CIESC Journal ›› 2023, Vol. 74 ›› Issue (2): 525-534.DOI: 10.11949/0438-1157.20221002

• Reviews and monographs • Previous Articles Next Articles

Mengbo ZHANG( ), Linjin LOU, Yirong FENG, Yuting ZHENG, Haomiao ZHANG(

), Linjin LOU, Yirong FENG, Yuting ZHENG, Haomiao ZHANG( ), Jingdai WANG, Yongrong YANG

), Jingdai WANG, Yongrong YANG

Received:2022-07-19

Revised:2022-10-10

Online:2023-03-21

Published:2023-02-05

Contact:

Haomiao ZHANG

张梦波( ), 楼琳瑾, 冯艺荣, 郑雨婷, 张浩淼(

), 楼琳瑾, 冯艺荣, 郑雨婷, 张浩淼( ), 王靖岱, 阳永荣

), 王靖岱, 阳永荣

通讯作者:

张浩淼

作者简介:张梦波(2000—),男,硕士研究生,22128096@zju.edu.cn

基金资助:CLC Number:

Mengbo ZHANG, Linjin LOU, Yirong FENG, Yuting ZHENG, Haomiao ZHANG, Jingdai WANG, Yongrong YANG. Research progress on synthesis of alkylaluminoxanes[J]. CIESC Journal, 2023, 74(2): 525-534.

张梦波, 楼琳瑾, 冯艺荣, 郑雨婷, 张浩淼, 王靖岱, 阳永荣. 烷基铝氧烷合成技术研究进展[J]. 化工学报, 2023, 74(2): 525-534.

Add to citation manager EndNote|Ris|BibTeX

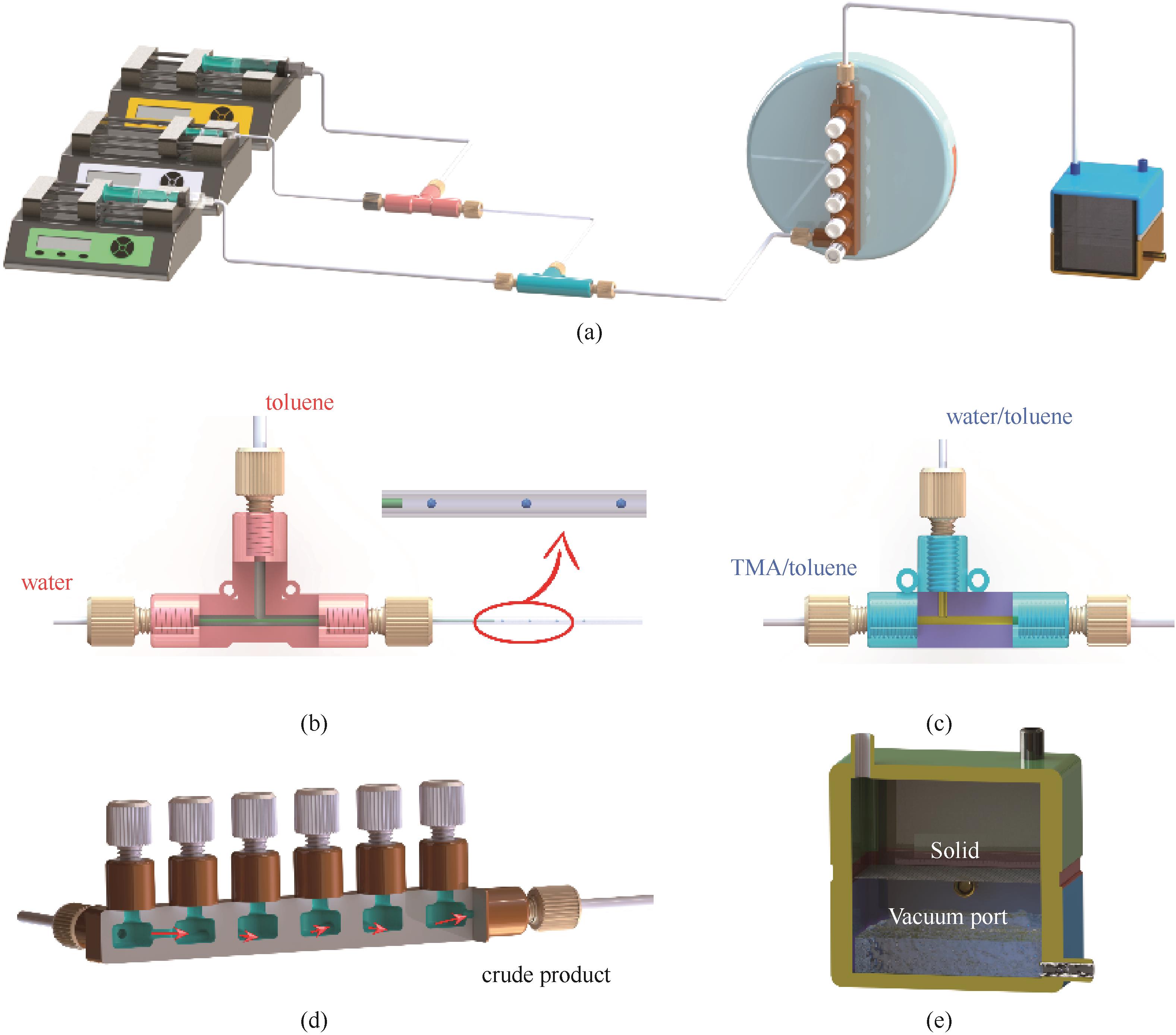

Fig.2 Schematic of the flow platform for MAO synthesis (a), capillary-based microdroplet generator (b), T-micromixer (c), 6 μCSTRs-in-series (d), and gas/liquid/solid three-phase separator (e)[59]

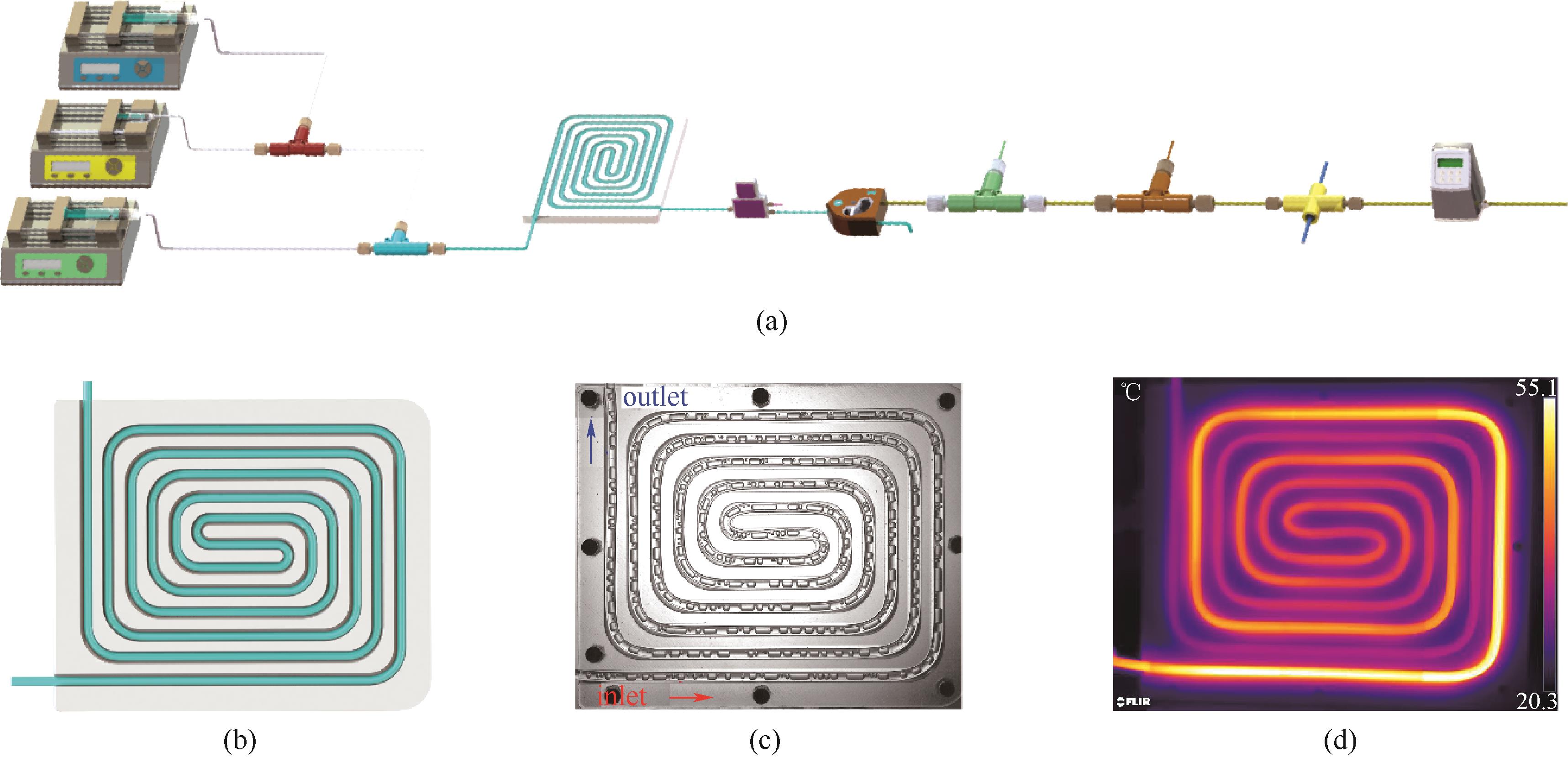

Fig.3 (a) Schematic of the flow platform for IBAO synthesis; (b) Schematic of coiled tubular microreactor; (c) Two-phase flow pattern distribution during the reaction; (d) temperature distribution during the reaction [69]

| 产品名称 | 产品型号 | 分子式 | 溶剂 | CAS号 |

|---|---|---|---|---|

| 3A型改性甲基铝氧烷 | MMAO-3A | —[(CH3)0.7(i-C4H9)0.3AlO] x — | 正庚烷 | 146905-79-5 |

| 7型改性甲基铝氧烷 | MMAO-7 | —[(CH3)0.86(n-C8H17)0.14AlO] x — | Isopar ETM | 206451-54-9 |

| 12型改性甲基铝氧烷 | MMAO-12 | —[(CH3)0.95(n-C8H17)0.05AlO] x — | 甲苯 | 206-54-9 |

Table 1 Representative commercial MMAO products

| 产品名称 | 产品型号 | 分子式 | 溶剂 | CAS号 |

|---|---|---|---|---|

| 3A型改性甲基铝氧烷 | MMAO-3A | —[(CH3)0.7(i-C4H9)0.3AlO] x — | 正庚烷 | 146905-79-5 |

| 7型改性甲基铝氧烷 | MMAO-7 | —[(CH3)0.86(n-C8H17)0.14AlO] x — | Isopar ETM | 206451-54-9 |

| 12型改性甲基铝氧烷 | MMAO-12 | —[(CH3)0.95(n-C8H17)0.05AlO] x — | 甲苯 | 206-54-9 |

| 1 | Kaminsky W. Discovery of methylaluminoxane as cocatalyst for olefin polymerization[J]. Macromolecules, 2012, 45(8): 3289-3297. |

| 2 | Kaminsky W. The discovery and evolution of metallocene-based olefin polymerization catalysts[J]. Rendiconti Lincei, 2017, 28(1): 87-95. |

| 3 | 吴江. 甲基铝氧烷合成技术研究[D]. 兰州: 兰州大学, 2007. |

| Wu J. Study in synthetic technology of methylaluminoxane[D]. Lanzhou: Lanzhou University, 2007. | |

| 4 | Zijlstra H S, Harder S. Methylalumoxane-history, production, properties, and applications[J]. European Journal of Inorganic Chemistry, 2015, 2015(1): 19-43. |

| 5 | Oliva L, Oliva P, Galdi N, et al. Solution structure and reactivity with metallocenes of AlMe2F: mimicking cation-anion interactions in metallocenium-methylalumoxane inner-sphere ion pairs[J]. Angewandte Chemie International Edition, 2017, 56(45): 14227-14231. |

| 6 | Rabinovich D. The allure of aluminium[J]. Nature Chemistry, 2012, 5: 76. |

| 7 | Glaser R, Sun X S. Thermochemistry of the initial steps of methylaluminoxane formation. Aluminoxanes and cycloaluminoxanes by methane elimination from dimethylaluminum hydroxide and its dimeric aggregates[J]. Journal of the American Chemical Society, 2011, 133(34): 13323-13336. |

| 8 | Linnolahti M, Severn J R, Pakkanen T A. Formation of nanotubular methylaluminoxanes and the nature of the active species in single-site α-olefin polymerization catalysis[J]. Angewandte Chemie International Edition, 2008, 47(48): 9279-9283. |

| 9 | Busico V, Cipullo R, Cutillo F, et al. Improving the performance of methylalumoxane: a facile and efficient method to trap “free” trimethylaluminum[J]. Journal of the American Chemical Society, 2003, 125(41): 12402-12403. |

| 10 | Linnolahti M, Severn J R, Pakkanen T A. Are aluminoxanes nanotubular? Structural evidence from a quantum chemical study[J]. Angewandte Chemie International Edition, 2006, 45(20): 3331-3334. |

| 11 | Pasynkiewicz S. Alumoxanes: synthesis, structures, complexes and rections[J]. Polyhedron, 1990, 9: 429-453. |

| 12 | Velthoen M E Z, Muñoz-Murillo A, Bouhmadi A, et al. The multifaceted role of methylaluminoxane in metallocene-based olefin polymerization catalysis[J]. Macromolecules, 2018, 51(2): 343-355. |

| 13 | Kleinschmidt R, van der leek Y, Reffke M, et al. Kinetics and mechanistic insight into propylene polymerization with different metallocenes and various aluminium alkyls as cocatalysts[J]. Journal of Molecular Catalysis A: Chemical, 1999, 148(1): 29-41. |

| 14 | Ioku A, Hasan T, Shiono T, et al. Effects of cocatalysts on propene polymerization with [t-BuNSiMe2(C5Me4)]TiMe2 [J]. Macromolecular Chemistry and Physics, 2002, 203(4): 748-755. |

| 15 | Hoff R. Handbook of Transition Metal Polymerization Catalysts [M]. 2nd ed. New Jersey: John Wiley & Sons, Inc., 2018. |

| 16 | Bochmann M. The chemistry of catalyst activation: the case of group 4 polymerization catalysts[J]. Organometallics, 2010, 29(21): 4711-4740. |

| 17 | Kaminsky W. The discovery of metallocene catalysts and their present state of the art[J]. Journal of Polymer Science Part A-Polymer Chemistry, 2004, 42(16): 3911-3921. |

| 18 | Edwards D N, Briggs J R, Marcinkowsky A E, et al. Process for the preparation of aluminoxanes: US4772736[P]. 1988-09-20. |

| 19 | Giannetti E, Nicoletti G M, Mazzocchi R. Homogeneous Ziegler Natta catalysis.2. Ethylene polymerization by IVB transition-metal complexes/methyl aluminoxane catalyst systems[J]. Journal of Polymer Science Part A: Polymer Chemistry, 1985, 23(8): 2117-2134. |

| 20 | Deavenport D L, Hodges Iii J T, Malpass D B, et al. Preparation of aluminoxanes: US5041585[P]. 1991-08-20. |

| 21 | 吴江, 韦少义, 陈雪蓉, 等. 一种雾化合成装置及其在烷基铝氧烷合成方面的应用: 102190677B[P]. 2010-03-03. |

| Wu J, Wei S Y, Chen X R, et al. A kind of atomization synthesis device and its application in the synthesis of alkyl aluminoxide: 102190677B[P]. 2010-03-03. | |

| 22 | Smith G Z Jr. Falling film aluminoxane process: US5103031[P]. 1992-04-07. |

| 23 | Kilpatrick A F R, Buffet J-C, Nørby P, et al. Synthesis and characterization of solid polymethylaluminoxane: a bifunctional activator and support for slurry-phase ethylene polymerization[J]. Chemistry of Materials, 2016, 28(20): 7444-7450. |

| 24 | 韦少义, 朱博超, 陈雪蓉, 等. 烷基铝氧烷的制备方法: 100413870C[P]. 2008-08-27. |

| Wei S Y, Zhu B C, Chen X R, et al. Preparation method of alkyl aluminoxicane: 100413870C[P]. 2008-08-27. | |

| 25 | Sinn H. Proposals for structure and effect of methylalumoxane based on mass balances and phase separation experiments[J]. Macromolecular Symposia, 1995, 97(1): 27-52. |

| 26 | Sinn H, Clausnitzer D, Winter H. Process for producing aluminum oxanes, in particular methylaluminum oxane, from water and organoaluminum compounds, in particular trimethylaluminum, in inert hydrocarbons: US5087713[P]. 1992-02-11. |

| 27 | Roberg J K, Burt E A. High yield aluminoxane synthesis process: US5663394[P]. 1997-09-02. |

| 28 | Cam D, Albizzati E, Cinquina P. Characterization of methylalumoxane by means of gel-permeation chromatography[J]. Makromolekulare Chemie-Macromolecular Chemistry and Physics, 1990, 191(7): 1641-1647. |

| 29 | Resconi L, Bossi S, Abis L. Study on the role of methylalumoxane in homogeneous olefin polymerization[J]. Macromolecules, 1990, 23(20): 4489-4491. |

| 30 | Soga K, Yu C H, Shiono T. Polymerization of alpha-olefins with the catalyst system prepared from a hydrated transition-metal compound and trimethylaluminum[J]. Makromolekulare Chemie-Rapid Communications, 1988, 9(3): 141-144. |

| 31 | Okajima Y, Nakayama Y, Shiono T, et al. Preparation of methylaluminoxane from CO2 and Me3Al[J]. European Journal of Inorganic Chemistry, 2019(18): 2392-2395. |

| 32 | Kinnunen T J J, Haukka M, Pakkanen T, et al. Four-coordinated bipyridine complexes of nickel for ethene polymerization — the role of ligand structure[J]. Journal of Organometallic Chemistry 2000, 613: 257-262. |

| 33 | Dalet T, Cramail H, Deffieux A. Non-hydrolytic route to aluminoxane-type derivative for metallocene activation towards olefin polymerisation[J]. Macromolecular Chemistry and Physics, 2004, 205(10): 1394-1401. |

| 34 | Jensen K F. Microreaction engineering — is small better?[J]. Chemical Engineering Science, 2001, 56(2): 293-303. |

| 35 | Newman S G, Jensen K F. The role of flow in green chemistry and engineering[J]. Green Chemistry, 2013, 15(6): 1456-1472. |

| 36 | Jensen K F. Flow chemistry—microreaction technology comes of age[J]. AIChE Journal, 2017, 63(3): 858-869. |

| 37 | 骆广生, 王凯, 王玉军, 等. 微化工系统的原理和应用[J]. 化工进展, 2011, 30(8): 1637-1642. |

| Luo G S, Wang K, Wang Y J, et al. Principles and applications of micro-structured chemical system[J]. Chemical Industry and Engineering Progress, 2011, 30(8): 1637-1642. | |

| 38 | Zhang J, Wang K, Teixeira A R, et al. Design and scaling up of microchemical systems: a review[J]. Annual review of chemical biomolecular engineering, 2017, 8: 285-305. |

| 39 | Bedard A C, Adamo A, Aroh K C, et al. Reconfigurable system for automated optimization of diverse chemical reactions[J]. Science, 2018, 361(6408): 1220-1225. |

| 40 | Britton J, Raston C L. Multi-step continuous-flow synthesis[J]. Chemical Society Reviews, 2017, 46(5): 1250-1271. |

| 41 | Liu D, Jing Y, Wang K, et al. Reaction study of α-phase NaYF4:Yb,Er generation via a tubular microreactor: discovery of an efficient synthesis strategy[J]. Nanoscale, 2019, 11(17): 8363-8371. |

| 42 | Reis M H, Leibfarth F A, Pitet L M. Polymerizations in continuous flow: recent advances in the synthesis of diverse polymeric materials[J]. ACS Macro Letters, 2020, 9(1): 123-133. |

| 43 | Zaquen N, Rubens M, Corrigan N, et al. Polymer synthesis in continuous flow reactors[J]. Progress in Polymer Science, 2020, 107: 101256. |

| 44 | Tonhauser C, Nataello A, Lowe H, et al. Microflow technology in polymer synthesis[J]. Macromolecules, 2012, 45(24): 9551-9570. |

| 45 | Marre S, Adamo A, Basak S, et al. Design and packaging of microreactors for high pressure and high temperature applications[J]. Industrial & Engineering Chemistry Research, 2010, 49(22): 11310-11320. |

| 46 | Ehrfeld W, Hessel V, Löwe H. Microreactors: New Technology for Modern Chemistry[M]. Mainz: IMM Mainz GmbH, 2000. |

| 47 | Zhang J S, Wang K, Lu Y C, et al. Beckmann rearrangement in a microstructured chemical system for the preparation of ε-caprolactam[J]. AIChE Journal, 2012, 58(3): 925-931. |

| 48 | Wang K, Zhang H, Shen Y, et al. Thermoformed fluoropolymer tubing for in-line mixing[J]. Reaction Chemistry & Engineering, 2018, 3(5): 707-713. |

| 49 | Cambie D, Bottecchia C, Straathof N J W, et al. Applications of continuous-flow photochemistry in organic synthesis, material science, and water treatment[J]. Chemical Reviews, 2016, 116(17): 10276-10341. |

| 50 | Buglioni L, Raymenants F, Slattery A, et al. Technological innovations in photochemistry for organic synthesis: flow chemistry, high-throughput experimentation, scale-up, and photoelectrochemistry[J]. Chemical Reviews, 2022, 122(2): 2752-2906. |

| 51 | Campbell Z S, Abolhasani M. Facile synthesis of anhydrous microparticles using plug-and-play microfluidic reactors[J]. Reaction Chemistry & Engineering, 2020, 5(7): 1198-1211. |

| 52 | Bennett J A, Kristof A J, Vasudevan V, et al. Microfluidic synthesis of elastomeric microparticles: a case study in catalysis of palladium-mediated cross-coupling[J]. AIChE Journal, 2018, 64(8): 3188-3197. |

| 53 | Lebl R, Zhu Y, Ng D, et al. Scalable continuous flow hydrogenations using Pd/Al2O3-coated rectangular cross-section 3D-printed static mixers[J]. Catalysis Today, 2022, 383: 55-63. |

| 54 | Maier M C, Valotta A, Hiebler K, et al. 3D printed reactors for synthesis of active pharmaceutical ingredients in continuous flow[J]. Organic Process Research & Development, 2020, 24(10): 2197-2207. |

| 55 | Zhang H M, Kopfmüller T, Achermann R, et al. Accessing multidimensional mixing via 3D printing and showerhead micromixer design[J]. AIChE Journal, 2020, 66(4): e16873. |

| 56 | Feng Y R, Zhang H M, Wang J D, et al. Performance evaluation and scale-up behavior of an engineered in-line mixer for 3D printing[J]. Industrial & Engineering Chemistry Research, 2021, 60(30): 11568-11578. |

| 57 | Zhang H M, Ładosz A, Jensen K F. Design and operation of an enhanced pervaporation device with static mixers[J]. AIChE Journal, 2022, 68(2): e17455. |

| 58 | Feng Y R, Mu H F, Liu X, et al. Leveraging 3D printing for the design of high-performance Venturi microbubble generators[J]. Industrial & Engineering Chemistry Research, 2020, 59(17): 8447-8455. |

| 59 | Feng Y R, Wang J, Zhang H M, et al. A 3D-printed continuous flow platform for the synthesis of methylaluminoxane[J]. Green Chemistry, 2021, 23(11): 4087-4094. |

| 60 | Zhang M B, Feng Y R, Lou L J, et al. Flow toolkit for measuring reaction enthalpy and application to highly exothermic synthesis of alkylaluminoxanes[J]. Organic Process Research & Development, 2022, 26(5): 1506-1513. |

| 61 | Pédeutour J-N, Radhakrishnan K, Cramail H, et al. Reactivity of metallocene catalysts for olefin polymerization: influence of activator nature and structure[J]. Macromolecular Rapid Communications, 2001, 22(14): 1095-1123. |

| 62 | Kissin Y V, Brandolini A J. An alternative route to methylalumoxane: synthesis, structure, and the use of model methylalumoxanes as cocatalysts for transition metal complexes in polymerization reactions[J]. Macromolecules, 2003, 36(1): 18-26. |

| 63 | Kaminsky W, Strubel C. Hydrogen transfer reactions of supported metallocene catalysts[J]. Journal of Molecular Catalysis A-Chemical, 1998, 128(1/2/3): 191-200. |

| 64 | Kaminsky W, Bark A, Steiger R. Stereospecific polymerization by metallocene aluminoxane catalysts[J]. Journal of Molecular Catalysis, 1992, 74(1/2/3): 109-119. |

| 65 | Chen E Y, Marks T J. Cocatalysts for metal-catalyzed olefin polymerization: activators, activation processes, and structure-activity relationships[J]. Chemical Reviews, 2000, 100(4): 1391-1434. |

| 66 | Velthoen M E Z, Boereboom J M, Bulo R E, et al. Insights into the activation of silica-supported metallocene olefin polymerization catalysts by methylaluminoxane[J]. Catalysis Today, 2019, 334: 223-230. |

| 67 | Baier M C, Zuideveld M A, Mecking S. Post-metallocenes in the industrial production of polyolefins[J]. Angewandte Chemie International Edition, 2014, 53(37): 9722-9744. |

| 68 | Stellbrink J, Niu A, Allgaier J, et al. Analysis of polymeric methylaluminoxane (MAO) via small angle neutron scattering[J]. Macromolecules, 2007, 40(14): 4972-4981. |

| 69 | Feng Y R, Zhang M B, Zhang H M, et al. Continuous synthesis of isobutylaluminoxanes in a compact and integrated approach[J]. Chemical Engineering Journal, 2021, 425: 131750. |

| 70 | Bravaya N M, Panin A N, Faingol'd E E, et al. Isobutylalumoxanes as high-performance activators of rac-Et(2-MeInd)2ZrMe2 in copolymerization of ethylene with propylene and ternary copolymerization of ethylene, propylene, and 5-ethylidene-2-norbornene[J]. Polymer Bulletin, 2015, 73(2): 473-491. |

| 71 | Zhang M B, Lou L J, Zheng Y T, et al. A two-stage flow strategy for the synthesis of isobutyl-modified methylaluminoxane[J]. Reaction Chemistry & Engineering, 2023, DOI:10.1039/D2RE00595F . |

| [1] | Qi WANG, Bin ZHANG, Xiaoxin ZHANG, Hujian WU, Haitao ZHAN, Tao WANG. Synthesis of isoxepac and 2-ethylanthraquinone catalyzed by chloroaluminate-triethylamine ionic liquid/P2O5 [J]. CIESC Journal, 2023, 74(S1): 245-249. |

| [2] | Jiali GE, Tuxiang GUAN, Xinmin QIU, Jian WU, Liming SHEN, Ningzhong BAO. Synthesis of FeF3 nanoparticles covered by vertical porous carbon for high performance Li-ion battery cathode [J]. CIESC Journal, 2023, 74(7): 3058-3067. |

| [3] | Bin LI, Zhenghu XU, Shuang JIANG, Tianyong ZHANG. Clean and efficient synthesis of accelerator CBS by hydrogen peroxide catalytic oxidation method [J]. CIESC Journal, 2023, 74(7): 2919-2925. |

| [4] | Yuming TU, Gaoyan SHAO, Jianjie CHEN, Feng LIU, Shichao TIAN, Zhiyong ZHOU, Zhongqi REN. Advances in the design, synthesis and application of calcium-based catalysts [J]. CIESC Journal, 2023, 74(7): 2717-2734. |

| [5] | Maolin DONG, Lidong CHEN, Liulian HUANG, Weibing WU, Hongqi DAI, Huiyang BIAN. Research progress in preparation of lignonanocellulose by acid hydrotropes and their functional applications [J]. CIESC Journal, 2023, 74(6): 2281-2295. |

| [6] | Tan ZHANG, Guang LIU, Jinping LI, Yuhan SUN. Performance regulation strategies of Ru-based nitrogen reduction electrocatalysts [J]. CIESC Journal, 2023, 74(6): 2264-2280. |

| [7] | Hanbing HE, Zhen LIU, Yong CHEN, Xiaofeng WANG, Jing ZENG. Synthesis and slurry control of manganese oxide powder for direct ink writing electrode [J]. CIESC Journal, 2023, 74(5): 2239-2247. |

| [8] | Feng WANG, Yu CHEN, Hongyan PEI, Dongdong LIU, Jing ZHANG, Lixin ZHANG. Design, synthesis and anti-fungal activity of 1,2,4-oxadiazole derivatives [J]. CIESC Journal, 2023, 74(3): 1390-1398. |

| [9] | Dingping LIU, Aihua CHEN, Xiangyang ZHANG, Wenhao HE, Hai WANG. Study on semi dry hydrolytic denitrification of aluminum ash [J]. CIESC Journal, 2023, 74(3): 1294-1302. |

| [10] | Runzhu LIU, Tiantian CHU, Xiaoa ZHANG, Chengzhong WANG, Junying ZHANG. Synthesis and properties of phenylene-containing α,ω-hydroxy-terminated fluorosilicone polymers [J]. CIESC Journal, 2023, 74(3): 1360-1369. |

| [11] | Haiou YUAN, Fangjun YE, Shuo ZHANG, Yiqing LUO, Xigang YUAN. Synthesis of heat-integrated distillation sequences with intermediate heat exchangers [J]. CIESC Journal, 2023, 74(2): 796-806. |

| [12] | Xianfu CHEN, Dongyu WANG, Yiqun FAN, Weihong XING, Xu QIAO. Research progress of porous ceramic membranes based on 3D printing technologies [J]. CIESC Journal, 2023, 74(1): 105-115. |

| [13] | Guojia YU, Dongyu JIN, Zhiyong ZHOU, Fan ZHANG, Zhongqi REN. Advances in the design, synthesis and application of porous liquids [J]. CIESC Journal, 2023, 74(1): 257-275. |

| [14] | Qiuhua ZHANG, Manlu LIU, Zheng WANG, Yiming ZHANG, Haijia SU. Biosynthesis of vitamin K2 and functional analysis of the biosynthetic enzymes involved in its menadione moiety [J]. CIESC Journal, 2023, 74(1): 342-354. |

| [15] | Xiaobing JU, Xuechun LI, Fang SUN. Effect on dithiosalicylic acid derivative on properties of photocuring materials [J]. CIESC Journal, 2022, 73(9): 4187-4193. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||