CIESC Journal ›› 2024, Vol. 75 ›› Issue (11): 3951-3972.DOI: 10.11949/0438-1157.20240878

• Reviews and monographs • Previous Articles Next Articles

Shengyi ZHUANG1,2( ), Chengwei LI1,2, Wenchao XIANG1,2(

), Chengwei LI1,2, Wenchao XIANG1,2( ), Junbo XU1,2, Chao YANG1,2(

), Junbo XU1,2, Chao YANG1,2( )

)

Received:2024-08-02

Revised:2024-09-10

Online:2024-12-26

Published:2024-11-25

Contact:

Wenchao XIANG, Chao YANG

庄晟逸1,2( ), 李成伟1,2, 向文超1,2(

), 李成伟1,2, 向文超1,2( ), 徐俊波1,2, 杨超1,2(

), 徐俊波1,2, 杨超1,2( )

)

通讯作者:

向文超,杨超

作者简介:庄晟逸(1990—),女,博士研究生,zhuangshengyi21@mails.ucas.ac.cn

基金资助:CLC Number:

Shengyi ZHUANG, Chengwei LI, Wenchao XIANG, Junbo XU, Chao YANG. Improved designs of negative Poisson’s ratio structure and their applications in aerospace engineering[J]. CIESC Journal, 2024, 75(11): 3951-3972.

庄晟逸, 李成伟, 向文超, 徐俊波, 杨超. 负泊松比结构的改进设计及其在航空航天中的应用[J]. 化工学报, 2024, 75(11): 3951-3972.

Add to citation manager EndNote|Ris|BibTeX

Fig.2 Classification of NPR structures(a1)—(a4) re-entrant type: re-entrant hexagon[16], double arrow-shaped[17], petal[18], and star-shaped structures[19]; (b1)—(b4) chiral type: trichiral, tetrachiral, anti-tetrachiral, and hexachiral structures[20]; (c1)—(c4) rotating rigid body: rotating triangles, rotating squares, rotating rectangles[21], and other rotating structures[22]; (d1)—(d4) perforate: I shaped slits, straight slits[23], elliptical holes[24], and other shape holes[25]

| 胞元类型 | 变形模式 | 泊松比解析式 | 文献 |

|---|---|---|---|

内凹六边形

|

| νs:母材泊松比;t:胞元壁宽;θ:内凹角; g:水平支撑柱长度;l:斜支撑柱长度 | [ |

六手性

|

| l: 韧带长度; t: 韧带厚度;β:韧带与径向夹角 | [ |

旋转矩形刚体

|

| a, b: 旋转刚体边长; θ:旋转刚体夹角 | [ |

穿孔板

|

| — | [ |

Table 1 Deformation patterns of representative auxetic unit cells and their analytical expressions of Poisson’s ratio

| 胞元类型 | 变形模式 | 泊松比解析式 | 文献 |

|---|---|---|---|

内凹六边形

|

| νs:母材泊松比;t:胞元壁宽;θ:内凹角; g:水平支撑柱长度;l:斜支撑柱长度 | [ |

六手性

|

| l: 韧带长度; t: 韧带厚度;β:韧带与径向夹角 | [ |

旋转矩形刚体

|

| a, b: 旋转刚体边长; θ:旋转刚体夹角 | [ |

穿孔板

|

| — | [ |

Fig.3 3D NPR structures(a1)—(a4) cubic lattices: (a1), (a2) re-entrant hexagon cubic lattice[40-43], (a3) chiral cubic lattice[44], and (a4) rotating solid[45]; (b1)—(b5) tubular structures: (b1) re-entrant structure, (b2) anti-trichiral structure[46], (b3) orthogonal elliptical holes[47], (b4) peanut-shaped holes[48], and (b5) rotating rectangle rigid tubular structure[49]; (c1)—(c3) other structures: (c1) chiral dodecahedron lattice[50], (c2) hexagonal perforated honeycomb[51], and (c3) star-shaped tubular structure[52]

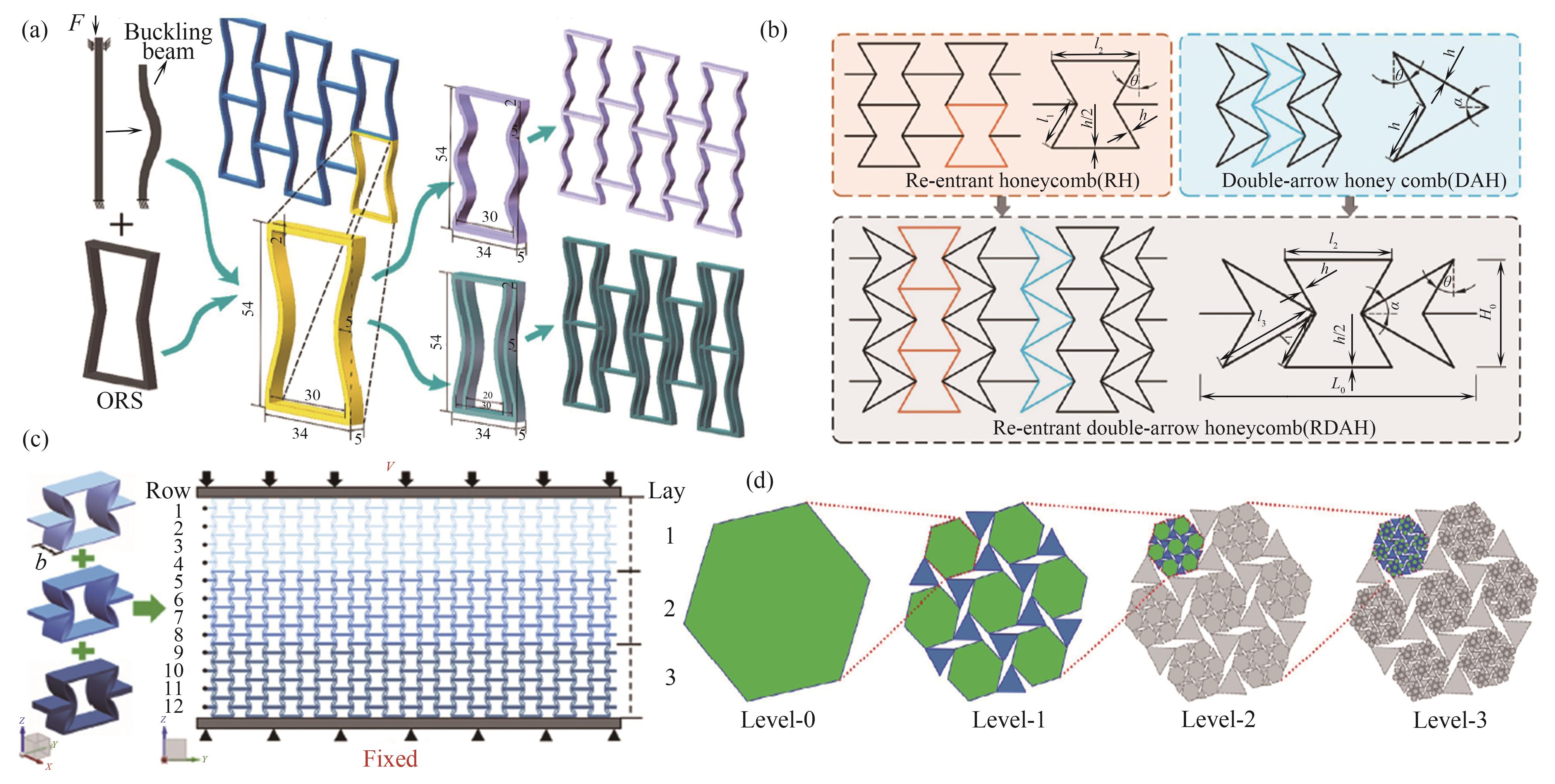

Fig.4 Reinforced design of re-entrant unit cells(a) horizontal and vertical strut[72]; (b) wedge-shaped parts[77]; (c) combined walls[74]; (d) comparison of the increasing rate of elastic modulus and relative Poisson's ratio

Fig.5 (a) Embedded hierarchical honeycomb[82]; (b) Vertex-based hierarchical honeycomb[85]; (c) 2-order anti-tetrachiral metastructure[90]; (d) Comparison of the increasing rate of elastic modulus and relative Poisson’s ratio

Fig.6 (a) Russian doll-type deployable cubes based on origami units[91]; (b) Stent based on a two-level hierarchical rotating square geometry[92]; (c) 3D auxetic hierarchical crash box model[93]

Fig.7 Graded re-entrant structures(a) thickness-graded[104]; (b) size-graded[99]; (c) deformation patterns of the angle-graded and uniform structures with the increase of compressive strain[105]

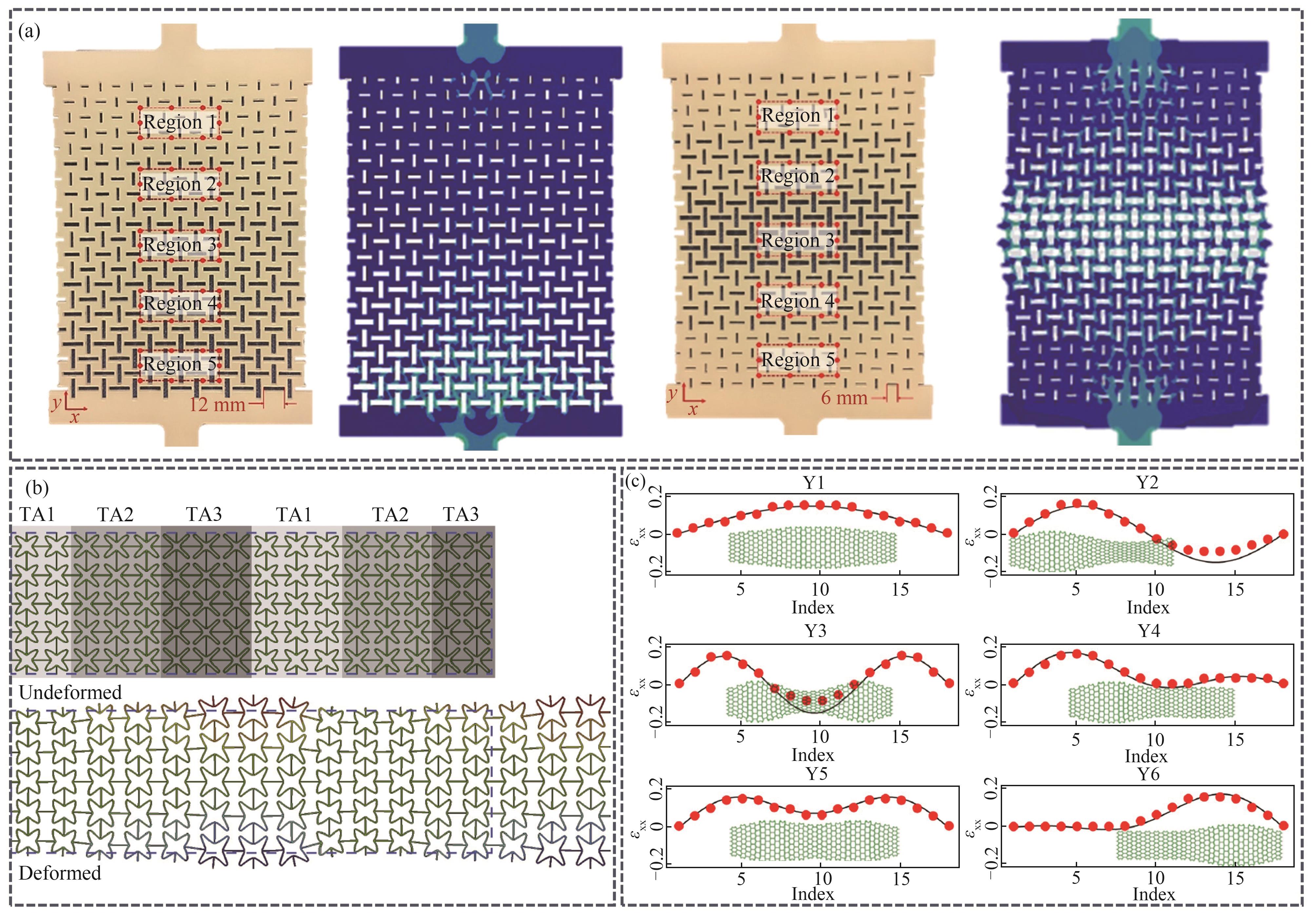

Fig.8 (a) Perforation cells with different gradient distributions and their tensile strain models[55]; (b) Graded mechanical metamaterials with three substructures and their tensile deformation[110]; (c) Comparison between the actual deformation and the target strain functions of the shape-matching metamaterials[111]

Fig. 9 (a) Optimal layout and dilation of the 2D nonuniform vascular stent[112]; (b) Experimental and FEA images of a cylindrical shell made of network materials under axial compression, as-fabricated and under tension[113]; (c) Soft bending actuator with asymmetric metamaterials and its deformed states under different pressures[114]

Fig.10 (a) Curved beams are used instead of the inclined beams to form cosine re-entrant structures[116]; (b) Geometric design of re-entrant double-arrow hybrid honeycomb[117]; (c) Schematics of graded re-entrant circular auxetic honeycombs[107]; (d) A level-3 hierarchical structure with synchronized deformation[89]

Fig.11 (a) Tape springs applied in satellite[121]; (b) The model of re-entrant tape spring[122]; (c) Reflector with elliptic voids and the displacement distribution [125]

Fig.12 (a) Airfoil profile with different cellular configurations[127, 131]; (b) The structure of morphing wing after deformation[128]; (c) Schematic diagram of variable area wing structure[129]; (d) Morphing wing skins with various lattice structures [130]

Fig.13 (a) Distribution of different homogenized cellular configurations for the gradient core[14]; (b) Fuselage section with NPR structure inserts below the cargo floor[137]

| 1 | Evans K E, Nkansah M A, Hutchinson I J, et al. Molecular network design[J]. Nature, 1991, 353(6340): 124. |

| 2 | Zhang J J, Lu G X, You Z. Large deformation and energy absorption of additively manufactured auxetic materials and structures: a review[J]. Composites Part B: Engineering, 2020, 201: 108340. |

| 3 | Li T T, Liu F, Wang L F. Enhancing indentation and impact resistance in auxetic composite materials[J]. Composites Part B: Engineering, 2020, 198: 108229. |

| 4 | Ju J, Summers J D. Compliant hexagonal periodic lattice structures having both high shear strength and high shear strain[J]. Materials & Design, 2011, 32(2): 512-524. |

| 5 | 任鑫, 张相玉, 谢亿民. 负泊松比材料和结构的研究进展[J]. 力学学报, 2019, 51(3): 656-687. |

| Ren X, Zhang X Y, Xie Y M. Research progress in auxetic materials and structures[J]. Chinese Journal of Theoretical and Applied Mechanics, 2019, 51(3): 656-687. | |

| 6 | Baughman R H, Shacklette J M, Zakhidov A A, et al. Negative Poisson’s ratios as a common feature of cubic metals[J]. Nature, 1998, 392(6674): 362-365. |

| 7 | Wang C Y, Wang W W, Zhao W Z, et al. Structure design and multi-objective optimization of a novel NPR bumper system[J]. Composites Part B: Engineering, 2018, 153: 78-96. |

| 8 | Contreras N, Zhang X H, Hao H, et al. Application of elastic metamaterials/meta-structures in civil engineering: a review[J]. Composite Structures, 2024, 327: 117663. |

| 9 | Jiang Y L, Shi K, Zhou L N, et al. 3D-printed auxetic-structured intervertebral disc implant for potential treatment of lumbar herniated disc[J]. Bioactive Materials, 2023, 20: 528-538. |

| 10 | Zheng X Y, Smith W, Jackson J, et al. Multiscale metallic metamaterials[J]. Nature Materials, 2016, 15(10): 1100-1106. |

| 11 | Mousanezhad D, Ebrahimi H, Haghpanah B, et al. Spiderweb honeycombs[J]. International Journal of Solids and Structures, 2015, 66: 218-227. |

| 12 | Ren L, Wang Z G, Ren L Q, et al. Graded biological materials and additive manufacturing technologies for producing bioinspired graded materials: an overview[J]. Composites Part B: Engineering, 2022, 242: 110086. |

| 13 | Prawoto Y. Seeing auxetic materials from the mechanics point of view: a structural review on the negative Poisson’s ratio[J]. Computational Materials Science, 2012, 58: 140-153. |

| 14 | Lira C, Scarpa F, Rajasekaran R. A gradient cellular core for aeroengine fan blades based on auxetic configurations[J]. Journal of Intelligent Material Systems and Structures, 2011, 22(9): 907-917. |

| 15 | Teng X C, Jiang W, Zhang X G, et al. A stretchable sandwich panel metamaterial with auxetic rotating-square surface[J]. International Journal of Mechanical Sciences, 2023, 251: 108334. |

| 16 | Zhang J J, Lu G X, Ruan D, et al. Tensile behavior of an auxetic structure: analytical modeling and finite element analysis[J]. International Journal of Mechanical Sciences, 2018, 136: 143-154. |

| 17 | Wang Y L, Zhao W Z, Zhou G, et al. Analysis and parametric optimization of a novel sandwich panel with double-V auxetic structure core under air blast loading[J]. International Journal of Mechanical Sciences, 2018, 142/143: 245-254. |

| 18 | Wang Z P, Poh L H, Dirrenberger J, et al. Isogeometric shape optimization of smoothed petal auxetic structures via computational periodic homogenization[J]. Computer Methods in Applied Mechanics and Engineering, 2017, 323: 250-271. |

| 19 | Xin Z, Fan W. Elastic modulus of star-shaped honeycomb structure with negative Poisson’s ratio[J]. Advanced Materials Research, 2014, 1049/1050: 409-412. |

| 20 | Alderson A, Alderson K L, Attard D, et al. Elastic constants of 3-, 4- and 6-connected chiral and anti-chiral honeycombs subject to uniaxial in-plane loading[J]. Composites Science and Technology, 2010, 70(7): 1042-1048. |

| 21 | Grima J N, Alderson A, Evans K E. Auxetic behaviour from rotating rigid units[J]. Physica Status Solidi B Basic Research, 2005, 242(3): 561-575. |

| 22 | Coulais C, Sabbadini A, Vink F, et al. Multi-step self-guided pathways for shape-changing metamaterials[J]. Nature, 2018, 561(7724): 512-515. |

| 23 | Mizzi L, Salvati E, Spaggiari A, et al. Highly stretchable two-dimensional auxetic metamaterial sheets fabricated via direct-laser cutting[J]. International Journal of Mechanical Sciences, 2020, 167: 105242. |

| 24 | Mizzi L, Mahdi E M, Titov K, et al. Mechanical metamaterials with star-shaped pores exhibiting negative and zero Poisson’s ratio[J]. Materials & Design, 2018, 146: 28-37. |

| 25 | Wang H, Zhang Y X, Lin W Q, et al. A novel two-dimensional mechanical metamaterial with negative Poisson’s ratio[J]. Computational Materials Science, 2020, 171: 109232. |

| 26 | Masters I G, Evans K E. Models for the elastic deformation of honeycombs[J]. Composite Structures, 1996, 35(4): 403-422. |

| 27 | Spadoni A, Ruzzene M. Elasto-static micropolar behavior of a chiral auxetic lattice[J]. Journal of the Mechanics and Physics of Solids, 2012, 60(1): 156-171. |

| 28 | Grima J N, Alderson A, Evans K E. Negative Poisson’s ratios from rotating rectangles[J]. Computational Methods in Science and Technology, 2004, 10(2): 137-145. |

| 29 | Gibson L J, Ashby M F, Schaejer G S, et al. The mechanics of two-dimensional cellular materials[J]. Proceedings of the Royal Society A, 1982, 382(1782): 25-42. |

| 30 | Grima J N, Attard D, Ellul B, et al. An improved analytical model for the elastic constants of auxetic and conventional hexagonal honeycombs[J]. Cellular Polymers, 2011, 30(6): 287-310. |

| 31 | Berinskii I E. In-plane elastic properties of auxetic multilattices[J]. Smart Material Structures, 2018, 27(7): 075012. |

| 32 | Ma C, Lei H S, Liang J, et al. Macroscopic mechanical response of chiral-type cylindrical metastructures under axial compression loading[J]. Materials & Design, 2018, 158: 198-212. |

| 33 | Prall D, Lakes R S. Properties of a chiral honeycomb with a Poisson’s ratio of -1[J]. International Journal of Mechanical Sciences, 1997, 39(3): 305-314. |

| 34 | Grima J N, Evans K E. Auxetic behavior from rotating triangles[J]. Journal of Materials Science, 2006, 41(10): 3193-3196. |

| 35 | Grima J N, Zammit V, Gatt R, et al. Auxetic behaviour from rotating semi-rigid units[J]. Physica Status Solidi B Basic Research, 2007, 244(3): 866-882. |

| 36 | Mizzi L, Azzopardi K M, Attard D, et al. Auxetic metamaterials exhibiting giant negative Poisson’s ratios[J]. Physica Status Solidi Rapid Research Letters, 2015, 9(7): 425-430. |

| 37 | Bertoldi K, Reis P M, Willshaw S, et al. Negative Poisson’s ratio behavior induced by an elastic instability[J]. Advanced Materials, 2010, 22(3): 361-366. |

| 38 | Taylor M, Francesconi L, Gerendás M, et al. Low porosity metallic periodic structures with negative Poisson’s ratio[J]. Advanced Materials, 2014, 26(15): 2365-2370. |

| 39 | Almgren R F. An isotropic three-dimensional structure with Poisson’s ratio =-1[J]. Journal of Elasticity, 1985, 15(4): 427-430. |

| 40 | Qi C, Pei L Z, Remennikov A, et al. Numerical and theoretical analysis of crushing strength of 3D re-entrant honeycomb[J]. Thin-Walled Structures, 2023, 182: 110140. |

| 41 | Li G F, Liu H T, Wang Y B, et al. Mechanical properties of 3D auxetic structure: emergence of transverse isotropy[J]. International Journal of Mechanical Sciences, 2023, 250: 108285. |

| 42 | Wang X T, Li X W, Ma L. Interlocking assembled 3D auxetic cellular structures[J]. Materials & Design, 2016, 99: 467-476. |

| 43 | Wang X T, Wang B, Li X W, et al. Mechanical properties of 3D re-entrant auxetic cellular structures[J]. International Journal of Mechanical Sciences, 2017, 131/132: 396-407. |

| 44 | Fu M H, Zheng B B, Li W H. A novel chiral three-dimensional material with negative Poisson’s ratio and the equivalent elastic parameters[J]. Composite Structures, 2017, 176: 442-448. |

| 45 | Andrade C, Ha C S, Lakes R. Extreme cosserat elastic cube structure with large magnitude of negative Poisson’s ratio[J]. Journal of Mechanics of Materials and Structures, 2018, 13(1): 93-101. |

| 46 | Hamzehei R, Rezaei S, Kadkhodapour J, et al. 2D triangular anti-trichiral structures and auxetic stents with symmetric shrinkage behavior and high energy absorption[J]. Mechanics of Materials, 2020, 142: 103291. |

| 47 | Han D, Zhang Y, Zhang X Y, et al. Mechanical characterization of a novel thickness gradient auxetic tubular structure under inclined load[J]. Engineering Structures, 2022, 273: 115079. |

| 48 | Zhang C, Xiao S H, Qin Q H, et al. Tunable compressive properties of a novel auxetic tubular material with low stress level[J]. Thin-Walled Structures, 2021, 164: 107882. |

| 49 | Lipton J I, MacCurdy R, Manchester Z, et al. Handedness in shearing auxetics creates rigid and compliant structures[J]. Science, 2018, 360(6389): 632-635. |

| 50 | Wu W W, Hu W X, Qian G A, et al. Mechanical design and multifunctional applications of chiral mechanical metamaterials: a review[J]. Materials & Design, 2019, 180: 107950. |

| 51 | He Y C, Bi Z F, Wang T T, et al. Design and mechanical properties analysis of hexagonal perforated honeycomb metamaterial[J]. International Journal of Mechanical Sciences, 2024, 270: 109091. |

| 52 | Lang J P, Han D, Zhang X G, et al. A star-shaped tubular structure with multiple-directional auxetic effect[J]. Thin-Walled Structures, 2023, 193: 111247. |

| 53 | Gatt R, Caruana-Gauci R, Attard D, et al. On the properties of real finite-sized planar and tubular stent-like auxetic structures[J]. Physica Status Solidi (b), 2014, 251(2): 321-327. |

| 54 | Hou Y, Neville R, Scarpa F, et al. Graded conventional-auxetic Kirigami sandwich structures: flatwise compression and edgewise loading[J]. Composites Part B: Engineering, 2014, 59: 33-42. |

| 55 | Yao J F, Sun R J, Scarpa F, et al. Two-dimensional graded metamaterials with auxetic rectangular perforations[J]. Composite Structures, 2021, 261: 113313. |

| 56 | Grima J N, Mizzi L, Azzopardi K M, et al. Auxetic perforated mechanical metamaterials with randomly oriented cuts[J]. Advanced Materials, 2016, 28(2): 385-389. |

| 57 | Ravirala N, Alderson A, Alderson K L. Interlocking hexagons model for auxetic behaviour[J]. Journal of Materials Science, 2007, 42(17): 7433-7445. |

| 58 | Wu Y Z, Fang J G, Wu C, et al. Additively manufactured materials and structures: a state-of-the-art review on their mechanical characteristics and energy absorption[J]. International Journal of Mechanical Sciences, 2023, 246: 108102. |

| 59 | Pei L Z, Qi C, Yang S, et al. A hierarchical fabrication method and crushing response of metallic 3D re-entrant honeycomb[J]. Thin-Walled Structures, 2022, 176: 109369. |

| 60 | Bourell D L, Beaman J J, Wohlers T. History and evolution of additive manufacturing[M]//Additive Manufacturing Processes. Ohio: ASM International, 2020: 11-18. |

| 61 | Fan J X, Zhang L, Wei S S, et al. A review of additive manufacturing of metamaterials and developing trends[J]. Materials Today, 2021, 50: 303-328. |

| 62 | Xu Y D, Šavija B. Auxetic cementitious composites (ACCs) with excellent compressive ductility: experiments and modeling[J]. Materials & Design, 2024, 237: 112572. |

| 63 | Mercer C, Speck T, Lee J Y, et al. Effects of geometry and boundary constraint on the stiffness and negative Poisson’s ratio behaviour of auxetic metamaterials under quasi-static and impact loading[J]. International Journal of Impact Engineering, 2022, 169: 104315. |

| 64 | Jiang H, Ziegler H, Zhang Z N, et al. 3D printed tubular lattice metamaterials for mechanically robust stents[J]. Composites Part B: Engineering, 2022, 236: 109809. |

| 65 | Auricchio F, Bacigalupo A, Gambarotta L, et al. A novel layered topology of auxetic materials based on the tetrachiral honeycomb microstructure[J]. Materials & Design, 2019, 179: 107883. |

| 66 | Lee W, Jeong Y, Yoo J, et al. Effect of auxetic structures on crash behavior of cylindrical tube[J]. Composite Structures, 2019, 208: 836-846. |

| 67 | Shen M H, Fu R L, Liu Y N, et al. Mechanical characterization of Al2O3 twisted honeycomb structures fabricated by digital light processing 3D printing[J]. Ceramics International, 2023, 49(17): 29348-29357. |

| 68 | Chen Y, Ye L. Designing and tailoring effective elastic modulus and negative Poisson’s ratio with continuous carbon fibres using 3D printing[J]. Composites Part A: Applied Science and Manufacturing, 2021, 150: 106625. |

| 69 | Blakey-Milner B, Gradl P, Snedden G, et al. Metal additive manufacturing in aerospace: a review[J]. Materials & Design, 2021, 209: 110008. |

| 70 | Liu X L, Gao L, Xiao M. Multiscale topology optimization framework for natural frequency maximization of multi-morphology lattice structures[J]. Composite Structures, 2024, 328: 117720. |

| 71 | Liu Y, Wang Y Z, Ren H Y, et al. Ultrastiff metamaterials generated through a multilayer strategy and topology optimization[J]. Nature Communications, 2024, 15(1): 2984. |

| 72 | Chen Z Y, Wu X, Xie Y M, et al. Re-entrant auxetic lattices with enhanced stiffness: a numerical study[J]. International Journal of Mechanical Sciences, 2020, 178: 105619. |

| 73 | Li X, Wang Q S, Yang Z Y, et al. Novel auxetic structures with enhanced mechanical properties[J]. Extreme Mechanics Letters, 2019, 27: 59-65. |

| 74 | Zhou Y, Pan Y, Chen L, et al. Mechanical behaviors of a novel auxetic honeycomb characterized by re-entrant combined-wall hierarchical substructures[J]. Materials Research Express, 2022, 9(11): 115802. |

| 75 | Qi C, Jiang F, Remennikov A, et al. Quasi-static crushing behavior of novel re-entrant circular auxetic honeycombs[J]. Composites Part B: Engineering, 2020, 197: 108117. |

| 76 | Wang Q, Yin W J, Yu H, et al. Hyperbolic-like structure with negative Poisson’s ratio: deformation mechanism and structural design[J]. Physica Status Solidi B Basic Research, 2021, 258(10): 2100011. |

| 77 | Zhang X Y, Ren X, Zhang Y, et al. A novel auxetic metamaterial with enhanced mechanical properties and tunable auxeticity[J]. Thin-Walled Structures, 2022, 174: 109162. |

| 78 | Zhang X L, Hao H N, Tian R L, et al. Quasi-static compression and dynamic crushing behaviors of novel hybrid re-entrant auxetic metamaterials with enhanced energy-absorption[J]. Composite Structures, 2022, 288: 115399. |

| 79 | Wang K, Chang Y H, Chen Y W, et al. Designable dual-material auxetic metamaterials using three-dimensional printing[J]. Materials & Design, 2015, 67: 159-164. |

| 80 | Harkati E, Daoudi N, Bezazi A, et al. In-plane elasticity of a multi re-entrant auxetic honeycomb[J]. Composite Structures, 2017, 180: 130-139. |

| 81 | Karathanasopoulos N, Reda H, Ganghoffer J F. Designing two-dimensional metamaterials of controlled static and dynamic properties[J]. Computational Materials Science, 2017, 138: 323-332. |

| 82 | Feng J M, Liang Q X, Dou Y, et al. Higher stiffness hierarchical embedded strengthening honeycomb metastructure with small negative Poisson’s ratio reduction[J]. Thin-Walled Structures, 2022, 179: 109561. |

| 83 | He Q, Feng J, Chen Y J, et al. Mechanical properties of spider-web hierarchical honeycombs subjected to out-of-plane impact loading[J]. Journal of Sandwich Structures & Materials, 2020, 22(3): 771-796. |

| 84 | Shen L M, Wang X X, Li Z D, et al. Elastic properties of an additive manufactured three-dimensional vertex-based hierarchical re-entrant structure[J]. Materials & Design, 2022, 216: 110527. |

| 85 | Shen L M, Wang Z G, Wang X X, et al. Negative Poisson’s ratio and effective Young’s modulus of a vertex-based hierarchical re-entrant honeycomb structure[J]. International Journal of Mechanical Sciences, 2021, 206: 106611. |

| 86 | Hou J H, Li D, Dong L. Mechanical behaviors of hierarchical cellular structures with negative Poisson’s ratio[J]. Journal of Materials Science, 2018, 53(14): 10209-10216. |

| 87 | Sun Y T, Pugno N M. In plane stiffness of multifunctional hierarchical honeycombs with negative Poisson’s ratio sub-structures[J]. Composite Structures, 2013, 106: 681-689. |

| 88 | Zhang W J, Zhao S Y, Sun R J, et al. In-plane mechanical behavior of a new star-re-entrant hierarchical metamaterial[J]. Polymers, 2019, 11(7): 1132. |

| 89 | Lu D J, Li Y F, Seifi H, et al. Designing novel structures with hierarchically synchronized deformations[J]. Extreme Mechanics Letters, 2018, 19: 1-6. |

| 90 | Wu W W, Tao Y, Xia Y, et al. Mechanical properties of hierarchical anti-tetrachiral metastructures[J]. Extreme Mechanics Letters, 2017, 16: 18-32. |

| 91 | Bobbert F S L, Janbaz S, van Manen T, et al. Russian doll deployable meta-implants: fusion of kirigami, origami, and multi-stability[J]. Materials & Design, 2020, 191: 108624. |

| 92 | Gatt R, Mizzi L, Azzopardi J I, et al. Hierarchical auxetic mechanical metamaterials[J]. Scientific Reports, 2015, 5: 8395. |

| 93 | Tan H L, He Z C, Li E, et al. Crashworthiness design and multi-objective optimization of a novel auxetic hierarchical honeycomb crash box[J]. Structural and Multidisciplinary Optimization, 2021, 64(4): 2009-2024. |

| 94 | Bates S R G, Farrow I R, Trask R S. Compressive behaviour of 3D printed thermoplastic polyurethane honeycombs with graded densities[J]. Materials & Design, 2019, 162: 130-142. |

| 95 | Mousanezhad D, Ghosh R, Ajdari A, et al. Impact resistance and energy absorption of regular and functionally graded hexagonal honeycombs with cell wall material strain hardening[J]. International Journal of Mechanical Sciences, 2014, 89: 413-422. |

| 96 | Limmahakhun S, Oloyede A, Sitthiseripratip K, et al. Stiffness and strength tailoring of cobalt chromium graded cellular structures for stress-shielding reduction[J]. Materials & Design, 2017, 114: 633-641. |

| 97 | Li Z, Jiang Y, Wang T, et al. In-plane crushing behaviors of piecewise linear graded honeycombs[J]. Composite Structures, 2019, 207: 425-437. |

| 98 | Zhang J H, Dong B J, Zhang W. Dynamic crushing of gradient auxetic honeycombs[J]. Journal of Vibration Engineering & Technologies, 2021, 9(3): 421-431. |

| 99 | Fang G D, Yuan S G, Meng S H, et al. Graded negative Poisson’s ratio honeycomb structure design and application[J]. Journal of Sandwich Structures & Materials, 2019, 21(7): 2527-2547. |

| 100 | Xu H H, Luo H C, Zhang X G, et al. Mechanical properties of aluminum foam filled re-entrant honeycomb with uniform and gradient designs[J]. International Journal of Mechanical Sciences, 2023, 244: 108075. |

| 101 | Li M X, Lu X F, Zhu X L, et al. Research on in-plane quasi-static mechanical properties of gradient tetra-chiral hyper-structures[J]. Advanced Engineering Materials, 2019, 21(3): 1801038. |

| 102 | Qi D X, Lu Q Y, He C W, et al. Impact energy absorption of functionally graded chiral honeycomb structures[J]. Extreme Mechanics Letters, 2019, 32: 100568. |

| 103 | Boldrin L, Hummel S, Scarpa F, et al. Dynamic behaviour of auxetic gradient composite hexagonal honeycombs[J]. Composite Structures, 2016, 149: 114-124. |

| 104 | Shao Y J, Meng J X, Ma G H, et al. Insight into the negative Poisson’s ratio effect of the gradient auxetic reentrant honeycombs[J]. Composite Structures, 2021, 274: 114366. |

| 105 | Wu X, Su Y T, Shi J. In-plane impact resistance enhancement with a graded cell-wall angle design for auxetic metamaterials[J]. Composite Structures, 2020, 247: 112451. |

| 106 | Xiao D B, Dong Z C, Li Y, et al. Compression behavior of the graded metallic auxetic reentrant honeycomb: experiment and finite element analysis[J]. Materials Science and Engineering: A, 2019, 758: 163-171. |

| 107 | Jiang F, Yang S, Zhang Y, et al. Fabrication and crushing response of graded re-entrant circular auxetic honeycomb[J]. International Journal of Mechanical Sciences, 2023, 242: 107999. |

| 108 | Dudek K K, Mizzi L, Iglesias Martínez J A, et al. Micro-scale graded mechanical metamaterials exhibiting versatile Poisson’s ratio[J]. Composite Structures, 2023, 319: 117151. |

| 109 | Han Y F, Lu W F. Evolutionary design of nonuniform cellular structures with optimized Poisson’s ratio distribution[J]. Materials & Design, 2018, 141: 384-394. |

| 110 | Wang Z P, Poh L H, Zhu Y L, et al. Systematic design of tetra-petals auxetic structures with stiffness constraint[J]. Materials & Design, 2019, 170: 107669. |

| 111 | Mirzaali M J, Janbaz S, Strano M, et al. Shape-matching soft mechanical metamaterials[J]. Scientific Reports, 2018, 8(1): 965. |

| 112 | Han Y F, Lu W F. Optimizing the deformation behavior of stent with nonuniform Poisson’s ratio distribution for curved artery[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2018, 88: 442-452. |

| 113 | Liu J X, Zhang Y H. Soft network materials with isotropic negative Poisson’s ratios over large strains[J]. Soft Matter, 2018, 14(5): 693-703. |

| 114 | Pan Q, Chen S T, Chen F F, et al. Programmable soft bending actuators with auxetic metamaterials[J]. Science China Technological Sciences, 2020, 63(12): 2518-2526. |

| 115 | Yang H, Wang B, Ma L. Mechanical properties of 3D double-U auxetic structures[J]. International Journal of Solids and Structures, 2019, 180/181: 13-29. |

| 116 | Zhang Z J, Zhang L A, Dong Y Y, et al. Mechanical properties of negative Poisson’s ratio metamaterial units and honeycomb structures with cosine-like re-entrant structure[J]. Materials Letters, 2023, 331: 133451. |

| 117 | Zhang W, Wang H L, Lou X, et al. On in-plane crushing behavior of a combined re-entrant double-arrow honeycomb[J]. Thin-Walled Structures, 2024, 194: 111303. |

| 118 | Montazeri A, Hasani A, Safarabadi M. Bending performance and failure mechanism of 3D-printed hybrid geometry honeycombs with various Poisson’s ratios[J]. Journal of Sandwich Structures & Materials, 2023, 25(7): 709-729. |

| 119 | Guo M F, Yang H, Zhou Y M, et al. Mechanical properties of 3D hybrid double arrow-head structure with tunable Poisson’s ratio[J]. Aerospace Science and Technology, 2021, 119: 107177. |

| 120 | Boston D M, Phillips F R, Henry T C, et al. Spanwise wing morphing using multistable cellular metastructures[J]. Extreme Mechanics Letters, 2022, 53: 101706. |

| 121 | Dewalque F, Collette J P, Brüls O. Mechanical behaviour of tape springs used in the deployment of reflectors around a solar panel[J]. Acta Astronautica, 2016, 123: 271-282. |

| 122 | Yang Y, Wang F, Liu J S. The exact solution of the bending moment in the folding process of negative Poisson’s ratio honeycomb tape spring and multi-objective optimization design[J]. Aerospace, 2023, 10(5): 390. |

| 123 | Hassan M R, Scarpa F, Ruzzene M, et al. Smart shape memory alloy chiral honeycomb[J]. Materials Science and Engineering: A, 2008, 481/482: 654-657. |

| 124 | Zeng J C, Song Y P. Poisson’s ratio adjustment of deployable antenna reflector material[C]//2023 7th International Conference on Electrical, Mechanical and Computer Engineering (ICEMCE). Xi’an, China: IEEE, 2023: 12-15. |

| 125 | Xu B, Fang H F, Cai G P, et al. Space-reconfigurable reflector with auxetic lattice material[J]. AIP Advances, 2022, 12(1): 015101. |

| 126 | Bornengo D, Scarpa F, Remillat C. Evaluation of hexagonal chiral structure for morphing airfoil concept[J]. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering, 2005, 219(3): 185-192. |

| 127 | Heo H, Ju J, Kim D M. Compliant cellular structures: application to a passive morphing airfoil[J]. Composite Structures, 2013, 106: 560-569. |

| 128 | 于征磊, 信仁龙, 张志辉, 等. 一种基于记忆合金负泊松比单元体的无人机变形翼结构: 111284679B[P]. 2022.09.06. |

| Yu Z L, Xin R L, Zhang Z H, et al. A deformable wing structure of UAV based on memory alloy negative Poisson’s ratio element: 111284679B[P]. 2022. 09. 06. | |

| 129 | 胡启华, 聂瑞, 张超, 等. 可调负泊松比蜂窝结构在变面积机翼上的应用[J]. 哈尔滨工业大学学报, 2024, 56(8): 24-33. |

| Hu Q H, Nie R, Zhang C, et al. Application of adjustable negative Poisson’s ratio honeycomb structure on variable-area wing[J]. Journal of Harbin Institute of Technology, 2024, 56(8): 24-33. | |

| 130 | Alsaidi B, Joe W Y, Akbar M. Computational analysis of 3D lattice structures for skin in real-scale camber morphing aircraft[J]. Aerospace, 2019, 6(7): 79. |

| 131 | Bettini P, Airoldi A, Sala G, et al. Composite chiral structures for morphing airfoils: numerical analyses and development of a manufacturing process[J]. Composites Part B: Engineering, 2010, 41(2): 133-147. |

| 132 | 于靖军, 谢岩, 裴旭. 负泊松比超材料研究进展[J]. 机械工程学报, 2018, 54(13): 1-14. |

| Yu J J, Xie Y, Pei X. State-of-art of metamaterials with negative Poisson’s ratio[J]. Journal of Mechanical Engineering, 2018, 54(13): 1-14. | |

| 133 | Alderson A, Alderson K L. Auxetic materials[J]. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering, 2007, 221(4): 565-575. |

| 134 | Li C, Shen H S, Wang H. Thermal post-buckling of sandwich beams with functionally graded negative Poisson’s ratio honeycomb core[J]. International Journal of Mechanical Sciences, 2019, 152: 289-297. |

| 135 | Li C, Shen H S, Wang H. Nonlinear bending of sandwich beams with functionally graded negative Poisson’s ratio honeycomb core[J]. Composite Structures, 2019, 212: 317-325. |

| 136 | Song K H, Li D W, Zhang C D, et al. Bio-inspired hierarchical honeycomb metastructures with superior mechanical properties[J]. Composite Structures, 2023, 304: 116452. |

| 137 | Wang T, An J H, He H, et al. A novel 3D impact energy absorption structure with negative Poisson’s ratio and its application in aircraft crashworthiness[J]. Composite Structures, 2021, 262: 113663. |

| 138 | Wu D F, Zheng L M, Pan B, et al. Thermal protection performance of metallic honeycomb core panel structures in non-steady thermal environments[J]. Experimental Heat Transfer, 2016, 29(1): 53-77. |

| 139 | Li C X, Li X F, Chen J L, et al. Optimization design of thermal protective characteristics of special-shaped honeycomb structure[J]. Case Studies in Thermal Engineering, 2024, 60: 104657. |

| 140 | Li P Q, Wang K F, Wang B L. Effects of unit cell parameters on the thermal shock resistance of auxetic honeycomb sandwich structures: combining discrete and continuum model[J]. Mechanics of Materials, 2024, 196: 105054. |

| 141 | Hu J S, Wang B L. Crack growth behavior and thermal shock resistance of ceramic sandwich structures with an auxetic honeycomb core[J]. Composite Structures, 2021, 260: 113256. |

| 142 | Tian L, Gu H D, Zhang Q Q, et al. Multifunctional hierarchical metamaterial for thermal insulation and electromagnetic interference shielding at elevated temperatures[J]. ACS Nano, 2023, 17(13): 12673-12683. |

| 143 | Ai L, Gao X L. Three-dimensional metamaterials with a negative Poisson’s ratio and a non-positive coefficient of thermal expansion[J]. International Journal of Mechanical Sciences, 2018, 135: 101-113. |

| 144 | Huang J X, Li W H, Chen M M, et al. An auxetic material with negative coefficient of thermal expansion and high stiffness[J]. Applied Composite Materials, 2022, 29(2): 777-802. |

| 145 | Yoon M H, Oh J H. Design of multi-auxetic microstructures for sound absorbing applications[J]. Advanced Composite Materials, 2023, 32(2): 225-236. |

| 146 | Kong W F, Fu T, Rabczuk T. Improvement of broadband low-frequency sound absorption and energy absorbing of arched curve Helmholtz resonator with negative Poisson’s ratio[J]. Applied Acoustics, 2024, 221: 110011. |

| [1] | Guanyu REN, Yifei ZHANG, Xinze LI, Wenjing DU. Numerical study on flow and heat transfer characteristics of airfoil printed circuit heat exchangers [J]. CIESC Journal, 2024, 75(S1): 108-117. |

| [2] | Yong YANG, Zixuan ZU, Yukun LI, Dongliang WANG, Zongliang FAN, Huairong ZHOU. Numerical simulation of CO2 absorption by alkali liquor in T-junction cylindrical microchannels [J]. CIESC Journal, 2024, 75(S1): 135-142. |

| [3] | Junhao HUANG, Keliang PANG, Fangyuan SUN, Fujun LIU, Zhiyuan GU, Long HAN, Yanquan DUAN, Yanhui FENG. Influence of bell structure of coke dry quenching furnace on coke distribution [J]. CIESC Journal, 2024, 75(S1): 158-169. |

| [4] | Xinyu DONG, Longfei BIAN, Yiyi YANG, Yuxuan ZHANG, Lu LIU, Teng WANG. Study on flow and heat transfer mechanism of supercritical CO2 in inclined upward tube under cooling conditions [J]. CIESC Journal, 2024, 75(S1): 195-205. |

| [5] | Qirui GUO, Liyuan REN, Kang CHEN, Xiangyu HUANG, Weihua MA, Leqin XIAO, Weiliang ZHOU. Numerical simulation of static mixing tubes for HTPB propellant slurry [J]. CIESC Journal, 2024, 75(S1): 206-216. |

| [6] | Kuangxi LI, Peiqian YU, Jiangyun WANG, Haoran WEI, Zhigang ZHENG, Liuhai FENG. Flow analysis and structure optimization of micro-bubble swirling air flotation device [J]. CIESC Journal, 2024, 75(S1): 223-234. |

| [7] | Zhangzhou WANG, Tianqi TANG, Jiajun XIA, Yurong HE. Battery thermal management performance simulation based on composite phase change material [J]. CIESC Journal, 2024, 75(S1): 329-338. |

| [8] | Jian HU, Jinghua JIANG, Shengjun FAN, Jianhao LIU, Haijiang ZOU, Wanlong CAI, Fenghao WANG. Research on heat extraction performance of deep U-type borehole heat exchanger [J]. CIESC Journal, 2024, 75(S1): 76-84. |

| [9] | Shuyue LI, Huan WANG, Shaoqiang ZHOU, Zhihong MAO, Yongmin ZHANG, Junwu WANG, Xiuhua WU. Numerical simulation of hydrogen reduction of U3O8 in fluidized bed reactors using CPFD method [J]. CIESC Journal, 2024, 75(9): 3133-3151. |

| [10] | Wuling ZHAO, Yi MAN. Research on framework of nanocellulose molecular structure prediction model based on variational encoder [J]. CIESC Journal, 2024, 75(9): 3221-3230. |

| [11] | Mengting ZHANG, Shulin WANG, Xi SANG, Xinghao YUAN, Gang XU. Artificial Cu-TM1459 metalloenzyme catalyzes asymmetric Michael addition reaction [J]. CIESC Journal, 2024, 75(9): 3255-3265. |

| [12] | Juhui CHEN, Tong SU, Dan LI, Liwei CHEN, Wensheng LYU, Fanqi MENG. Study on the heat transfer characteristics of microchannels under the action of fin-shaped spoilers [J]. CIESC Journal, 2024, 75(9): 3122-3132. |

| [13] | Xiaoyu QIAN, Xuan RUAN, Shuiqing LI. Structural reconstruction and levitation of dielectric particle layers in electric fields [J]. CIESC Journal, 2024, 75(8): 2756-2762. |

| [14] | Ziliang ZHU, Shuang WANG, Yu'ang JIANG, Mei LIN, Qiuwang WANG. Solid-liquid phase change algorithm with Euler-Lagrange iteration [J]. CIESC Journal, 2024, 75(8): 2763-2776. |

| [15] | Aiming DENG, Yurong HE, Tianqi TANG, Yanwei HU. Simulation of effect of draft plate on particle growth process in spray fluidized beds [J]. CIESC Journal, 2024, 75(8): 2787-2799. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||