CIESC Journal ›› 2022, Vol. 73 ›› Issue (5): 2194-2205.DOI: 10.11949/0438-1157.20211588

• Energy and environmental engineering • Previous Articles Next Articles

Zhiqiang GUO1( ),Kezhou YAN1(

),Kezhou YAN1( ),Jiyuan ZHANG2,Dandan LIU2,Yangyan GAO3,Yanxia GUO1

),Jiyuan ZHANG2,Dandan LIU2,Yangyan GAO3,Yanxia GUO1

Received:2021-11-09

Revised:2022-01-27

Online:2022-05-24

Published:2022-05-05

Contact:

Kezhou YAN

郭志强1( ),燕可洲1(

),燕可洲1( ),张吉元2,柳丹丹2,高阳艳3,郭彦霞1

),张吉元2,柳丹丹2,高阳艳3,郭彦霞1

通讯作者:

燕可洲

作者简介:郭志强(1996—),男,硕士研究生,基金资助:CLC Number:

Zhiqiang GUO, Kezhou YAN, Jiyuan ZHANG, Dandan LIU, Yangyan GAO, Yanxia GUO. Influence mechanism of coal gangue / coal fly ash on the sodium reduction roasting reaction of red mud[J]. CIESC Journal, 2022, 73(5): 2194-2205.

郭志强, 燕可洲, 张吉元, 柳丹丹, 高阳艳, 郭彦霞. 煤矸石/粉煤灰对赤泥钠化还原焙烧反应的影响机制[J]. 化工学报, 2022, 73(5): 2194-2205.

Add to citation manager EndNote|Ris|BibTeX

| 物质 | Al2O3/% | SiO2/% | CaO/% | Na2O/% | Fe2O3/% | TiO2/% | MgO/% | K2O/% | LOI/% | Al/Si |

|---|---|---|---|---|---|---|---|---|---|---|

| 煤矸石 | 21.06 | 41.36 | 0.95 | 0.43 | 2.52 | 0.77 | 0.50 | 2.00 | 23.4 | 0.61 |

| 粉煤灰 | 29.90 | 44.40 | 2.72 | 0.86 | 2.67 | 1.25 | 0.45 | 1.50 | 15.79 | 0.79 |

| 赤泥 | 27.40 | 22.40 | 19.40 | 9.89 | 7.81 | 3.95 | 0.92 | 0.81 | 7.42 | 1.43 |

Table 1 Chemical compositions of coal gangue, coal fly ash and red mud

| 物质 | Al2O3/% | SiO2/% | CaO/% | Na2O/% | Fe2O3/% | TiO2/% | MgO/% | K2O/% | LOI/% | Al/Si |

|---|---|---|---|---|---|---|---|---|---|---|

| 煤矸石 | 21.06 | 41.36 | 0.95 | 0.43 | 2.52 | 0.77 | 0.50 | 2.00 | 23.4 | 0.61 |

| 粉煤灰 | 29.90 | 44.40 | 2.72 | 0.86 | 2.67 | 1.25 | 0.45 | 1.50 | 15.79 | 0.79 |

| 赤泥 | 27.40 | 22.40 | 19.40 | 9.89 | 7.81 | 3.95 | 0.92 | 0.81 | 7.42 | 1.43 |

Fig.4 Relative contents of active phase and magnetic phase in the sodium reduction roasting products of CG-RM and CFA-RM systems with different amount of sodium additives

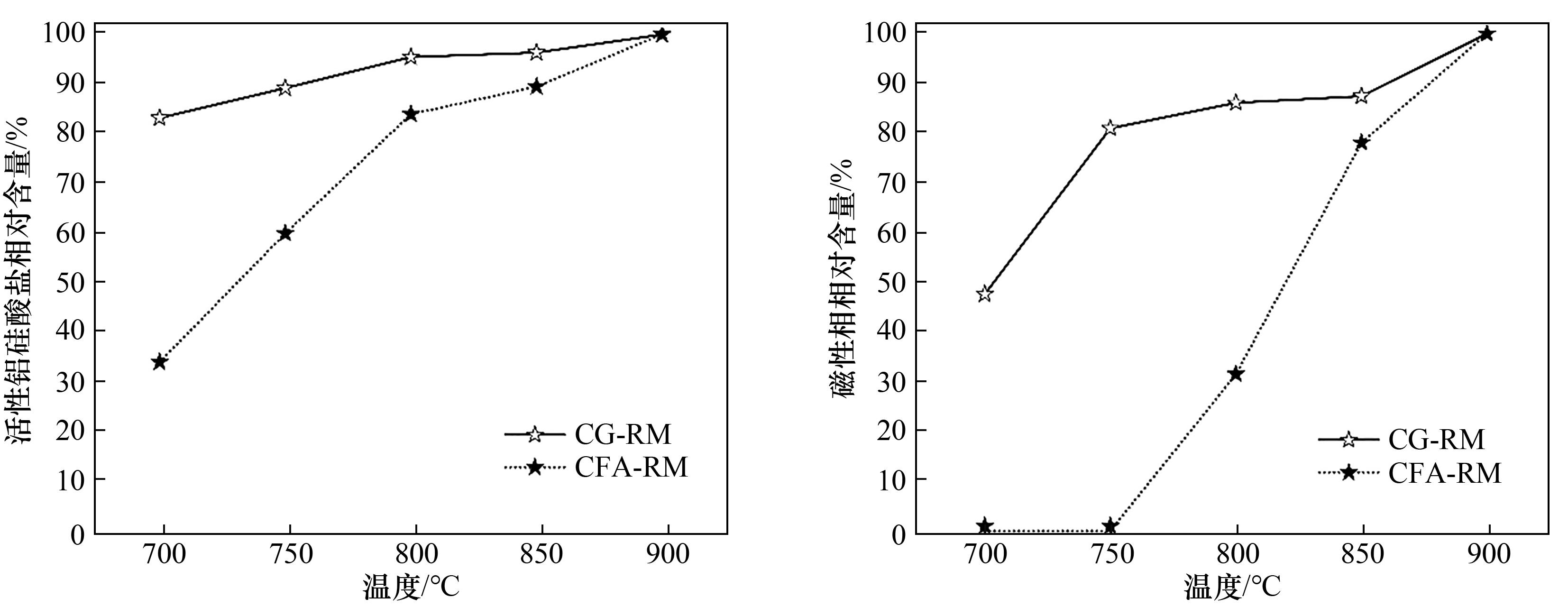

Fig.6 Relative contents of active phase and magnetic phase in the sodium reduction roasting products of CG-RM and CFA-RM systems in different temperature

| 体系 | 钠铝硅比(mol) | 温度/℃ | 时间/min |

|---|---|---|---|

| 煤矸石-赤泥-碳酸钠 | 1.2∶1∶1 | 800 | 90 |

| 粉煤灰-赤泥-碳酸钠 | 1.5∶1∶1 | 850 | 150 |

Table 2 Difference of optimum experimental conditions for sodium reduction roasting of coal gangue-red mud and coal fly ash-red mud systems

| 体系 | 钠铝硅比(mol) | 温度/℃ | 时间/min |

|---|---|---|---|

| 煤矸石-赤泥-碳酸钠 | 1.2∶1∶1 | 800 | 90 |

| 粉煤灰-赤泥-碳酸钠 | 1.5∶1∶1 | 850 | 150 |

| 物质 | 水分/% | 灰分/% | 挥发分/% | 固定碳/% |

|---|---|---|---|---|

| 煤矸石 | 0.53 | 75.46 | 9.07 | 14.94 |

| 粉煤灰 | 0.17 | 88.81 | 1.66 | 9.36 |

Table 3 Industrial composition test of coal gangue and coal fly ash

| 物质 | 水分/% | 灰分/% | 挥发分/% | 固定碳/% |

|---|---|---|---|---|

| 煤矸石 | 0.53 | 75.46 | 9.07 | 14.94 |

| 粉煤灰 | 0.17 | 88.81 | 1.66 | 9.36 |

| 项目 | 高岭石 | 莫来石 |

|---|---|---|

| 空间群 | C 1 C | P b n m |

| 晶胞体积 | 656.9 ?3 | 323.3 ?3 |

| 晶格参数 | a : 5.148 ? b : 8.920 ? c : 14.535 ? α : 90.000° β : 100.200° γ : 90.000° | a : 7.430 ? b : 7.580 ? c : 5.740 ? α : 90.000° β : 90.000° γ : 90.000° |

Table 4 Basic crystal structure parameters of kaolinite and mullite

| 项目 | 高岭石 | 莫来石 |

|---|---|---|

| 空间群 | C 1 C | P b n m |

| 晶胞体积 | 656.9 ?3 | 323.3 ?3 |

| 晶格参数 | a : 5.148 ? b : 8.920 ? c : 14.535 ? α : 90.000° β : 100.200° γ : 90.000° | a : 7.430 ? b : 7.580 ? c : 5.740 ? α : 90.000° β : 90.000° γ : 90.000° |

| 矿物 | 键类型 | 键长/nm | 重叠布局数 |

|---|---|---|---|

| 高岭石 | Si—O | 1.628 | 0.535 |

| Al—O | 2.420 | 0.0287 | |

| 莫来石 | Si—O | 1.624 | 0.588 |

| Al—O | 1.837 | 0.368 |

Table 5 Average bond length and overlap number of kaolinite and mullite

| 矿物 | 键类型 | 键长/nm | 重叠布局数 |

|---|---|---|---|

| 高岭石 | Si—O | 1.628 | 0.535 |

| Al—O | 2.420 | 0.0287 | |

| 莫来石 | Si—O | 1.624 | 0.588 |

| Al—O | 1.837 | 0.368 |

| 1 | Reddy P S, Reddy N G, Serjun V Z, et al. Properties and assessment of applications of red mud (bauxite residue): current status and research needs[J]. Waste and Biomass Valorization, 2021, 12(3): 1185-1217. |

| 2 | Wang S H, Jin H X, Deng Y, et al. Comprehensive utilization status of red mud in China: a critical review[J]. Journal of Cleaner Production, 2021, 289: 125136. |

| 3 | Khairul M A, Zanganeh J, Moghtaderi B. The composition, recycling and utilisation of Bayer red mud[J]. Resources, Conservation and Recycling, 2019, 141: 483-498. |

| 4 | Muraleedharan M, Nadir Y. Factors affecting the mechanical properties and microstructure of geopolymers from red mud and granite waste powder: a review[J]. Ceramics International, 2021, 47(10): 13257-13279. |

| 5 | 仇雅丽, 李长明, 王德亮, 等. 赤泥/煤基铁炭材料的制备及其脱除废水Cr(Ⅵ)的性能[J]. 化工学报, 2018, 69(7): 3216-3225. |

| Qiu Y L, Li C M, Wang D L, et al. Preparation of red mud/coal based material and its performance to remove Cr(Ⅵ) in waste water[J]. CIESC Journal, 2018, 69(7): 3216-3225. | |

| 6 | Wang M F, Liu X M. Applications of red mud as an environmental remediation material: a review[J]. Journal of Hazardous Materials, 2021, 408: 124420. |

| 7 | 王超, 李长明, 皇甫林, 等. 赤泥催化剂的制备及其对模拟烟气中微量氨的脱除性能[J]. 化工学报, 2019, 70(3): 1056-1064. |

| Wang C, Li C M, Huangfu L, et al. Preparation of red mud-based catalyst and performance for trace ammonia in simulative tail gas[J]. CIESC Journal, 2019, 70(3): 1056-1064. | |

| 8 | Liu X, Han Y X, He F Y, et al. Characteristic, hazard and iron recovery technology of red mud—a critical review[J]. Journal of Hazardous Materials, 2021, 420: 126542. |

| 9 | Hu G Y, Tang H H, He D D, et al. Selective extraction of sodium from red mud by dry digestion[J]. Minerals Engineering, 2021, 173: 107180. |

| 10 | Li S W, Pan J, Zhu D Q, et al. A new route for separation and recovery of Fe, Al and Ti from red mud[J]. Resources, Conservation and Recycling, 2021, 168: 105314. |

| 11 | Liu X, Gao P, Yuan S, et al. Clean utilization of high-iron red mud by suspension magnetization roasting[J]. Minerals Engineering, 2020, 157: 106553. |

| 12 | Yuan S, Liu X, Gao P, et al. A semi-industrial experiment of suspension magnetization roasting technology for separation of iron minerals from red mud[J]. Journal of Hazardous Materials, 2020, 394: 122579. |

| 13 | Wang J Y, Sun P P, Xue H M, et al. Red mud derived facile hydrothermal synthesis of hierarchical porous α-Fe2O3 microspheres as efficient adsorbents for removal of Congo red[J]. Journal of Physics and Chemistry of Solids, 2020, 140: 109379. |

| 14 | Zhu X B, Niu Z P, Li W, et al. A novel process for recovery of aluminum, iron, vanadium, scandium, titanium and silicon from red mud[J]. Journal of Environmental Chemical Engineering, 2020, 8(2): 103528. |

| 15 | Gao F, Zhang J H, Deng X J, et al. Comprehensive recovery of iron and aluminum from ordinary bayer red mud by reductive sintering-magnetic separation–digesting process[J]. JOM, 2019, 71(9): 2936-2943. |

| 16 | 马荣锴, 罗星, 冯吉福, 等. 赤泥还原提铁及钪的走向分析[J]. 有色金属工程, 2020, 10(2): 54-59. |

| Ma R K, Luo X, Feng J F, et al. Reduction extraction of iron from red mud and the scandium trend analysis[J]. Nonferrous Metals Engineering, 2020, 10(2): 54-59. | |

| 17 | 王丽明, 刘涛, 白春霞, 等. 山东某赤泥提铁试验研究[J]. 现代矿业, 2019, 35(11): 8-10. |

| Wang L M, Liu T, Bai C X, et al. Experimental study on iron extracting from red mud in Shandong[J]. Modern Mining, 2019, 35(11): 8-10. | |

| 18 | Agrawal S, Rayapudi V, Dhawan N. Comparison of microwave and conventional carbothermal reduction of red mud for recovery of iron values[J]. Minerals Engineering, 2019, 132: 202-210. |

| 19 | Liu J P, Li X Y, Lu Y S, et al. Effects of Na/Al ratio on mechanical properties and microstructure of red mud-coal metakaolin geopolymer[J]. Construction and Building Materials, 2020, 263: 120653. |

| 20 | Wang X P, Sun T C, Wu S C, et al. A novel utilization of Bayer red mud through co-reduction with a limonitic laterite ore to prepare ferronickel[J]. Journal of Cleaner Production, 2019, 216: 33-41. |

| 21 | Guo Y X, Zhao Q, Yan K Z, et al. Novel process for alumina extraction via the coupling treatment of coal gangue and bauxite red mud[J]. Industrial & Engineering Chemistry Research, 2014, 53(11): 4518-4521. |

| 22 | Guo Y X, Zhao Z S, Zhao Q, et al. Novel process of alumina extraction from coal fly ash by pre-desilicating-Na2CO3 activation-acid leaching technique[J]. Hydrometallurgy, 2017, 169: 418-425. |

| 23 | 郭玉梅, 曹丽琼, 郭彦霞, 等. 煤矸石和赤泥协同提取氧化铝过程矿相转变研究[J]. 化工学报, 2019, 70(4): 1542-1549. |

| Guo Y M, Cao L Q, Guo Y X, et al. Mineral transformation in process of combined extraction of alumina from coal gangue and red mud[J]. CIESC Journal, 2019, 70(4): 1542-1549. | |

| 24 | Guo Y X, Li J, Yan K Z, et al. A prospective process for alumina extraction via the co-treatment of coal fly ash and bauxite red mud: investigation of the process[J]. Hydrometallurgy, 2019, 186: 98-104. |

| 25 | 张吉元, 柳丹丹, 郭晓方, 等. 赤泥-煤矸石协同还原焙烧回收Fe、Al有价元素[J]. 环境工程学报, 2021, 15(10): 3306-3315. |

| Zhang J Y, Liu D D, Guo X F, et al. Valuable element recovery of Fe and Al by reduction roasting of red mud and coal gangue[J]. Chinese Journal of Environmental Engineering, 2021, 15(10): 3306-3315. | |

| 26 | 孙亮, 李玉虎, 宋健清, 等. 焙烧制度对稀土精矿中铁、铝等杂质浸出行为的影响[J]. 有色金属科学与工程, 2021, 12(4): 27-32, 81. |

| Sun L, Li Y H, Song J Q, et al. Effects of roasting system on the leaching behavior of iron and aluminum impurities in rare earth concentrates[J]. Nonferrous Metals Science and Engineering, 2021, 12(4): 27-32, 81. | |

| 27 | 孙开, 王维, 张子阳, 等. 高铁赤泥碳热还原制备镍铁合金[J]. 粉末冶金材料科学与工程, 2021, 26(6): 560-566. |

| Sun K, Wang W, Zhang Z Y, et al. Preparation of Ni-Fe alloy by carbothermal reduction of high iron red mud[J]. Materials Science and Engineering of Powder Metallurgy, 2021, 26(6): 560-566. | |

| 28 | 姜涛, 刘牡丹, 李光辉, 等. 钠盐对高铝褐铁矿还原焙烧铝铁分离的影响[J]. 中国有色金属学报, 2010, 20(6): 1226-1233. |

| Jiang T, Liu M D, Li G H, et al. Effects of sodium-salt on Al-Fe separation by reduction roasting for high-aluminum content limonite[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(6): 1226-1233. | |

| 29 | 冉敬, 郭创锋, 杜谷, 等. X射线衍射全谱拟合法分析蓝晶石的矿物含量[J]. 岩矿测试, 2019, 38(6): 660-667. |

| Ran J, Guo C F, Du G, et al. Quantitative analysis of mineral composition of kyanite by X-ray diffraction with rietveld refinement method[J]. Rock and Mineral Analysis, 2019, 38(6): 660-667. | |

| 30 | 宋刘斌, 黎安娴, 肖忠良, 等. 第一性原理在锂离子电池电极材料中的应用研究[J]. 化工学报, 2019, 70(6): 2051-2059. |

| Song L B, Li A X, Xiao Z L, et al. Application research status of first-principles in lithium-ion battery electrode materials[J]. CIESC Journal, 2019, 70(6): 2051-2059. | |

| 31 | Li X J, Hayashi J I, Li C Z. FT-Raman spectroscopic study of the evolution of char structure during the pyrolysis of a Victorian brown coal[J]. Fuel, 2006, 85(12/13): 1700-1707. |

| 32 | Gruner J W. The crystal structure of kaolinite[J]. Zeitschrift Für Kristallographie-Crystalline Materials, 1932, 83(1/2/3/4/5/6): 75-88. |

| 33 | Taylor W H. ⅩⅩⅧ . The structure of sillimanite and mullite[J]. Zeitschrift Für Kristallographie-Crystalline Materials, 1928, 68(1/2/3/4/5/6): 503-521. |

| 34 | 丁治英, 敬珊珊, 陈启元. 含锌矿物的微观结构与反应活性[J]. 中国科技论文, 2015, 10(18): 2178-2181, 2186. |

| Ding Z Y, Jing S S, Chen Q Y. Microstructures and reaction activity of zinc - bearing minerals[J]. China Sciencepaper, 2015, 10(18): 2178-2181, 2186. |

| [1] | Runmiao GAO, Mengjie SONG, Enyuan GAO, Long ZHANG, Xuan ZHANG, Keke SHAO, Zekang ZHEN, Zhengyong JIANG. Review on greenhouse gas reduction related to refrigerants in cold chain [J]. CIESC Journal, 2023, 74(S1): 1-7. |

| [2] | Chao HU, Yuming DONG, Wei ZHANG, Hongling ZHANG, Peng ZHOU, Hongbin XU. Preparation of high-concentration positive electrolyte of vanadium redox flow battery by activating vanadium pentoxide with highly concentrated sulfuric acid [J]. CIESC Journal, 2023, 74(S1): 338-345. |

| [3] | Song HE, Qiaomai LIU, Guangshuo XIE, Simin WANG, Juan XIAO. Two-phase flow simulation and surrogate-assisted optimization of gas film drag reduction in high-concentration coal-water slurry pipeline [J]. CIESC Journal, 2023, 74(9): 3766-3774. |

| [4] | Xiaoxiong FAN, Lifang HAO, Chuigang FAN, Songgeng LI. Study on the catalytic denitrification performance of low-temperature NH3-SCR over LaMnO3/biochar catalyst [J]. CIESC Journal, 2023, 74(9): 3821-3830. |

| [5] | Manzheng ZHANG, Meng XIAO, Peiwei YAN, Zheng MIAO, Jinliang XU, Xianbing JI. Working fluid screening and thermodynamic optimization of hazardous waste incineration coupled organic Rankine cycle system [J]. CIESC Journal, 2023, 74(8): 3502-3512. |

| [6] | Rubin ZENG, Zhongjie SHEN, Qinfeng LIANG, Jianliang XU, Zhenghua DAI, Haifeng LIU. Study of the sintering mechanism of Fe2O3 nanoparticles based on molecular dynamics simulation [J]. CIESC Journal, 2023, 74(8): 3353-3365. |

| [7] | Chen HAN, Youmin SITU, Bin ZHU, Jianliang XU, Xiaolei GUO, Haifeng LIU. Study of reaction and flow characteristics in multi-nozzle pulverized coal gasifier with co-processing of wastewater [J]. CIESC Journal, 2023, 74(8): 3266-3278. |

| [8] | Qiyu ZHANG, Lijun GAO, Yuhang SU, Xiaobo MA, Yicheng WANG, Yating ZHANG, Chao HU. Recent advances in carbon-based catalysts for electrochemical reduction of carbon dioxide [J]. CIESC Journal, 2023, 74(7): 2753-2772. |

| [9] | Yuanhao QU, Wenyi DENG, Xiaodan XIE, Yaxin SU. Study on electro-osmotic dewatering of sludge assisted by activated carbon/graphite [J]. CIESC Journal, 2023, 74(7): 3038-3050. |

| [10] | Chao KANG, Jinpeng QIAO, Shengchao YANG, Chao PENG, Yuanpeng FU, Bin LIU, Jianrong LIU, Aleksandrova TATIANA, Chenlong DUAN. Research progress on activation extraction of valuable metals in coal gangue [J]. CIESC Journal, 2023, 74(7): 2783-2799. |

| [11] | Yuying GUO, Jiaqiang JING, Wanni HUANG, Ping ZHANG, Jie SUN, Yu ZHU, Junxuan FENG, Hongjiang LU. Water-lubricated drag reduction and pressure drop model modification for heavy oil pipeline [J]. CIESC Journal, 2023, 74(7): 2898-2907. |

| [12] | Xueyan WEI, Yong QIAN. Experimental study on the low to medium temperature oxidation characteristics and kinetics of micro-size iron powder [J]. CIESC Journal, 2023, 74(6): 2624-2638. |

| [13] | Jipeng ZHOU, Wenjun HE, Tao LI. Reaction engineering calculation of deactivation kinetics for ethylene catalytic oxidation over irregular-shaped catalysts [J]. CIESC Journal, 2023, 74(6): 2416-2426. |

| [14] | Tan ZHANG, Guang LIU, Jinping LI, Yuhan SUN. Performance regulation strategies of Ru-based nitrogen reduction electrocatalysts [J]. CIESC Journal, 2023, 74(6): 2264-2280. |

| [15] | Zhaoguang CHEN, Yuxiang JIA, Meng WANG. Modeling neutralization dialysis desalination driven by low concentration waste acid and its validation [J]. CIESC Journal, 2023, 74(6): 2486-2494. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||