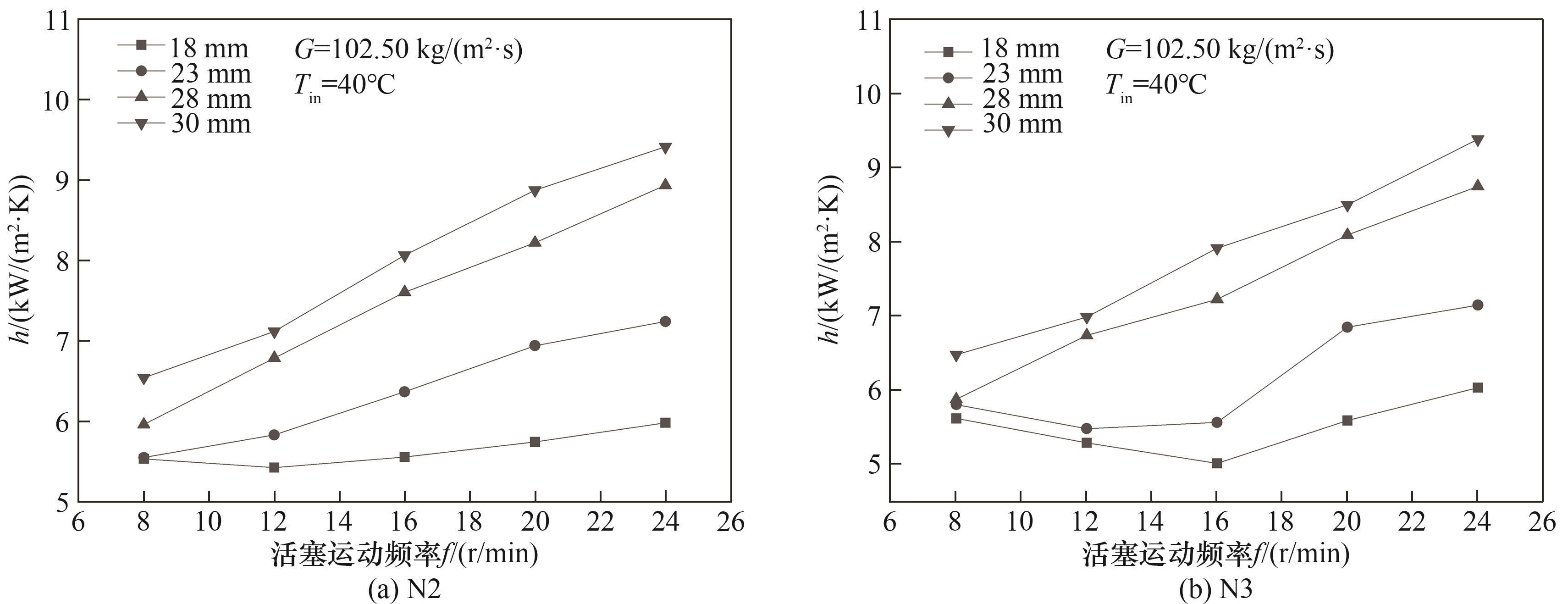

图10 不同类型脉动压力与相分离结构协同作用饱和沸腾传热系数

Fig. 10 Heat transfer coefficient of saturated boiling under the synergistic effect of different types of fluctuating pressure and phase separation structure

| 工况 | 热通量/(kW/m2) | 工况 | 热通量/(kW/m2) |

|---|---|---|---|

| A | 15.05 | H | 77.58 |

| B | 23.27 | I | 87.61 |

| C | 32.33 | J | 97.08 |

| D | 40.62 | K | 105.36 |

| E | 50.85 | L | 114.86 |

| F | 60.02 | M | 124.89 |

| G | 68.29 |

表4 热通量工况范围

Table 4 Operating range of heat flux density

| 工况 | 热通量/(kW/m2) | 工况 | 热通量/(kW/m2) |

|---|---|---|---|

| A | 15.05 | H | 77.58 |

| B | 23.27 | I | 87.61 |

| C | 32.33 | J | 97.08 |

| D | 40.62 | K | 105.36 |

| E | 50.85 | L | 114.86 |

| F | 60.02 | M | 124.89 |

| G | 68.29 |

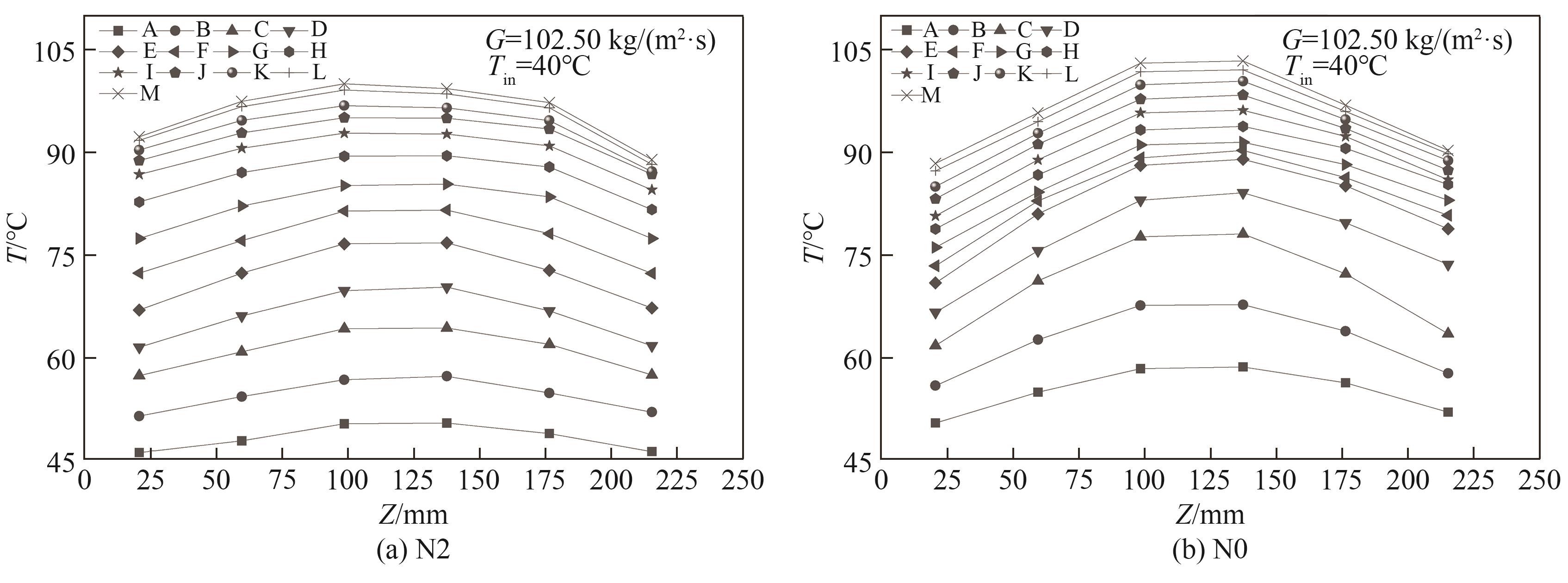

图16 脉动压力与相分离结构协同作用下沿程壁面温度分布

Fig.16 Temperature distribution along the wall under the synergistic effect of fluctuating pressure and phase separation structure

| [1] | 江河, 袁俊飞, 王林, 等. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| Jiang H, Yuan J F, Wang L, et al. Experimental study on the effect of flow sharing cavity structure on phase change flow characteristics in microchannels[J]. CIESC Journal, 2023, 74(S1): 235-244. | |

| [2] | Wang B, Hu Y W, He Y R, et al. Dynamic instabilities of flow boiling in micro-channels: a review[J]. Applied Thermal Engineering, 2022, 214: 118773. |

| [3] | 刘文竹, 云和明, 王宝雪, 等. 基于场协同和火积耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| Liu W Z, Yun H M, Wang B X, et al. Research on topology optimization of microchannel based on field synergy and entransy dissipation[J]. CIESC Journal, 2023, 74(8): 3329-3341. | |

| [4] | 邬智宇, 张伟, 孙远志, 等. 微通道内流动沸腾强化换热研究进展[J]. 微纳电子技术, 2019, 56(2): 126-132. |

| Wu Z Y, Zhang W, Sun Y Z, et al. Research progress on the flow boiling heat transfer enhancement in the microchannel[J]. Micronanoelectronic Technology, 2019, 56(2): 126-132. | |

| [5] | 谭丕强, 刘晓扬, 杨晓美, 等. 车用燃料电池热管理技术的研究进展[J]. 太阳能学报, 2025, 46(9): 390-398. |

| Tan P Q, Liu X Y, Yang X M, et al. Research progress of thermal management for automotive fuel cells[J]. Acta Energiae Solaris Sinica, 2025, 46(9): 390-398. | |

| [6] | Rui Z L, Sun H, Ma J, et al. Experimental study and prediction on the thermal management performance of SDS aqueous solution based microchannel flow boiling system[J]. Energy, 2023, 282: 128747. |

| [7] | Gugulothu R, Reddy K V K, Somanchi N S, et al. A review on enhancement of heat transfer techniques[J]. Materials Today: Proceedings, 2017, 4(2): 1051-1056. |

| [8] | Mandev E, Manay E. Effects of surface roughness in multiple microchannels on mixed convective heat transfer[J]. Applied Thermal Engineering, 2022, 217: 119102. |

| [9] | Heidarian A, Rafee R, Valipour M S. Hydrodynamic analysis of the nanofluids flow in a microchannel with hydrophobic and superhydrophobic surfaces[J]. Journal of the Taiwan Institute of Chemical Engineers, 2021, 124: 266-275. |

| [10] | Mukherjee S, Jana S, Chandra Mishra P, et al. Experimental investigation on thermo-physical properties and subcooled flow boiling performance of Al2O3/water nanofluids in a horizontal tube[J]. International Journal of Thermal Sciences, 2021, 159: 106581. |

| [11] | Zhou J Y, Luo X P, He B L, et al. Comprehensive evaluation of graphene/R141b nanofluids enhanced heat transfer performance of minichannel heat sinks[J]. Powder Technology, 2022, 397: 116997. |

| [12] | Li T F, Luo X P, He B L, et al. Flow boiling heat transfer enhancement in vertical minichannel heat sink with non-uniform microcavity arrays under electric field[J]. Experimental Thermal and Fluid Science, 2023, 149: 110997. |

| [13] | Saadatmand A, Goharkhah M, Nejad A M. Heat transfer enhancement in mini channel heat sinks utilizing corona wind: a numerical study[J]. International Journal of Heat and Mass Transfer, 2022, 182: 121970. |

| [14] | Rahman M E, Weibel J A. Mapping the amplitude and frequency of pressure drop oscillations via a transient numerical model to assess their severity during microchannel flow boiling[J]. International Journal of Heat and Mass Transfer, 2022, 194: 123065. |

| [15] | AbdulHussein W A, Abed A M, Mohammed D B, et al. Investigation of boiling process of different fluids in microchannels and nanochannels in the presence of external electric field and external magnetic field using molecular dynamics simulation[J]. Case Studies in Thermal Engineering, 2022, 35: 102105. |

| [16] | Mehrizi A A, Besharati F, Jahanian O, et al. Numerical investigation of conjugate heat transfer in a microchannel with a hydrophobic surface utilizing nanofluids under a magnetic field[J]. Physics of Fluids, 2021, 33(5): 052002. |

| [17] | Yang P, Zhang Y H, Wang X F, et al. Heat transfer measurement and flow regime visualization of two-phase pulsating flow in an evaporator[J]. International Journal of Heat and Mass Transfer, 2018, 127: 1014-1024. |

| [18] | Jiang X C, Zhang S W, Li Y J, et al. High performance heat sink with counter flow diverging microchannels[J]. International Journal of Heat and Mass Transfer, 2020, 162: 120344. |

| [19] | Jiang X C, Waqar Ali Shah S, Liu J, et al. Design of micro-nano structures for counter flow diverging microchannel heat sink with extraordinarily high energy efficiency[J]. Applied Thermal Engineering, 2022, 209: 118229. |

| [20] | Mohiuddin A, Loganathan R, Gedupudi S. Experimental investigation of flow boiling in rectangular mini/micro-channels of different aspect ratios without and with vapour venting membrane[J]. Applied Thermal Engineering, 2020, 168: 114837. |

| [21] | Sharma D, Ghosh D P, Saha S K, et al. Thermohydraulic characterization of flow boiling in a nanostructured microchannel heat sink with vapor venting manifold[J]. International Journal of Heat and Mass Transfer, 2019, 130: 1249-1259. |

| [22] | Yeszhanov A B, Korolkov I V, Dosmagambetova S S, et al. Recent progress in the membrane distillation and impact of track-etched membranes[J]. Polymers, 2021, 13(15): 2520. |

| [23] | Wu X Q, Wu X, Wang T Y, et al. Omniphobic surface modification of electrospun nanofiber membrane via vapor deposition for enhanced anti-wetting property in membrane distillation[J]. Journal of Membrane Science, 2020, 606: 118075. |

| [24] | Su Q W, Zhang J Y, Zhang L Z. Fouling resistance improvement with a new superhydrophobic electrospun PVDF membrane for seawater desalination[J]. Desalination, 2020, 476: 114246. |

| [25] | Li Y, Wu H Y. Experiment investigation on flow boiling heat transfer in a bidirectional counter-flow microchannel heat sink[J]. International Journal of Heat and Mass Transfer, 2022, 187: 122500. |

| [26] | Xu G Q, Fu J, Quan Y K, et al. Experimental investigation on heat transfer characteristics of hexamethyldisiloxane (MM) at supercritical pressures for medium/high temperature ORC applications[J]. International Journal of Heat and Mass Transfer, 2020, 156: 119852. |

| [27] | Kim D E, Kim M H. Experimental investigation of heat transfer in vertical upward and downward supercritical CO2 flow in a circular tube[J]. International Journal of Heat and Fluid Flow, 2011, 32(1): 176-191. |

| [28] | Lee P S, Garimella S V. Saturated flow boiling heat transfer and pressure drop in silicon microchannel arrays[J]. International Journal of Heat and Mass Transfer, 2008, 51(3/4): 789-806. |

| [29] | Habibishandiz M, Saghir M Z. A critical review of heat transfer enhancement methods in the presence of porous media, nanofluids, and microorganisms[J]. Thermal Science and Engineering Progress, 2022, 30: 101267. |

| [30] | Qu W L, Mudawar I. Flow boiling heat transfer in two-phase micro-channel heat sinks (Ⅰ): Experimental investigation and assessment of correlation methods[J]. International Journal of Heat and Mass Transfer, 2003, 46(15): 2755-2771. |

| [31] | Moffat R J. Describing the uncertainties in experimental results[J]. Experimental Thermal and Fluid Science, 1988, 1(1): 3-17. |

| [1] | 孙睿, 王军锋, 许浩洁, 李步发, 徐雅弦. 喷雾冷却技术及其强化传热机制研究进展[J]. 化工学报, 2025, 76(4): 1404-1421. |

| [2] | 范佳媛, 曾文慧, 任志超, 张文涛, 吕霜. 多熔点相变乳液的制备及性能强化研究[J]. 化工学报, 2025, 76(4): 1863-1874. |

| [3] | 刘萍, 邱雨生, 李世婧, 孙瑞奇, 申晨. 微通道内纳米流体传热流动特性[J]. 化工学报, 2025, 76(1): 184-197. |

| [4] | 罗小平, 侯云天, 范一杰. 逆流相分离结构微细通道流动沸腾传热与均温性[J]. 化工学报, 2024, 75(7): 2474-2485. |

| [5] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [6] | 申利梅, 胡博兴, 谢雨霏, 曾伟豪, 张晓屿. 超薄平板热管传热性能的实验研究[J]. 化工学报, 2023, 74(S1): 198-205. |

| [7] | 王海, 林宏, 王晨, 许浩洁, 左磊, 王军锋. 高压静电场强化多孔介质表面沸腾传热特性研究[J]. 化工学报, 2023, 74(7): 2869-2879. |

| [8] | 张贲, 王松柏, 魏子亚, 郝婷婷, 马学虎, 温荣福. 超亲水多孔金属结构驱动的毛细液膜冷凝及传热强化[J]. 化工学报, 2023, 74(7): 2824-2835. |

| [9] | 李昀, 曹杰, 华夏, 吴慧英. 短程逆流式微通道内的流动沸腾传热特性实验研究[J]. 化工学报, 2023, 74(11): 4501-4514. |

| [10] | 熊昊, 梁潇予, 张晨曦, 白浩隆, 范晓宇, 魏飞. 重质油直接制化工品:多级逆流下行催化裂解技术[J]. 化工学报, 2023, 74(1): 86-104. |

| [11] | 林志敏, 王崇兆, 强国智, 刘树山, 王良璧. 润滑油在内插同轴交叉翼型涡产生器管内流动与传热特性分析[J]. 化工学报, 2022, 73(11): 4957-4973. |

| [12] | 刘作华, 周毅林, 熊黠, 陶长元, 王运东. 逆流桨强化搅拌槽内流体混沌混合及流场结构失稳研究[J]. 化工学报, 2022, 73(1): 222-231. |

| [13] | 林伟翔, 苏港川, 陈强, 文键, 王斯民. 基于超声技术的沉浸式换热器强化传热研究[J]. 化工学报, 2021, 72(8): 4055-4063. |

| [14] | 高峰, 陈永昌, 赵金龙, 马重芳. 磁场对熔盐射流冲击传热的影响[J]. 化工学报, 2020, 71(S2): 92-97. |

| [15] | 郎中敏, 吴刚强, 赫文秀, 韩晓星, 苟延梦, 李双莹. 二氧化铈/水基纳米流体核沸腾传热特性[J]. 化工学报, 2020, 71(5): 2061-2068. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号