• •

收稿日期:2025-09-11

修回日期:2025-11-07

出版日期:2025-11-27

通讯作者:

李伟,刘峥

作者简介:彭瑞(2000—),男,硕士研究生,pr788566@163.com

基金资助:

Rui PENG( ), Wei LI(

), Wei LI( ), Yuyuan CAO, Zheng LIU(

), Yuyuan CAO, Zheng LIU( ), Rongting GUO

), Rongting GUO

Received:2025-09-11

Revised:2025-11-07

Online:2025-11-27

Contact:

Wei LI, Zheng LIU

摘要:

为解决锂硫电池(Li-S)正极材料存在的低导电、高膨胀和穿梭效应的不足,本文借助超声辅助、冷冻干燥、喷雾干燥等手段,设计制备出P-MXene Ti3C2Tx/CNT(PMC)硫载体。将PMC与升华硫(S)在高温烧结下制备出正极材料P-MXene Ti3C2Tx/CNT/S(PMC/S),二者都具有多孔球状形貌,且存在丰富的介孔、大孔,同时也证实了S被均匀地负载在PMC上。将PMC/S正极组装成扣式半电池,对性能测试,PMC/S在0.1 C下具有1271.90 mAh·g-1的高比容量,循环500次后仍具有531.1 mAh·g-1的比容量。利用PMC硫载体进行可视化吸附实验以及对称电池的组装,对比于二维片层碳化钛(MXene Ti3C2Tx),PMC硫载体对多硫化锂(LiPSs)的吸附作用和催化转化能力均有显著提高。研究结果揭示了MXene Ti3C2Tx与碳纳米管(CNT)的协同作用是 PMC具备优异性能的内在原因。

中图分类号:

彭瑞, 李伟, 曹钰媛, 刘峥, 郭容婷. P-MXene Ti3C2Tx/CNT多孔微球硫载体复合材料的制备及电化学性能研究[J]. 化工学报, DOI: 10.11949/0438-1157.20251027.

Rui PENG, Wei LI, Yuyuan CAO, Zheng LIU, Rongting GUO. Preparation and Electrochemical Performance of P-MXene Ti3C2Tx/CNT Porous Microsphere Sulfur Host Composite Materials[J]. CIESC Journal, DOI: 10.11949/0438-1157.20251027.

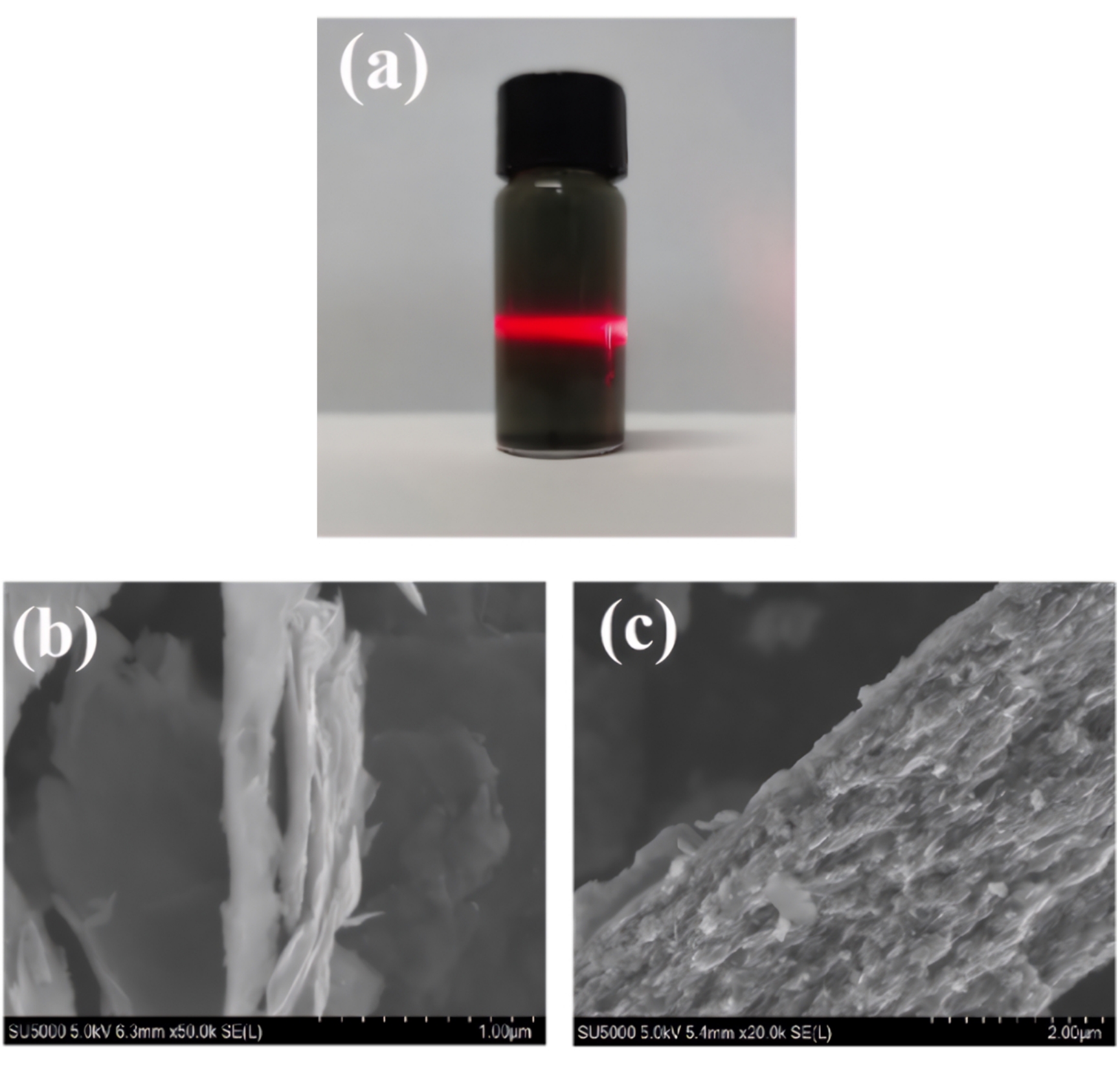

图2(a) 少层MXene Ti3C2Tx分散液的丁达尔效应图,(b, c) 少层多孔PM的SEM图

Figure 2 (a) Tyndall effect of the few-layer MXene Ti3C2Tx dispersion, (b, c) SEM images of the few-layer porous PM

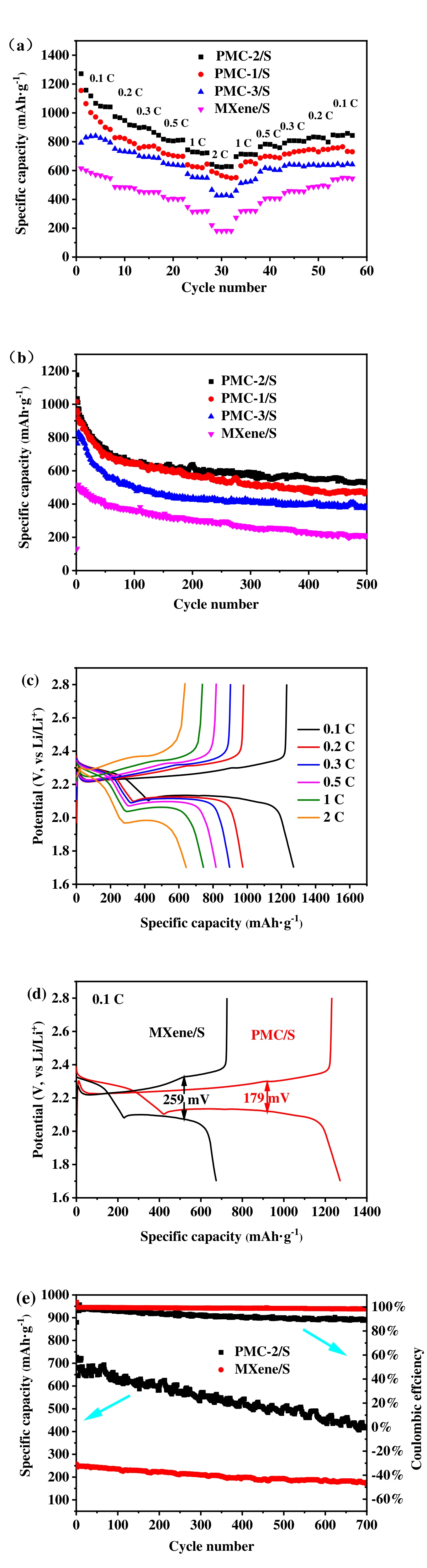

图10 含一系列PMC/S正极(包括PMC-1/S、PMC-2/S、PMC-3/S)的(a)倍率性能、(b)0.1 C循环性能;,(c)在不同倍率下PMC-2/S的充电-放电曲线,(d)在0.1 C下PMC-2/S、MXene Ti3C2Tx/S的充电-放电曲线平台电位差的比较和PMC-2/S在1 C下的长循环性能(e)

Figure 10 (a) rate performance and (b) 0.1 C cycle performance of a series of PMC/S (including PMC-1/S, PMC-2/S and PMC-3/S), (c) the charge-discharge curves of PMC-2/S at different current densities; (d) the comparison of the platform difference of the charge-discharge curve of PMC-2/S and MXene Ti3C2Tx/S at 0.1 C and(e)Long cycle performance of PMC-2/S at 1 C

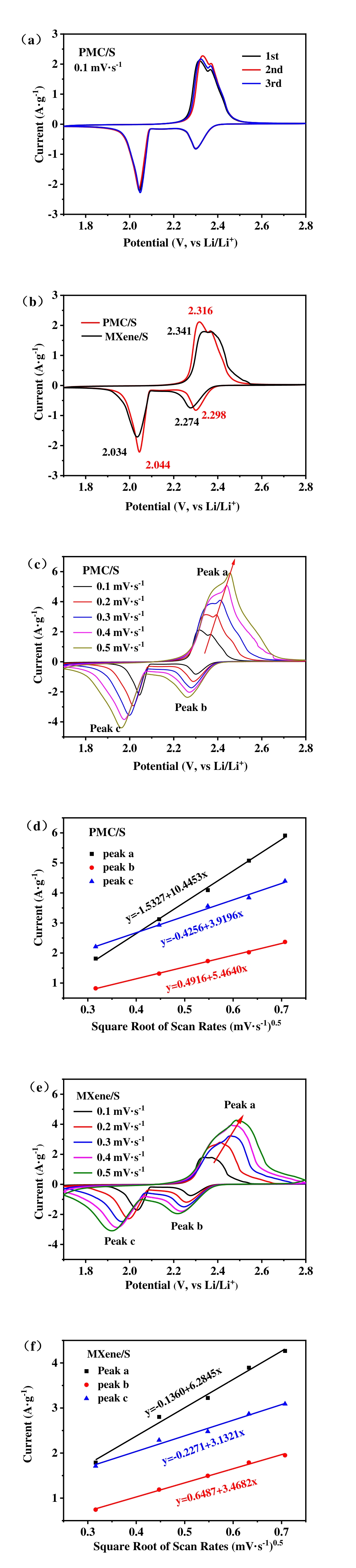

图11 (a,b)PMC/S和MXene Ti3C2Tx/S的CV曲线,(c-f)0.1-0.5 mV·s-1PMC/S和MXene Ti3C2Tx/S的CV曲线及对应的氧化还原电流峰值与扫描速率之间的相应线性关系

Figure 11 (a, b) CV curves of PMC/S and MXene Ti3C2Tx/S, (c-f) CV curves of PMC/S and MXene Ti3C2Tx/S at 0.1-0.5 mV·s-1, and the corresponding linear relationship between the peak REDOX current and the scanning rate

图12(a) PMC/S、(b) MXene Ti3C2Tx/S循环100圈前后的EIS图(插图为对应的等效电路图)

Figure 18 EIS before and after 100 cycles of (a) PMC/S, (b) MXene Ti3C2Tx/S (The illustration is the corresponding equivalent circuit diagram)

| Samples | Before cycling | After 100th cycle | ||

|---|---|---|---|---|

| Rs (ohm) | Rct (ohm) | Rs (ohm) | Rct (ohm) | |

| MXene Ti3C2Tx/S | 6.632 | 27.970 | 13.060 | 9.782 |

| PMC/S | 2.711 | 7.638 | 6.777 | 10.470 |

表1 PMC/S和 MXene Ti3C2Tx/S循环100圈前后的EIS图拟合结果

Table 1 EIS fitting results before and after 100 cycles of PMC/S and MXene Ti3C2Tx/S

| Samples | Before cycling | After 100th cycle | ||

|---|---|---|---|---|

| Rs (ohm) | Rct (ohm) | Rs (ohm) | Rct (ohm) | |

| MXene Ti3C2Tx/S | 6.632 | 27.970 | 13.060 | 9.782 |

| PMC/S | 2.711 | 7.638 | 6.777 | 10.470 |

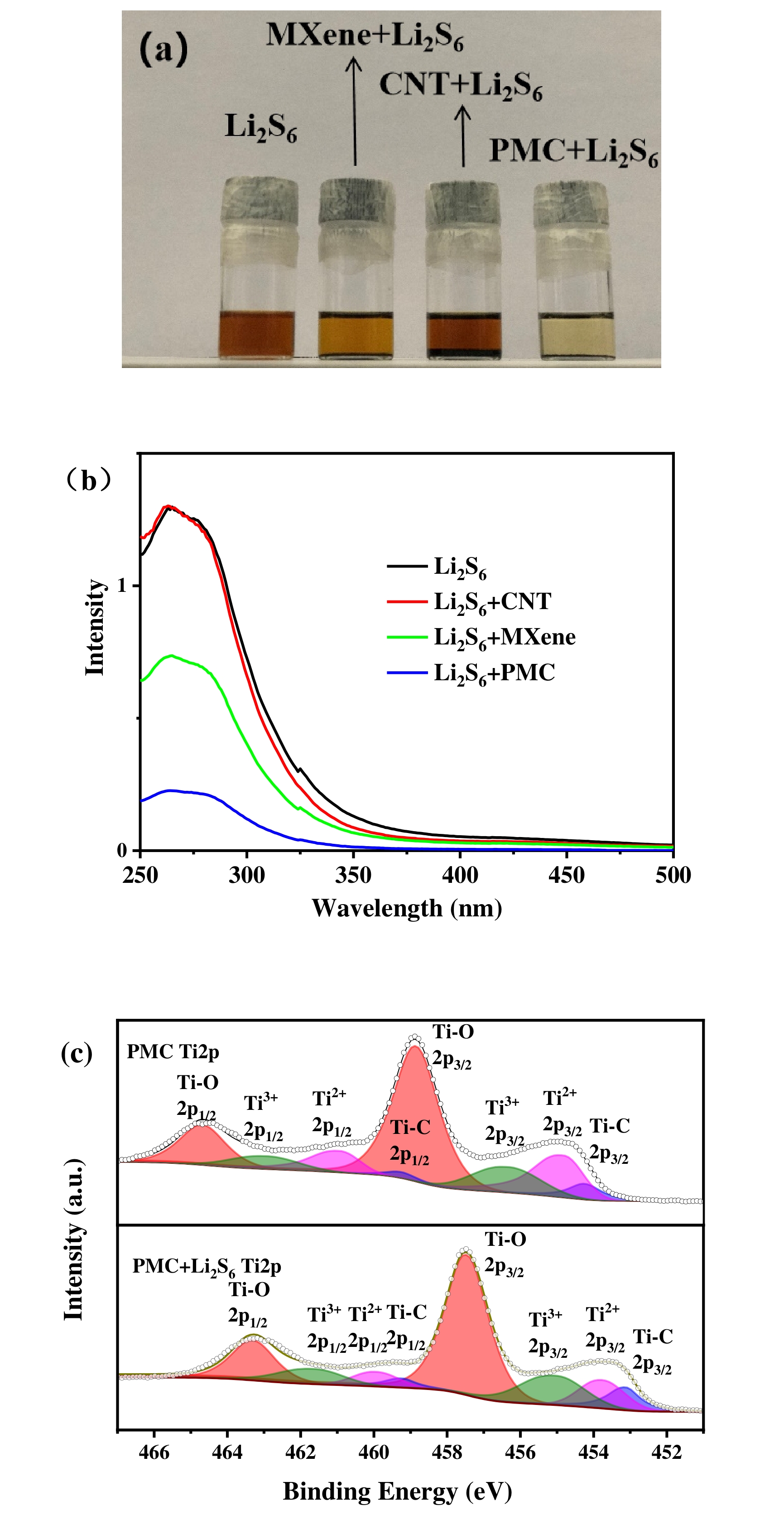

图13(a) PMC硫载体对Li2S6的吸附结果图,(b)对应样品的上清液紫外-可见光光谱测试,(c)吸附Li2S6后的样品的XPS图谱

Figure 13 (a) The adsorption of PMC sulfur host on Li2S6, (b) the UV-visible spectrum test results of the supernatant of the corresponding sample, and (c) the XPS spectrum of the sample after adsorption of Li2S6

| [1] | Zhang Y Z, Sun C W. Composite lithium protective layer formed in situ for stable lithium metal batteries[J]. ACS Applied Materials & Interfaces, 2021, 13(10): 12099-12105. |

| [2] | Akhtar N, Sun X G, Akram M Y, et al. A gelatin-based artificial SEI for lithium deposition regulation and polysulfide shuttle suppression in lithium-sulfur batteries[J]. Journal of Energy Chemistry, 2021, 52: 310-317. |

| [3] | Zhao Y Y, Ye Y S, Wu F, et al. Anode interface engineering and architecture design for high-performance lithium–sulfur batteries[J]. Advanced Materials, 2019, 31(12): 1806532. |

| [4] | Lin Y L, Huang S, Zhong L, et al. Organic liquid electrolytes in Li-S batteries: actualities and perspectives[J]. Energy Storage Materials, 2021, 34: 128-147. |

| [5] | Zhang X, Li J, Gao C, et al. Promoting the conversion of Li2S by functional additives phenyl diselenide in Lithium–Sulfur batteries[J]. Journal of Power Sources, 2021, 482: 228967. |

| [6] | Chen S R, Wang D W, Zhao Y M, et al. Superior performance of a lithium–sulfur battery enabled by a dimethyl trisulfide containing electrolyte[J]. Small Methods, 2018, 2(6): 1800038. |

| [7] | Fan L, Chen S H, Zhu J Y, et al. Simultaneous suppression of the dendrite formation and shuttle effect in a lithium–sulfur battery by bilateral solid electrolyte interface[J]. Advanced Science, 2018, 5(9): 1700934. |

| [8] | Bai Y, Zhao Y B, Li W D, et al. Organic-inorganic multi-scale enhanced interfacial engineering of sulfide solid electrolyte in Li-S battery[J]. Chemical Engineering Journal, 2020, 396: 125334. |

| [9] | Shao D S, Yang L, Luo K L, et al. Preparation and performances of the modified gel composite electrolyte for application of quasi-solid-state lithium sulfur battery[J]. Chemical Engineering Journal, 2020, 389: 124300. |

| [10] | Lei D N, Shi K, Ye H, et al. Progress and perspective of solid-state lithium–sulfur batteries[J]. Advanced Functional Materials, 2018, 28(38): 1707570. |

| [11] | Phuc N H H, Hikima K, Muto H, et al. Recent developments in materials design for all-solid-state Li–S batteries[J]. Critical Reviews in Solid State and Materials Sciences, 2022, 47(3): 283-308. |

| [12] | Zhang X Z, Chen Z H, Shui L L, et al. The fabrication of a 3D current collector with bitter melon-like TiO2–NCNFs for highly stable lithium–sulfur batteries[J]. Nanoscale Advances, 2019, 1(2): 527-531. |

| [13] | Pei F, Fu A, Ye W B, et al. Robust lithium metal anodes realized by lithiophilic 3D porous current collectors for constructing high-energy lithium–sulfur batteries[J]. ACS Nano, 2019, 13(7): 8337-8346. |

| [14] | Yuan W, Qiu Z Q, Wang C, et al. Design and interface optimization of a sandwich-structured cathode for lithium-sulfur batteries[J]. Chemical Engineering Journal, 2020, 381: 122648. |

| [15] | Shin D, Song Y, Nam D, et al. High-capacity sulfur copolymer cathode with metallic fibril-based current collector and conductive capping layer[J]. Journal of Materials Chemistry A, 2021, 9(4): 2334-2344. |

| [16] | Zhou C, He Q, Li Z H, et al. A robust electrospun separator modified with in situ grown metal-organic frameworks for lithium-sulfur batteries[J]. Chemical Engineering Journal, 2020, 395: 124979. |

| [17] | Cheng P, Guo P Q, Sun K, et al. CeO2 decorated graphene as separator modification material for capture and boost conversion of polysulfide in lithium-sulfur batteries[J]. Journal of Membrane Science, 2021, 619: 118780. |

| [18] | Chen P, Wang Z X, Zhang B Y, et al. Multi-functional TiO2 nanosheets/carbon nanotubes modified separator enhanced cycling performance for lithium-sulfur batteries[J]. International Journal of Energy Research, 2020, 44(4): 3231-3240. |

| [19] | Liu X, Ma H, Hu C C, et al. Tg-C3N4-coated functional separator as polysulfide barrier of high-performance lithium-sulfur batteries[J]. Nanotechnology, 2021, 32(47): 475401. |

| [20] | Li H T, Jin Q, Li D M, et al. Mo2C-embedded carambola-like N,S-rich carbon framework as the interlayer material for high-rate lithium–sulfur batteries in a wide temperature range[J]. ACS Applied Materials & Interfaces, 2020, 12(20): 22971-22980. |

| [21] | Fan Z H, Zhang C, Hua W X, et al. Enhanced chemical trapping and catalytic conversion of polysulfides by diatomite/MXene hybrid interlayer for stable Li-S batteries[J]. Journal of Energy Chemistry, 2021, 62: 590-598. |

| [22] | Xu Z, Wang Z, Wang M R, et al. Large-scale synthesis of Fe9S10/Fe3O4@C heterostructure as integrated trapping-catalyzing interlayer for highly efficient lithium-sulfur batteries[J]. Chemical Engineering Journal, 2021, 422: 130049. |

| [23] | Zhu D M, Long T, Xu B, et al. Recent advances in interlayer and separator engineering for lithium-sulfur batteries[J]. Journal of Energy Chemistry, 2021, 57: 41-60. |

| [24] | Ji X L, Lee K T, Nazar L F. A highly ordered nanostructured carbon–sulphur cathode for lithium–sulphur batteries[J]. Nature Materials, 2009, 8(6): 500-506. |

| [25] | Park J, Yu S H, Sung Y E. Design of structural and functional nanomaterials for lithium-sulfur batteries[J]. Nano Today, 2018, 18: 35-64. |

| [26] | Zhang L L, Wang Y J, Niu Z Q, et al. Advanced nanostructured carbon-based materials for rechargeable lithium-sulfur batteries[J]. Carbon, 2019, 141: 400-416. |

| [27] | Fang R P, Chen K, Yin L C, et al. The regulating role of carbon nanotubes and graphene in lithium-ion and lithium–sulfur batteries[J]. Advanced Materials, 2019, 31(9): 1800863. |

| [28] | Shulaker M M, Hills G, Patil N, et al. Carbon nanotube computer[J]. Nature, 2013, 501(7468): 526-530. |

| [29] | Ma L B, Wu J X, Li Y, et al. Rational design of carbon nanotube architectures for lithium–chalcogen batteries: Advances and perspectives[J]. Energy Storage Materials, 2021, 42: 723-752. |

| [30] | Ye X M, Ma J, Hu Y S, et al. MWCNT porous microspheres with an efficient 3D conductive network for high performance lithium–sulfur batteries[J]. Journal of Materials Chemistry A, 2016, 4(3): 775-780. |

| [31] | Feng J N, Liu W D, Shi C, et al. Enabling fast diffusion/conversion kinetics by thiourea-induced wrinkled N, S Co-doped functional MXene for lithium-sulfur battery[J]. Energy Storage Materials, 2024, 67: 103328. |

| [32] | Xiong D B, Huang S Z, Fang D L, et al. Porosity engineering of MXene membrane towards polysulfide inhibition and fast lithium ion transportation for lithium–sulfur batteries[J]. Small, 2021, 17(34): 2007442. |

| [33] | Bian R J, He G L, Zhi W Q, et al. Ultralight MXene-based aerogels with high electromagnetic interference shielding performance[J]. Journal of Materials Chemistry C, 2019, 7(3): 474-478. |

| [34] | Kumar V S, Kummari S, Catanante G, et al. A label-free impedimetric immunosensor for zearalenone based on CS-CNT-Pd nanocomposite modified screen-printed disposable electrodes[J]. Sensors and Actuators B: Chemical, 2023, 377: 133077. |

| [35] | Zhang Y G, Li G R, Wang J Y, et al. "Sauna" activation toward intrinsic lattice deficiency in carbon nanotube microspheres for high-energy and long-lasting lithium–sulfur batteries[J]. Advanced Energy Materials, 2021, 11(26): 2100497. |

| [36] | Zhang N N, Huang S, Yuan Z S, et al. Direct self-assembly of MXene on Zn anodes for dendrite-free aqueous zinc-ion batteries[J]. Angewandte Chemie International Edition, 2021, 60(6): 2861-2865. |

| [37] | Zhang J, Yang L, Wang H B, et al. In situ hydrothermal growth of TiO2 nanoparticles on a conductive Ti3C2TX MXene nanosheet: a synergistically active Ti-based nanohybrid electrocatalyst for enhanced N2 reduction to NH3 at ambient conditions[J]. Inorganic Chemistry, 2019, 58(9): 5414-5418. |

| [38] | Zhang Y, Huang Y Y, Srot V, et al. Enhanced pseudo-capacitive contributions to high-performance sodium storage in TiO2/C nanofibers via double effects of sulfur modification[J]. Nano-Micro Letters, 2020, 12(1): 165. |

| [39] | Li W L, Chen K, Xu Q C, et al. Mo2C/C hierarchical double-shelled hollow spheres as sulfur host for advanced Li-S batteries[J]. Angewandte Chemie International Edition, 2021, 60(39): 21512-21520. |

| [40] | Wang S Z, Feng S P, Liang J W, et al. Insight into MoS2–MoN heterostructure to accelerate polysulfide conversion toward high-energy-density lithium–sulfur batteries[J]. Advanced Energy Materials, 2021, 11(11): 2003314. |

| [41] | Liu P, Zhong W, Du W Y, et al. Suppressed shuttling effect of polysulfides using three-dimensional nickel hydroxide polyhedrons for advanced lithium-sulfur batteries[J]. Journal of Colloid and Interface Science, 2021, 593: 89-95. |

| [42] | Li Z, Zhang F, Cao T, et al. Highly stable lithium–sulfur batteries achieved by a SnS/porous carbon nanosheet architecture modified celgard separator[J]. Advanced Functional Materials, 2020, 30(48): 2006297. |

| [43] | Park G D, Kang Y C. Aerosol-assisted synthesis of porous and hollow carbon-carbon nanotube composite microspheres as sulfur host materials for high-performance Li-S batteries[J]. Applied Surface Science, 2019, 495: 143637. |

| [44] | Shi T Y, Zhao C Y, Yin C, et al. Incorporation ZnS quantum dots into carbon nanotubes for high-performance lithium–sulfur batteries[J]. Nanotechnology, 2020, 31(49): 495406. |

| [45] | Zhang L, Bi J Y, Zhao Z K, et al. Sulfur@Self-assembly 3D MXene hybrid cathode material for lithium-sulfur batteries[J]. Electrochimica Acta, 2021, 370: 137759. |

| [46] | Zhao J, Qi Y R, Yang Q J, et al. Chessboard structured electrode design for Li-S batteries Based on MXene nanosheets[J]. Chemical Engineering Journal, 2022, 429: 131997. |

| [1] | 赵维, 邢文乐, 韩朝旭, 袁兴中, 蒋龙波. g-C3N4基非金属异质结光催化降解水中有机污染物的研究进展[J]. 化工学报, 2025, 76(9): 4752-4769. |

| [2] | 郭铮铮, 赵一丹, 王辅强, 裴璐, 靳彦岭, 任芳, 任鹏刚. 异质结构MoS2/RGO/NiFe2O4复合材料的构筑及电磁波吸收性能研究[J]. 化工学报, 2025, 76(7): 3719-3732. |

| [3] | 郭乃胜, 朱小波, 王双, 陈平, 褚召阳, 王志臣. 聚氨酯改性沥青高低温性能及影响因素的研究进展[J]. 化工学报, 2025, 76(6): 2505-2523. |

| [4] | 何军, 李勇, 赵楠, 何孝军. 碳负载硒掺杂硫化钴在锂硫电池中的性能研究[J]. 化工学报, 2025, 76(6): 2995-3008. |

| [5] | 石孟琪, 王欢, 王守娟, 席跃宾, 孔凡功. 木质素基炭材料的制备及其在锂硫电池中的研究进展[J]. 化工学报, 2025, 76(4): 1463-1483. |

| [6] | 马钟琛, 魏子杰, 朱明涛, 叶恒棣, 郭学益, 谭磊. 一步氧化法制备锰酸锂正极材料用电池级四氧化三锰[J]. 化工学报, 2025, 76(3): 1363-1374. |

| [7] | 李远华, 凌思棋, 封科军, 冯颖, 郭于菁, 谢世桓. 基于cMOFs的固定化脂肪酶微反应器的构筑及其扁桃酸催化应用[J]. 化工学报, 2025, 76(3): 1170-1179. |

| [8] | 肖俊兵, 邹博, 任建地, 刘昌会, 贾传坤. 基于相图分析的氯化物复合熔盐储热性能研究[J]. 化工学报, 2025, 76(3): 963-974. |

| [9] | 肖俊兵, 钟湘宇, 任建地, 钟芳芳, 刘昌会, 贾传坤. 基于生物碳材料强化的硬脂酸相变材料储热性能研究[J]. 化工学报, 2025, 76(3): 1312-1322. |

| [10] | 刘彦贝, 王若名, 刘娟, Raza Taimoor, 陆玉正, Raza Rizwan, 朱斌, 李松波, 安胜利, 云斯宁. CeO2@La0.6Sr0.4Co0.2Fe0.8O3-δ 电解质的制备及半导体离子燃料电池性能研究[J]. 化工学报, 2025, 76(3): 1353-1362. |

| [11] | 肖志华, 房浩楠, 郑方植, 孙冬, 陶丽达, 李永峰, 徐春明, 马新龙. NaCl辅助构筑高性能沥青基硬炭负极材料[J]. 化工学报, 2025, 76(2): 846-857. |

| [12] | 李文宝, 胡锦鹏, 杜淼, 潘鹏举, 单国荣. 强韧P(SBMA-co-AAc)/SiO2复合水凝胶海洋防污减阻涂层[J]. 化工学报, 2025, 76(2): 787-796. |

| [13] | 王芾涵, 王慧儒, 赵成卓, 刘振宇, 刘伟军, 卞宏友. 石蜡/TPMS结构多孔AlSi10Mg合金复合相变材料蓄热性能实验研究[J]. 化工学报, 2025, 76(10): 5414-5425. |

| [14] | 周池楼, 李治宇, 郑益然. 高压氢环境下丁腈橡胶密封件氢致鼓泡断裂研究[J]. 化工学报, 2025, 76(10): 5262-5276. |

| [15] | 徐子易, 席阳, 宋泽文, 周海骏. 碳纳米材料在锌离子电池中的应用研究进展[J]. 化工学报, 2025, 76(1): 40-52. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号