CIESC Journal ›› 2020, Vol. 71 ›› Issue (10): 4642-4651.DOI: 10.11949/0438-1157.20200609

• Catalysis, kinetics and reactors • Previous Articles Next Articles

Shouying HUANG( ),Xiong XIONG,Pei HE,Jianhao WANG,Ying LI,Hongkai LIU,Jing LYU,Xinbin MA(

),Xiong XIONG,Pei HE,Jianhao WANG,Ying LI,Hongkai LIU,Jing LYU,Xinbin MA( )

)

Received:2020-05-18

Revised:2020-07-15

Online:2020-10-05

Published:2020-10-05

Contact:

Xinbin MA

黄守莹( ),熊雄,贺培,王建豪,李媖,刘宏开,吕静,马新宾(

),熊雄,贺培,王建豪,李媖,刘宏开,吕静,马新宾( )

)

通讯作者:

马新宾

作者简介:黄守莹(1985—),女,博士,副教授,基金资助:CLC Number:

Shouying HUANG, Xiong XIONG, Pei HE, Jianhao WANG, Ying LI, Hongkai LIU, Jing LYU, Xinbin MA. Study on binder of extruded mordenite catalyst for dimethyl ether carbonylation[J]. CIESC Journal, 2020, 71(10): 4642-4651.

黄守莹, 熊雄, 贺培, 王建豪, 李媖, 刘宏开, 吕静, 马新宾. 二甲醚羰基化丝光沸石成型催化剂黏结剂的研究[J]. 化工学报, 2020, 71(10): 4642-4651.

Add to citation manager EndNote|Ris|BibTeX

| MOR质量/g | 黏结剂种类 | 黏结剂质量/g | 去离子水质量/g | 硝酸质量/g | 命名 |

|---|---|---|---|---|---|

| 10 | 无 | 0 | 0 | 0 | MOR-P |

| 9 | 拟薄水铝石 | 1 | 6 | 0.125 | 10NI |

| 8 | 拟薄水铝石 | 2 | 6 | 0.125 | 20NI |

| 9 | 硅溶胶 | 1 | 6 | 0.125 | 10Si |

| 8 | 硅溶胶 | 2 | 6 | 0.125 | 20Si |

| 8 | 拟薄水铝石+硅溶胶 | 2 | 6 | 0.125 | 10NI10Si |

Table 1 Formula and nomenclature for catalyst

| MOR质量/g | 黏结剂种类 | 黏结剂质量/g | 去离子水质量/g | 硝酸质量/g | 命名 |

|---|---|---|---|---|---|

| 10 | 无 | 0 | 0 | 0 | MOR-P |

| 9 | 拟薄水铝石 | 1 | 6 | 0.125 | 10NI |

| 8 | 拟薄水铝石 | 2 | 6 | 0.125 | 20NI |

| 9 | 硅溶胶 | 1 | 6 | 0.125 | 10Si |

| 8 | 硅溶胶 | 2 | 6 | 0.125 | 20Si |

| 8 | 拟薄水铝石+硅溶胶 | 2 | 6 | 0.125 | 10NI10Si |

| 样品 | F/(N/cm) | F0/(N/cm) | m | F10% |

|---|---|---|---|---|

| 10NI | 83 | 93 | 2.80 | 35 |

| 20NI | 177 | 197 | 3.21 | 103 |

| 10Si | 47 | 52 | 2.84 | 22 |

| 20Si | 105 | 117 | 3.28 | 47 |

| 10NI10Si | 142 | 158 | 3.99 | 80 |

Table 2 Statistics of strength data for the extruded MOR

| 样品 | F/(N/cm) | F0/(N/cm) | m | F10% |

|---|---|---|---|---|

| 10NI | 83 | 93 | 2.80 | 35 |

| 20NI | 177 | 197 | 3.21 | 103 |

| 10Si | 47 | 52 | 2.84 | 22 |

| 20Si | 105 | 117 | 3.28 | 47 |

| 10NI10Si | 142 | 158 | 3.99 | 80 |

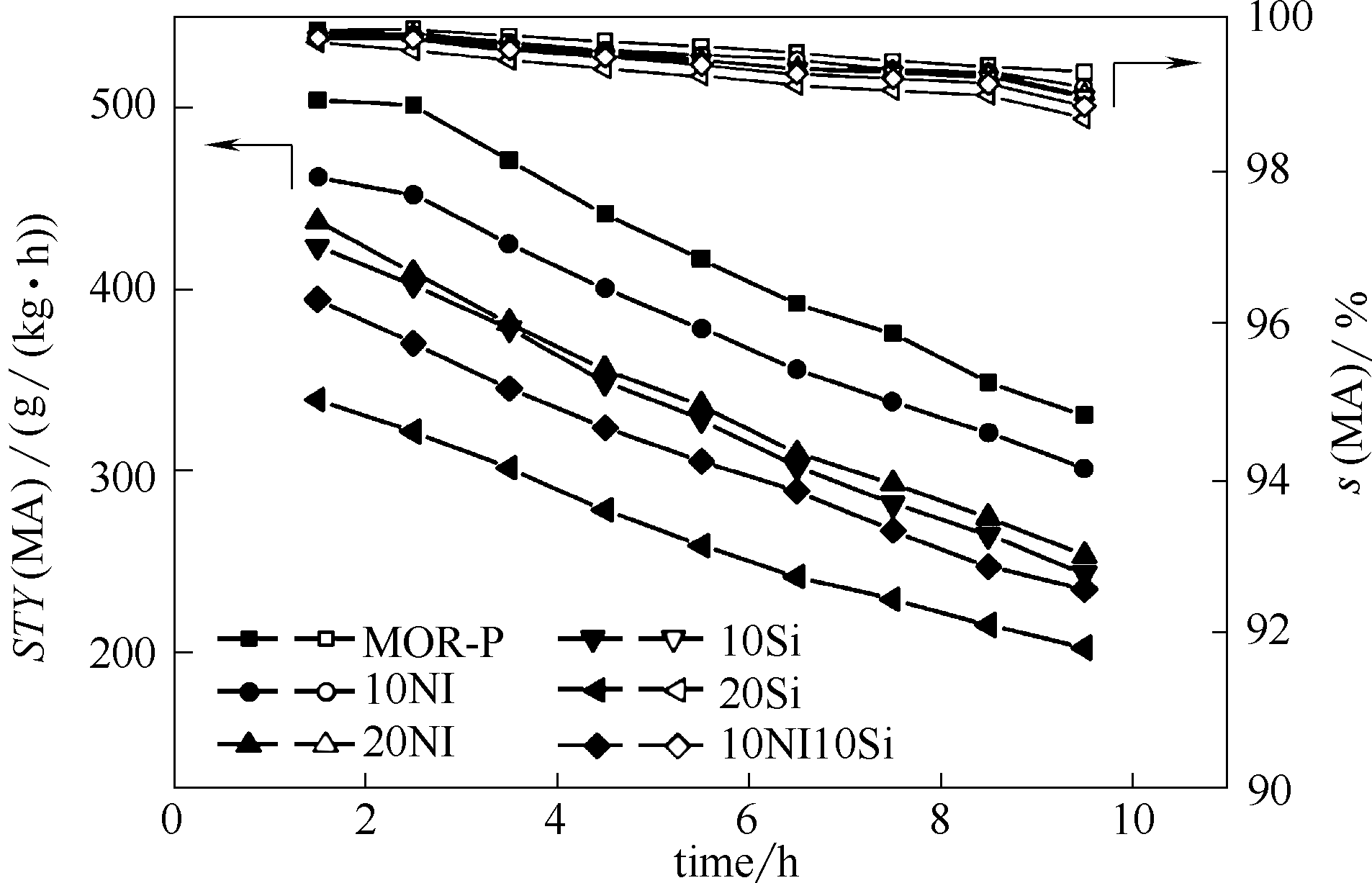

Fig. 3 Catalytic performance of parent and extruded catalyst in DME carbonylation (Reaction conditions: T=200℃, p=1.5 MPa, DME∶CO∶Ar=1∶47∶2, GHSV=6000 h-1)

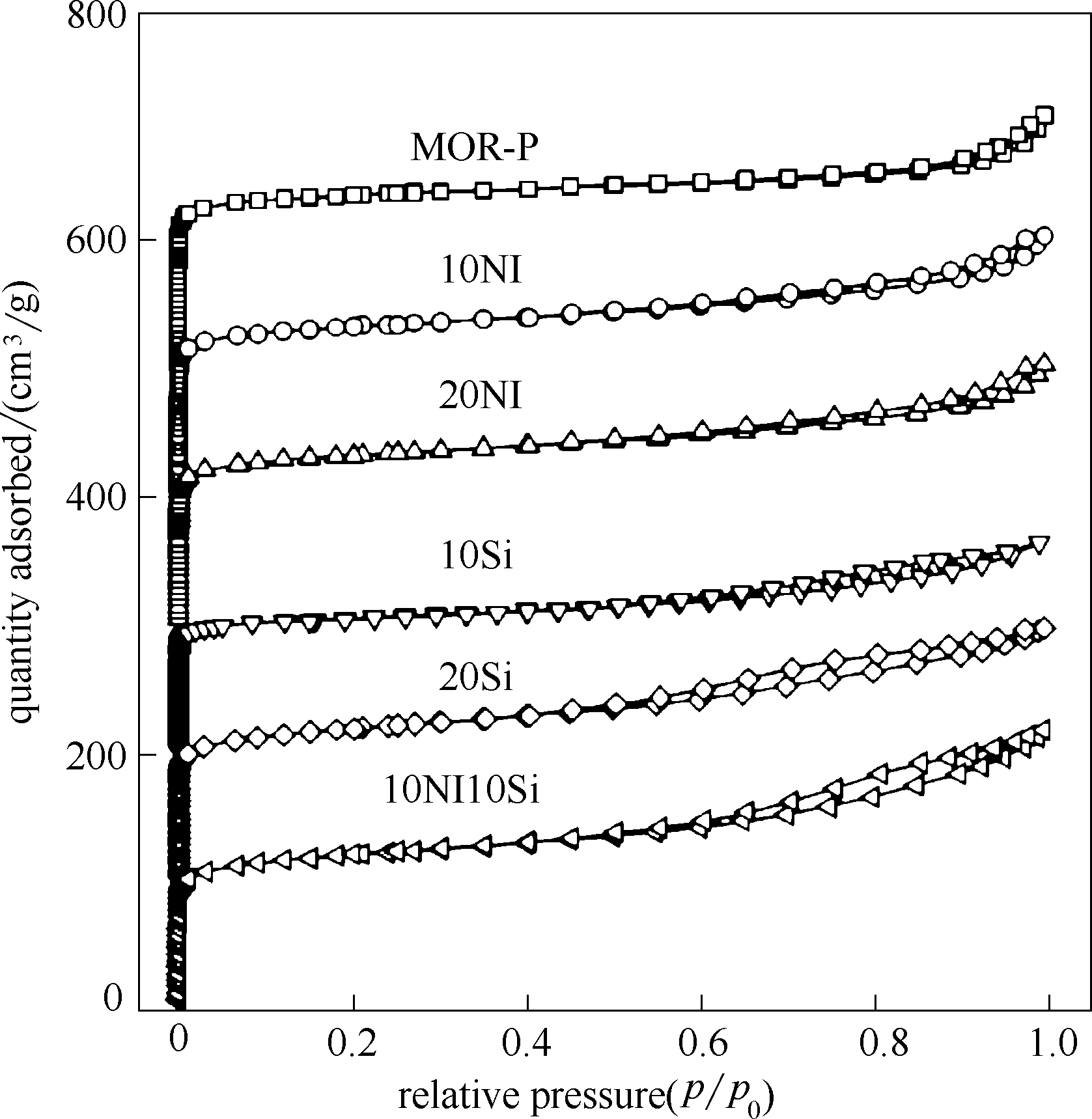

Fig.5 Nitrogen adsorption-desorption isotherms of the parent and extruded MOR (except for 10NI10Si, the isotherms for other samples are shifted 100 cm3/g upward respect to each other)

| 样品 | SBET/ (m2/g) | Smicro/ (m2/g) | Smeso/ (m2/g) | Vmicro/ (cm3/g) | Vmeso/(cm3/g) | Dmeso/nm |

|---|---|---|---|---|---|---|

| MOR-P | 462 | 431 | 31 | 0.159 | 0.109 | 8.1 |

| 10NI | 449 | 399 | 50 | 0.145 | 0.126 | 5.6 |

| 20NI | 449 | 385 | 74 | 0.141 | 0.136 | 5.7 |

| 10Si | 435 | 365 | 70 | 0.132 | 0.132 | 4.2 |

| 20Si | 398 | 299 | 99 | 0.109 | 0.154 | 4.4 |

| 10NI10Si | 435 | 338 | 97 | 0.116 | 0.159 | 5.0 |

| NI① | 283 | — | 283 | — | 0.296 | 6.0 |

| Si② | 331 | — | 331 | — | 0.411 | 4.1 |

Table 3 Textural properties of parent and extruded MOR

| 样品 | SBET/ (m2/g) | Smicro/ (m2/g) | Smeso/ (m2/g) | Vmicro/ (cm3/g) | Vmeso/(cm3/g) | Dmeso/nm |

|---|---|---|---|---|---|---|

| MOR-P | 462 | 431 | 31 | 0.159 | 0.109 | 8.1 |

| 10NI | 449 | 399 | 50 | 0.145 | 0.126 | 5.6 |

| 20NI | 449 | 385 | 74 | 0.141 | 0.136 | 5.7 |

| 10Si | 435 | 365 | 70 | 0.132 | 0.132 | 4.2 |

| 20Si | 398 | 299 | 99 | 0.109 | 0.154 | 4.4 |

| 10NI10Si | 435 | 338 | 97 | 0.116 | 0.159 | 5.0 |

| NI① | 283 | — | 283 | — | 0.296 | 6.0 |

| Si② | 331 | — | 331 | — | 0.411 | 4.1 |

| 样品 | 弱酸峰/℃ | 酸含量/(μmol/g) | 中强酸峰/℃ | 酸含量/(μmol/g) | 强酸峰/℃ | 酸含量/(μmol/g) |

|---|---|---|---|---|---|---|

| MOR-P | 209.7 | 255 | 331.1 | 262 | 535.1 | 1110 |

| 10NI | 213.4 | 233 | 380.4 | 288 | 537.3 | 1007 |

| 20NI | 214.0 | 234 | 378.2 | 317 | 538.1 | 950 |

| 10Si | 211.5 | 217 | 340.2 | 215 | 530.2 | 903 |

| 20Si | 212.0 | 180 | 341.2 | 176 | 531.2 | 739 |

| 10NI10Si | 213.0 | 247 | 350.6 | 227 | 533.4 | 864 |

Table 4 The de-convolution results of NH3-TPD profiles

| 样品 | 弱酸峰/℃ | 酸含量/(μmol/g) | 中强酸峰/℃ | 酸含量/(μmol/g) | 强酸峰/℃ | 酸含量/(μmol/g) |

|---|---|---|---|---|---|---|

| MOR-P | 209.7 | 255 | 331.1 | 262 | 535.1 | 1110 |

| 10NI | 213.4 | 233 | 380.4 | 288 | 537.3 | 1007 |

| 20NI | 214.0 | 234 | 378.2 | 317 | 538.1 | 950 |

| 10Si | 211.5 | 217 | 340.2 | 215 | 530.2 | 903 |

| 20Si | 212.0 | 180 | 341.2 | 176 | 531.2 | 739 |

| 10NI10Si | 213.0 | 247 | 350.6 | 227 | 533.4 | 864 |

| 样品 | Btotal/(μmol/g) | B12-MR/(μmol/g) | L12-MR/(μmol/g) | B8-MR/(μmol/g) | B8-MR/B12-MR |

|---|---|---|---|---|---|

| MOR-P | 1110 | 351 | 47 | 759 | 2.2 |

| 10NI | 1007 | 307 | 73 | 700 | 2.3 |

| 20NI | 950 | 292 | 91 | 658 | 2.3 |

| 10Si | 903 | 294 | 45 | 609 | 2.1 |

| 20Si | 739 | 241 | 41 | 498 | 2.1 |

| 10NI10Si | 864 | 279 | 63 | 585 | 2.1 |

Table 5 The amounts of acid for parent and extruded MOR

| 样品 | Btotal/(μmol/g) | B12-MR/(μmol/g) | L12-MR/(μmol/g) | B8-MR/(μmol/g) | B8-MR/B12-MR |

|---|---|---|---|---|---|

| MOR-P | 1110 | 351 | 47 | 759 | 2.2 |

| 10NI | 1007 | 307 | 73 | 700 | 2.3 |

| 20NI | 950 | 292 | 91 | 658 | 2.3 |

| 10Si | 903 | 294 | 45 | 609 | 2.1 |

| 20Si | 739 | 241 | 41 | 498 | 2.1 |

| 10NI10Si | 864 | 279 | 63 | 585 | 2.1 |

| 样品 | Smicro/ (m2/g) | B8-MR/ (μmol/g) | STY(MA)/ (g/(kg·h)) | TOF/h-1 |

|---|---|---|---|---|

| MOR-P | 431 | 759 | 504 | 9.1 |

| 10NI | 399 | 700 | 469 | 9.0 |

| 20NI | 385 | 658 | 437 | 9.0 |

| 10Si | 365 | 609 | 414 | 9.1 |

| 20Si | 299 | 498 | 340 | 9.1 |

| 10NI10Si | 338 | 585 | 395 | 9.1 |

Table 6 The specific surface area (Smicro), B8-MR and catalytic performance of the parent and extruded MOR

| 样品 | Smicro/ (m2/g) | B8-MR/ (μmol/g) | STY(MA)/ (g/(kg·h)) | TOF/h-1 |

|---|---|---|---|---|

| MOR-P | 431 | 759 | 504 | 9.1 |

| 10NI | 399 | 700 | 469 | 9.0 |

| 20NI | 385 | 658 | 437 | 9.0 |

| 10Si | 365 | 609 | 414 | 9.1 |

| 20Si | 299 | 498 | 340 | 9.1 |

| 10NI10Si | 338 | 585 | 395 | 9.1 |

| 1 | Goldemberg J. Ethanol for a sustainable energy future[J]. Science, 2007, 315(5813): 808-810. |

| 2 | Li Y, Huang S Y, Cheng Z Z, et al. Promoting the activity of Ce-incorporated MOR in dimethyl ether carbonylation through tailoring the distribution of Brønsted acids[J]. Applied Catalysis B: Environmental, 2019, 256: 117777-117788. |

| 3 | 李振宇, 黄格省, 杨延翔, 等. 燃料乙醇生产技术路线分析及产业发展建议[J]. 现代化工, 2011, 31(8): 1-5. |

| Li Z Y, Huang G S, Yang Y X, et al. Technical route analysis of fuel ethanol production and industrial development suggestions[J]. Modern Chemical Industry, 2011, 31(8): 1-5. | |

| 4 | Zeng C Y, Hu Q L. 2018 petroleum & chemical industry development report[J]. Chinese Journal of Chemical Engineering, 2019, 27: 2606-2614. |

| 5 | 黄守莹, 王悦, 吕静, 等. 合成气经二甲醚/乙酸甲酯制无水乙醇的研究进展[J]. 化工学报, 2016, 67(1): 240-247. |

| Huang S Y, Wang Y, Lyu J, et al. Advances in indirect synthesis of ethanol from syngas via dimethyl ether/methyl acetate[J]. CIESC Journal, 2016, 67(1): 240-247. | |

| 6 | Yang G H, Meng F Z, Tsubaki N, et al. A new method of ethanol synthesis from dimethyl ether and syngas in a sequential dual bed reactor with the modified zeolite and Cu/ZnO catalysts[J]. Catalysis Today, 2011, 164(1): 425-428. |

| 7 | Cheung P, Bhan A, Sunley G J, et al. Site requirements and elementary steps in dimethyl ether carbonylation catalyzed by acidic zeolites[J]. Journal of Catalysis, 2007, 245(1): 110-123. |

| 8 | Bhan A, Iglesia E. A link between reactivity and local structure in acid catalysis on zeolites[J]. Accounts of Chemical Research, 2008, 41(4): 559-567. |

| 9 | Bhan A, Allian A D, Sunley G J, et al. Specificity of sites within eight-membered ring zeolite channels for carbonylation of methyls to acetyls[J]. Journal of the American Chemical Society, 2007, 129(16): 4919-4924. |

| 10 | Boronat M, Sánchez C M, Law D, et al. Enzyme-like specificity in zeolites: a unique site position in mordenite for selective carbonylation of methanol and dimethyl ether with CO[J]. Journal of the American Chemical Society, 2008, 130(48): 16316-16323. |

| 11 | Li B J, Wang C, Han B, et al. Insight into dimethyl ether carbonylation reaction over mordenite zeolite from in-situ solid-state NMR spectroscopy[J]. The Journal of Physical Chemistry C, 2013, 117(11): 5840-5847. |

| 12 | Reule A A, Sawada J A, Semagina N. Effect of selective 4-membered ring dealumination on mordenite-catalyzed dimethyl ether carbonylation[J]. Journal of Catalysis, 2017, 349: 98-109. |

| 13 | Wang X S, Li R J, Yu C C, et al. Influence of acid site distribution on dimethyl ether carbonylation over mordenite[J]. Industrial & Engineering Chemistry Research, 2019, 58(39): 18065-18072. |

| 14 | Wang M X, Huang S Y, Lv J, et al. Modifying the acidity of H-MOR and its catalytic carbonylation of dimethyl ether[J]. Chinese Journal of Catalysis, 2016, 37(9): 1530-1537. |

| 15 | Li Y, Yu M, Cai K, et al. Template-induced Al distribution in MOR and enhanced activity in dimethyl ether carbonylation[J]. Physical Chemistry Chemical Physics, 2020, 22: 11374-11381. |

| 16 | Liu J L, Xue H F, Huang X M, et al. Stability enhanacement of H-mordenite in dimethyl ether carbonylation to methyl acetate by pre-adsorption of pyridine[J]. Chinese Journal of Catalysis, 2010, 31(7): 729-738. |

| 17 | Ma M, Huang X M, Zhang E S, et al. Synthesis of mordenite nanosheets with shortened channel lengths and enhanced catalytic activity[J]. Journal of Materials Chemistry A, 2017, 5: 8887-8891. |

| 18 | Wang X S, Li R J, Yu C C, et al. Enhancing the dimethyl ether carbonylation performance over mordenite catalysts by simple alkaline treatment[J]. Fuel, 2019, 239: 794-893. |

| 19 | de Jong K P. Synthesis of Solid Catalyst[M]. Winheim: Wiley-VCH Verlag GmbH & Co., 2009. |

| 20 | Li L Y, Wang Q Y, Liu H C, et al. Preparation of spherical mordenite zeolite assemblies with excellent catalytic performance for dimethyl ether carbonylation[J]. ACS Applied Materials & Interfaces, 2018, 10(38): 32239-32246. |

| 21 | Jasra R A, Tyagi B, Badheka Y M, et al. Effect of clay binder on sorption and catalytic properties of zeolite pellets[J]. Industrial & Engineering Chemistry Research, 2003, 42(14): 3263-3272. |

| 22 | Lucas A D, Valverde J L, Sanchez P, et al. Influence of the binder on the n-octane hydroisomerization over palladium-containing zeolite catalysts[J]. Industrial & Engineering Chemistry Research, 2004, 43(26): 8217-8225. |

| 23 | Shen X L, Zhou Y M, Kong J, et al. Influence of pseudo-boehmite binder modified dealuminated mordenite on Friedel-Crafts alkylation[J]. Journal of Porous Materials, 2015, 22: 179-185. |

| 24 | Li Y, Sun Q, Huang S Y, et al. Dimethyl ether carbonylation over pyridine-modified MOR: enhanced stability influenced by acidity[J]. Catalysis Today, 2018, 311: 81-88. |

| 25 | Cheng Z Z, Huang S Y, Li Y, et al. Deactivation kinetics for the carbonylation of dimethyl ether to methyl acetate on H-MOR[J]. Industrial & Engineering Chemistry Research, 2017, 56(46): 13618-13627. |

| 26 | Li Y D, Wu D F, Zhang J P, et al. Measurement and statistics of single pellet mechanical strength of differently shaped catalysts[J]. Powder Technology, 2000, 113(1/2): 176-184. |

| 27 | Deng S W, Wang Y B, Zhuang G L, et al. Micromechanical simulation of the pore size effect on the structural stability of brittle porous materials with bicontinuous morphology[J]. Physical Chemistry Chemical Physics, 2019, 21: 12895-12904. |

| 28 | Liu G Z, Guo J H, Meng F X, et al. Effects of colloidal silica binder on catalytic activity and adhesion of HZSM-5 coatings for structured reactors[J]. Chinese Journal of Chemical Engineering, 2014, 22(8): 875-881. |

| 29 | Whiting G T, Chung S H, Stosic D, et al. Multiscale mechanistic insights of shaped catalyst body formulations and their impact on catalytic properties[J]. ACS Catalysis, 2019, 9(6): 4792-4803. |

| 30 | Liu Y H, Zhao N, Xian H, et al. Facilely synthesized H-mordenite nanosheet assembly for carbonylation of dimethyl ether[J]. Applied Materials & Interfaces, 2015, 7(16): 8398-8403. |

| 31 | Osman A I, Dahrieh J K, Rooney D W, et al. Surface hydrophobicity and acidity effect on alumina catalyst in catalytic methanol dehydration reaction[J]. Journal of Chemical Technology & Biotechnology, 2017, 92(12): 2952-2962. |

| 32 | Zhou W W, Zhang Y N, Tao X J, et al. Effects of gallium addition to mesoporous alumina by impregnation on dibenzothiophene hydrodesulfurization performances of the corresponding NiMo supported catalysts[J]. Fuel, 2018, 228: 152-163. |

| 33 | Emeis C A. Determination of integrated molar extinction coefficients for infrared absorption bands of pyridine adsorbed on solid acid catalyst[J]. Journal of Catalyst, 1993, 141: 347-354. |

| 34 | Garderen N V, Clemens F J, Aneziris C G, et al. Improved γ-alumina support based pseudo-boehmite shaped by micro-extrusion process for oxygen carrier support application[J]. Ceramics International, 2012, 38(7): 5481-5492. |

| [1] | Jie CHEN, Yongsheng LIN, Kai XIAO, Chen YANG, Ting QIU. Study on catalytic synthesis of sec-butanol by tunable choline-based basic ionic liquids [J]. CIESC Journal, 2023, 74(9): 3716-3730. |

| [2] | Yitong LI, Hang GUO, Hao CHEN, Fang YE. Study on operating conditions of proton exchange membrane fuel cells with non-uniform catalyst distributions [J]. CIESC Journal, 2023, 74(9): 3831-3840. |

| [3] | Xuejin YANG, Jintao YANG, Ping NING, Fang WANG, Xiaoshuang SONG, Lijuan JIA, Jiayu FENG. Research progress in dry purification technology of highly toxic gas PH3 [J]. CIESC Journal, 2023, 74(9): 3742-3755. |

| [4] | Xin YANG, Xiao PENG, Kairu XUE, Mengwei SU, Yan WU. Preparation of molecularly imprinted-TiO2 and its properties of photoelectrocatalytic degradation of solubilized PHE [J]. CIESC Journal, 2023, 74(8): 3564-3571. |

| [5] | Feifei YANG, Shixi ZHAO, Wei ZHOU, Zhonghai NI. Sn doped In2O3 catalyst for selective hydrogenation of CO2 to methanol [J]. CIESC Journal, 2023, 74(8): 3366-3374. |

| [6] | Kaixuan LI, Wei TAN, Manyu ZHANG, Zhihao XU, Xuyu WANG, Hongbing JI. Design of cobalt-nitrogen-carbon/activated carbon rich in zero valent cobalt active site and application of catalytic oxidation of formaldehyde [J]. CIESC Journal, 2023, 74(8): 3342-3352. |

| [7] | Pan LI, Junyang MA, Zhihao CHEN, Li WANG, Yun GUO. Effect of the morphology of Ru/α-MnO2 on NH3-SCO performance [J]. CIESC Journal, 2023, 74(7): 2908-2918. |

| [8] | Yajie YU, Jingru LI, Shufeng ZHOU, Qingbiao LI, Guowu ZHAN. Construction of nanomaterial and integrated catalyst based on biological template: a review [J]. CIESC Journal, 2023, 74(7): 2735-2752. |

| [9] | Yuming TU, Gaoyan SHAO, Jianjie CHEN, Feng LIU, Shichao TIAN, Zhiyong ZHOU, Zhongqi REN. Advances in the design, synthesis and application of calcium-based catalysts [J]. CIESC Journal, 2023, 74(7): 2717-2734. |

| [10] | Qiyu ZHANG, Lijun GAO, Yuhang SU, Xiaobo MA, Yicheng WANG, Yating ZHANG, Chao HU. Recent advances in carbon-based catalysts for electrochemical reduction of carbon dioxide [J]. CIESC Journal, 2023, 74(7): 2753-2772. |

| [11] | Jipeng ZHOU, Wenjun HE, Tao LI. Reaction engineering calculation of deactivation kinetics for ethylene catalytic oxidation over irregular-shaped catalysts [J]. CIESC Journal, 2023, 74(6): 2416-2426. |

| [12] | Tan ZHANG, Guang LIU, Jinping LI, Yuhan SUN. Performance regulation strategies of Ru-based nitrogen reduction electrocatalysts [J]. CIESC Journal, 2023, 74(6): 2264-2280. |

| [13] | Kuikui HAN, Xianglong TAN, Jinzhi LI, Ting YANG, Chun ZHANG, Yongfen ZHANG, Hongquan LIU, Zhongwei YU, Xuehong GU. Four-channel hollow fiber MFI zeolite membrane for the separation of xylene isomers [J]. CIESC Journal, 2023, 74(6): 2468-2476. |

| [14] | Feng ZHU, Kailin CHEN, Xiaofeng HUANG, Yinzhu BAO, Wenbin LI, Jiaxin LIU, Weiqiang WU, Wangwei GAO. Performance study of KOH modified carbide slag for removal of carbonyl sulfide [J]. CIESC Journal, 2023, 74(6): 2668-2679. |

| [15] | Chen WANG, Xiufeng SHI, Xianfeng WU, Fangjia WEI, Haohong ZHANG, Yin CHE, Xu WU. Preparation of Mn3O4 catalyst by redox method and study on its catalytic oxidation performance and mechanism of toluene [J]. CIESC Journal, 2023, 74(6): 2447-2457. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||