CIESC Journal ›› 2021, Vol. 72 ›› Issue (7): 3801-3813.DOI: 10.11949/0438-1157.20201928

• Energy and environmental engineering • Previous Articles Next Articles

KE Lanting1( ),WANG Yuanpeng1,ZHENG Yanmei1,LI Qingbiao1,2(

),WANG Yuanpeng1,ZHENG Yanmei1,LI Qingbiao1,2( )

)

Received:2020-12-28

Revised:2021-02-05

Online:2021-07-05

Published:2021-07-05

Contact:

LI Qingbiao

通讯作者:

李清彪

作者简介:柯蓝婷(1988—),女,博士研究生,基金资助:CLC Number:

KE Lanting, WANG Yuanpeng, ZHENG Yanmei, LI Qingbiao. Component analysis and comprehensive evaluation of biomethane systems[J]. CIESC Journal, 2021, 72(7): 3801-3813.

柯蓝婷, 王远鹏, 郑艳梅, 李清彪. 生物甲烷系统的组分分析与综合评价[J]. 化工学报, 2021, 72(7): 3801-3813.

Add to citation manager EndNote|Ris|BibTeX

| 重金属 | |||

|---|---|---|---|

| As | 10 | 10 | 15 |

| Cd | 30 | 5 | 1.0 |

| Cr | 2 | 50 | 90 |

| Cu | 5 | 1000 | 50 |

| Hg | 40 | 1 | 0.25 |

| Pb | 5 | 10 | 70 |

| Zn | 1 | 1000 | 175 |

Table 1 Toxic response factors and background reference level of heavy metals

| 重金属 | |||

|---|---|---|---|

| As | 10 | 10 | 15 |

| Cd | 30 | 5 | 1.0 |

| Cr | 2 | 50 | 90 |

| Cu | 5 | 1000 | 50 |

| Hg | 40 | 1 | 0.25 |

| Pb | 5 | 10 | 70 |

| Zn | 1 | 1000 | 175 |

| 组分 | ||

|---|---|---|

| As | 0.5 | 40 |

| Cd | 0.1 | 1.0 |

| Cr | 1.5 | 300 |

| Cu | 2 | 400 |

| Hg | 0.05 | 1.5 |

| Pb | 1 | 500 |

| Zn | 5 | 500 |

| COD | 500 | — |

| NH4+-N | 25 | — |

| PO43- | 1 | — |

Table 2 Background reference level of component in biomethane system

| 组分 | ||

|---|---|---|

| As | 0.5 | 40 |

| Cd | 0.1 | 1.0 |

| Cr | 1.5 | 300 |

| Cu | 2 | 400 |

| Hg | 0.05 | 1.5 |

| Pb | 1 | 500 |

| Zn | 5 | 500 |

| COD | 500 | — |

| NH4+-N | 25 | — |

| PO43- | 1 | — |

| 运行参数 | 牛粪 | 猪粪 | 秸秆 | 餐厨垃圾 | 鸡粪 |

|---|---|---|---|---|---|

| 原料质量/g | 22.30 | 24.81 | 5.20 | 22.19 | 23.32 |

| TS含量/% | 28.14 | 25.01 | 92.03 | 20.67 | 25.16 |

| VS含量/% | 17.94 | 16.12 | 76.85 | 18.03 | 17.15 |

| 初始TS质量/g | 6.28 | 6.20 | 4.79 | 4.59 | 5.87 |

| 初始VS质量/g | 4.00 | 4.00 | 4.00 | 4.00 | 4.00 |

| 反应后TS质量/g | 3.51 | 3.03 | 2.82 | 2.69 | 3.05 |

| TS移除率/% | 44.11 | 51.13 | 41.13 | 41.39 | 48.04 |

| 反应体积/L | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 |

Table 3 Basic parameters of biomethane systems from five substrates

| 运行参数 | 牛粪 | 猪粪 | 秸秆 | 餐厨垃圾 | 鸡粪 |

|---|---|---|---|---|---|

| 原料质量/g | 22.30 | 24.81 | 5.20 | 22.19 | 23.32 |

| TS含量/% | 28.14 | 25.01 | 92.03 | 20.67 | 25.16 |

| VS含量/% | 17.94 | 16.12 | 76.85 | 18.03 | 17.15 |

| 初始TS质量/g | 6.28 | 6.20 | 4.79 | 4.59 | 5.87 |

| 初始VS质量/g | 4.00 | 4.00 | 4.00 | 4.00 | 4.00 |

| 反应后TS质量/g | 3.51 | 3.03 | 2.82 | 2.69 | 3.05 |

| TS移除率/% | 44.11 | 51.13 | 41.13 | 41.39 | 48.04 |

| 反应体积/L | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 |

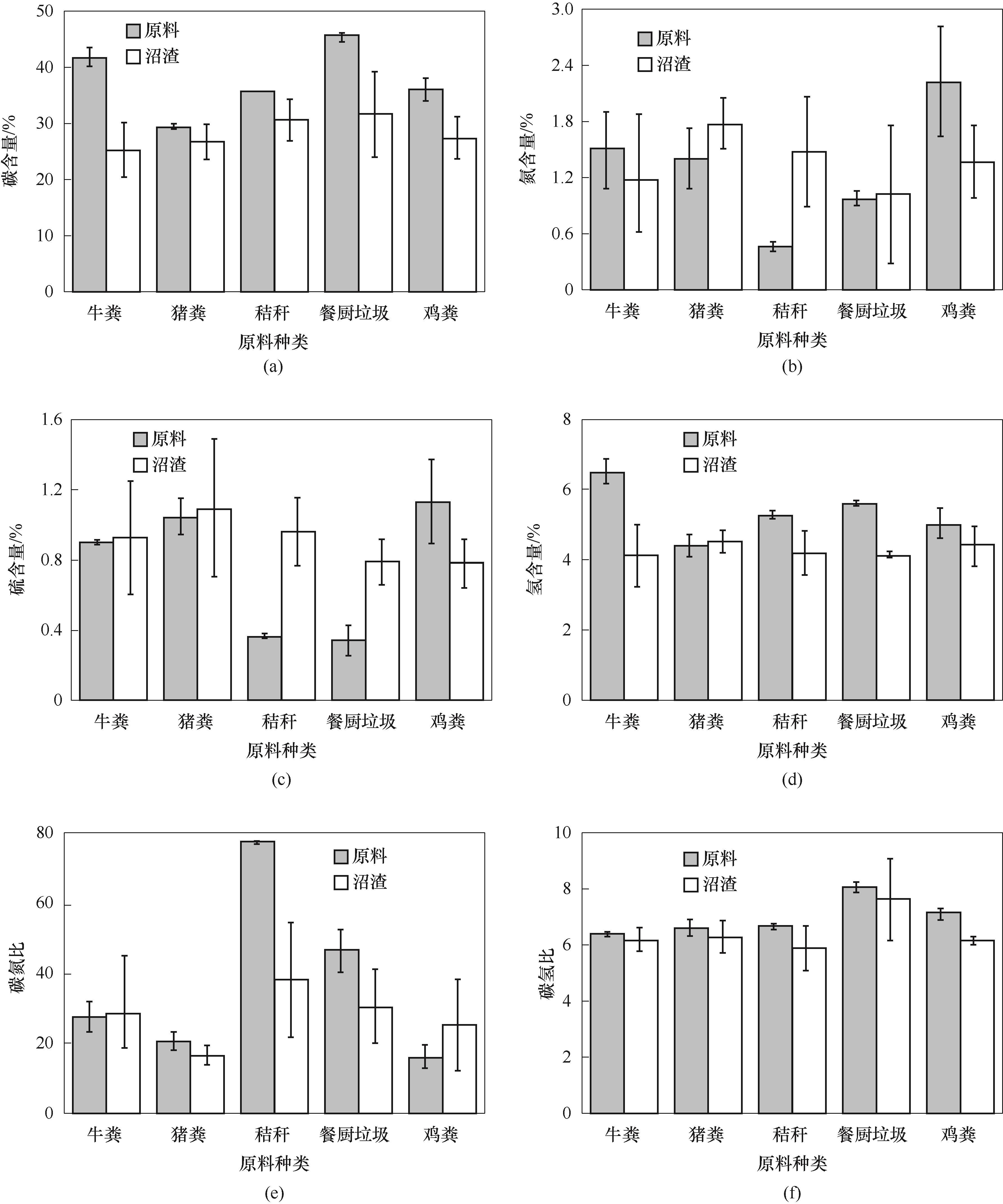

Fig.5 C content (a), N content (b), S content (c), H content (d), C∶N (e) and C∶H (f) of raw material and residue from biomethane systems of five substrates

| 重金属种类 | 浓度分布 | 牛粪 | 猪粪 | 秸秆 | 餐厨垃圾 | 鸡粪 |

|---|---|---|---|---|---|---|

| As | 原料浓度/(mg·kg-1) | 0.516±0.061 | 0.773±0.088 | 0.412±0.056 | 0.498±0.084 | 0.731±0.013 |

| 沼液浓度/(μg·L-1) | 3.460±0.358 | 9.739±0.401 | 3.904±0.258 | 3.848±0.100 | 16.336±0.996 | |

| 沼渣浓度/(mg·kg-1) | 0.617±0.056 | 0.713±0.077 | 0.541±0.023 | 1.003±0.091 | 0.263±0.027 | |

| Cd | 原料浓度/(mg·kg-1) | 0.135±0.004 | 0.287±0.066 | 0.239±0..018 | 0.094±0.008 | 0.201±0.009 |

| 沼液浓度/(μg·L-1) | 0.590±0.029 | 0.332±0.050 | 0.162±0.017 | 0.559±0.057 | 1.106±0.098 | |

| 沼渣浓度/(mg·kg-1) | 0.421±0.050 | 0.278±0.008 | 0.376±0.051 | 0.288±0.062 | 0.478±0.010 | |

| Cr | 原料浓度/(mg·kg-1) | 5.240±0.098 | 10.329±0.935 | 3.049±0.122 | 2.926±0.435 | 1.020±0.313 |

| 沼液浓度/(μg·L-1) | 26.466±4.773 | 15.157±0.589 | 17.052±0.846 | 27.126±0.939 | 54.288±5.010 | |

| 沼渣浓度/(mg·kg-1) | 3.528±0.077 | 6.546±0.883 | 6.927±0.601 | 2.104±0.624 | 3.550±0.269 | |

| Cu | 原料浓度/(mg·kg-1) | 25.427±0.925 | 65.325±6.034 | 36.164±2.090 | 15.185±0.751 | 52.814±5.689 |

| 沼液浓度/(μg·L-1) | 102.554±8.971 | 59.666±6.817 | 28.726±2.851 | 45.549±2.013 | 178.156±8.678 | |

| 沼渣浓度/(mg·kg-1) | 64.140±6.192 | 110.277±8.713 | 71.441±6.191 | 24.857±0.844 | 78.480±4.647 | |

| Hg | 原料浓度/(mg·kg-1) | 0.124±0.019 | 0.059±0.002 | 0.048±0.003 | 0.327±0.057 | 0.028±0.002 |

| 沼液浓度/(μg·L-1) | 0.236±0.008 | 0.004±0.000 | 0.193±0.015 | 0.117±0.007 | 0.506±0.041 | |

| 沼渣浓度/(mg·kg-1) | 0.179±0.009 | 0.146±0.014 | 0.030±0.002 | 0.835±0.053 | 0.228±0.015 | |

| Pb | 原料浓度/(mg·kg-1) | 0.519±0.061 | 0.647±0.084 | 0.419±0.041 | 0.248±0.012 | 0.211±0.040 |

| 沼液浓度/(μg·L-1) | 3.420±0.074 | 1.090±0.082 | 1.736±0.093 | 1.311±0.082 | 1.999±0.080 | |

| 沼渣浓度/(mg·kg-1) | 1.094±0.053 | 0.987±0.069 | 0.734±0.031 | 0.411±0.034 | 0.500±0.039 | |

| Zn | 原料浓度/(mg·kg-1) | 173.933±9.156 | 284.267±18.677 | 238.230±19.560 | 54.942±4.733 | 212.408±11.427 |

| 沼液浓度/(μg·L-1) | 410.492±30.889 | 172.310±5.965 | 154.432±9.269 | 246.271±8.343 | 497.088±28.334 | |

| 沼渣浓度/(mg·kg-1) | 246.751±14.917 | 500.338±47.739 | 463.365±13.419 | 118.443±7.612 | 357.921±20.907 |

Table 4 Heavy metals content of biomethane systems from five substrates

| 重金属种类 | 浓度分布 | 牛粪 | 猪粪 | 秸秆 | 餐厨垃圾 | 鸡粪 |

|---|---|---|---|---|---|---|

| As | 原料浓度/(mg·kg-1) | 0.516±0.061 | 0.773±0.088 | 0.412±0.056 | 0.498±0.084 | 0.731±0.013 |

| 沼液浓度/(μg·L-1) | 3.460±0.358 | 9.739±0.401 | 3.904±0.258 | 3.848±0.100 | 16.336±0.996 | |

| 沼渣浓度/(mg·kg-1) | 0.617±0.056 | 0.713±0.077 | 0.541±0.023 | 1.003±0.091 | 0.263±0.027 | |

| Cd | 原料浓度/(mg·kg-1) | 0.135±0.004 | 0.287±0.066 | 0.239±0..018 | 0.094±0.008 | 0.201±0.009 |

| 沼液浓度/(μg·L-1) | 0.590±0.029 | 0.332±0.050 | 0.162±0.017 | 0.559±0.057 | 1.106±0.098 | |

| 沼渣浓度/(mg·kg-1) | 0.421±0.050 | 0.278±0.008 | 0.376±0.051 | 0.288±0.062 | 0.478±0.010 | |

| Cr | 原料浓度/(mg·kg-1) | 5.240±0.098 | 10.329±0.935 | 3.049±0.122 | 2.926±0.435 | 1.020±0.313 |

| 沼液浓度/(μg·L-1) | 26.466±4.773 | 15.157±0.589 | 17.052±0.846 | 27.126±0.939 | 54.288±5.010 | |

| 沼渣浓度/(mg·kg-1) | 3.528±0.077 | 6.546±0.883 | 6.927±0.601 | 2.104±0.624 | 3.550±0.269 | |

| Cu | 原料浓度/(mg·kg-1) | 25.427±0.925 | 65.325±6.034 | 36.164±2.090 | 15.185±0.751 | 52.814±5.689 |

| 沼液浓度/(μg·L-1) | 102.554±8.971 | 59.666±6.817 | 28.726±2.851 | 45.549±2.013 | 178.156±8.678 | |

| 沼渣浓度/(mg·kg-1) | 64.140±6.192 | 110.277±8.713 | 71.441±6.191 | 24.857±0.844 | 78.480±4.647 | |

| Hg | 原料浓度/(mg·kg-1) | 0.124±0.019 | 0.059±0.002 | 0.048±0.003 | 0.327±0.057 | 0.028±0.002 |

| 沼液浓度/(μg·L-1) | 0.236±0.008 | 0.004±0.000 | 0.193±0.015 | 0.117±0.007 | 0.506±0.041 | |

| 沼渣浓度/(mg·kg-1) | 0.179±0.009 | 0.146±0.014 | 0.030±0.002 | 0.835±0.053 | 0.228±0.015 | |

| Pb | 原料浓度/(mg·kg-1) | 0.519±0.061 | 0.647±0.084 | 0.419±0.041 | 0.248±0.012 | 0.211±0.040 |

| 沼液浓度/(μg·L-1) | 3.420±0.074 | 1.090±0.082 | 1.736±0.093 | 1.311±0.082 | 1.999±0.080 | |

| 沼渣浓度/(mg·kg-1) | 1.094±0.053 | 0.987±0.069 | 0.734±0.031 | 0.411±0.034 | 0.500±0.039 | |

| Zn | 原料浓度/(mg·kg-1) | 173.933±9.156 | 284.267±18.677 | 238.230±19.560 | 54.942±4.733 | 212.408±11.427 |

| 沼液浓度/(μg·L-1) | 410.492±30.889 | 172.310±5.965 | 154.432±9.269 | 246.271±8.343 | 497.088±28.334 | |

| 沼渣浓度/(mg·kg-1) | 246.751±14.917 | 500.338±47.739 | 463.365±13.419 | 118.443±7.612 | 357.921±20.907 |

| Raw materials | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| EUP | ECP | GWP | EUP | ECP | |||||

| Slurry | Residue | Slurry | Residue | ||||||

| CAM | -0.24382 | -0.16872 | -0.00741 | -0.00287 | -0.04395 | -0.05687 | -0.00036 | -0.10063 | 0.20044 |

| SM | -0.20177 | -0.28099 | -0.00603 | -0.00436 | -0.07127 | -0.05886 | -0.00021 | -0.12024 | 0.22180 |

| St | -0.11954 | -0.16757 | -0.00713 | -0.00359 | -0.05011 | -0.05375 | -0.00015 | -0.10172 | 0.07066 |

| KW | -0.15366 | -0.09018 | -0.00805 | -0.00256 | -0.16480 | -0.04585 | -0.00023 | -0.07413 | -0.05178 |

| CHM | -0.24622 | -0.19075 | -0.00644 | -0.00404 | -0.15710 | -0.05133 | -0.00059 | -0.11157 | 0.10590 |

Table 5 Green degree of biomethane systems from five substrates

| Raw materials | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| EUP | ECP | GWP | EUP | ECP | |||||

| Slurry | Residue | Slurry | Residue | ||||||

| CAM | -0.24382 | -0.16872 | -0.00741 | -0.00287 | -0.04395 | -0.05687 | -0.00036 | -0.10063 | 0.20044 |

| SM | -0.20177 | -0.28099 | -0.00603 | -0.00436 | -0.07127 | -0.05886 | -0.00021 | -0.12024 | 0.22180 |

| St | -0.11954 | -0.16757 | -0.00713 | -0.00359 | -0.05011 | -0.05375 | -0.00015 | -0.10172 | 0.07066 |

| KW | -0.15366 | -0.09018 | -0.00805 | -0.00256 | -0.16480 | -0.04585 | -0.00023 | -0.07413 | -0.05178 |

| CHM | -0.24622 | -0.19075 | -0.00644 | -0.00404 | -0.15710 | -0.05133 | -0.00059 | -0.11157 | 0.10590 |

| 1 | Patinvoh R J, Taherzadeh M J. Challenges of biogas implementation in developing countries[J]. Current Opinion in Environmental Science & Health, 2019, 12: 30-37. |

| 2 | Ferreira S F, Buller L S, Berni M, et al. Environmental impact assessment of end-uses of biomethane[J]. Journal of Cleaner Production, 2019, 230: 613-621. |

| 3 | Xiao Y Q, Yang H N, Yang H, et al. Improved biogas production of dry anaerobic digestion of swine manure[J]. Bioresource Technology, 2019, 294: 122188. |

| 4 | Gu Y, Chen X H, Liu Z G, et al. Effect of inoculum sources on the anaerobic digestion of rice straw[J]. Bioresource Technology, 2014, 158: 149-155. |

| 5 | Zhang T, Yang Y H, Xie D T. Insights into the production potential and trends of China's rural biogas[J]. International Journal of Energy Research, 2015, 39(8): 1068-1082. |

| 6 | Scheutz C, Fredenslund A M. Total methane emission rates and losses from 23 biogas plants[J]. Waste Management, 2019, 97: 38-46. |

| 7 | Wang S L, Jena U, Das K C. Biomethane production potential of slaughterhouse waste in the United States[J]. Energy Conversion and Management, 2018, 173: 143-157. |

| 8 | Scarlat N, Fahl F, Dallemand J F, et al. A spatial analysis of biogas potential from manure in Europe[J]. Renewable and Sustainable Energy Reviews, 2018, 94: 915-930. |

| 9 | Holm-Nielsen J B, Al Seadi T, Oleskowicz-Popiel P. The future of anaerobic digestion and biogas utilization[J]. Bioresource Technology, 2009, 100(22): 5478-5484. |

| 10 | Baena-Moreno F M, Malico I, Rodríguez-Galán M, et al. The importance of governmental incentives for small biomethane plants in South Spain[J]. Energy, 2020, 206: 118158. |

| 11 | Cucchiella F, D'Adamo I, Gastaldi M. An economic analysis of biogas-biomethane chain from animal residues in Italy[J]. Journal of Cleaner Production, 2019, 230: 888-897. |

| 12 | Giwa A S, Ali N, Ahmad I, et al. Prospects of China's biogas: fundamentals, challenges and considerations[J]. Energy Reports, 2020, 6: 2973-2987. |

| 13 | 北极星环保网. 2017年沼气发电市场前景分析: 2020年总量将达440亿立方米 [EB/OL]. [2020-11-29].. |

| Beijixing Environmental Protection Network. Biogas generation prospect analysis: the biogas production will reach 44 billion m3 by 2020 [EB/OL]. [2020-11-29].. | |

| 14 | Li K, Liu R H, Sun C. Comparison of anaerobic digestion characteristics and kinetics of four livestock manures with different substrate concentrations[J]. Bioresource Technology, 2015, 198: 133-140. |

| 15 | Dai X H, Hua Y, Liu R, et al. Biomethane production by typical straw anaerobic digestion: deep insights of material compositions and surface properties[J]. Bioresource Technology, 2020, 313: 123643. |

| 16 | Mao C L, Feng Y Z, Wang X J, et al. Review on research achievements of biogas from anaerobic digestion[J]. Renewable and Sustainable Energy Reviews, 2015, 45: 540-555. |

| 17 | Li H, Chen Z, Fu D, et al. Improved ADM1 for modelling C, N, P fates in anaerobic digestion process of pig manure and optimization approaches to biogas production[J]. Renewable Energy, 2020, 146: 2330-2336. |

| 18 | 武斌, 张香平, 许亚晶, 等. 生物甲烷系统技术评价与集成的研究进展[J]. 化工进展, 2014, 33(7): 1659-1670. |

| Wu B, Zhang X P, Xu Y J, et al. Progress of evaluation and integration of biomethane system[J]. Chemical Industry and Engineering Progress, 2014, 33(7): 1659-1670. | |

| 19 | Mahanty B, Zafar M, Han M J, et al. Optimization of co-digestion of various industrial sludges for biogas production and sludge treatment: methane production potential experiments and modeling[J]. Waste Management, 2014, 34(6): 1018-1024. |

| 20 | Zhang T, Liu L, Song Z, et al. Biogas production by co-digestion of goat manure with three crop residues[J]. PLoS One, 2013, 8(6): e66845. |

| 21 | Fernández-Rodríguez J, Pérez M, Romero L I. Comparison of mesophilic and thermophilic dry anaerobic digestion of OFMSW: kinetic analysis[J]. Chemical Engineering Journal, 2013, 232: 59-64. |

| 22 | Perez M, Romero L I, Sales D. Organic matter degradation kinetics in an anaerobic thermophilic fluidised bed bioreactor[J]. Anaerobe, 2001, 7(1): 25-35. |

| 23 | Li Y Q, Zhang R H, Chen C, et al. Biogas production from co-digestion of corn stover and chicken manure under anaerobic wet, hemi-solid, and solid state conditions[J]. Bioresource Technology, 2013, 149: 406-412. |

| 24 | Akbulut A, Kose R, Akbulut A. Technical and economic assessments of biogas production in a family size digester utilizing different feedstock rotations: Döğer case study[J]. International Journal of Green Energy, 2014, 11(2): 113-128. |

| 25 | Nasr N, Elbeshbishy E, Hafez H, et al. Comparative assessment of single-stage and two-stage anaerobic digestion for the treatment of thin stillage[J]. Bioresource Technology, 2012, 111: 122-126. |

| 26 | Li H L, Lindmark J, Nordlander E, et al. Using the solid digestate from a wet anaerobic digestion process as an energy resource[J]. Energy Technology, 2013, 1(1): 94-101. |

| 27 | Zheng X R, Liu Y Q, Huang J M, et al. The influence of variables on the bioavailability of heavy metals during the anaerobic digestion of swine manure[J]. Ecotoxicology and Environmental Safety, 2020, 195: 110457. |

| 28 | Kuo W C, Sneve M A, Parkin G F. Formation of soluble microbial products during anaerobic treatment[J]. Water Environment Research, 1996, 68(3): 279-285. |

| 29 | Wang Y J, Feng L S, Zhao X S, et al. Characteristics of volatile compounds removal in biogas slurry of pig manure by ozone oxidation and organic solvents extraction[J]. Journal of Environmental Sciences, 2013, 25(9): 1800-1807. |

| 30 | Chen W L, Lin S C, Huang C H, et al. Wide-scope screening for pharmaceutically active substances in a leafy vegetable cultivated under biogas slurry irrigation[J]. Science of the Total Environment, 2021, 750: 141519. |

| 31 | 李祎雯, 曲英华, 徐奕琳, 等. 不同发酵原料沼液的养分含量及变化[J]. 中国沼气, 2012, 30(3): 17-20, 24. |

| Li Y W, Qu Y H, Xu Y L, et al. Change of nutrition contents of biogas slurry with different fermentation raw materials[J]. China Biogas, 2012, 30(3): 17-20, 24. | |

| 32 | 靳红梅, 常志州, 叶小梅, 等. 江苏省大型沼气工程沼液理化特性分析[J]. 农业工程学报, 2011, 27(1): 291-296. |

| Jin H M, Chang Z Z, Ye X M, et al. Physical and chemical characteristics of anaerobically digested slurry from large-scale biogas project in Jiangsu Province[J]. Transactions of the Chinese Society of Agricultural Engineering, 2011, 27(1): 291-296. | |

| 33 | 柯蓝婷, 王海涛, 王远鹏, 等. 不同来源家庭户用沼气池沼液成分分析及风险评价[J]. 化工学报, 2014, 65(5): 1840-1847. |

| Ke L T, Wang H T, Wang Y P, et al. Component analysis and risk assessment of anaerobically digested slurry from households in China[J]. CIESC Journal, 2014, 65(5): 1840-1847. | |

| 34 | 国家环境保护总局. 水和废水监测分析方法[M]. 4版. 北京: 中国环境出版社, 2002. |

| State Environmental Protection Administration. Water and Wastewater Monitoring and Analysis Methods[M]. 4th ed. Beijing: China Environmental Science Press, 2002. | |

| 35 | Hakanson L. An ecological risk index for aquatic pollution control: a sedimentological approach[J]. Water Research, 1980, 14(8): 975-1001. |

| 36 | Zhang X P, Li C S, Fu C, et al. Environmental impact assessment of chemical process using the green degree method[J]. Industrial & Engineering Chemistry Research, 2008, 47(4): 1085-1094. |

| 37 | Yan R Y, Li Z X, Diao Y Y, et al. Green process for methacrolein separation with ionic liquids in the production of methyl methacrylate[J]. AIChE Journal, 2011, 57(9): 2388-2396. |

| 38 | 付超, 张香平, 闫瑞一, 等. 绿色度方法中环境影响因子权值的确定[J]. 计算机与应用化学, 2008, 25(9): 1068-1074. |

| Fu C, Zhang X P, Yan R Y, et al. Weighting factors of environmental impact categories in green degree method[J]. Computers and Applied Chemistry, 2008, 25(9): 1068-1074. | |

| 39 | 邢赜. 沼液营养物的沸石吸附回收与利用[D]. 重庆: 西南大学, 2013. |

| Xing Z. Adsorption and its utilization of nutrient from biogas slurry by zeolite[D]. Chongqing: Southwest University, 2013. | |

| 40 | 李恒, 柯蓝婷, 王海涛, 等. 低劣生物质厌氧产甲烷过程的模拟研究进展[J]. 化工学报, 2014, 65(5): 1577-1586. |

| Li H, Ke L T, Wang H T, et al. Simulation research on anaerobic digestion biogas generation from low-grade biomass[J]. CIESC Journal, 2014, 65(5): 1577-1586. | |

| 41 | Labatut R A, Angenent L T, Scott N R. Biochemical methane potential and biodegradability of complex organic substrates[J]. Bioresource Technology, 2011, 102(3): 2255-2264. |

| 42 | Triolo J M, Sommer S G, Møller H B, et al. A new algorithm to characterize biodegradability of biomass during anaerobic digestion: influence of lignin concentration on methane production potential[J]. Bioresource Technology, 2011, 102(20): 9395-9402. |

| 43 | Li W W, Khalid H, Amin F R, et al. Biomethane production characteristics, kinetic analysis, and energy potential of different paper wastes in anaerobic digestion[J]. Renewable Energy, 2020, 157: 1081-1088. |

| 44 | Li H, Tan F, Ke L T, et al. Mass balances and distributions of C, N, and P in the anaerobic digestion of different substrates and relationships between products and substrates[J]. Chemical Engineering Journal, 2016, 287: 329-336. |

| [1] | Yue CAO, Chong YU, Zhi LI, Minglei YANG. Industrial data driven transition state detection with multi-mode switching of a hydrocracking unit [J]. CIESC Journal, 2023, 74(9): 3841-3854. |

| [2] | Guang WANG, Fashun SHAN, Yucheng QIAN, Jianfang JIAO. Incipient fault detection method for chemical process based on ensemble learning transfer entropy [J]. CIESC Journal, 2023, 74(7): 2967-2978. |

| [3] | Yurong DANG, Chunlan MO, Kerui SHI, Yingcong FANG, Ziyang ZHANG, Zuoshun LI. Comprehensive evaluation model combined with genetic algorithm for the study on the performance of ORC system with zeotropic mixture [J]. CIESC Journal, 2023, 74(5): 1884-1895. |

| [4] | Jinyu GUO, Zhe WANG, Yuan LI. Fault detection method based on kernel entropy independent component analysis [J]. CIESC Journal, 2022, 73(8): 3647-3658. |

| [5] | Libang LIU, Song YANG, Zhijian WANG, Xinxin HE, Wenlei ZHAO, Shoujun LIU, Wenguang DU, Jie MI. Prediction of coke quality based on improved WOA-LSTM [J]. CIESC Journal, 2022, 73(3): 1291-1299. |

| [6] | Cheng ZHANG, Lizhi PAN, Yuan LI. Fault detection and diagnosis method based on weighted statistical feature KICA [J]. CIESC Journal, 2022, 73(2): 827-837. |

| [7] | Zhenlin ZHU, Songlin WANG, Bingxue JIANG, Jiaxu LI, Wei DENG, Haiqiang WU, Xuan YANG, Pingwei LIU, Wenjun WANG. Study on biodegradation of polyesters and their evaluation methods [J]. CIESC Journal, 2022, 73(1): 110-121. |

| [8] | Jinyu GUO, Wentao LI, Yuan LI. Application of adaptive algorithm of online reduced KECA in fault detection [J]. CIESC Journal, 2021, 72(8): 4227-4238. |

| [9] | JIA Xiaoping, SHI Lei, YANG Youqi. Challenges of eco-industrial parks development and opportunities for process systems engineering [J]. CIESC Journal, 2021, 72(5): 2373-2391. |

| [10] | ZHU Xiongzhuo, ZHANG Hanwen, YANG Chunjie. MWPCA blast furnace anomaly monitoring algorithm based on Gaussian mixture model [J]. CIESC Journal, 2021, 72(3): 1539-1548. |

| [11] | LI Yuan, YANG Dongsheng, ZHAO Liying, ZHANG Cheng. Fault detection using hierarchical variational Gaussian mixture model and principal polynomial analysis [J]. CIESC Journal, 2021, 72(3): 1616-1626. |

| [12] | Zhenzhen YE, Xinqi CHEN, Jian WANG, Bofan LI, Chaojie CUI, Gang ZHANG, Luming QIAN, Ying JIN, Weizhong QIAN. Evaluation of aging performance under high temperature of ionic liquid-based pouch supercapacitor [J]. CIESC Journal, 2021, 72(12): 6351-6360. |

| [13] | Huimin YUN, Jianjun DAI, Hui LI, Xiaotao BI. Economic and environmental assessment of biomass coupled coal-fired power generation [J]. CIESC Journal, 2021, 72(12): 6311-6327. |

| [14] | Xiufeng LIU, Shi ZHANG, Zhijie ZHOU, Hao ZHENG, Chengze WANG, Hongyuan SHI, Mengjie LI. Study on structure optimization of heat exchanger and evaluation index of heat transfer performance [J]. CIESC Journal, 2020, 71(S1): 98-105. |

| [15] | Mingyue DENG, Jianchang LIU, Peng XU, Shubin TAN, Liangliang SHANG. New fault detection and diagnosis strategy for nonlinear industrial process based on KECA [J]. CIESC Journal, 2020, 71(5): 2151-2163. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||