CIESC Journal ›› 2024, Vol. 75 ›› Issue (6): 2201-2213.DOI: 10.11949/0438-1157.20231386

• Fluid dynamics and transport phenomena • Previous Articles Next Articles

Fei LU1,2( ), Bona LU2,3(

), Bona LU2,3( ), Guangwen XU1

), Guangwen XU1

Received:2023-12-28

Revised:2024-03-26

Online:2024-07-03

Published:2024-06-25

Contact:

Bona LU

通讯作者:

鲁波娜

作者简介:卢飞(1997—),男,硕士研究生,flu@ipe.ac.cn

基金资助:CLC Number:

Fei LU, Bona LU, Guangwen XU. Analysis of criteria for ideal flow patterns in gas-solid micro fluidized bed reaction analyzer[J]. CIESC Journal, 2024, 75(6): 2201-2213.

卢飞, 鲁波娜, 许光文. 气固微型流化床反应分析仪的理想流型判据分析[J]. 化工学报, 2024, 75(6): 2201-2213.

Add to citation manager EndNote|Ris|BibTeX

| Parameter | Value |

|---|---|

| particle diameter dp/µm | 53 |

| particle density ρp/(kg·m-3) | 1400 |

| gas density ρg/(kg·m-3) | 1.225 |

| gas viscosity µg/(Pa·s) | 1.7894×10-5 |

| minimum fluidization velocity Umf/(mm·s-1) | 4.9 |

| operating gas velocity Ug/(mm·s-1) | 4—40 |

Table 1 Physical properties and operating parameters used for simulation validation

| Parameter | Value |

|---|---|

| particle diameter dp/µm | 53 |

| particle density ρp/(kg·m-3) | 1400 |

| gas density ρg/(kg·m-3) | 1.225 |

| gas viscosity µg/(Pa·s) | 1.7894×10-5 |

| minimum fluidization velocity Umf/(mm·s-1) | 4.9 |

| operating gas velocity Ug/(mm·s-1) | 4—40 |

| Type of particles | Ug/Umf | Dt/mm | Hs/mm |

|---|---|---|---|

| Geldart A(dp=92 μm, ρp=1200 kg·m-3, Ar=35.0341) | 2,3,4,5,6,7 | 5,10,15,20,30 | 10,15,20,25,30,35,40 |

| Geldart B(dp=240 μm, ρp=2644 kg·m-3, Ar=1371.1474) | 1,2,3,4,5,6 | 5,10,15,20,30 | 10,15,20,25,30,35,40 |

Table 2 The range of variation of various parameters used for flow pattern analysis

| Type of particles | Ug/Umf | Dt/mm | Hs/mm |

|---|---|---|---|

| Geldart A(dp=92 μm, ρp=1200 kg·m-3, Ar=35.0341) | 2,3,4,5,6,7 | 5,10,15,20,30 | 10,15,20,25,30,35,40 |

| Geldart B(dp=240 μm, ρp=2644 kg·m-3, Ar=1371.1474) | 1,2,3,4,5,6 | 5,10,15,20,30 | 10,15,20,25,30,35,40 |

| 项目 | 公式 |

|---|---|

| E(t)函数 | |

| 平均停留时间 | |

| 方差 | |

| 无量纲方差 | |

| 斜度S | |

| E( |

Table 3 The relevant formulas for the residence time distribution (RTD) function

| 项目 | 公式 |

|---|---|

| E(t)函数 | |

| 平均停留时间 | |

| 方差 | |

| 无量纲方差 | |

| 斜度S | |

| E( |

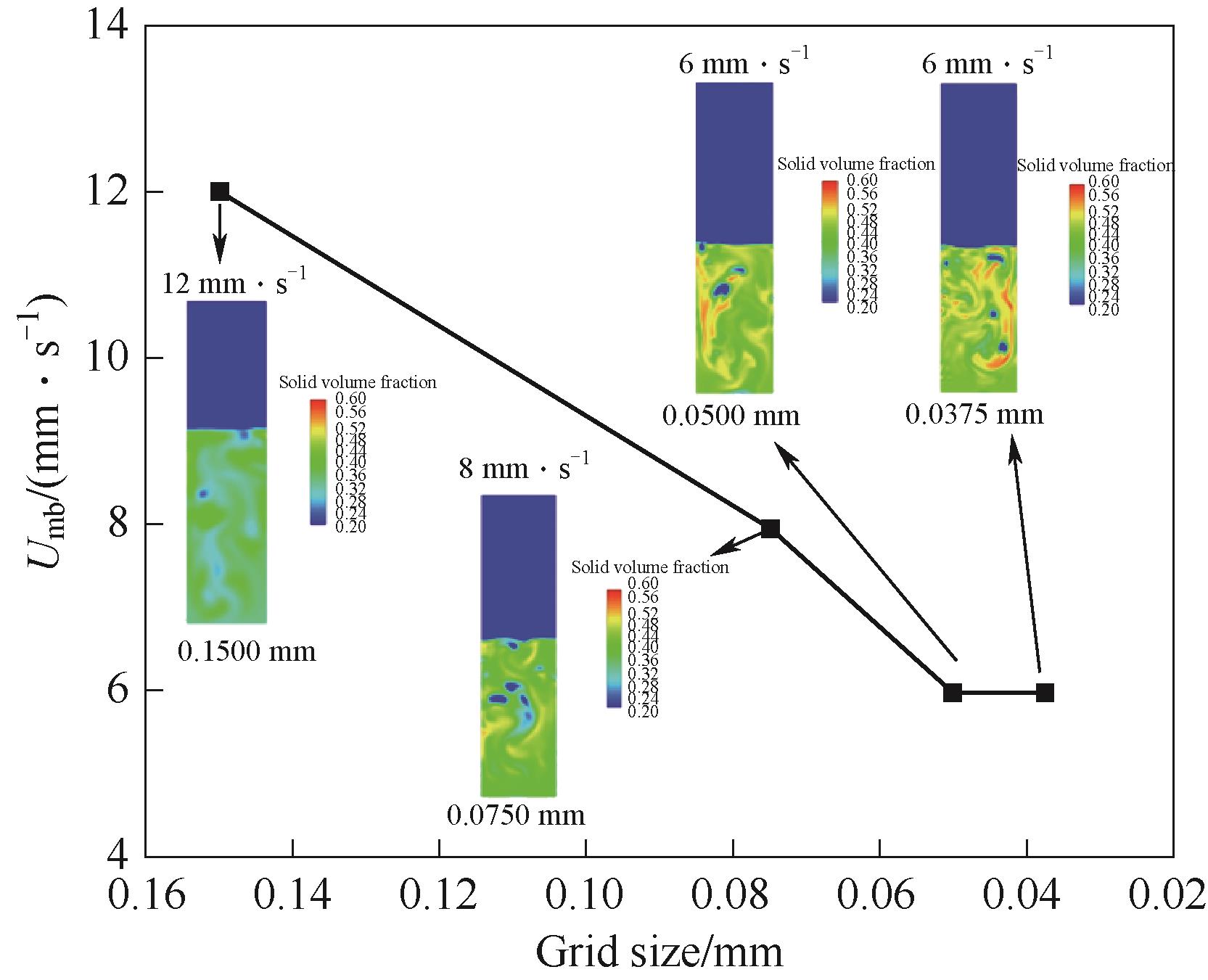

Fig.3 The variation of incipient bubbling fluidization velocity Umb with grid size (dp = 53 µm, ρp = 1400 kg·m-3, ρg = 1.225 kg·m-3, μg = 1.7894×10-5 Pa·s)

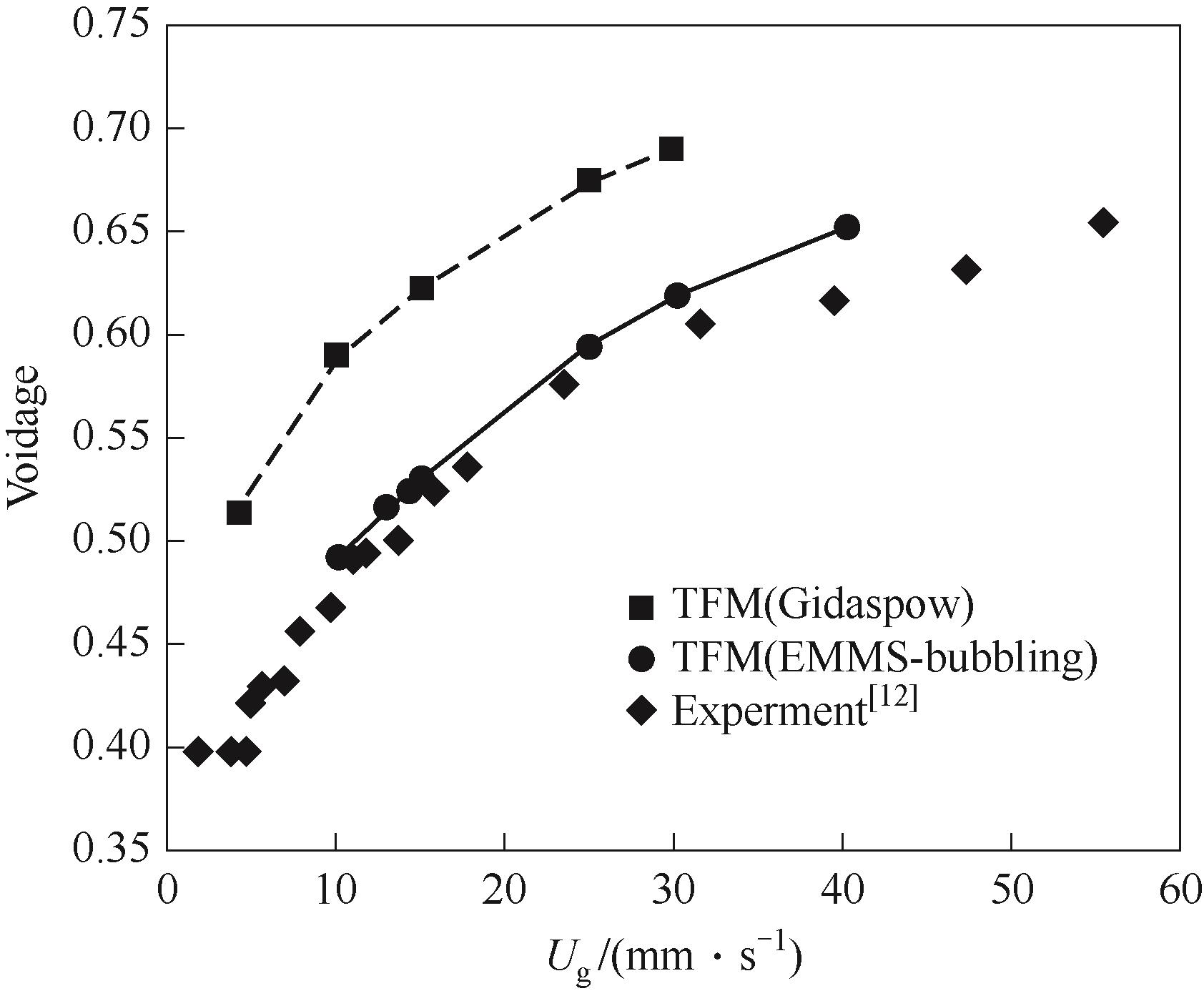

Fig.5 Comparison between simulated and experimental values of bed porosity at different gas velocities (dp = 53 µm, ρp = 1400 kg·m-3, ρg = 1.225 kg·m-3, μg = 1.7894×10-5 Pa·s, Umf = 4.9 mm·s-1)

| Ug/mm·s-1 | εο(Exp.) | Gidaspow | EMMS-bubbling | ||

|---|---|---|---|---|---|

| εο | Relative error/% | εο | Relative error/% | ||

| 10 | 0.4728 | 0.5912 | 25.03 | 0.4938 | 4.43 |

| 15 | 0.5168 | 0.6237 | 20.69 | 0.5230 | 2.55 |

| 25 | 0.5811 | 0.6747 | 16.11 | 0.5948 | 2.35 |

| 30 | 0.5970 | 0.6910 | 15.74 | 0.6181 | 3.53 |

Table 4 The relative error between simulated bed porosity and experiment using different drag models

| Ug/mm·s-1 | εο(Exp.) | Gidaspow | EMMS-bubbling | ||

|---|---|---|---|---|---|

| εο | Relative error/% | εο | Relative error/% | ||

| 10 | 0.4728 | 0.5912 | 25.03 | 0.4938 | 4.43 |

| 15 | 0.5168 | 0.6237 | 20.69 | 0.5230 | 2.55 |

| 25 | 0.5811 | 0.6747 | 16.11 | 0.5948 | 2.35 |

| 30 | 0.5970 | 0.6910 | 15.74 | 0.6181 | 3.53 |

| Type of particles | Ug/Umf | S | |||||

|---|---|---|---|---|---|---|---|

| Geldart A (dp=92 μm, ρp=1200 kg·m-3,Umf=0.0091 m·s-1, Dt/dp=109) | 2 | 3.9100 | 0.7209 | 0.8944 | 0.4498 | 0.0585 | 1.7587 |

| 3 | 2.5921 | 0.6298 | 0.3261 | 0.7338 | 0.0485 | 1.9021 | |

| 4 | 1.9510 | 0.6338 | 0.1820 | 0.9837 | 0.0478 | 1.9192 | |

| 5 | 1.5519 | 0.5924 | 0.1166 | 1.2138 | 0.0484 | 1.8837 | |

| 6 | 1.3086 | 0.5735 | 0.0840 | 1.4261 | 0.0491 | 1.8662 | |

| 7 | 1.1244 | 0.5515 | 0.0628 | 1.6330 | 0.0497 | 1.8361 | |

| Geldart B (dp=240 μm, ρp=2644 kg·m-3, Umf=0.1032 m·s-1, Dt/dp=42) | 1 | 0.7061 | 0.5523 | 0.0233 | 2.6343 | 0.0468 | 1.8601 |

| 2 | 0.3793 | 0.5826 | 0.0083 | 4.2471 | 0.0576 | 1.6109 | |

| 3 | 0.2498 | 0.6218 | 0.0047 | 5.6837 | 0.0753 | 1.4198 | |

| 4 | 0.1881 | 0.5986 | 0.0035 | 6.3570 | 0.0992 | 1.1958 | |

| 5 | 0.1558 | 1.0118 | 0.0026 | 10.2803 | 0.1087 | 1.6017 | |

| 6 | 0.1296 | 0.8004 | 0.0011 | 12.8732 | 0.0662 | 1.6684 |

Table 5 The gas RTD characteristic parameters in micro fluidized beds at different operating gas velocities (Dt = 10 mm, Hs = 20 mm)

| Type of particles | Ug/Umf | S | |||||

|---|---|---|---|---|---|---|---|

| Geldart A (dp=92 μm, ρp=1200 kg·m-3,Umf=0.0091 m·s-1, Dt/dp=109) | 2 | 3.9100 | 0.7209 | 0.8944 | 0.4498 | 0.0585 | 1.7587 |

| 3 | 2.5921 | 0.6298 | 0.3261 | 0.7338 | 0.0485 | 1.9021 | |

| 4 | 1.9510 | 0.6338 | 0.1820 | 0.9837 | 0.0478 | 1.9192 | |

| 5 | 1.5519 | 0.5924 | 0.1166 | 1.2138 | 0.0484 | 1.8837 | |

| 6 | 1.3086 | 0.5735 | 0.0840 | 1.4261 | 0.0491 | 1.8662 | |

| 7 | 1.1244 | 0.5515 | 0.0628 | 1.6330 | 0.0497 | 1.8361 | |

| Geldart B (dp=240 μm, ρp=2644 kg·m-3, Umf=0.1032 m·s-1, Dt/dp=42) | 1 | 0.7061 | 0.5523 | 0.0233 | 2.6343 | 0.0468 | 1.8601 |

| 2 | 0.3793 | 0.5826 | 0.0083 | 4.2471 | 0.0576 | 1.6109 | |

| 3 | 0.2498 | 0.6218 | 0.0047 | 5.6837 | 0.0753 | 1.4198 | |

| 4 | 0.1881 | 0.5986 | 0.0035 | 6.3570 | 0.0992 | 1.1958 | |

| 5 | 0.1558 | 1.0118 | 0.0026 | 10.2803 | 0.1087 | 1.6017 | |

| 6 | 0.1296 | 0.8004 | 0.0011 | 12.8732 | 0.0662 | 1.6684 |

| Type of particles | Dt/mm | Dt/dp | S | |||||

|---|---|---|---|---|---|---|---|---|

| Geldart A (dp=92 μm, ρp=1200 kg·m-3, Ug= 4Umf, Hs=20 mm) | 5 | 54 | 0.5778 | 0.6614 | 0.0129 | 3.7417 | 0.0387 | 2.1620 |

| 10 | 109 | 1.9510 | 0.6338 | 0.1820 | 0.9837 | 0.0478 | 1.9192 | |

| 15 | 163 | 2.8654 | 0.6841 | 0.4930 | 0.6024 | 0.0601 | 1.7262 | |

| 20 | 217 | 3.4392 | 0.7599 | 0.8653 | 0.4592 | 0.0732 | 1.5793 | |

| 30 | 326 | 4.1145 | 0.9198 | 1.6549 | 0.3429 | 0.0978 | 1.4109 | |

| Geldart B (dp=240 μm, ρp=2644 kg·m-3, Ug= 1Umf, Hs=20 mm) | 5 | 21 | 0.1858 | 0.4273 | 0.0015 | 10.3461 | 0.0428 | 1.9223 |

| 10 | 42 | 0.7061 | 0.5523 | 0.0233 | 2.6343 | 0.0468 | 1.8601 | |

| 15 | 63 | 1.0042 | 0.6624 | 0.0636 | 1.5990 | 0.0630 | 1.6057 | |

| 20 | 83 | 1.1938 | 0.7697 | 0.1053 | 1.2529 | 0.0739 | 1.4957 | |

| 30 | 125 | 1.4222 | 0.9441 | 0.1785 | 1.1184 | 0.0883 | 1.5906 |

Table 6 The gas RTD characteristic parameters in micro fluidized beds at different bed diameters (Hs = 20 mm)

| Type of particles | Dt/mm | Dt/dp | S | |||||

|---|---|---|---|---|---|---|---|---|

| Geldart A (dp=92 μm, ρp=1200 kg·m-3, Ug= 4Umf, Hs=20 mm) | 5 | 54 | 0.5778 | 0.6614 | 0.0129 | 3.7417 | 0.0387 | 2.1620 |

| 10 | 109 | 1.9510 | 0.6338 | 0.1820 | 0.9837 | 0.0478 | 1.9192 | |

| 15 | 163 | 2.8654 | 0.6841 | 0.4930 | 0.6024 | 0.0601 | 1.7262 | |

| 20 | 217 | 3.4392 | 0.7599 | 0.8653 | 0.4592 | 0.0732 | 1.5793 | |

| 30 | 326 | 4.1145 | 0.9198 | 1.6549 | 0.3429 | 0.0978 | 1.4109 | |

| Geldart B (dp=240 μm, ρp=2644 kg·m-3, Ug= 1Umf, Hs=20 mm) | 5 | 21 | 0.1858 | 0.4273 | 0.0015 | 10.3461 | 0.0428 | 1.9223 |

| 10 | 42 | 0.7061 | 0.5523 | 0.0233 | 2.6343 | 0.0468 | 1.8601 | |

| 15 | 63 | 1.0042 | 0.6624 | 0.0636 | 1.5990 | 0.0630 | 1.6057 | |

| 20 | 83 | 1.1938 | 0.7697 | 0.1053 | 1.2529 | 0.0739 | 1.4957 | |

| 30 | 125 | 1.4222 | 0.9441 | 0.1785 | 1.1184 | 0.0883 | 1.5906 |

| Type of particles | Hs/mm | Hs/dp | S | |||||

|---|---|---|---|---|---|---|---|---|

| Geldart A (dp=92 μm, ρp=1200 kg·m-3,Ug= 4Umf, Dt=10 mm) | 10 | 109 | 2.4550 | 0.5731 | 0.2589 | 0.8171 | 0.0430 | 2.0060 |

| 15 | 163 | 2.1465 | 0.5754 | 0.2035 | 0.9209 | 0.0442 | 1.9767 | |

| 20 | 217 | 1.9510 | 0.6338 | 0.1820 | 0.9837 | 0.0478 | 1.9192 | |

| 25 | 272 | 1.7770 | 0.6331 | 0.1646 | 1.0288 | 0.0521 | 1.8282 | |

| 30 | 326 | 1.6204 | 0.6505 | 0.1605 | 1.0419 | 0.0611 | 1.6883 | |

| 35 | 380 | 1.5353 | 0.7716 | 0.1574 | 1.0896 | 0.0668 | 1.6729 | |

| 40 | 435 | 1.4118 | 0.8737 | 0.1493 | 1.1430 | 0.0749 | 1.6137 | |

| Geldart B (dp=240 μm, ρp=2644 kg·m-3, Ug= 1Umf, Dt=10 mm) | 10 | 42 | 0.9550 | 0.5111 | 0.0405 | 2.0146 | 0.0444 | 1.9239 |

| 15 | 63 | 0.8087 | 0.5265 | 0.0299 | 2.3322 | 0.0457 | 1.8861 | |

| 20 | 83 | 0.7061 | 0.5523 | 0.0233 | 2.6343 | 0.0468 | 1.8601 | |

| 25 | 104 | 0.6222 | 0.5502 | 0.0188 | 2.9247 | 0.0487 | 1.8197 | |

| 30 | 125 | 0.5472 | 0.5480 | 0.0148 | 3.2993 | 0.0493 | 1.8054 | |

| 35 | 146 | 0.4666 | 0.4142 | 0.0129 | 3.6054 | 0.0593 | 1.6823 | |

| 40 | 167 | 0.4140 | 0.5820 | 0.0092 | 4.3143 | 0.0535 | 1.7861 |

Table 7 The gas RTD characteristic parameters in micro fluidized beds at different static bed heights (Dt = 10 mm)

| Type of particles | Hs/mm | Hs/dp | S | |||||

|---|---|---|---|---|---|---|---|---|

| Geldart A (dp=92 μm, ρp=1200 kg·m-3,Ug= 4Umf, Dt=10 mm) | 10 | 109 | 2.4550 | 0.5731 | 0.2589 | 0.8171 | 0.0430 | 2.0060 |

| 15 | 163 | 2.1465 | 0.5754 | 0.2035 | 0.9209 | 0.0442 | 1.9767 | |

| 20 | 217 | 1.9510 | 0.6338 | 0.1820 | 0.9837 | 0.0478 | 1.9192 | |

| 25 | 272 | 1.7770 | 0.6331 | 0.1646 | 1.0288 | 0.0521 | 1.8282 | |

| 30 | 326 | 1.6204 | 0.6505 | 0.1605 | 1.0419 | 0.0611 | 1.6883 | |

| 35 | 380 | 1.5353 | 0.7716 | 0.1574 | 1.0896 | 0.0668 | 1.6729 | |

| 40 | 435 | 1.4118 | 0.8737 | 0.1493 | 1.1430 | 0.0749 | 1.6137 | |

| Geldart B (dp=240 μm, ρp=2644 kg·m-3, Ug= 1Umf, Dt=10 mm) | 10 | 42 | 0.9550 | 0.5111 | 0.0405 | 2.0146 | 0.0444 | 1.9239 |

| 15 | 63 | 0.8087 | 0.5265 | 0.0299 | 2.3322 | 0.0457 | 1.8861 | |

| 20 | 83 | 0.7061 | 0.5523 | 0.0233 | 2.6343 | 0.0468 | 1.8601 | |

| 25 | 104 | 0.6222 | 0.5502 | 0.0188 | 2.9247 | 0.0487 | 1.8197 | |

| 30 | 125 | 0.5472 | 0.5480 | 0.0148 | 3.2993 | 0.0493 | 1.8054 | |

| 35 | 146 | 0.4666 | 0.4142 | 0.0129 | 3.6054 | 0.0593 | 1.6823 | |

| 40 | 167 | 0.4140 | 0.5820 | 0.0092 | 4.3143 | 0.0535 | 1.7861 |

| 1 | Di Renzo A, Scala F, Heinrich S. Recent advances in fluidized bed hydrodynamics and transport phenomena-progress and understanding[J]. Processes, 2021, 9(4): 639-642. |

| 2 | 王荘, 吕潇, 邵媛媛, 等. 流态化的往昔寻觅及未来启示[J]. 化工学报, 2021, 72(12): 5904-5927. |

| Wang Z, Lyu X, Shao Y Y, et al. Early exploration of fluidization theory and its inspiration to the future[J]. CIESC Journal, 2021, 72(12): 5904-5927. | |

| 3 | Han Z N, Yue J R, Geng S L, et al. State-of-the-art hydrodynamics of gas-solid micro fluidized beds[J]. Chemical Engineering Science, 2020, 232: 116345. |

| 4 | Qie Z P, Alhassawi H, Sun F, et al. Characteristics and applications of micro fluidized beds (MFBs)[J]. Chemical Engineering Journal, 2021, 428(2): 131330. |

| 5 | Potic B, Kersten S, Ye M, et al. Fluidization with hot compressed water in micro-reactors[J]. Chemical Engineering Science, 2005, 60(22): 5982-5990. |

| 6 | Scott D S, Piskorz J. Low rate entrainment feeder for fine solids[J]. Industrial & Engineering Chemistry Fundamentals, 1982, 21(3): 319-322. |

| 7 | Liu X J, Hao W Q, Wang K X, et al. Acquiring real kinetics of reactions in the inhibitory atmosphere containing product gases using micro fluidized bed[J]. AIChE Journal, 2021, 67(9): e17325. |

| 8 | Yu J, Yao C B, Zeng X, et al. Biomass pyrolysis in a micro-fluidized bed reactor: characterization and kinetics[J]. Chemical Engineering Journal, 2011, 168(2): 839-847. |

| 9 | Saadatkhah N, Carillo Garcia A, Ackermann S, et al. Experimental methods in chemical engineering: thermogravimetric analysis—TGA[J]. The Canadian Journal of Chemical Engineering, 2020, 98(1): 34-43. |

| 10 | McDonough J, Law R, Reay D, et al. Fluidization in small-scale gas-solid 3D-printed fluidized beds[J]. Chemical Engineering Science, 2019, 200: 294-309. |

| 11 | Liu X H, Xu G W, Gao S Q. Micro fluidized beds: wall effect and operability[J]. Chemical Engineering Journal, 2008, 137(2): 302-307. |

| 12 | Wang F, Fan L S. Gas-solid fluidization in mini- and micro-channels[J]. Industrial & Engineering Chemistry Research, 2011, 50(8): 4741-4751. |

| 13 | Vanni F, Caussat B, Ablitzer C, et al. Effects of reducing the reactor diameter on the fluidization of a very dense powder[J]. Powder Technology, 2015, 277: 268-274. |

| 14 | Guo Q J, Xu Y, Yue X. Fluidization characteristics in micro-fluidized beds of various inner diameters[J]. Chemical Engineering & Technology, 2009, 32(12): 1992-1999. |

| 15 | Rao A, Curtis J S, Hancock B C, et al. The effect of column diameter and bed height on minimum fluidization velocity[J]. AIChE Journal, 2010, 56(9): 2304-2311. |

| 16 | Trachsel F, Günther A, Khan S, et al. Measurement of residence time distribution in microfluidic systems[J]. Chemical Engineering Science, 2005, 60(21): 5729-5737. |

| 17 | 胡丹丹, 耿素龙, 曾玺, 等. 返混对气-固反应特性测试和活化能表征的影响[J]. 化工学报, 2021, 72(3): 1354-1363. |

| Hu D D, Geng S L, Zeng X, et al. Gas back-mixing characteristics and the effects on gas-solid reaction behavior and activation energy characterization[J]. CIESC Journal, 2021, 72(3): 1354-1363. | |

| 18 | Geng S L, Han Z N, Yue J R, et al. Conditioning micro fluidized bed for maximal approach of gas plug flow[J]. Chemical Engineering Journal, 2018, 351: 110-118. |

| 19 | Wang C, Han Z N, Bai H L, et al. Further analysis of the near-plug gas flow conditions in micro gas-solid fluidized beds[J]. Powder Technology, 2022, 404: 117508. |

| 20 | 李铁男, 赵碧丹, 赵鹏, 等. 气固流化床启动阶段挡板内构件受力特性的CFD-DEM模拟[J]. 化工学报, 2022, 73(6): 2649-2661. |

| Li T N, Zhao B D, Zhao P, et al. CFD-DEM simulation of the force acting on immersed baffles during the start-up stage of a gas-solid fluidized bed[J]. CIESC Journal, 2022, 73(6): 2649-2661. | |

| 21 | Moliner C, Marchelli F, Spanachi N, et al. CFD simulation of a spouted bed: comparison between the discrete element method (DEM) and the two fluid model (TFM)[J]. Chemical Engineering Journal, 2019, 377: 120466. |

| 22 | 林俊杰, 罗坤, 王帅, 等. Coarse-grained CFD-DEM方法在不同流态流化床中的模拟验证[J]. 化工学报, 2019, 70(5): 1702-1712. |

| Lin J J, Luo K, Wang S, et al. Verification of coarse-grained CFD-DEM method in multiple flow regimes[J]. CIESC Journal, 2019, 70(5): 1702-1712. | |

| 23 | Wang J W, van der Hoef M A, Kuipers J A M. Why the two-fluid model fails to predict the bed expansion characteristics of Geldart A particles in gas-fluidized beds: a tentative answer[J]. Chemical Engineering Science, 2009, 64(3): 622-625. |

| 24 | Liu X X, Zhu C Q, Geng S J, et al. Two-fluid modeling of Geldart A particles in gas-solid micro-fluidized beds[J]. Particuology, 2015, 21(4): 118-127. |

| 25 | Fullmer W D, Hrenya C M. Quantitative assessment of fine-grid kinetic-theory-based predictions of mean-slip in unbounded fluidization[J]. AIChE Journal, 2016, 62(1): 11-17. |

| 26 | Radl S, Sundaresan S. A drag model for filtered Euler-Lagrange simulations of clustered gas-particle suspensions[J]. Chemical Engineering Science, 2014, 117: 416-425. |

| 27 | Li S J, Zhao P, Xu J, et al. Direct comparison of CFD-DEM simulation and experimental measurement of Geldart A particles in a micro-fluidized bed[J]. Chemical Engineering Science, 2021, 242: 116725. |

| 28 | Li S J, Zhao P, Xu J, et al. CFD-DEM simulation of polydisperse gas-solid flow of Geldart A particles in bubbling micro-fluidized beds[J]. Chemical Engineering Science, 2022, 253: 117551. |

| 29 | Geldart D. Types of gas fluidization[J]. Powder Technology, 1973, 7(5): 285-292. |

| 30 | Syamlal M, Rogers W, Obrien T J. MFIX documentation theory guide[R]. USDOE Morgantown Energy Technology Center (METC), WV (United States), 1993. |

| 31 | Ahmadi G, Ma D. A thermodynamical formulation for dispersed multiphase turbulent flow(1): Basic theory[J]. International Journal of Multiphase Flow, 1990, 16(2): 323-340. |

| 32 | Ma D, Ahmadi G. A thermodynamical formulation for dispersed multiphase turbulent flow(2): Simple shear flows for dense mixtures[J]. International Journal of Multiphase Flow, 1990, 16(2): 341-351. |

| 33 | Gidaspow D, Bezburuah R, Ding J. Hydrodynamics of circulating fluidized beds: kinetic theory approach[R]. Illinois Inst. Tech.of, Chicago, (United States)IL. Dept. of Chemical Engineering, 1991. |

| 34 | Schaeffer D G. Instability in the evolution equations describing incompressible granular flow[J]. Journal of Differential Equations, 1987, 66(1): 19-50. |

| 35 | Yang Z, Lu B N, Wang W. Coupling artificial neural network with EMMS drag for simulation of dense fluidized beds[J]. Chemical Engineering Science, 2021, 246: 117003. |

| 36 | Hong K, Shi Z S, Ullah A, et al. Extending the bubble-based EMMS model to CFB riser simulations[J]. Powder Technology, 2014, 266: 424-432. |

| 37 | Patil D J, van Sint Annaland M, Kuipers J A M. Critical comparison of hydrodynamic models for gas-solid fluidized beds(part Ⅱ): Freely bubbling gas-solid fluidized beds[J]. Chemical Engineering Science, 2005, 60(1): 73-84. |

| 38 | Hulme I, Clavelle E, van der Lee L, et al. CFD modeling and validation of bubble properties for a bubbling fluidized bed[J]. Industrial & Engineering Chemistry Research, 2005, 44(12): 4254-4266. |

| 39 | Cao J T, Cheng Z H, Fang Y T, et al. Simulation and experimental studies on fluidization properties in a pressurized jetting fluidized bed[J]. Powder Technology, 2008, 183(1): 127-132. |

| 40 | Levenspiel O. Tracer Technology: Modeling the Flow of Fluids[M]. Berlin: Springer Science & Business Media, 2011: 5-26. |

| 41 | Guío-Pérez D C, Pröll T, Hofbauer H. Solids residence time distribution in the secondary reactor of a dual circulating fluidized bed system[J]. Chemical Engineering Science, 2013, 104: 269-284. |

| 42 | Ham J H, Platzer B. Semi-empirical equations for the residence time distributions in disperse systems(part 1): Continuous phase[J]. Chemical Engineering & Technology, 2004, 27(11): 1172-1178. |

| [1] | Jiayu XU, Feiguo CHEN, Ji XU, Wei GE. Multiscale mixing index for granular systems [J]. CIESC Journal, 2024, 75(6): 2214-2221. |

| [2] | Bin HUANG, Shengjie FENG, Cheng FU, Wei ZHANG. Numerical study on spreading characteristics of droplet impact on single fiber [J]. CIESC Journal, 2024, 75(6): 2233-2242. |

| [3] | Juan LI, Yaowen CAO, Zhangyu ZHU, Lei SHI, Jia LI. Numerical study and structural optimization of microchannel flow and heat transfer characteristics of bionic homocercal fin microchannels [J]. CIESC Journal, 2024, 75(5): 1802-1815. |

| [4] | Jinshan WANG, Shixue WANG, Yu ZHU. Influence of cooling surface temperature difference on the high temperature proton-exchange membrane fuel cell performance [J]. CIESC Journal, 2024, 75(5): 2026-2035. |

| [5] | Yifei LI, Xinyu DONG, Weishu WANG, Lu LIU, Yifan ZHAO. Numerical study on heat transfer of dry ice sublimation spray cooling on the surface of micro-ribbed plate [J]. CIESC Journal, 2024, 75(5): 1830-1842. |

| [6] | Fan LIU, Yuantong ZHANG, Cheng TAO, Chengyu HU, Xiaoping YANG, Jinjia WEI. Performance of manifold microchannel liquid cooling [J]. CIESC Journal, 2024, 75(5): 1777-1786. |

| [7] | Jing LI, Fangfang ZHANG, Shuaishuai WANG, Jianhua XU, Pengyuan ZHANG. Effect of cavity structure on flammability limit of n-butane partially premixed flame [J]. CIESC Journal, 2024, 75(5): 2081-2090. |

| [8] | Lei XIE, Yongsheng XU, Mei LIN. Comparative study on single-phase flow and heat transfer of different cross-section rib-soft tail structures [J]. CIESC Journal, 2024, 75(5): 1787-1801. |

| [9] | Wenya WANG, Wei ZHANG, Xiaoling LOU, Ruofei ZHONG, Bingbing CHEN, Junxian YUN. Multi-microtubes formation and simulation of nanocellulose-embedded cryogel microspheres [J]. CIESC Journal, 2024, 75(5): 2060-2071. |

| [10] | Xiaoying JI, Yuan ZHENG, Xiaopeng LI, Zhen YANG, Wei ZHANG, Shirui QIU, Qianying ZHANG, Canghai LUO, Dongpeng SUN, Dong CHEN, Dongliang LI. Controlled preparation of droplets, particles and capsules by microfluidics and their applications [J]. CIESC Journal, 2024, 75(4): 1455-1468. |

| [11] | Shiliang GU, Boren TAN, Quanzhong CHENG, Weijie YAO, Zhipeng DONG, Feng XU, Yong WANG. Numerical simulation of hydraulic characteristics in axial flow pump type mixer [J]. CIESC Journal, 2024, 75(3): 815-822. |

| [12] | Baiping XU, Ruifeng LIANG, Huiwen YU, Guiqun WU, Shuping XIAO. Simulation of intra-cavity distribution mixing under the action of enhanced triangular rotor of twin-screw extruder [J]. CIESC Journal, 2024, 75(3): 858-866. |

| [13] | Nan TU, Xiaoqun LIU, Chiyu WANG, Jiabin FANG. Study on adaptability of scaling law to residence time distribution in bubbling fluidized beds with continuous operation [J]. CIESC Journal, 2024, 75(2): 543-552. |

| [14] | Yao ZHOU, Xiaoping YANG, Yicheng NI, Jiping LIU, Jinjia WEI, Junjie YAN. Numerical simulation of two-phase steam ejector applied in novel loop heat pipe [J]. CIESC Journal, 2024, 75(1): 268-278. |

| [15] | Yijiang WANG, Li SUN, Menghan LIU, Jinhong YANG, Guoyuan WANG. Optimization on parameter of plate-fin-and-tube air cooler in mines based on response surface method [J]. CIESC Journal, 2024, 75(1): 279-291. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||