CIESC Journal ›› 2025, Vol. 76 ›› Issue (4): 1375-1390.DOI: 10.11949/0438-1157.20240963

• Reviews and monographs • Previous Articles Next Articles

Junde ZHAO1,2( ), Aiguo ZHOU2, Yanlin CHEN1,2, Jiale ZHENG2, Tianshu GE1(

), Aiguo ZHOU2, Yanlin CHEN1,2, Jiale ZHENG2, Tianshu GE1( )

)

Received:2024-08-27

Revised:2024-10-05

Online:2025-05-12

Published:2025-04-25

Contact:

Tianshu GE

赵俊德1,2( ), 周爱国2, 陈彦霖1,2, 郑家乐2, 葛天舒1(

), 周爱国2, 陈彦霖1,2, 郑家乐2, 葛天舒1( )

)

通讯作者:

葛天舒

作者简介:赵俊德(2000—),女,硕士研究生,zhaojunde@sjtu.edu.cn

基金资助:CLC Number:

Junde ZHAO, Aiguo ZHOU, Yanlin CHEN, Jiale ZHENG, Tianshu GE. Current status of energy consumption of adsorption CO2 direct air capture[J]. CIESC Journal, 2025, 76(4): 1375-1390.

赵俊德, 周爱国, 陈彦霖, 郑家乐, 葛天舒. 吸附法CO2直接空气捕集技术能耗现状[J]. 化工学报, 2025, 76(4): 1375-1390.

Add to citation manager EndNote|Ris|BibTeX

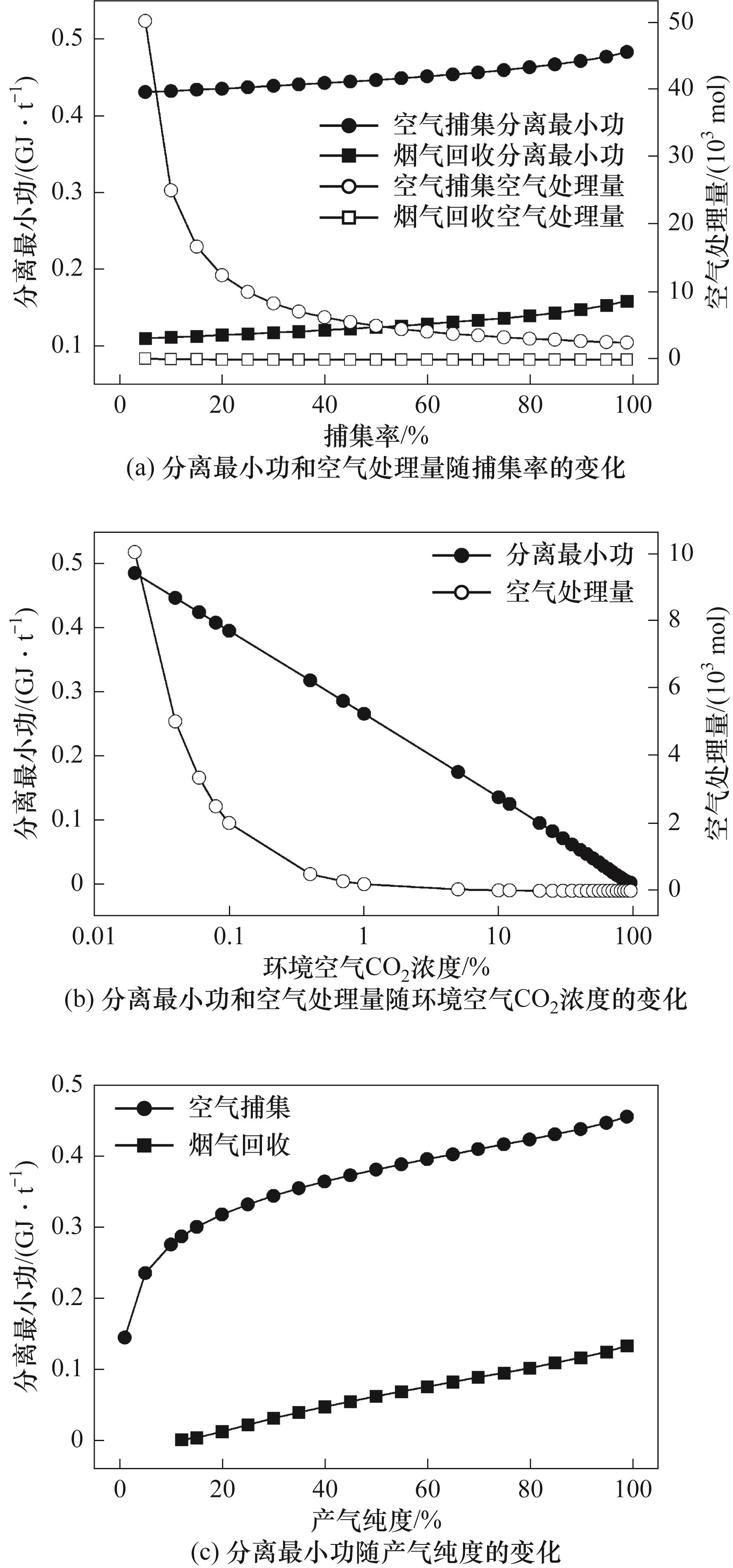

Fig.4 Variation of the minimum work of separation and air handling capacity with capture rate, ambient air CO2 concentration and product gas purity in air capture and flue gas recovery

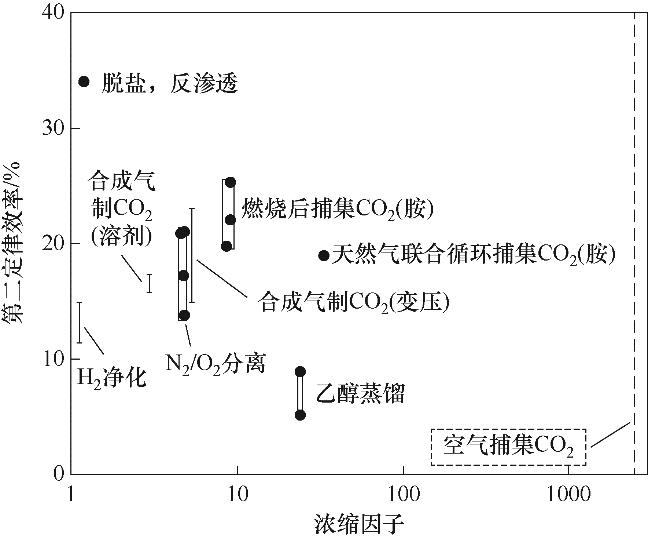

Fig.5 Empirical relationship between the concentration factor of industrial separation processes vs the achieved second-law efficiency of those processes[24]

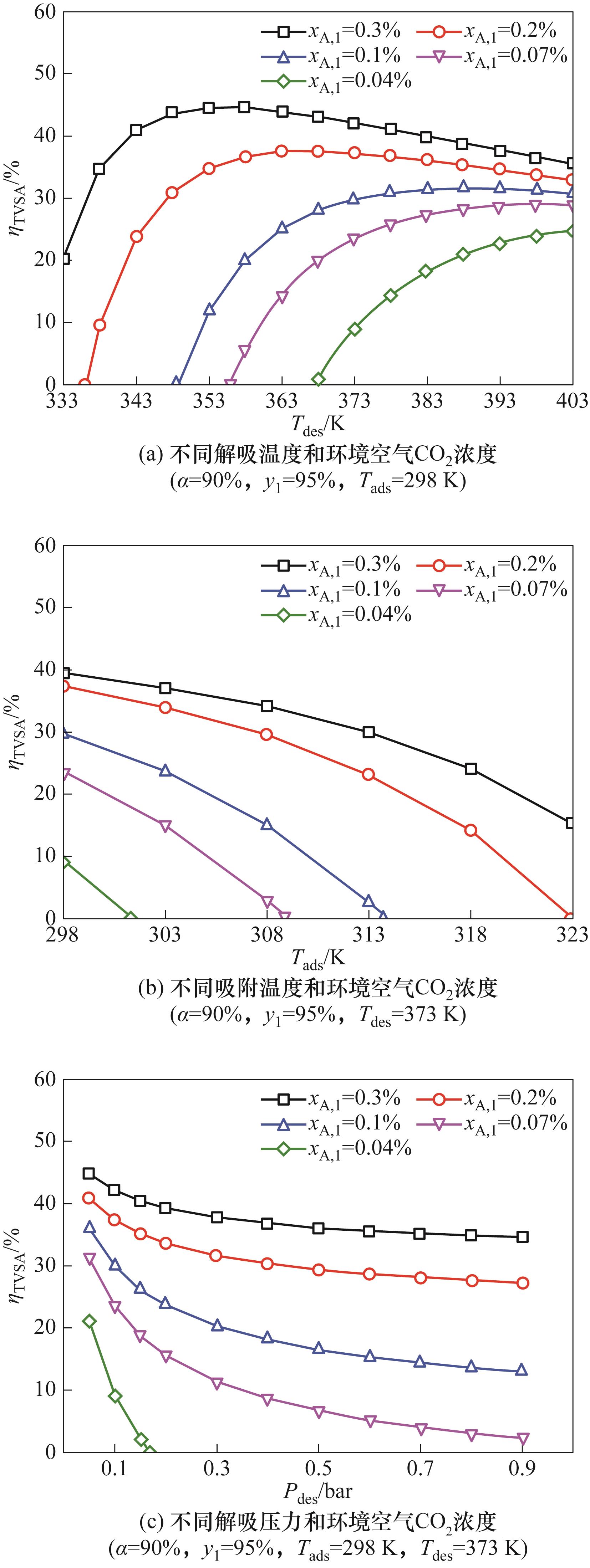

Fig.6 The second-law efficiency of TVSA at different desorption temperature, adsorption temperature, desorption pressure and ambient air CO2 concentration[25]

| Volume flow/(m3·h-1) | Pressure drop/Pa |

|---|---|

| 200 | 16 |

| 400 | 31 |

| 600 | 58 |

| 800 | 98 |

Table 1 Pressure drop test results for adsorption bed structures from Climeworks[40]

| Volume flow/(m3·h-1) | Pressure drop/Pa |

|---|---|

| 200 | 16 |

| 400 | 31 |

| 600 | 58 |

| 800 | 98 |

| 1 | National Oceanic and Atmospheric Administration. Climate change: atmospheric carbon dioxide[EB/OL]. [2024-07-31]. . |

| 2 | Rogelj J, Schaeffer M, Meinshausen M, et al. Zero emission targets as long-term global goals for climate protection[J]. Environmental Research Letters, 2015, 10(10): 105007. |

| 3 | Smith P, Davis S J, Creutzig F, et al. Biophysical and economic limits to negative CO2 emissions[J]. Nature Climate Change, 2016, 6(1): 42-50. |

| 4 | 吴娇. 海洋升温与酸化背景下三角褐指藻光抑制及恢复研究[D]. 广州: 广州大学, 2024. |

| Wu J. Study on photoinhibition and recovery of Phaeodactylum tricornutum in the context of ocean warming and acidification[D]. Guangzhou: Guangzhou University, 2024. | |

| 5 | Matthews H D, Caldeira K. Stabilizing climate requires near‐zero emissions[J]. Geophysical Research Letters, 2008, 35(4): 032388. |

| 6 | Davis S J, Lewis N S, Shaner M, et al. Net-zero emissions energy systems[J]. Science, 2018, 360(6396): 1-9. |

| 7 | 周红军, 周颖, 徐春明. 中国碳中和目标下CO2转化的思考与实践[J]. 化工进展, 2022, 41(6): 3381-3385. |

| Zhou H J, Zhou Y, Xu C M. Exploration of the CO2 conversion under China's carbon neutrality goal[J]. Chemical Industry and Engineering Progress, 2022, 41(6): 3381-3385. | |

| 8 | Lee S Y, Park S J. A review on solid adsorbents for carbon dioxide capture[J]. Journal of Industrial and Engineering Chemistry, 2015, 23: 1-11. |

| 9 | Lackner K, Ziock H J, Grimes P. Carbon dioxide extraction from air: is it an option?[R/OL]. [2023-07-31]. . |

| 10 | Sánchez J M, Maroño M, Cillero D, et al. Laboratory- and bench-scale studies of a sweet water-gas-shift catalyst for H2 and CO2 production in pre-combustion CO2 capture[J]. Fuel, 2013, 114: 191-198. |

| 11 | Babu P, Kumar R, Linga P. A new porous material to enhance the kinetics of clathrate process: application to precombustion carbon dioxide capture[J]. Environmental Science & Technology, 2013, 47(22): 13191-13198. |

| 12 | Cotton A, Patchigolla K, Oakey J E. Minor and trace element emissions from post-combustion CO2 capture from coal: experimental and equilibrium calculations[J]. Fuel, 2014, 117: 391-407. |

| 13 | Goto K, Yogo K, Higashii T. A review of efficiency penalty in a coal-fired power plant with post-combustion CO2 capture[J]. Applied Energy, 2013, 111: 710-720. |

| 14 | Skorek-Osikowska A, Bartela L, Kotowicz J, et al. Thermodynamic and economic analysis of the different variants of a coal-fired, 460 MW power plant using oxy-combustion technology[J]. Energy Conversion and Management, 2013, 76: 109-120. |

| 15 | Wall T, Stanger R, Liu Y. Gas cleaning challenges for coal-fired oxy-fuel technology with carbon capture and storage[J]. Fuel, 2013, 108: 85-90. |

| 16 | Lackner K S. A guide to CO2 sequestration[J]. Science, 2003, 300(5626): 1677-1678. |

| 17 | Wang X, Song C. Carbon capture from flue gas and the atmosphere: a perspective[J]. Frontiers in Energy Research, 2020, 8: 560849. |

| 18 | Seipp C A, Williams N J, Kidder M K, et al. CO2 capture from ambient air by crystallization with a guanidine sorbent[J]. Angewandte Chemie, 2017, 129(4): 1062-1065. |

| 19 | Keith D W. Why capture CO2 from the atmosphere?[J]. Science, 2009, 325(5948): 1654-1655. |

| 20 | Shi X, Xiao H, Azarabadi H, et al. Sorbents for the direct capture of CO2 from ambient air[J]. Angewandte Chemie International Edition, 2020, 59(18): 6984-7006. |

| 21 | United States Department of Energy, National Energy Technology Laboratory. Carbon dioxide removal project map[EB/OL]. [2024-09-26]. . |

| 22 | Brandani S. Carbon dioxide capture from air: a simple analysis[J]. Energy & Environment, 2012, 23(2/3): 319-328. |

| 23 | Kulkarni A R, Sholl D S. Analysis of equilibrium-based TSA processes for direct capture of CO2 from air[J]. Industrial & Engineering Chemistry Research, 2012, 51(25): 8631-8645. |

| 24 | House K Z, Baclig A C, Ranjan M, et al. Economic and energetic analysis of capturing CO2 from ambient air[J]. Proceedings of the National Academy of Sciences, 2011, 108(51): 20428-20433. |

| 25 | Zhao R, Liu L, Zhao L, et al. Thermodynamic exploration of temperature vacuum swing adsorption for direct air capture of carbon dioxide in buildings[J]. Energy Conversion and Management, 2019, 183: 418-426. |

| 26 | Zhao R, Deng S, Liu Y, et al. Carbon pump: fundamental theory and applications[J]. Energy, 2017, 119: 1131-1143. |

| 27 | Jiang L, Roskilly A P, Wang R Z. Performance exploration of temperature swing adsorption technology for carbon dioxide capture[J]. Energy Conversion and Management, 2018, 165: 396-404. |

| 28 | Clausse M, Merel J, Meunier F. Numerical parametric study on CO2 capture by indirect thermal swing adsorption[J]. International Journal of Greenhouse Gas Control, 2011, 5(5): 1206-1213. |

| 29 | Pirngruber G D, Guillou F, Gomez A, et al. A theoretical analysis of the energy consumption of post-combustion CO2 capture processes by temperature swing adsorption using solid sorbents[J]. International Journal of Greenhouse Gas Control, 2013, 14: 74-83. |

| 30 | Veneman R, Frigka N, Zhao W, et al. Adsorption of H2O and CO2 on supported amine sorbents[J]. International Journal of Greenhouse Gas Control, 2015, 41: 268-275. |

| 31 | Shen C, Liu Z, Li P, et al. Two-stage VPSA process for CO2 capture from flue gas using activated carbon beads[J]. Industrial & Engineering Chemistry Research, 2012, 51(13): 5011-5021. |

| 32 | Oreggioni G D, Brandani S, Luberti M, et al. CO2 capture from syngas by an adsorption process at a biomass gasification CHP plant: its comparison with amine-based CO2 capture[J]. International Journal of Greenhouse Gas Control, 2015, 35: 71-81. |

| 33 | Wilson S M W, Tezel F H. Direct dry air capture of CO2 using VTSA with faujasite zeolites[J]. Industrial & Engineering Chemistry Research, 2020, 59(18): 8783-8794. |

| 34 | Mazzotti M, Baciocchi R, Desmond M J, et al. Direct air capture of CO2 with chemicals: optimization of a two-loop hydroxide carbonate system using a countercurrent air-liquid contactor[J]. Climatic Change, 2013, 118(1): 119-135. |

| 35 | Ergun S. Fluid flow through packed columns[J]. Chemical Engineering Progress, 1952, 48: 89-94. |

| 36 | 曹伟波. 壁流蜂窝式微填充床的制备及其在变压吸附过程的应用[D]. 杭州: 浙江大学, 2017. |

| Cao W B. Fabrication of honeycomb wall-flow micro packed bed and application in PSA process[D]. Hangzhou: Zhejiang University, 2017. | |

| 37 | Sinha A, Darunte L A, Jones C W, et al. Systems design and economic analysis of direct air capture of CO2 through temperature vacuum swing adsorption using MIL-101(Cr)-PEI-800 and mmen-Mg2 (dobpdc) MOF adsorbents[J]. Industrial & Engineering Chemistry Research, 2017, 56(3): 750-764. |

| 38 | Yang R T. Gas Separation by Adsorption Processes[M]. Butterworth-Heinemann, 1987. |

| 39 | Yasushi A, Tatsuji M. Filter for purifying exhaust gases: EP0766993A2[P]. 1997-04-09. |

| 40 | Gebald C, Piatkowski N, Rüesch T, et al. Low-pressure drop structure of particle adsorbent bed for adsorption gas separation process: WO2014170184[P]. 2014-10-23. |

| 41 | Couck S, Lefevere J, Mullens S, et al. CO2, CH4 and N2 separation with a 3DFD-printed ZSM-5 monolith[J]. Chemical Engineering Journal, 2017, 308: 719-726. |

| 42 | Couck S, Cousin-Saint-Remi J, van der Perre S, et al. 3D-printed SAPO-34 monoliths for gas separation[J]. Microporous and Mesoporous Materials, 2018, 255: 185-191. |

| 43 | Thakkar H, Eastman S, Hajari A, et al. 3D-printed zeolite monoliths for CO2 removal from enclosed environments[J]. ACS Applied Materials & Interfaces, 2016, 8(41): 27753-27761. |

| 44 | Thakkar H, Eastman S, Al-Mamoori A, et al. Formulation of aminosilica adsorbents into 3D-printed monoliths and evaluation of their CO2 capture performance[J]. ACS Applied Materials & Interfaces, 2017, 9(8): 7489-7498. |

| 45 | Bollini P, Choi S, Drese J H, et al. Oxidative degradation of aminosilica adsorbents relevant to postcombustion CO2 capture[J]. Energy & Fuels, 2011, 25(5): 2416-2425. |

| 46 | Heydari-Gorji A, Sayari A. Thermal, oxidative, and CO2-induced degradation of supported polyethylenimine adsorbents[J]. Industrial & Engineering Chemistry Research, 2012, 51(19): 6887-6894. |

| 47 | Ahmadalinezhad A, Sayari A. Oxidative degradation of silica-supported polyethylenimine for CO2 adsorption: insights into the nature of deactivated species[J]. Physical Chemistry Chemical Physics, 2013, 16(4): 1529-1535. |

| 48 | Choi S, Drese J H, Jones C W. Adsorbent materials for carbon dioxide capture from large anthropogenic point sources[J]. ChemSusChem, 2009, 2(9): 796-854. |

| 49 | Samanta A, Zhao A, Shimizu G K H, et al. Post-combustion CO2 capture using solid sorbents: a review[J]. Industrial & Engineering Chemistry Research, 2012, 51(4): 1438-1463. |

| 50 | Quang D V, Dindi A, Rayer A V, et al. Impregnation of amines onto porous precipitated silica for CO2 capture[J]. Energy Procedia, 2014, 63: 2122-2128. |

| 51 | Sinha A, Realff M J. A parametric study of the techno‐economics of direct CO2 air capture systems using solid adsorbents[J]. AIChE Journal, 2019, 65(7): e16607. |

| 52 | Zhu X C, Ge T S, Yang F, et al. Design of steam-assisted temperature vacuum-swing adsorption processes for efficient CO2 capture from ambient air[J]. Renewable and Sustainable Energy Reviews, 2021, 137: 110651. |

| 53 | Min Y J, Ganesan A, Realff M J, et al. Direct air capture of CO2 using poly(ethyleneimine)-functionalized expanded poly(tetrafluoroethylene)/silica composite structured sorbents[J]. ACS Applied Materials & Interfaces, 2022, 14(36): 40992-41002. |

| 54 | Sujan A R, Pang S H, Zhu G, et al. Direct CO2 capture from air using poly(ethylenimine)-loaded polymer/silica fiber sorbents[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(5): 5264-5273. |

| 55 | Didas S A, Sakwa-Novak M A, Foo G S, et al. Effect of amine surface coverage on the co-adsorption of CO2 and water: spectral deconvolution of adsorbed species[J]. The Journal of Physical Chemistry Letters, 2014, 5(23): 4194-4200. |

| 56 | Wurzbacher J A, Gebald C, Piatkowski N, et al. Concurrent separation of CO2 and H2O from air by a temperature-vacuum swing adsorption/desorption cycle[J]. Environmental Science & Technology, 2012, 46(16): 9191-9198. |

| 57 | Sehaqui H, Gálvez M E, Becatinni V, et al. Fast and reversible direct CO2 capture from air onto all-polymer nanofibrillated cellulose-polyethylenimine foams[J]. Environmental Science & Technology, 2015, 49(5): 3167-3174. |

| 58 | Elfving J, Bajamundi C, Kauppinen J, et al. Modelling of equilibrium working capacity of PSA, TSA and TVSA processes for CO2 adsorption under direct air capture conditions[J]. Journal of CO2 Utilization, 2017, 22: 270-277. |

| 59 | Kumar D R, Rosu C, Sujan A R, et al. Alkyl-aryl amine-rich molecules for CO2 removal via direct air capture[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(29): 10971-10982. |

| 60 | Gebald C, Repond N, Wurzbacher J A. Steam assisted vacuum desorption process for carbon dioxide capture: US201515324775[P]. 2019-05-07. |

| 61 | Stampi-Bombelli V, van der Spek M, Mazzotti M. Analysis of direct capture of CO2 from ambient air via steam-assisted temperature-vacuum swing adsorption[J]. Adsorption, 2020, 26(7): 1183-1197. |

| 62 | van der Giesen C, Meinrenken C J, Kleijn R, et al. A life cycle assessment case study of coal-fired electricity generation with humidity swing direct air capture of CO2 versus MEA-based postcombustion capture[J]. Environmental Science & Technology, 2017, 51(2): 1024-1034. |

| 63 | 葛天舒, 徐静, 赵俊德, 等. 一种热泵驱动的回热型直接空气碳捕集系统: 202311163513.X[P]. 2023-12-22. |

| Ge T S, Xu J, Zhao J D, et al. A heat pump driven regenerative direct air carbon capture system: 202311163513. X[P] 2023-12-22. | |

| 64 | 葛天舒, 徐静, 赵俊德. CO2再循环吹扫的热泵驱动直接空气碳捕集系统及其方法: 202310897457.6[P]. 2023-10-27. |

| Ge T S, Xu J, Zhao J D. Direct air carbon capture system driven by heat pump for CO2 recirculation blowing and its method: 202310897457.6[P] 2023-10-27. | |

| 65 | National Academies of Sciences E, Medicine. Negative Emissions Technologies and Reliable Sequestration: A Research Agenda[M]. Washington, D.C.: National Academies Press, 2019. |

| 66 | Gebald C, Wurzbacher J A, Borgschulte A, et al. Single-component and binary CO2 and H2O adsorption of amine-functionalized cellulose[J]. Environmental Science & Technology, 2014, 48(4): 2497-2504. |

| 67 | Gutknecht V, Snæbjörnsdóttir S Ó, Sigfússon B, et al. Creating a carbon dioxide removal solution by combining rapid mineralization of CO2 with direct air capture[J]. Energy Procedia, 2018, 146: 129-134. |

| 68 | Beuttler C, Charles L, Wurzbacher J. The role of direct air capture in mitigation of anthropogenic greenhouse gas emissions[J]. Frontiers in Climate, 2019, 1: 10. |

| 69 | Ji Y, Liu W, Yong J Y, et al. Techno-economic analysis on temperature vacuum swing adsorption system integrated with pre-dehumidification for direct air capture[J]. Carbon Capture Science & Technology, 2024, 12: 100199. |

| 70 | Sanz-Pérez E S, Murdock C R, Didas S A, et al. Direct capture of CO2 from ambient air[J]. Chemical Reviews, 2016, 116(19): 11840-11876. |

| 71 | 赵洁. CO2/H2O竞争吸附碳捕集基础及应用研究[D]. 天津: 天津大学, 2022. |

| Zhao J. Fundamental and application research of CO2 and H2O competitive adsorption on carbon capture[D]. Tianjin: Tianjin University, 2022. | |

| 72 | National Renewable Energy Laboratory. Life cycle greenhouse gas emissions from electricity generation: update[R/OL]. [2024-07-09]. . |

| 73 | Sabatino F, Grimm A, Gallucci F, et al. A comparative energy and costs assessment and optimization for direct air capture technologies[J]. Joule, 2021, 5(8): 2047-2076. |

| 74 | Hong W Y. A techno-economic review on carbon capture, utilisation and storage systems for achieving a net-zero CO2 emissions future[J]. Carbon Capture Science & Technology, 2022, 3: 100044. |

| 75 | Erans M, Sanz-Pérez E S, Hanak D P, et al. Direct air capture: process technology, techno-economic and socio-political challenges[J]. Energy & Environmental Science, 2022, 15(4): 1360-1405. |

| [1] | Tianzi CAI, Haifeng ZHANG, Haidan LIN, Zilong ZHANG, Pengyu ZHOU, Bolin WANG, Xiaonian LI. A density functional theory study on the sensing of dissolved gases CO and CO2 in transformer oil using boron-doped nitrogen-based graphene [J]. CIESC Journal, 2025, 76(4): 1841-1851. |

| [2] | Zhenglei HE, Dingding HU. Multi-objective optimization of papermaking wastewater based on multi-agent reinforcement learning [J]. CIESC Journal, 2025, 76(4): 1617-1634. |

| [3] | Yihao JIN, Junxin LUO, Zhangmao HU, Wei WANG, Qian YIN. Experimental investigation on hydrophilic functionalized MgSO4/expanded vermiculite composites for water adsorption and heat storage [J]. CIESC Journal, 2025, 76(4): 1852-1862. |

| [4] | Yao FU, Yingjuan SHAO, Wenqi ZHONG. Experimental study on cyclic heat storage performance of TiO2-doped calcium based materials under pressurized carbonation [J]. CIESC Journal, 2025, 76(3): 1180-1190. |

| [5] | Lyusheng ZHANG, Zhihong WANG, Qing LIU, Xuewen LI, Renmin TAN. Research progress in carbon dioxide capture using liquid-liquid phase change absorbents [J]. CIESC Journal, 2025, 76(3): 933-950. |

| [6] | Jiayi YAO, Donghui ZHANG, Zhongli TANG, Wenbin LI. Research on carbon capture by pressure swing adsorption based on two-stage dual reflux [J]. CIESC Journal, 2025, 76(2): 744-754. |

| [7] | Jingyu JIA, Deqi KONG, Yuanhui SHEN, Donghui ZHANG, Wenbin LI, Zhongli TANG. Simulation and analysis of ammonia separation process by pressure swing adsorption from synthetic ammonia reactor-off gas [J]. CIESC Journal, 2025, 76(2): 718-730. |

| [8] | Fei CHANG, Renbo SHI, Shihua LIU, Wenqian GAO, Yifei WANG, Bin ZHENG, Yixuan JIAO, Xingying LAN, Chunming XU, Yehua HAN. Product life cycle carbon footprint evaluation for petrochemical industry [J]. CIESC Journal, 2025, 76(2): 419-437. |

| [9] | Hanbin WANG, Shuai HU, Fenglei BI, Junsen LI, Laibin HE. Desorption performance analysis of a metal hydride reactor with novel corrugated fins based on finite element method [J]. CIESC Journal, 2025, 76(1): 221-230. |

| [10] | Jiaxin WANG, Yanhong WEI, Shunyang NONG, Yanshu XIONG, Mei LI, Wen LI. Molecular mechanism analysis of melanoidin adsorption by polyamine-modified chitosan aerogel based on multiple quantum chemical theory calculations [J]. CIESC Journal, 2025, 76(1): 107-119. |

| [11] | Yanlin CHEN, Aiguo ZHOU, Jiale ZHENG, Chuanruo YANG, Tianshu GE. Effects of support materials on amine-impregnated DAC adsorbents [J]. CIESC Journal, 2024, 75(S1): 217-222. |

| [12] | Linfeng MA, Aitong OU, Zhiyuan LI, Yao LI, Runze LIU, Xiaole WU, Jingtao XU. High-efficiency adsorption of heavy metal ions by Na2S modified biochar: preparation and adsorption mechanism [J]. CIESC Journal, 2024, 75(7): 2594-2603. |

| [13] | Xianggang ZHANG, Yulong CHANG, Hualin WANG, Xia JIANG. Low energy consumption non-phase change second drying of waste straw and other biomass [J]. CIESC Journal, 2024, 75(7): 2433-2445. |

| [14] | Taohong WANG, Chao WANG, Zheng LI, Ying LIU, Ge TIAN, Ganggang CHANG, Xiaoyu YANG, Zongbi BAO. Immobilize Cu(Ⅰ) into π-complexed MOF adsorbent for selectivity separation of ethane/ethylene [J]. CIESC Journal, 2024, 75(7): 2565-2573. |

| [15] | Zhong JI, Yanling ZHAO, Yumeng CHEN, Linxia GAO, Yipeng WANG, Huan LIU. Adsorption performance and mechanism of ZSM-5 molecular sieves on typical coating VOCs [J]. CIESC Journal, 2024, 75(6): 2332-2343. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||