化工学报 ›› 2023, Vol. 74 ›› Issue (S1): 165-171.DOI: 10.11949/0438-1157.20230172

收稿日期:2023-02-27

修回日期:2023-03-29

出版日期:2023-06-05

发布日期:2023-09-27

通讯作者:

杜文静

作者简介:张双星(2000—),男,硕士研究生,2663928761@qq.com

Shuangxing ZHANG( ), Fangchen LIU, Yifei ZHANG, Wenjing DU(

), Fangchen LIU, Yifei ZHANG, Wenjing DU( )

)

Received:2023-02-27

Revised:2023-03-29

Online:2023-06-05

Published:2023-09-27

Contact:

Wenjing DU

摘要:

为研究低温工质对脉动热管相变蓄热器的影响,搭建了脉动热管相变蓄放热试验台。实验选用的低温工质为R-134a,相变材料为石蜡,蓄热器由一组自主设计的脉动热管组成。实验结果表明,采用R-134a作为工质能够实现脉动热管蓄热器的正常蓄热和放热。在蓄热过程中,加热功率的增加会减少蓄热时间,但同时也会增加蓄热器内的最大温差;在放热过程中,冷却水温度的降低会减少石蜡的凝固时间,当水温由20℃变为5℃,石蜡的凝固时间缩短了34.8%。冷却水流量的增加也会减少石蜡的凝固时间,水流量由10 L/h变为40 L/h,凝固时间缩短了9.5%。在约3 h的放热实验后,相变材料的温度与室温接近。

中图分类号:

张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171.

Shuangxing ZHANG, Fangchen LIU, Yifei ZHANG, Wenjing DU. Experimental study on phase change heat storage and release performance of R-134a pulsating heat pipe[J]. CIESC Journal, 2023, 74(S1): 165-171.

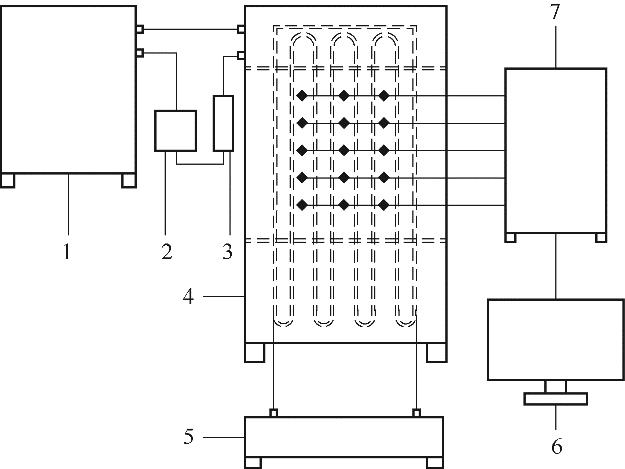

图1 脉动热管相变蓄放热实验台示意图1—low-temperature thermostatic bath; 2—micro flowmeter; 3—float flowmeter; 4—pulsating heat pipe phase change accumulator; 5—alternating current power supply; 6—computer; 7—paperless recorder

Fig.1 Schematic diagram of phase change storage and release experimental platform for pulsating heat pipe

| 设备名称 | 设备参数 |

|---|---|

| 低温恒温槽 | 厂家:LAUDA,型号:WKL1000,精度:±0.5℃ |

| 无纸记录仪 | 厂家:YOKOGAWA,型号:GX20,精度:±0.1℃ |

| 交流电源 | 厂家:国电亚光电源有限公司,型号:HYB1760-0.5 KVA,精度:±0.1 A,±0.1V |

| 电子流量计 | 厂家:上海基深仪器仪表有限公司,型号:M6Y,精度:±0.5 L/h |

| T型热电偶 | 测温范围:-200~350℃,精度:±0.5℃ |

表1 相关设备的详细参数

Table 1 Detailed parameters of related devices

| 设备名称 | 设备参数 |

|---|---|

| 低温恒温槽 | 厂家:LAUDA,型号:WKL1000,精度:±0.5℃ |

| 无纸记录仪 | 厂家:YOKOGAWA,型号:GX20,精度:±0.1℃ |

| 交流电源 | 厂家:国电亚光电源有限公司,型号:HYB1760-0.5 KVA,精度:±0.1 A,±0.1V |

| 电子流量计 | 厂家:上海基深仪器仪表有限公司,型号:M6Y,精度:±0.5 L/h |

| T型热电偶 | 测温范围:-200~350℃,精度:±0.5℃ |

| 加热功率/W | 相变时间/min | 功率变化率/% | 相变时间 变化率/% |

|---|---|---|---|

| 100 | 103 | 0 | 0 |

| 150 | 73 | 50 | 29.1 |

| 200 | 50.5 | 100 | 51.0 |

表2 加热功率对融化时间的影响

Table 2 Influence of heating power on melting time

| 加热功率/W | 相变时间/min | 功率变化率/% | 相变时间 变化率/% |

|---|---|---|---|

| 100 | 103 | 0 | 0 |

| 150 | 73 | 50 | 29.1 |

| 200 | 50.5 | 100 | 51.0 |

| 1 | 屈健. 脉动热管技术研究及应用进展[J]. 化工进展, 2013, 32(1): 33-41. |

| Qu J. Oscillating heat pipes: state of the art and applications[J]. Chemical Industry and Engineering Progress, 2013, 32(1): 33-41. | |

| 2 | Motahar S, Khodabandeh R. Experimental study on the melting and solidification of a phase change material enhanced by heat pipe[J]. International Communications in Heat and Mass Transfer, 2016, 73: 1-6. |

| 3 | Robak C W, Bergman T L, Faghri A. Enhancement of latent heat energy storage using embedded heat pipes[J]. International Journal of Heat and Mass Transfer, 2011, 54(15/16): 3476-3484. |

| 4 | Zhang X, Wu S C, Zhang C B, et al. Dynamic heat transfer characteristics of gravity heat pipe with heat storage[J]. Journal of Energy Storage, 2022, 53: 105134. |

| 5 | Jung E G, Boo J H. Thermal analytical model of latent thermal storage with heat pipe heat exchanger for concentrated solar power[J]. Solar Energy, 2014, 102: 318-332. |

| 6 | Amini A, Miller J, Jouhara H. An investigation into the use of the heat pipe technology in thermal energy storage heat exchangers[J]. Energy, 2017, 136: 163-172. |

| 7 | Ladekar C, Choudhary S K, Khandare S S. Experimental investigation for the optimization of heat pipe performance in latent heat thermal storage[J]. Journal of Mechanical Science and Technology, 2017, 31(6): 2627-2634. |

| 8 | Akachi H. Structure of a heat pipe: US4921041[P]. 1990-05-01. |

| 9 | Akachi H. Structure of micro-heat pipe: US5219020[P]. 1993-06-15. |

| 10 | 周跃国. 脉动热管启动及运行特性的可视化实验研究[D]. 重庆: 重庆大学, 2010. |

| Zhou Y G. Visual experiment study on start-up and operating characteristics of pulsating heat pipe[D]. Chongqing: Chongqing University, 2010. | |

| 11 | 杨蔚原, 张正芳, 马同泽. 脉动热管运行的可视化实验研究[J]. 工程热物理学报, 2001, 22(S1): 117-120. |

| Yang W Y, Zhang Z F, Ma T Z. Flow visualization of looped pulsating heat pipe[J]. Journal of Engineering Thermophysics, 2001, 22(S1): 117-120. | |

| 12 | 曹小林, 席战利, 周晋, 等. 脉动热管运行可视化及传热与流动特性的实验研究[J]. 热能动力工程, 2004, 19(4): 411-415, 441. |

| Cao X L, Xi Z L, Zhou J, et al. Experimental investigation of the visualization of pulsating heat-pipe operation as well as heat transfer and flow characteristics[J]. Journal of Engineering for Thermal Energy and Power, 2004, 19(4): 411-415, 441. | |

| 13 | 冼海珍, 刘登瀛, 杨勇平, 等. 一种用振荡流热管做吸热内管的太阳能真空玻璃集热管: 101021365A[P]. 2008-12-31. |

| Liu X H. Solar energy vacuum glass heat accumulating tube utilizing oscillating flow heat tube as heat internal tube: 101021365A[P]. 2008-12-31. | |

| 14 | 郭良安. 脉动热管的实验研究[D]. 大连: 大连海事大学, 2011. |

| Guo L A. Experimental investigation of oscillating heat pipes[D]. Dalian: Dalian Maritime University, 2011. | |

| 15 | Charoensawan P, Khandekar S, Groll M, et al. Closed loop pulsating heat pipes[J]. Applied Thermal Engineering, 2003, 23(16): 2009-2020. |

| 16 | Khandekar S, Charoensawan P, Groll M, et al. Closed loop pulsating heat pipes (Part B): Visualization and semi-empirical modeling[J]. Applied Thermal Engineering, 2003, 23(16): 2021-2033. |

| 17 | Ayel V, Araneo L, Scalambra A, et al. Experimental study of a closed loop flat plate pulsating heat pipe under a varying gravity force[J]. International Journal of Thermal Sciences, 2015, 96: 23-34. |

| 18 | Mangini D, Mameli M, Georgoulas A, et al. A pulsating heat pipe for space applications: ground and microgravity experiments[J]. International Journal of Thermal Sciences, 2015, 95: 53-63. |

| 19 | Mameli M, Manno V, Filippeschi S, et al. Thermal instability of a closed loop pulsating heat pipe: combined effect of orientation and filling ratio[J]. Experimental Thermal and Fluid Science, 2014, 59: 222-229. |

| 20 | Mameli M, Araneo L, Filippeschi S, et al. Thermal response of a closed loop pulsating heat pipe under a varying gravity force[J]. International Journal of Thermal Sciences, 2014, 80: 11-22. |

| 21 | Iwata N, Ogawa H, Miyazaki Y. Maximum heat transfer and operating temperature of oscillating heat pipe[J]. Journal of Heat Transfer, 2016, 138(12): 122002. |

| 22 | Zhao J T, Rao Z H, Liu C Z, et al. Experimental investigation on thermal performance of phase change material coupled with closed-loop oscillating heat pipe (PCM/CLOHP) used in thermal management[J]. Applied Thermal Engineering, 2016, 93: 90-100. |

| 23 | 赵佳腾. 面向储热的脉动热管流动与传热特性及强化机理研究[D]. 徐州: 中国矿业大学, 2018. |

| Zhao J T. Characteristics of flow and heat transfer and enhancement mechanism of oscillating heat pipe for thermal energy storage[D]. Xuzhou: China University of Mining and Technology, 2018. | |

| 24 | Khalilmoghadam P, Rajabi-Ghahnavieh A, Shafii M B. A novel energy storage system for latent heat recovery in solar still using phase change material and pulsating heat pipe[J]. Renewable Energy, 2021, 163: 2115-2127. |

| 25 | Zhao J T, Jiang W, Liu C Z, et al. Thermal performance enhancement of an oscillating heat pipe with external expansion structure for thermal energy recovery and storage[J]. Applied Thermal Engineering, 2019, 155: 667-675. |

| 26 | 罗孝学, 章学来, 邹长贞, 等. 脉动热管相变蓄热器放热性能实验分析[J]. 热力发电, 2018, 47(4): 123-130. |

| Luo X X, Zhang X L, Zou C Z, et al. Experimental analysis on heat release performance of pulsating heat pipe phase change heat accumulator[J]. Thermal Power Generation, 2018, 47(4): 123-130. | |

| 27 | 罗孝学, 章学来, 华维三, 等. 脉动热管相变蓄热器蓄热实验分析[J]. 化工学报, 2017, 68(7): 2722-2729. |

| Luo X X, Zhang X L, Hua W S, et al. Experimental analysis on heat storage of pulsating heat pipe phase change heat accumulator[J]. CIESC Journal, 2017, 68(7): 2722-2729. | |

| 28 | 罗孝学, 章学来, 华维三, 等. 一种脉动热管相变蓄放热试验装置的设计[J]. 流体机械, 2017, 45(4): 63-67. |

| Luo X X, Zhang X L, Hua W S, et al. Design of pulsating heat pipe type phase change thermal storage experimental device[J]. Fluid Machinery, 2017, 45(4): 63-67. | |

| 29 | 罗孝学, 章学来, 华维三, 等. 应用于相变蓄热的脉动热管换热器在不同倾角下放热性能的试验研究[J]. 流体机械, 2017, 45(7): 62-67. |

| Luo X X, Zhang X L, Hua W S, et al. Experimental study on heat transfer performance of pulsating heat pipe heat exchanger with phase change heat storage at different inclination[J]. Fluid Machinery, 2017, 45(7): 62-67. | |

| 30 | Ling Y Z, Zhang X S, Wang F, et al. Performance study of phase change materials coupled with three-dimensional oscillating heat pipes with different structures for electronic cooling[J]. Renewable Energy, 2020, 154: 636-649. |

| [1] | 朱子良, 王爽, 姜宇昂, 林梅, 王秋旺. 欧拉-拉格朗日迭代固-液相变算法[J]. 化工学报, 2024, 75(8): 2763-2776. |

| [2] | 曲玖哲, 杨鹏, 杨绪飞, 张伟, 宇波, 孙东亮, 王晓东. 硅基微柱簇阵列微通道流动沸腾实验研究[J]. 化工学报, 2024, 75(8): 2840-2851. |

| [3] | 杨明军, 巩广军, 郑嘉男, 宋永臣. 泥质低渗水合物降压开采特性与模型研究[J]. 化工学报, 2024, 75(8): 2909-2916. |

| [4] | 方立昌, 李梓龙, 陈博, 苏政, 贾莉斯, 王智彬, 陈颖. 基于相变微胶囊悬浮液的芯片阵列冷却特性研究[J]. 化工学报, 2024, 75(7): 2455-2464. |

| [5] | 余清杰, 杨洪海, 刘玉浩, 方海洲, 何伟琪, 王军, 卢心诚. 脉动热管温度信号的小波分析及流型识别[J]. 化工学报, 2024, 75(7): 2497-2504. |

| [6] | 李新泽, 张双星, 杨洪海, 杜文静. 基于电池冷却用新型脉动热管性能的实验研究[J]. 化工学报, 2024, 75(6): 2222-2232. |

| [7] | 李怡菲, 董新宇, 王为术, 刘璐, 赵一璠. 微肋板表面干冰升华喷雾冷却传热数值模拟[J]. 化工学报, 2024, 75(5): 1830-1842. |

| [8] | 刘昌会, 肖桐, 刘庆祎, 耿龙, 赵佳腾. 多孔二氧化钛强化的相变材料储热机理研究[J]. 化工学报, 2024, 75(2): 706-714. |

| [9] | 陶明清, 慕明昊, 程滕, 王博. 喷雾耦合降温强化旋风分离器脱除细颗粒物的研究[J]. 化工学报, 2024, 75(2): 584-592. |

| [10] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [11] | 吴延鹏, 刘乾隆, 田东民, 陈凤君. 相变材料与热管耦合的电子器件热管理研究进展[J]. 化工学报, 2023, 74(S1): 25-31. |

| [12] | 王海, 林宏, 王晨, 许浩洁, 左磊, 王军锋. 高压静电场强化多孔介质表面沸腾传热特性研究[J]. 化工学报, 2023, 74(7): 2869-2879. |

| [13] | 史昊鹏, 钟达文, 廉学新, 张君峰. 朝下多尺度沟槽翅片结构表面沸腾换热实验研究[J]. 化工学报, 2023, 74(7): 2880-2888. |

| [14] | 史方哲, 甘云华. 超薄热管启动特性和传热性能数值模拟[J]. 化工学报, 2023, 74(7): 2814-2823. |

| [15] | 邢美波, 张中天, 景栋梁, 张洪发. 磁调控水基碳纳米管协同多孔材料强化相变储/释能特性[J]. 化工学报, 2023, 74(7): 3093-3102. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号