CIESC Journal ›› 2023, Vol. 74 ›› Issue (6): 2427-2435.DOI: 10.11949/0438-1157.20230258

• Catalysis, kinetics and reactors • Previous Articles Next Articles

Xiqing ZHANG1( ), Yanting WANG1(

), Yanting WANG1( ), Yanhong XU2, Shuling CHANG1, Tingting SUN1, Ding XUE3, Lihong ZHANG1(

), Yanhong XU2, Shuling CHANG1, Tingting SUN1, Ding XUE3, Lihong ZHANG1( )

)

Received:2023-03-20

Revised:2023-05-28

Online:2023-07-27

Published:2023-06-05

Contact:

Lihong ZHANG

张希庆1( ), 王琰婷1(

), 王琰婷1( ), 徐彦红2, 常淑玲1, 孙婷婷1, 薛定3, 张立红1(

), 徐彦红2, 常淑玲1, 孙婷婷1, 薛定3, 张立红1( )

)

通讯作者:

张立红

作者简介:张希庆(1997—),男,硕士研究生,zhangxiqing1997@163.com基金资助:CLC Number:

Xiqing ZHANG, Yanting WANG, Yanhong XU, Shuling CHANG, Tingting SUN, Ding XUE, Lihong ZHANG. Effect of Mg content on isobutane dehydrogenation properties over nanosheets supported Pt-In catalysts[J]. CIESC Journal, 2023, 74(6): 2427-2435.

张希庆, 王琰婷, 徐彦红, 常淑玲, 孙婷婷, 薛定, 张立红. Mg量影响的纳米片负载Pt-In催化异丁烷脱氢性能[J]. 化工学报, 2023, 74(6): 2427-2435.

Add to citation manager EndNote|Ris|BibTeX

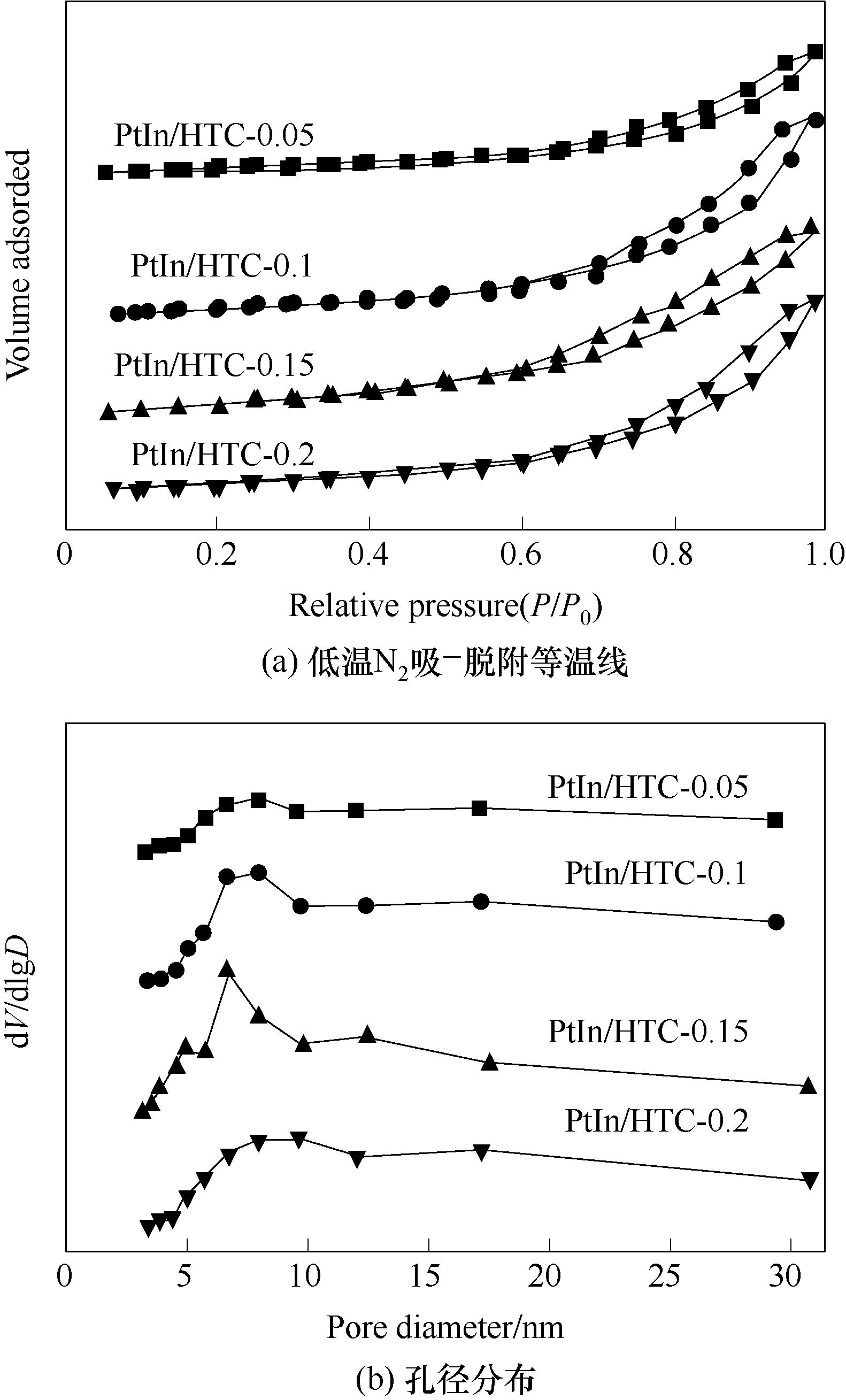

Fig.4 Low temperature N2 adsorption-desorption isotherms and pore size distribution curves of calcined catalysts PtIn/HTC-x (x = 0.05, 0.1, 0.15, 0.2 mol·L-1)

| 催化剂 | 比表面积/(m2·g-1) | 孔体积/(cm3·g-1) | 平均孔径/nm |

|---|---|---|---|

| PtIn/HTC-0.05 | 136 | 0.34 | 6.6 |

| PtIn/HTC-0.1 | 173 | 0.58 | 6.6 |

| PtIn/HTC-0.15 | 247 | 0.57 | 6.6 |

| PtIn/HTC-0.2 | 203 | 0.56 | 7.8 |

Table 1 Textural data of calcined catalysts PtIn/HTC-x (x = 0.05, 0.1, 0.15, 0.2 mol·L-1)

| 催化剂 | 比表面积/(m2·g-1) | 孔体积/(cm3·g-1) | 平均孔径/nm |

|---|---|---|---|

| PtIn/HTC-0.05 | 136 | 0.34 | 6.6 |

| PtIn/HTC-0.1 | 173 | 0.58 | 6.6 |

| PtIn/HTC-0.15 | 247 | 0.57 | 6.6 |

| PtIn/HTC-0.2 | 203 | 0.56 | 7.8 |

| 催化剂 | TM /℃ | 总峰面积 | 峰面积占比/% | ||||

|---|---|---|---|---|---|---|---|

| Ⅰ | Ⅱ | Ⅲ | Ⅰ | Ⅱ | Ⅲ | ||

| PtIn/HTC-0.05 | 150 | 189 | 295 | 121 | 14.5 | 26.8 | 58.7 |

| PtIn/HTC-0.1 | 147 | 187 | 263 | 111 | 13.3 | 29.7 | 57.0 |

| PtIn/HTC-0.15 | 150 | 190 | 265 | 88 | 23.3 | 30.2 | 46.5 |

| PtIn/HTC-0.2 | 144 | 184 | 315 | 64 | 20.4 | 32.3 | 47.3 |

Table 2 NH3-TPD results of calcined catalysts PtIn/HTC-x (x = 0.05, 0.1, 0.15, 0.2 mol·L-1)

| 催化剂 | TM /℃ | 总峰面积 | 峰面积占比/% | ||||

|---|---|---|---|---|---|---|---|

| Ⅰ | Ⅱ | Ⅲ | Ⅰ | Ⅱ | Ⅲ | ||

| PtIn/HTC-0.05 | 150 | 189 | 295 | 121 | 14.5 | 26.8 | 58.7 |

| PtIn/HTC-0.1 | 147 | 187 | 263 | 111 | 13.3 | 29.7 | 57.0 |

| PtIn/HTC-0.15 | 150 | 190 | 265 | 88 | 23.3 | 30.2 | 46.5 |

| PtIn/HTC-0.2 | 144 | 184 | 315 | 64 | 20.4 | 32.3 | 47.3 |

| 催化剂 | TM /℃ | 总峰面积 At | 各峰面积 | 峰面积比 | |||

|---|---|---|---|---|---|---|---|

| Ⅰ | Ⅱ | AⅠ | AⅡ | AII/AI | AII/At | ||

| PtIn/HTC-0.05 | 345 | 520 | 502 | 417 | 85 | 0.20 | 0.17 |

| PtIn/HTC-0.1 | 398 | 529 | 761 | 637 | 124 | 0.19 | 0.16 |

| PtIn/HTC-0.15 | 407 | 536 | 613 | 534 | 79 | 0.15 | 0.13 |

| PtIn/HTC-0.2 | 446 | 570 | 419 | 329 | 90 | 0.27 | 0.21 |

Table 3 H2-TPR results of calcined catalysts PtIn/HTC-x (x = 0.05, 0.1, 0.15, 0.2 mol·L-1)

| 催化剂 | TM /℃ | 总峰面积 At | 各峰面积 | 峰面积比 | |||

|---|---|---|---|---|---|---|---|

| Ⅰ | Ⅱ | AⅠ | AⅡ | AII/AI | AII/At | ||

| PtIn/HTC-0.05 | 345 | 520 | 502 | 417 | 85 | 0.20 | 0.17 |

| PtIn/HTC-0.1 | 398 | 529 | 761 | 637 | 124 | 0.19 | 0.16 |

| PtIn/HTC-0.15 | 407 | 536 | 613 | 534 | 79 | 0.15 | 0.13 |

| PtIn/HTC-0.2 | 446 | 570 | 419 | 329 | 90 | 0.27 | 0.21 |

| 催化剂 | In 3d5/2 结合能 /eV | In 3d3/2 结合能 /eV | In3+/In0① | ||

|---|---|---|---|---|---|

| In0 | In3+ | In0 | In3+ | ||

| PtIn/HTR-0.05 | 444.5 | 445.8 | 452.2 | 453.2 | 1.57 |

| PtIn/HTR-0.1 | 444.5 | 445.6 | 452.2 | 453.1 | 2.00 |

| PtIn/HTR-0.15 | 444.7 | 445.6 | 452.3 | 453.3 | 2.87 |

| PtIn/HTR-0.2 | 444.5 | 445.5 | 452.2 | 453.1 | 2.27 |

Table 4 In 3d region data of reduced catalysts PtIn/HTR-x (x = 0.05,0.1,0.15,0.2 mol·L-1)

| 催化剂 | In 3d5/2 结合能 /eV | In 3d3/2 结合能 /eV | In3+/In0① | ||

|---|---|---|---|---|---|

| In0 | In3+ | In0 | In3+ | ||

| PtIn/HTR-0.05 | 444.5 | 445.8 | 452.2 | 453.2 | 1.57 |

| PtIn/HTR-0.1 | 444.5 | 445.6 | 452.2 | 453.1 | 2.00 |

| PtIn/HTR-0.15 | 444.7 | 445.6 | 452.3 | 453.3 | 2.87 |

| PtIn/HTR-0.2 | 444.5 | 445.5 | 452.2 | 453.1 | 2.27 |

| 1 | Venugopalan A T, Kandasamy P, Gupta N N, et al. Promoted mesoporous Fe-alumina catalysts for the non-oxidative dehydrogenation of isobutane[J]. Catalysis Communications, 2021, 150: 106263. |

| 2 | Im J, Choi M. Physicochemical stabilization of Pt against sintering for a dehydrogenation catalyst with high activity, selectivity, and durability[J]. ACS Catalysis, 2016, 6(5): 2819-2826. |

| 3 | 郭丹, 方雨洁, 许一寒, 等. 乙烷和二氧化碳催化转化的研究进展[J]. 化工学报, 2022, 73(8): 3406-3416. |

| Guo D, Fang Y J, Xu Y H, et al. Research progress of the catalytic conversion of ethane and carbon dioxide[J]. CIESC Journal, 2022, 73(8): 3406-3416. | |

| 4 | Gao X Q, Song W, Li W C, et al. Anti-coke behavior of an alumina nanosheet supported Pt-Sn catalyst for isobutane dehydrogenation[J]. Catalysis Science & Technology, 2021, 11(7): 2597-2603. |

| 5 | Zhu Y R, An Z, Song H Y, et al. Lattice-confined Sn (Ⅳ/Ⅱ) stabilizing raft-like Pt clusters: high selectivity and durability in propane dehydrogenation[J]. ACS Catalysis, 2017, 7(10): 6973-6978. |

| 6 | Liu J F, Zhou W, Jiang D Y, et al. Insights into the doping effect of rare-earth metal on ZnAl2O4 supported PtSn catalyzed isobutane dehydrogenation[J]. Catalysis Today, 2021, 368: 58-65. |

| 7 | Xia K, Lang W Z, Li P P, et al. The properties and catalytic performance of PtIn/Mg(Al)O catalysts for the propane dehydrogenation reaction: effects of pH value in preparing Mg(Al)O supports by the co-precipitation method[J]. Journal of Catalysis, 2016, 338: 104-114. |

| 8 | Xia K, Lang W Z, Li P P, et al. The influences of Mg/Al molar ratio on the properties of PtIn/Mg(Al)O-x catalysts for propane dehydrogenation reaction[J]. Chemical Engineering Journal, 2016, 284: 1068-1079. |

| 9 | Tolek W, Suriye K, Praserthdam P, et al. Effect of preparation method on the Pt-In modified Mg(Al)O catalysts over dehydrogenation of propane[J]. Catalysis Today, 2020, 358: 100-108. |

| 10 | Bauer T, Maisel S, Blaumeiser D, et al. Operando DRIFTS and DFT study of propane dehydrogenation over solid- and liquid-supported Ga x Pt y catalysts[J]. ACS Catalysis, 2019, 9(4): 2842-2853. |

| 11 | Rochlitz L, Searles K, Alfke J, et al. Silica-supported, narrowly distributed, subnanometric Pt-Zn particles from single sites with high propane dehydrogenation performance[J]. Chemical Science, 2020, 11(6): 1549-1555. |

| 12 | Xu M, Wei M. Layered double hydroxide-based catalysts: recent advances in preparation, structure, and applications[J]. Advanced Functional Materials, 2018, 28(47): 1802943. |

| 13 | Zhang M, Song Z, Guo M Q, et al. Effect of reduction atmosphere on structure and catalytic performance of PtIn/Mg(Al)O/ZnO for propane dehydrogenation[J]. Catalysts, 2020, 10(5): 485. |

| 14 | Li J X, Zhang M, Song Z, et al. Hierarchical PtIn/Mg(Al)O derived from reconstructed PtIn-hydrotalcite-like compounds for highly efficient propane dehydrogenation[J]. Catalysts, 2019, 9(9): 767. |

| 15 | Li Z, Sun Y, Liu X E, et al. Bottom-up fabrication of ultrathin CoFe layered double hydroxide nanosheets on oxidized carbon nanotube as a water oxidation electrocatalyst[J]. Journal of Alloys and Compounds, 2021, 857: 157570. |

| 16 | Wang Z L, Xu S M, Xu Y Q, et al. Single Ru atoms with precise coordination on a monolayer layered double hydroxide for efficient electrooxidation catalysis[J]. Chemical Science, 2019, 10(2): 378-384. |

| 17 | Chi H Y, Dong J W, Li T, et al. Scaled-up synthesis of defect-rich layered double hydroxide monolayers without organic species for efficient oxygen evolution reaction[J]. Green Energy & Environment, 2022, 7(5): 975-982. |

| 18 | Guo T T, Chen L Y, Li Y W, et al. Controllable synthesis of ultrathin defect-rich LDH nanoarrays coupled with MOF-derived Co-NC microarrays for efficient overall water splitting[J]. Small, 2022, 18(29): 2107739. |

| 19 | Zhao Y F, Wang Q, Bian T, et al. Ni3+ doped monolayer layered double hydroxide nanosheets as efficient electrodes for supercapacitors[J]. Nanoscale, 2015, 7(16): 7168-7173. |

| 20 | Yu J F, Martin B R, Clearfield A, et al. One-step direct synthesis of layered double hydroxide single-layer nanosheets[J]. Nanoscale, 2015, 7(21): 9448-9451. |

| 21 | Zhao Y F, Zhao Y X, Waterhouse G I N, et al. Layered-double-hydroxide nanosheets as efficient visible-light-driven photocatalysts for dinitrogen fixation[J]. Advanced Materials, 2017, 29(42): 1703828. |

| 22 | Wang Y, Zhao F L, Feng Y Y, et al. Ultrathin layered double hydroxide nanosheets prepared by original precursor method for photoelectrochemical photodetectors[J]. Nano Research, 2022, 15(10): 9392-9401. |

| 23 | Huo J M, Ma Z L, Wang Y, et al. Monodispersed Pt sites supported on NiFe-LDH from synchronous anchoring and reduction for high efficiency overall water splitting[J]. Small, 2023, 19(11): 2207044. |

| 24 | Yu J F, Liu J J, Clearfield A, et al. Synthesis of layered double hydroxide single-layer nanosheets in formamide[J]. Inorganic Chemistry, 2016, 55(22): 12036-12041. |

| 25 | Yue Y Z, Liu F, Zhao L, et al. Loading oxide nano sheet supported Ni-Co alloy nanoparticles on the macroporous walls of monolithic alumina and their catalytic performance for ethanol steam reforming[J]. International Journal of Hydrogen Energy, 2015, 40(22): 7052-7063. |

| 26 | Chen Z K, Huang M H, Cölfen H. Synthesis of ultrathin metal oxide and hydroxide nanosheets using formamide in water at room temperature[J]. CrystEngComm, 2021, 23(21): 3794-3801. |

| 27 | Wang Q, Chen L F, Guan S L, et al. Ultrathin and vacancy-rich CoAl-layered double hydroxide/graphite oxide catalysts: promotional effect of cobalt vacancies and oxygen vacancies in alcohol oxidation[J]. ACS Catalysis, 2018, 8(4): 3104-3115. |

| 28 | Gao W, Zhao Y F, Chen H R, et al. Core shell Cu@(CuCo-alloy)/Al2O3 catalysts for the synthesis of higher alcohols from syngas[J]. Green Chemistry, 2015, 17(3): 1525-1534. |

| 29 | Shi J J, Zhou Y M, Zhang Y W, et al. Synthesis of magnesium-modified mesoporous Al2O3 with enhanced catalytic performance for propane dehydrogenation[J]. Journal of Materials Science, 2014, 49(16): 5772-5781. |

| 30 | Jiang H X, Yao C X, Wang Y D, et al. Synthesis and catalytic performance of highly dispersed platinum nanoparticles supported on alumina via supercritical fluid deposition[J]. The Journal of Supercritical Fluids, 2020, 166: 105014. |

| [1] | Xuejin YANG, Jintao YANG, Ping NING, Fang WANG, Xiaoshuang SONG, Lijuan JIA, Jiayu FENG. Research progress in dry purification technology of highly toxic gas PH3 [J]. CIESC Journal, 2023, 74(9): 3742-3755. |

| [2] | Jie CHEN, Yongsheng LIN, Kai XIAO, Chen YANG, Ting QIU. Study on catalytic synthesis of sec-butanol by tunable choline-based basic ionic liquids [J]. CIESC Journal, 2023, 74(9): 3716-3730. |

| [3] | Yitong LI, Hang GUO, Hao CHEN, Fang YE. Study on operating conditions of proton exchange membrane fuel cells with non-uniform catalyst distributions [J]. CIESC Journal, 2023, 74(9): 3831-3840. |

| [4] | Feifei YANG, Shixi ZHAO, Wei ZHOU, Zhonghai NI. Sn doped In2O3 catalyst for selective hydrogenation of CO2 to methanol [J]. CIESC Journal, 2023, 74(8): 3366-3374. |

| [5] | Kaixuan LI, Wei TAN, Manyu ZHANG, Zhihao XU, Xuyu WANG, Hongbing JI. Design of cobalt-nitrogen-carbon/activated carbon rich in zero valent cobalt active site and application of catalytic oxidation of formaldehyde [J]. CIESC Journal, 2023, 74(8): 3342-3352. |

| [6] | Xin YANG, Xiao PENG, Kairu XUE, Mengwei SU, Yan WU. Preparation of molecularly imprinted-TiO2 and its properties of photoelectrocatalytic degradation of solubilized PHE [J]. CIESC Journal, 2023, 74(8): 3564-3571. |

| [7] | Yajie YU, Jingru LI, Shufeng ZHOU, Qingbiao LI, Guowu ZHAN. Construction of nanomaterial and integrated catalyst based on biological template: a review [J]. CIESC Journal, 2023, 74(7): 2735-2752. |

| [8] | Yuming TU, Gaoyan SHAO, Jianjie CHEN, Feng LIU, Shichao TIAN, Zhiyong ZHOU, Zhongqi REN. Advances in the design, synthesis and application of calcium-based catalysts [J]. CIESC Journal, 2023, 74(7): 2717-2734. |

| [9] | Qiyu ZHANG, Lijun GAO, Yuhang SU, Xiaobo MA, Yicheng WANG, Yating ZHANG, Chao HU. Recent advances in carbon-based catalysts for electrochemical reduction of carbon dioxide [J]. CIESC Journal, 2023, 74(7): 2753-2772. |

| [10] | Pan LI, Junyang MA, Zhihao CHEN, Li WANG, Yun GUO. Effect of the morphology of Ru/α-MnO2 on NH3-SCO performance [J]. CIESC Journal, 2023, 74(7): 2908-2918. |

| [11] | Tan ZHANG, Guang LIU, Jinping LI, Yuhan SUN. Performance regulation strategies of Ru-based nitrogen reduction electrocatalysts [J]. CIESC Journal, 2023, 74(6): 2264-2280. |

| [12] | Chen WANG, Xiufeng SHI, Xianfeng WU, Fangjia WEI, Haohong ZHANG, Yin CHE, Xu WU. Preparation of Mn3O4 catalyst by redox method and study on its catalytic oxidation performance and mechanism of toluene [J]. CIESC Journal, 2023, 74(6): 2447-2457. |

| [13] | Yong LI, Jiaqi GAO, Chao DU, Yali ZHAO, Boqiong LI, Qianqian SHEN, Husheng JIA, Jinbo XUE. Construction of Ni@C@TiO2 core-shell dual-heterojunctions for advanced photo-thermal catalytic hydrogen generation [J]. CIESC Journal, 2023, 74(6): 2458-2467. |

| [14] | Jipeng ZHOU, Wenjun HE, Tao LI. Reaction engineering calculation of deactivation kinetics for ethylene catalytic oxidation over irregular-shaped catalysts [J]. CIESC Journal, 2023, 74(6): 2416-2426. |

| [15] | Xu GUO, Yongzheng ZHANG, Houbing XIA, Na YANG, Zhenzhen ZHU, Jingyao QI. Research progress in the removal of water pollutants by carbon-based materials via electrooxidation [J]. CIESC Journal, 2023, 74(5): 1862-1874. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||