CIESC Journal ›› 2023, Vol. 74 ›› Issue (7): 2717-2734.DOI: 10.11949/0438-1157.20230193

• Reviews and monographs • Previous Articles Next Articles

Yuming TU( ), Gaoyan SHAO, Jianjie CHEN, Feng LIU, Shichao TIAN, Zhiyong ZHOU, Zhongqi REN(

), Gaoyan SHAO, Jianjie CHEN, Feng LIU, Shichao TIAN, Zhiyong ZHOU, Zhongqi REN( )

)

Received:2023-03-06

Revised:2023-07-05

Online:2023-08-31

Published:2023-07-05

Contact:

Zhongqi REN

涂玉明( ), 邵高燕, 陈健杰, 刘凤, 田世超, 周智勇, 任钟旗(

), 邵高燕, 陈健杰, 刘凤, 田世超, 周智勇, 任钟旗( )

)

通讯作者:

任钟旗

作者简介:涂玉明(1995—),男,博士研究生,tuyumingbuct@yeah.net

基金资助:CLC Number:

Yuming TU, Gaoyan SHAO, Jianjie CHEN, Feng LIU, Shichao TIAN, Zhiyong ZHOU, Zhongqi REN. Advances in the design, synthesis and application of calcium-based catalysts[J]. CIESC Journal, 2023, 74(7): 2717-2734.

涂玉明, 邵高燕, 陈健杰, 刘凤, 田世超, 周智勇, 任钟旗. 钙基催化剂的设计合成及应用研究进展[J]. 化工学报, 2023, 74(7): 2717-2734.

Add to citation manager EndNote|Ris|BibTeX

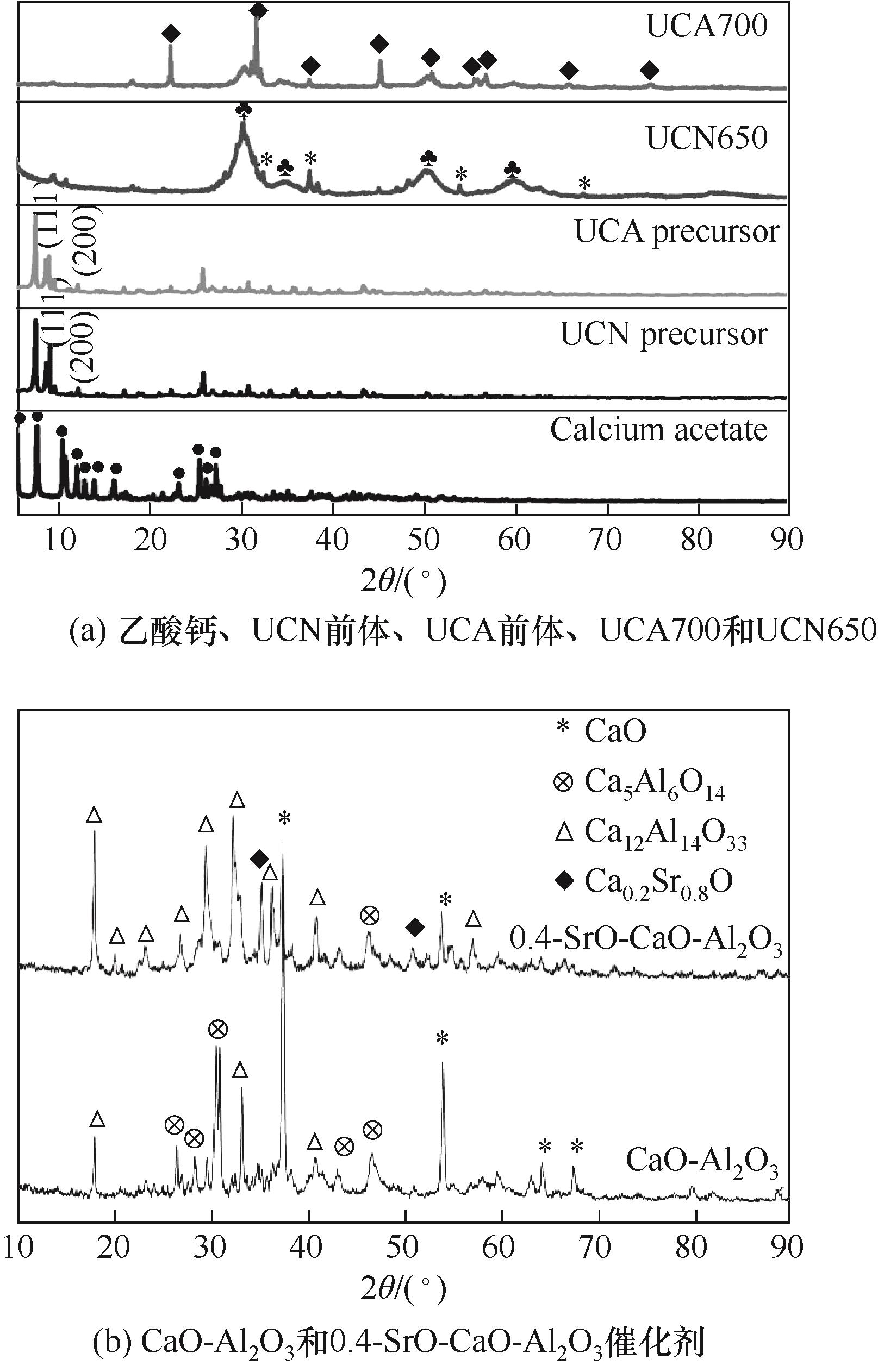

Fig.3 XRD patterns of calcium acetate, UCN precursor, UCA precursor, UCA700 and UCN650 (UCN, UCA represent activation in nitrogen and air atmosphere, respectively) (CaZrO3, Ca x Zr y O x+2y )[29], CaO-Al2O3 and 0.4-SrO-CaO-Al2O3 catalysts[31]

| 催化剂 | 转化率/% | 稳定性 |

|---|---|---|

| CaO[ | 87 | 多次使用后下降了30% |

| CaO/SBC[ | 93.4 | 多次使用后下降了9% |

| CaO-ZrO2[ | 97 | 使用3次后保持在93%以上 |

| CaO-MgO[ | 98.4 | 使用5次后保持在93%以上 |

| Ca/APB[ | 81.6 | 使用10次后基本保持稳定 |

| CaP-600[ | 99 | 微量浸出 |

Table 1 Comparison of the effects of different catalysts in the biodiesel synthesis process

| 催化剂 | 转化率/% | 稳定性 |

|---|---|---|

| CaO[ | 87 | 多次使用后下降了30% |

| CaO/SBC[ | 93.4 | 多次使用后下降了9% |

| CaO-ZrO2[ | 97 | 使用3次后保持在93%以上 |

| CaO-MgO[ | 98.4 | 使用5次后保持在93%以上 |

| Ca/APB[ | 81.6 | 使用10次后基本保持稳定 |

| CaP-600[ | 99 | 微量浸出 |

| 催化剂 | 废水类型 | COD/ (mg·L-1) | COD 去 除率/% |

|---|---|---|---|

| 煤基活性炭[ | 煤化工废水生化出水 | 283.8 | 32.16 |

| AC[ | 纺织废水 | 2570 | 50 |

| FeO x /AC[ | 炼油厂废水 | 54.6~256 | 40 |

| γ-Al2O3[ | 石化废水 | 750 | 46 |

| CuCo/CAFNi[ | 煤气化废水 | 70~80 | 60~65 |

| Mn x Ce1-x /γ-Al2O3[ | 焦化废水 | 150 | 45.6 |

| Al2O3-PDA-Ca x O y[ | 石化废水(生化出水) | 140~160 | 62 |

| Ca-C/Al2O3[ | 化工园区废水(生化出水) | 100~129 | 65 |

| Al2O3-PDA-SA-Ca x O y[ | 化工园区废水(生化出水) | 100~129 | 66 |

Table 2 Comparison of the effectiveness of different catalysts in treating actual wastewater

| 催化剂 | 废水类型 | COD/ (mg·L-1) | COD 去 除率/% |

|---|---|---|---|

| 煤基活性炭[ | 煤化工废水生化出水 | 283.8 | 32.16 |

| AC[ | 纺织废水 | 2570 | 50 |

| FeO x /AC[ | 炼油厂废水 | 54.6~256 | 40 |

| γ-Al2O3[ | 石化废水 | 750 | 46 |

| CuCo/CAFNi[ | 煤气化废水 | 70~80 | 60~65 |

| Mn x Ce1-x /γ-Al2O3[ | 焦化废水 | 150 | 45.6 |

| Al2O3-PDA-Ca x O y[ | 石化废水(生化出水) | 140~160 | 62 |

| Ca-C/Al2O3[ | 化工园区废水(生化出水) | 100~129 | 65 |

| Al2O3-PDA-SA-Ca x O y[ | 化工园区废水(生化出水) | 100~129 | 66 |

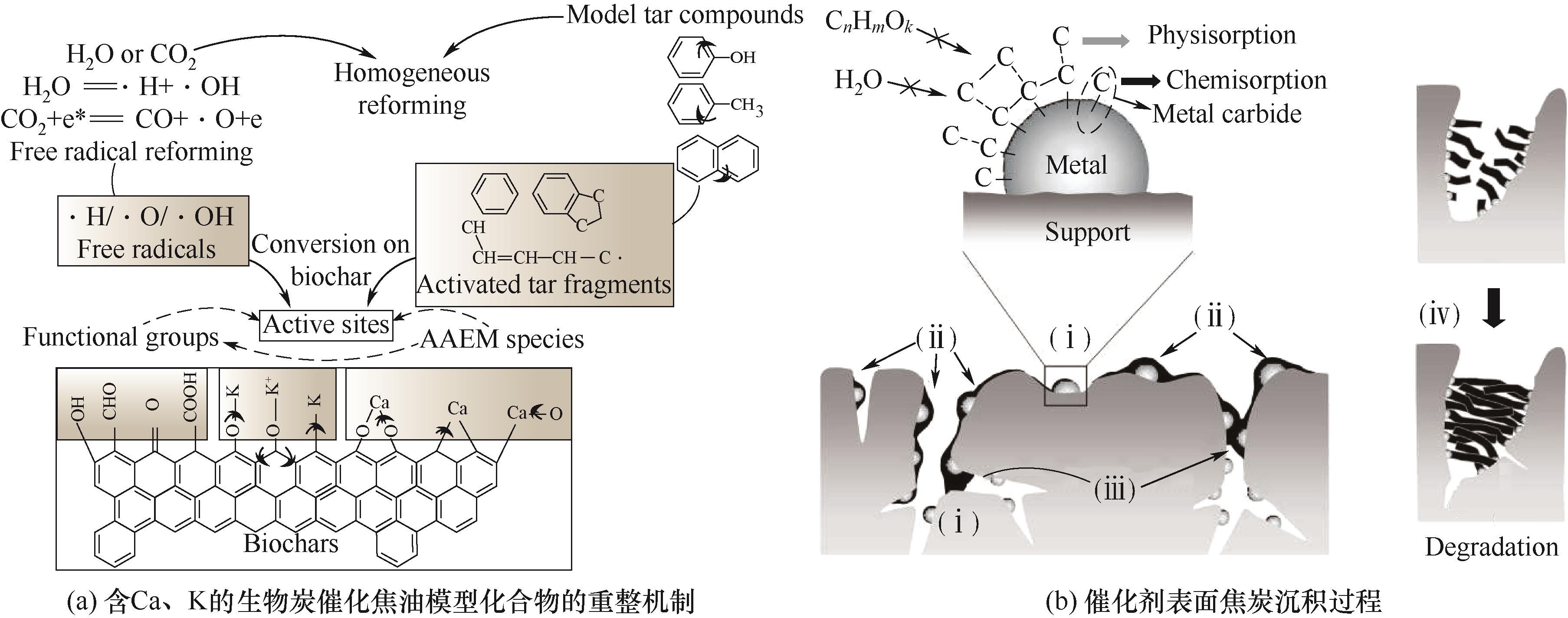

Fig.10 Mechanism of Ca- and K-containing biochar-catalyzed reformation of tar model compounds (a)[70]; Catalyst surface coke deposition process (b)[72]: chemisorption of carbon on catalytically active surface particles (ⅰ), coke encapsulation of inorganic molecules (ⅱ), coke deposition blocking porous structures (ⅲ), and catalyst structural degradation due to coke deposition (ⅳ)

Fig.11 Comparison of the effect of Ca-based catalysts (a); XRD pattern of Ca-based catalysts (b); Schematic representation of the reaction mechanism (c)[74]

| 催化剂 | 反应体系 | 反应温度/℃ | 转化率/% | H2摩尔分数/% |

|---|---|---|---|---|

| 白云石颗粒[ | 模拟焦油(乙酸、苯) | 850 | 99.8、18.7 | — |

| 白云石焙烧物[ | 生物质焦油 | 900 | 95.14 | — |

| Ca-K/生物炭[ | 模拟焦油(甲苯、萘) | 800 | 86~100 | 62 |

| Ca/CPC[ | 模拟焦油(甲苯) | 900 | 94.4 | 68.5 |

| Fe6Al4Ca1[ | 煤焦油 | 900 | 90 | 50 |

| Ni/生物炭[ | 生物质焦油 | 800 | 96.5 | — |

| Fe/生物炭[ | 生物质焦油 | 800 | 92.6 | 39.88 |

| Cu/生物炭[ | 生物质焦油 | 800 | 90.6 | — |

Table 3 Comparison of the effects of different catalysts in tar cracking reforming process

| 催化剂 | 反应体系 | 反应温度/℃ | 转化率/% | H2摩尔分数/% |

|---|---|---|---|---|

| 白云石颗粒[ | 模拟焦油(乙酸、苯) | 850 | 99.8、18.7 | — |

| 白云石焙烧物[ | 生物质焦油 | 900 | 95.14 | — |

| Ca-K/生物炭[ | 模拟焦油(甲苯、萘) | 800 | 86~100 | 62 |

| Ca/CPC[ | 模拟焦油(甲苯) | 900 | 94.4 | 68.5 |

| Fe6Al4Ca1[ | 煤焦油 | 900 | 90 | 50 |

| Ni/生物炭[ | 生物质焦油 | 800 | 96.5 | — |

| Fe/生物炭[ | 生物质焦油 | 800 | 92.6 | 39.88 |

| Cu/生物炭[ | 生物质焦油 | 800 | 90.6 | — |

| 1 | Li X H, Jia Y S, Chen D H, et al. Study of bifunctional calcium-based catalysts for PCDD/Fs removal in medical waste pyrolysis-combustion process[J]. Chemical Engineering and Processing - Process Intensification, 2023, 188: 109377. |

| 2 | Adepoju T F, Ibeh M A, Udoetuk E N, et al. Quaternary blend of Carica papaya - Citrus sinesis - Hibiscus sabdariffa - waste used oil for biodiesel synthesis using CaO-based catalyst derived from binary mix of Lattorina littorea and Mactra coralline shell[J]. Renewable Energy, 2021, 171: 22-33. |

| 3 | 林启睿, 许增栋, 吴素芳. 纳米钙基吸附剂脱碳强化生物乙醇蒸汽重整制氢工艺[J]. 高校化学工程学报, 2018, 32(1): 163-169. |

| Lin Q R, Xu Z D, Wu S F. Hydrogen production via sorption enhanced steam reforming of bio-ethanol using nano Ca-based adsorbents[J]. Journal of Chemical Engineering of Chinese Universities, 2018, 32(1): 163-169. | |

| 4 | 张德静, 常飞, 薛伟, 等. 天然钙基催化剂在制备生物柴油中的研究进展[J]. 天然气化工(C1化学与化工), 2013, 38(2): 89-94. |

| Zhang D J, Chang F, Xue W, et al. Application of natural calcium-based catalysts in synthesis of biodiesel: a review[J]. Natural Gas Chemical Industry, 2013, 38(2): 89-94. | |

| 5 | Tanpure S, Ghanwat V, Shinde B, et al. The eggshell waste transformed green and efficient synthesis of K-Ca (OH)2 catalyst for room temperature synthesis of chalcones[J]. Polycyclic Aromatic Compounds, 2022, 42(4): 1322-1340. |

| 6 | Kouzu M, Kasuno T, Tajika M, et al. Calcium oxide as a solid base catalyst for transesterification of soybean oil and its application to biodiesel production[J]. Fuel, 2008, 87(12): 2798-2806. |

| 7 | Wei Z K, Xu C L, Li B X. Application of waste eggshell as low-cost solid catalyst for biodiesel production[J]. Bioresource Technology, 2009, 100(11): 2883-2885. |

| 8 | 黄继明, 刘润清, 韦恩光, 等. CaO/MgO复合固体碱催化剂催化降解PET[J]. 工程塑料应用, 2018, 46(7): 46-50. |

| Huang J M, Liu R Q, Wei E G, et al. Degradation behaviors of PET catalyzed by CaO/MgO composite as solid base catalyst[J]. Engineering Plastics Application, 2018, 46(7): 46-50. | |

| 9 | 付希, 王宜涛, 张月, 等. CaO-ZnO固体碱催化剂的制备及其催化大豆油酯交换反应的性能[J]. 石油化工, 2017, 46(5): 552-557. |

| Fu X, Wang Y T, Zhang Y, et al. Preparation of CaO-ZnO solid base catalysts and their catalytic performances for transesterification of soybean oil[J]. Petrochemical Technology, 2017, 46 (5): 552-557. | |

| 10 | Chang Y H, Tseng W C, Kaun C C, et al. Mg2Fe2O5 nanoparticle-decorated Ca2Fe2O5-CaFe2O4 heterostructure for efficient photocatalytic CO2 conversion[J]. ACS Sustainable Chemistry & Engineering, 2022, 10(38): 12651-12658. |

| 11 | Kesić Ž, Lukić I, Zdujić M, et al. Assessment of CaTiO3, CaMnO3, CaZrO3 and Ca2Fe2O5 perovskites as heterogeneous base catalysts for biodiesel synthesis[J]. Fuel Processing Technology, 2016, 143: 162-168. |

| 12 | Bihanic C, Diliberto S, Pelissier F, et al. Eco-CaMnO x : a greener generation of eco-catalysts for eco-friendly oxidation processes[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(10): 4044-4057. |

| 13 | Kesserwan F, Ahmad M N, Khalil M, et al. Hybrid CaO/Al2O3 aerogel as heterogeneous catalyst for biodiesel production[J]. Chemical Engineering Journal, 2020, 385: 123834. |

| 14 | Sun H, Sun K, Wang F, et al. Catalytic self-activation of Ca-doped coconut shell for in situ synthesis of hierarchical porous carbon supported CaO transesterification catalyst[J]. Fuel, 2021, 285: 119192. |

| 15 | Lin Z Y, Huang H, Cheng L, et al. Tuning the p-orbital electron structure of s-block metal Ca enables a high-performance electrocatalyst for oxygen reduction[J]. Advanced Materials, 2021, 33(51): 2107103. |

| 16 | Tu Y M, Chen J J, Shao G Y, et al. Preparation and application of green calcium-based catalyst for advanced treatment of salty wastewater with ozone[J]. Journal of Cleaner Production, 2022, 362: 132464. |

| 17 | Chen J J, Tu Y M, Shao G Y, et al. Catalytic ozonation performance of calcium-loaded catalyst (Ca-C/Al2O3) for effective treatment of high salt organic wastewater[J]. Separation and Purification Technology, 2022, 301: 121937. |

| 18 | Shao G Y, Zhou Z Y, Tu Y M, et al. Calcium-based catalyst for ozone catalytic oxidation for advanced treatment of high salt organic wastewater[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2022, 654: 130149. |

| 19 | Simsek S, Uslu S. Comparative evaluation of the influence of waste vegetable oil and waste animal oil-based biodiesel on diesel engine performance and emissions[J]. Fuel, 2020, 280: 118613. |

| 20 | Costa M J, Silva M R L, Ferreira E E A, et al. Enzymatic biodiesel production by hydroesterification using waste cooking oil as feedstock[J]. Chemical Engineering and Processing - Process Intensification, 2020, 157: 108131. |

| 21 | Jung J M, Oh J I, Kim J G, et al. Valorization of sewage sludge via non-catalytic transesterification[J]. Environment International, 2019, 131: 105035. |

| 22 | Yaşar F. Biodiesel production via waste eggshell as a low-cost heterogeneous catalyst: its effects on some critical fuel properties and comparison with CaO[J]. Fuel, 2019, 255: 115828. |

| 23 | Navas M B, Ruggera J F, Lick I D, et al. A sustainable process for biodiesel production using Zn/Mg oxidic species as active, selective and reusable heterogeneous catalysts[J]. Bioresources and Bioprocessing, 2020, 7(1): 1-13. |

| 24 | Xie W L, Li H T. Alumina-supported potassium iodide as a heterogeneous catalyst for biodiesel production from soybean oil[J]. Journal of Molecular Catalysis A: Chemical, 2006, 255(1/2): 1-9. |

| 25 | Karpagam R, Rani K, Ashokkumar B, et al. Green energy from Coelastrella sp. M-60: bio-nanoparticles mediated whole biomass transesterification for biodiesel production[J]. Fuel, 2020, 279: 118490. |

| 26 | Bedir Ö, Doğan T H. Comparison of catalytic activities of Ca-based catalysts from waste in biodiesel production[J]. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2021, DOI: 10.1080/15567036.2021.1883159 . |

| 27 | Samart C, Chaiya C Y, Reubroycharoen P. Biodiesel production by methanolysis of soybean oil using calcium supported on mesoporous silica catalyst[J]. Energy Conversion and Management, 2010, 51(7): 1428-1431. |

| 28 | Wang Y Z, Li D N, Zhao D D, et al. Calcium-loaded municipal sludge-biochar as an efficient and stable catalyst for biodiesel production from vegetable oil[J]. ACS Omega, 2020, 5(28): 17471-17478. |

| 29 | Li H, Wang Y B, Ma X L, et al. Synthesis of CaO/ZrO2 based catalyst by using UiO-66(Zr) and calcium acetate for biodiesel production[J]. Renewable Energy, 2022, 185: 970-977. |

| 30 | Fan M M, Liu Y L, Zhang P B, et al. Blocky shapes Ca-Mg mixed oxides as a water-resistant catalyst for effective synthesis of biodiesel by transesterification[J]. Fuel Processing Technology, 2016, 149: 163-168. |

| 31 | Zhang Y J, Niu S L, Han K H, et al. Synthesis of the SrO-CaO-Al2O3 trimetallic oxide catalyst for transesterification to produce biodiesel[J]. Renewable Energy, 2021, 168: 981-990. |

| 32 | Wang S X, Shan R, Wang Y Z, et al. Synthesis of calcium materials in biochar matrix as a highly stable catalyst for biodiesel production[J]. Renewable Energy, 2019, 130: 41-49. |

| 33 | Acosta P I, Campedelli R R, Correa E L, et al. Efficient production of biodiesel by using a highly active calcium oxide prepared in presence of pectin as heterogeneous catalyst[J]. Fuel, 2020, 271: 117651. |

| 34 | Stamenković O S, Veljković V B, Todorović Z B, et al. Modeling the kinetics of calcium hydroxide catalyzed methanolysis of sunflower oil[J]. Bioresource Technology, 2010, 101(12): 4423-4430. |

| 35 | Tasić M B, Miladinović M R, Stamenković O S, et al. Kinetic modeling of sunflower oil methanolysis catalyzed by calcium-based catalysts[J]. Chemical Engineering & Technology, 2015, 38(9): 1550-1556. |

| 36 | Ramos M, Soares Dias A P, Teodoro F. Soybean oil ethanolysis over Ca based catalyst. Statistical optimization of reaction conditions[J]. Reaction Kinetics, Mechanisms and Catalysis, 2020, 130(1): 433-445. |

| 37 | Díaz-Muñoz L L, Reynel-Ávila H E, Mendoza-Castillo D I, et al. Optimization of flamboyant-based catalysts functionalized with calcium for fatty acid methyl esters production via transesterification[J]. Fuel, 2021, 302: 121125. |

| 38 | Mazaheri H, Ong H C, Masjuki H H, et al. Rice bran oil based biodiesel production using calcium oxide catalyst derived from Chicoreus brunneus shell[J]. Energy, 2018, 144: 10-19. |

| 39 | Karunadasa K S P, Manoratne C H, Pitawala H M T G A, et al. Thermal decomposition of calcium carbonate (calcite polymorph) as examined by in situ high-temperature X-ray powder diffraction[J]. Journal of Physics and Chemistry of Solids, 2019, 134: 21-28. |

| 40 | Suppes G J, Bockwinkel K, Lucas S, et al. Calcium carbonate catalyzed alcoholysis of fats and oils[J]. Journal of the American Oil Chemists' Society, 2001, 78(2): 139-146. |

| 41 | Wang J L, Bai Z Y. Fe-based catalysts for heterogeneous catalytic ozonation of emerging contaminants in water and wastewater[J]. Chemical Engineering Journal, 2017, 312: 79-98. |

| 42 | Jia J B, Zhang P Y, Chen L. Catalytic decomposition of gaseous ozone over manganese dioxides with different crystal structures[J]. Applied Catalysis B: Environmental, 2016, 189: 210-218. |

| 43 | Feng X J, Yin C K, Lan H X, et al. Insights into the multiple roles of Ca2+ ion in peroxymonosulfate activation over Mn2O3 for organic pollutants degradation[J]. Journal of Environmental Chemical Engineering, 2021, 9(6): 106669. |

| 44 | Abou-Elyazed A S, Sun Y, El-Nahas A M, et al. Solvent-free synthesis and characterization of Ca2+-doped UiO-66(Zr) as heterogeneous catalyst for esterification of oleic acid with methanol: a joint experimental and computational study[J]. Materials Today Sustainability, 2022, 18: 100110. |

| 45 | Liao M H, Chen J D, Li L X, et al. Effective degradation of nitrotoluenes in wastewater by heterogeneous catalytic ozonation in the presence of calcium oxide[C]//AIP Conference Proceedings. Hubei, 2017. |

| 46 | Hsu Y C, Chen J H, Yang H C. Calcium enhanced COD removal for the ozonation of phenol solution[J]. Water Research, 2007, 41(1): 71-78. |

| 47 | 全学军, 晏云鹏, 程治良, 等. Ca(OH)2催化臭氧去除废水有机污染物的方法: 103351051A[P]. 2015-04-29. |

| Quan X J, Yan Y P, Cheng Z L, et al. Method for removing organic pollutants in waste water by taking Ca(OH)2 as catalyst of ozone: 103351051A[P]. 2015-04-29. | |

| 48 | Lee W J, Bao Y P, Hu X, et al. Hybrid catalytic ozonation-membrane filtration process with CeO x and MnO x impregnated catalytic ceramic membranes for micropollutants degradation[J]. Chemical Engineering Journal, 2019, 378: 121670. |

| 49 | Han P W, Lv H X, Li X G, et al. Perovskite CaZrO3 for efficient ozonation treatment of organic pollutants in wastewater[J]. Catalysis Science & Technology, 2021, 11(11): 3697-3705. |

| 50 | Wang Y X, Xie Y B, Sun H Q, et al. Hierarchical shape-controlled mixed-valence calcium manganites for catalytic ozonation of aqueous phenolic compounds[J]. Catalysis Science & Technology, 2016, 6(9): 2918-2929. |

| 51 | Wang S H, Zhou L L, Zheng M, et al. Catalytic ozonation over Ca2Fe2O5 for the degradation of quinoline in an aqueous solution[J]. Industrial & Engineering Chemistry Research, 2022, 61(19): 6343-6353. |

| 52 | Zhou Z Y, Kong D L, Zhu H Y, et al. Preparation and adsorption characteristics of an ion-imprinted polymer for fast removal of N i ( Ⅱ ) ions from aqueous solution[J]. Journal of Hazardous Materials, 2018, 341: 355-364. |

| 53 | Kong D L, Qiao N, Wang N, et al. Facile preparation of a nano-imprinted polymer on magnetite nanoparticles for the rapid separation of lead ions from aqueous solution[J]. Physical Chemistry Chemical Physics, 2018, 20(18): 12870-12878. |

| 54 | Kong D L, Qiao N, Liu H, et al. Fast and efficient removal of copper using sandwich-like graphene oxide composite imprinted materials[J]. Chemical Engineering Journal, 2017, 326: 141-150. |

| 55 | Liu C, Chen X X, Zhang J, et al. Advanced treatment of bio-treated coal chemical wastewater by a novel combination of microbubble catalytic ozonation and biological process[J]. Separation and Purification Technology, 2018, 197: 295-301. |

| 56 | Bilińska L, Blus K, Bilińska M, et al. Industrial textile wastewater ozone treatment: catalyst selection[J]. Catalysts, 2020, 10(6): 611. |

| 57 | Chen C M, Chen H S, Guo X, et al. Advanced ozone treatment of heavy oil refining wastewater by activated carbon supported iron oxide[J]. Journal of Industrial and Engineering Chemistry, 2014, 20(5): 2782-2791. |

| 58 | Vittenet J, Aboussaoud W, Mendret J, et al. Catalytic ozonation with γ-Al2O3 to enhance the degradation of refractory organics in water[J]. Applied Catalysis A: General, 2015, 504: 519-532. |

| 59 | Wei K J, Cao X X, Gu W C, et al. Ni-induced C-Al2O3-framework (NiCAF) supported core-multishell catalysts for efficient catalytic ozonation: a structure-to-performance study[J]. Environmental Science & Technology, 2019, 53(12): 6917-6926. |

| 60 | He C, Wang J B, Wang C R, et al. Catalytic ozonation of bio-treated coking wastewater in continuous pilot- and full-scale system: efficiency, catalyst deactivation and in situ regeneration[J]. Water Research, 2020, 183: 116090. |

| 61 | 任钟旗, 陈健杰, 周智勇, 等. 用于含盐有机废水深度处理的钙基碳包覆臭氧氧化催化剂: 115228495A[P]. 2022-10-25. |

| Ren Z Q, Chen J J, Zhou Z Y, et al. Calcium-based carbon-coated ozone oxidation catalyst for advanced treatment of salt-containing organic wastewater: 115228495A[P]. 2022-10-25. | |

| 62 | 任钟旗, 邵高燕, 周智勇, 等. 用于含盐有机废水深度处理的Ca基臭氧催化氧化催化剂及其制备方法: 115055174A[P]. 2022-09-16. |

| Ren Z Q, Shao G Y, Zhou Z Y, et al. Ca-based catalytic ozonation catalyst for deep treatment of salt-containing organic wastewater and preparation method of Ca-based catalytic ozonation catalyst: 115055174A[P]. 2022-09-16. | |

| 63 | Frainetti A J, Klinghoffer N B. Recent experimental advances on the utilization of biochar as a tar reforming catalyst: a review[J]. International Journal of Hydrogen Energy, 2023, 48(22): 8022-8044. |

| 64 | Abdoulmoumine N, Adhikari S, Kulkarni A, et al. A review on biomass gasification syngas cleanup[J]. Applied Energy, 2015, 155: 294-307. |

| 65 | 王聪哲, 许桂英. 天然非均相焦油裂解催化剂研究进展[J]. 现代化工, 2018, 38(12): 34-38, 40. |

| Wang C Z, Xu G Y. Study progress in natural heterogeneous catalysts for tar cracking[J]. Modern Chemical Industry, 2018, 38(12): 34-38, 40. | |

| 66 | 巩伟, 阴秀丽, 谢建军, 等. 多孔白云石颗粒催化裂解生物质焦油的动力学研究[J]. 太阳能学报, 2010, 31(7): 800-805. |

| Gong W, Yin X L, Xie J J, et al. Kinetic study of tar catalytic cracking over porous granular dolomite catalyst[J]. Acta Energiae Solaris Sinica, 2010, 31(7): 800-805. | |

| 67 | 孙云娟, 蒋剑春. 生物质热解气化产物中焦油的催化裂解研究[J]. 林产化学与工业, 2007, 27(5): 15-20. |

| Sun Y J, Jiang J C. Study on catalytic cracking of tar derived from biomass pyrolysis and gasification[J]. Chemistry and Industry of Forest Products, 2007, 27(5): 15-20. | |

| 68 | Guan G Q, Chen G, Kasai Y, et al. Catalytic steam reforming of biomass tar over iron- or nickel-based catalyst supported on calcined scallop shell[J]. Applied Catalysis B: Environmental, 2012, 115/116: 159-168. |

| 69 | Guo F Q, Jia X P, Liang S, et al. Development of biochar-based nanocatalysts for tar cracking/reforming during biomass pyrolysis and gasification[J]. Bioresource Technology, 2020, 298: 122263. |

| 70 | Feng D D, Zhao Y J, Zhang Y, et al. Effects of K and Ca on reforming of model tar compounds with pyrolysis biochars under H2O or CO2 [J]. Chemical Engineering Journal, 2016, 306: 422-432. |

| 71 | Feng D D, Zhao Y J, Zhang Y, et al. Roles and fates of K and Ca species on biochar structure during in situ tar H2O reforming over nascent biochar[J]. International Journal of Hydrogen Energy, 2017, 42(34): 21686-21696. |

| 72 | Ochoa A, Bilbao J, Gayubo A G, et al. Coke formation and deactivation during catalytic reforming of biomass and waste pyrolysis products: a review[J]. Renewable and Sustainable Energy Reviews, 2020, 119: 109600. |

| 73 | Dong Q, Li H J, Zhang S P, et al. Biomass tar cracking and syngas production using rice husk char-supported nickel catalysts coupled with microwave heating[J]. RSC Advances, 2018, 8(71): 40873-40882. |

| 74 | Gu J, Wang S X, Lu T, et al. Synthesis and evaluation of pyrolysis waste peat char supported catalyst for steam reforming of toluene[J]. Renewable Energy, 2020, 160: 964-973. |

| 75 | Wang C P, Yan H, Yu Y B, et al. Chemical looping reforming of coal tar vapor on the surface of CaO-modified Fe-based oxygen carrier[J]. Energy & Fuels, 2020, 34(7): 8534-8542. |

| 76 | Shen Y F, Yoshikawa K. Tar conversion and vapor upgrading via in situ catalysis using silica-based nickel nanoparticles embedded in rice husk char for biomass pyrolysis/gasification[J]. Industrial & Engineering Chemistry Research, 2014, 53(27): 10929-10942. |

| 77 | Guo F Q, Li X L, Liu Y, et al. Catalytic cracking of biomass pyrolysis tar over char-supported catalysts[J]. Energy Conversion and Management, 2018, 167: 81-90. |

| 78 | Wang H M, Bing W H, Chen C Y, et al. Geometric effect promoted hydrotalcites catalysts towards aldol condensation reaction[J]. Chinese Journal of Catalysis, 2020, 41(8): 1279-1287. |

| 79 | Luo X, Wang Y Y, Xie X L, et al. Catalytic ozonation of cinnamaldehyde to benzaldehyde over Ca(OH)2 [J]. ChemistrySelect, 2021, 6(20): 5052-5060. |

| 80 | Luo X, Hou Y R, Xie X L, et al. Role of water on ozonation of cinnamaldehyde to benzaldehyde under Ca(OH)2 catalysis: a combined in situ DRIFTS and DFT study[J]. Applied Surface Science, 2021, 569: 151071. |

| 81 | Wu J F, Su T M, Jiang Y X, et al. In situ DRIFTS study of O3 adsorption on CaO, γ-Al2O3, CuO, α-Fe2O3 and ZnO at room temperature for the catalytic ozonation of cinnamaldehyde[J]. Applied Surface Science, 2017, 412: 290-305. |

| 82 | Sharma A, Lee B K. A novel nanocomposite of Ca(OH)2-incorporated zeolite as an additive to reduce atmospheric emissions of PM and VOCs during asphalt production[J]. Environmental Science: Nano, 2017, 4(3): 613-624. |

| 83 | Hu E L, Shang S M, Chiu K. Removal of reactive dyes in textile effluents by catalytic ozonation pursuing on-site effluent recycling[J]. Molecules, 2019, 24(15): 2755. |

| 84 | Cao H B, Xing L L, Wu G G, et al. Promoting effect of nitration modification on activated carbon in the catalytic ozonation of oxalic acid[J]. Applied Catalysis B: Environmental, 2014, 146: 169-176. |

| [1] | Jie CHEN, Yongsheng LIN, Kai XIAO, Chen YANG, Ting QIU. Study on catalytic synthesis of sec-butanol by tunable choline-based basic ionic liquids [J]. CIESC Journal, 2023, 74(9): 3716-3730. |

| [2] | Yitong LI, Hang GUO, Hao CHEN, Fang YE. Study on operating conditions of proton exchange membrane fuel cells with non-uniform catalyst distributions [J]. CIESC Journal, 2023, 74(9): 3831-3840. |

| [3] | Xuejin YANG, Jintao YANG, Ping NING, Fang WANG, Xiaoshuang SONG, Lijuan JIA, Jiayu FENG. Research progress in dry purification technology of highly toxic gas PH3 [J]. CIESC Journal, 2023, 74(9): 3742-3755. |

| [4] | Yuyuan ZHENG, Zhiwei GE, Xiangyu HAN, Liang WANG, Haisheng CHEN. Progress and prospect of medium and high temperature thermochemical energy storage of calcium-based materials [J]. CIESC Journal, 2023, 74(8): 3171-3192. |

| [5] | Feifei YANG, Shixi ZHAO, Wei ZHOU, Zhonghai NI. Sn doped In2O3 catalyst for selective hydrogenation of CO2 to methanol [J]. CIESC Journal, 2023, 74(8): 3366-3374. |

| [6] | Kaixuan LI, Wei TAN, Manyu ZHANG, Zhihao XU, Xuyu WANG, Hongbing JI. Design of cobalt-nitrogen-carbon/activated carbon rich in zero valent cobalt active site and application of catalytic oxidation of formaldehyde [J]. CIESC Journal, 2023, 74(8): 3342-3352. |

| [7] | Xin YANG, Xiao PENG, Kairu XUE, Mengwei SU, Yan WU. Preparation of molecularly imprinted-TiO2 and its properties of photoelectrocatalytic degradation of solubilized PHE [J]. CIESC Journal, 2023, 74(8): 3564-3571. |

| [8] | Yajie YU, Jingru LI, Shufeng ZHOU, Qingbiao LI, Guowu ZHAN. Construction of nanomaterial and integrated catalyst based on biological template: a review [J]. CIESC Journal, 2023, 74(7): 2735-2752. |

| [9] | Chunyu LIU, Huanyu ZHOU, Yue MA, Changtao YUE. Drying characteristics and mathematical model of CaO-conditioned oil sludge [J]. CIESC Journal, 2023, 74(7): 3018-3027. |

| [10] | Pan LI, Junyang MA, Zhihao CHEN, Li WANG, Yun GUO. Effect of the morphology of Ru/α-MnO2 on NH3-SCO performance [J]. CIESC Journal, 2023, 74(7): 2908-2918. |

| [11] | Qiyu ZHANG, Lijun GAO, Yuhang SU, Xiaobo MA, Yicheng WANG, Yating ZHANG, Chao HU. Recent advances in carbon-based catalysts for electrochemical reduction of carbon dioxide [J]. CIESC Journal, 2023, 74(7): 2753-2772. |

| [12] | Tan ZHANG, Guang LIU, Jinping LI, Yuhan SUN. Performance regulation strategies of Ru-based nitrogen reduction electrocatalysts [J]. CIESC Journal, 2023, 74(6): 2264-2280. |

| [13] | Chen WANG, Xiufeng SHI, Xianfeng WU, Fangjia WEI, Haohong ZHANG, Yin CHE, Xu WU. Preparation of Mn3O4 catalyst by redox method and study on its catalytic oxidation performance and mechanism of toluene [J]. CIESC Journal, 2023, 74(6): 2447-2457. |

| [14] | Yong LI, Jiaqi GAO, Chao DU, Yali ZHAO, Boqiong LI, Qianqian SHEN, Husheng JIA, Jinbo XUE. Construction of Ni@C@TiO2 core-shell dual-heterojunctions for advanced photo-thermal catalytic hydrogen generation [J]. CIESC Journal, 2023, 74(6): 2458-2467. |

| [15] | Jipeng ZHOU, Wenjun HE, Tao LI. Reaction engineering calculation of deactivation kinetics for ethylene catalytic oxidation over irregular-shaped catalysts [J]. CIESC Journal, 2023, 74(6): 2416-2426. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||