CIESC Journal ›› 2020, Vol. 71 ›› Issue (5): 2283-2291.DOI: 10.11949/0438-1157.20191468

• Energy and environmental engineering • Previous Articles Next Articles

Shiming XU( ),Zhiqiang LIU,Xi WU,Youwen ZHANG,Junyong HU,Debing WU,Qiang LENG,Dongxu JIN,Ping WANG

),Zhiqiang LIU,Xi WU,Youwen ZHANG,Junyong HU,Debing WU,Qiang LENG,Dongxu JIN,Ping WANG

Received:2019-12-04

Revised:2020-01-14

Online:2020-05-05

Published:2020-05-05

Contact:

Shiming XU

徐士鸣( ),刘志强,吴曦,张又文,胡军勇,吴德兵,冷强,金东旭,王平

),刘志强,吴曦,张又文,胡军勇,吴德兵,冷强,金东旭,王平

通讯作者:

徐士鸣

作者简介:徐士鸣(1957—),男,教授,博导,基金资助:CLC Number:

Shiming XU, Zhiqiang LIU, Xi WU, Youwen ZHANG, Junyong HU, Debing WU, Qiang LENG, Dongxu JIN, Ping WANG. Experimental study on the hydrogen production with RED reactor powered by concentration gradient energy[J]. CIESC Journal, 2020, 71(5): 2283-2291.

徐士鸣, 刘志强, 吴曦, 张又文, 胡军勇, 吴德兵, 冷强, 金东旭, 王平. 溶液浓差能驱动的逆电渗析反应器制氢实验研究[J]. 化工学报, 2020, 71(5): 2283-2291.

Add to citation manager EndNote|Ris|BibTeX

| 实验设备 | 型号 | 参数 | 精度 |

|---|---|---|---|

| 电导率仪 | METTLER TOLEDO FE38 | 电导率 | ±0.5% mS·cm-1 |

| 数字万用表 | KEITHLEY | 电流、电压 | ±0.016% V / 0.17% A |

| 电子分析天平 | OHAUS Scout SE | 质量 | 0.001g |

| 低温恒温槽 | Biosafer - 1020DC | 温度 | ±0.05 K |

| 蠕动泵 | LONGER BT300 - 2J | 体积流率 | — |

| 电极液蠕动泵 | Kamoer KCP PRO2-N40 | 体积流率 | ±5% ml·min-1 |

| 可调直流电阻器 | ZX92A | 电阻 | ±0.1%Ω |

Table 1 Mode, parameter and accuracy of experiment equipment

| 实验设备 | 型号 | 参数 | 精度 |

|---|---|---|---|

| 电导率仪 | METTLER TOLEDO FE38 | 电导率 | ±0.5% mS·cm-1 |

| 数字万用表 | KEITHLEY | 电流、电压 | ±0.016% V / 0.17% A |

| 电子分析天平 | OHAUS Scout SE | 质量 | 0.001g |

| 低温恒温槽 | Biosafer - 1020DC | 温度 | ±0.05 K |

| 蠕动泵 | LONGER BT300 - 2J | 体积流率 | — |

| 电极液蠕动泵 | Kamoer KCP PRO2-N40 | 体积流率 | ±5% ml·min-1 |

| 可调直流电阻器 | ZX92A | 电阻 | ±0.1%Ω |

| 名称 | 参数 | 符号 | 单位 | 数值 |

|---|---|---|---|---|

| RED反应器外形 | 电池单元数 | N | — | 40 |

| 长 | — | cm | 25 | |

| 宽 | — | cm | 20 | |

| 电极 | 长 | — | cm | 10 |

| 宽 | — | cm | 10 | |

| 网孔 | — | mm×mm | 1×3 | |

| 离子交换膜 | 选择性系数① | αCEM | — | 0.96 |

| αAEM | — | 0.95 | ||

| 面电阻② | RCEM | Ω·cm2 | 6.1 | |

| RAEM | Ω·cm2 | 3.5 | ||

| 膜厚 | δm | mm | 0.16 | |

| 水渗透率 | — | ml·bar-1·m-2·h-1③ | 3.5,3 | |

| 爆破强度 | — | kg·cm-2 | 4.7,5 | |

| 丝网隔垫 | 隔垫厚 | δ | mm | 0.22 |

| 孔隙率 | ε | % | 67 | |

| 阻挡系数 | f | — | 1.73 | |

| 遮蔽系数 | β | — | 2.02 |

Table 2 Basic parameters of each part in RED reactor

| 名称 | 参数 | 符号 | 单位 | 数值 |

|---|---|---|---|---|

| RED反应器外形 | 电池单元数 | N | — | 40 |

| 长 | — | cm | 25 | |

| 宽 | — | cm | 20 | |

| 电极 | 长 | — | cm | 10 |

| 宽 | — | cm | 10 | |

| 网孔 | — | mm×mm | 1×3 | |

| 离子交换膜 | 选择性系数① | αCEM | — | 0.96 |

| αAEM | — | 0.95 | ||

| 面电阻② | RCEM | Ω·cm2 | 6.1 | |

| RAEM | Ω·cm2 | 3.5 | ||

| 膜厚 | δm | mm | 0.16 | |

| 水渗透率 | — | ml·bar-1·m-2·h-1③ | 3.5,3 | |

| 爆破强度 | — | kg·cm-2 | 4.7,5 | |

| 丝网隔垫 | 隔垫厚 | δ | mm | 0.22 |

| 孔隙率 | ε | % | 67 | |

| 阻挡系数 | f | — | 1.73 | |

| 遮蔽系数 | β | — | 2.02 |

| 浓度/(mol·L-1) | 过膜流速/ (cm·s-1) | 输出电流/A | |

|---|---|---|---|

| 稀溶液 | 浓溶液 | ||

| 0.01~0.15 | 1~5 | 0.1~0.5 | 0.1~0.35 |

Table 3 Ranges of experimental parameters

| 浓度/(mol·L-1) | 过膜流速/ (cm·s-1) | 输出电流/A | |

|---|---|---|---|

| 稀溶液 | 浓溶液 | ||

| 0.01~0.15 | 1~5 | 0.1~0.5 | 0.1~0.35 |

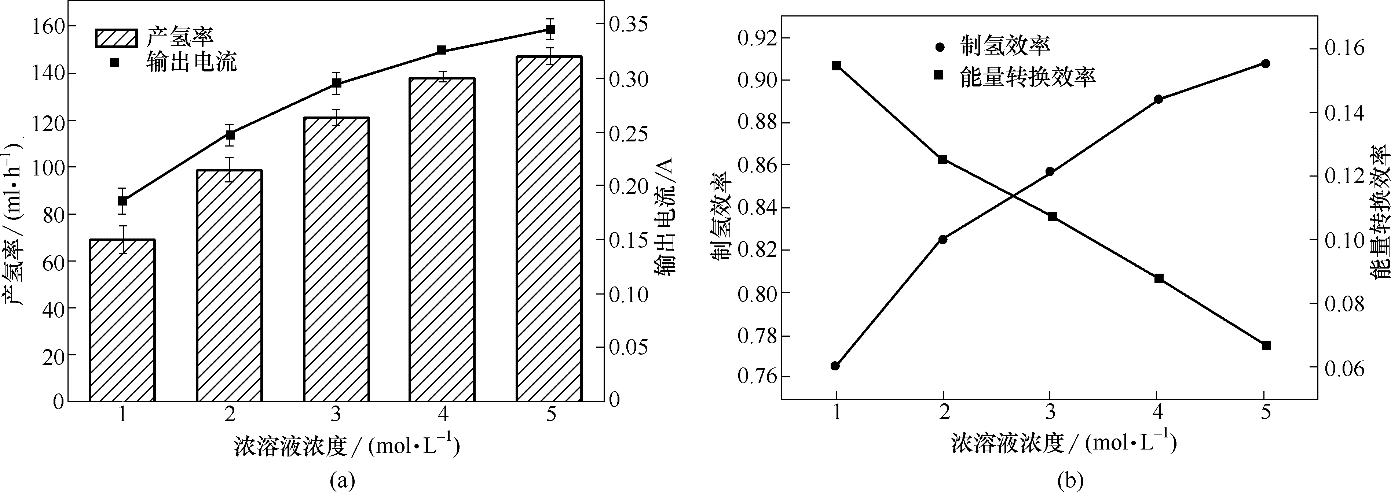

Fig.4 Variations of short circuit current, hydrogen production rate, hydrogen production and energy conversion efficiency of RED reactor with inlet concentration of HC

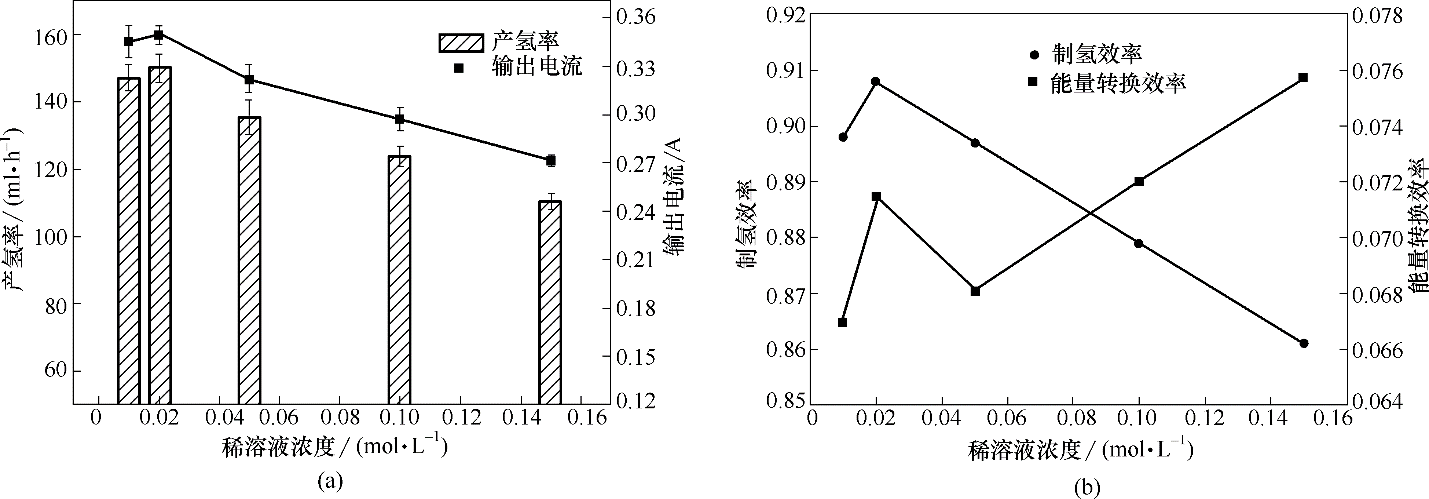

Fig.5 Variations of short circuit current, hydrogen production rate, hydrogen production and energy conversion efficiency of RED reactor with inlet concentration of LC

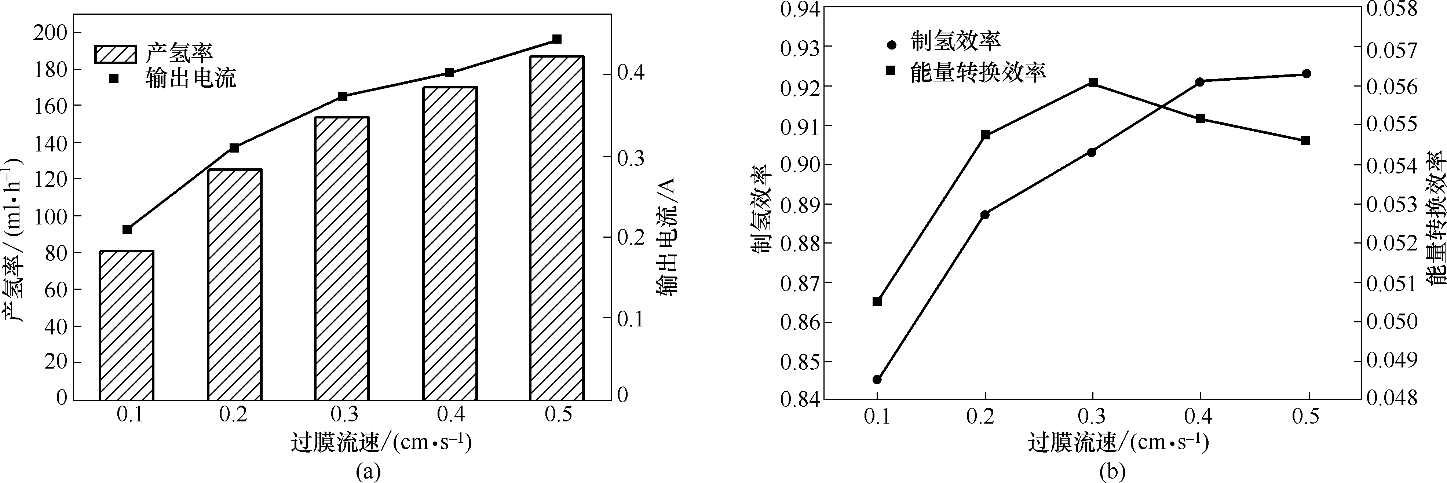

Fig.6 Variations of short circuit current, hydrogen production rate, hydrogen production and energy conversion efficiency of RED reactor with solution flow velocity on membrane

| 1 | Momirlan M, Veziroglu T N. The properties of hydrogen as fuel tomorrow in sustainable energy system for a cleaner planet[J]. International Journal of Hydrogen Energy, 2005, 30(7): 795-802. |

| 2 | Lei Q, Wang B G, Wang P C, et al. Hydrogen generation with acid/alkaline amphoteric water electrolysis[J]. Journal of Energy Chemistry, 2019, 38: 162-169. |

| 3 | Santos D M F, Sequeira C A C, Figueiredo J L. Hydrogen production by alkaline water electrolysis[J]. Quimica Nova, 2013, 36(8): 1176-1193. |

| 4 | Zeng K, Zhang D K. Recent progress in alkaline water electrolysis for hydrogen production and applications[J]. Progress in Energy and Combustion Science, 2010, 36(3): 307-326. |

| 5 | 温福宇, 杨金辉, 宗旭, 等. 太阳能光催化制氢研究进展[J]. 化学进展, 2009, 21(11): 2285-2302. |

| Wen F Y, Yang J H, Zong X, et al. Photocatalytic hydrogen production utilizing solar energy[J]. Progress in Chemistry, 2009, 21(11): 2285-2302. | |

| 6 | 吴曦, 徐士鸣. 一种低品位热能驱动的电极液自循环式制氢方法: 201910103003.0[P]. 2019-02-01. |

| Wu X, Xu S M. Low-grade heat energy driven electrode liquid self-circulating hydrogen production method: 201910103003.0[P]. 2019-02-01. | |

| 7 | Khawaji A D, Kutubkhanah I K, Wie J M. Advances in seawater desalination technologies[J]. Desalination, 2008, 221(1/2/3): 47-69. |

| 8 | Xu S M, Xu L, Wu X, et al. Air-gap diffusion distillation: theory and experiment[J]. Desalination, 2019, 467: 64-78. |

| 9 | 解利昕, 李凭力, 王世昌. 海水淡化技术现状及各种淡化方法评述[J]. 化工进展, 2003, 22(10): 1081-1084. |

| Xie L X, Li P L, Wang S C. A review of seawater desalination and comparison of desalting processes[J]. Chemical Industry and Engineering Progress, 2003, 22(10): 1081-1084. | |

| 10 | Hatzell M C, Zhu X P, Logan B E. Simultaneous hydrogen generation and waste acid neutralization in a reverse electrodialysis system[J]. ACS Sustainable Chemistry & Engineering, 2014, 2(9): 2211-2216. |

| 11 | Chen X, Jiang C, Zhang Y, et al. Storable hydrogen production by reverse electro-electrodialysis (REED) [J]. Journal of Membrane Science, 2017, 544: 397-405. |

| 12 | 徐士鸣, 吴德兵, 吴曦, 等. 氯化锂溶液为工质的溶液浓差发电实验研究[J]. 大连理工大学学报, 2017, 57(4): 337-343. |

| Xu S M, Wu D B, Wu X, et al. Experimental study of solution concentration difference power generation with lithium chloride solution as working fluid[J]. Journal of Dalian University of Technology, 2017, 57(4): 337-343. | |

| 13 | 徐士鸣, 张凯, 吴曦, 等. 电流与浓差对逆电渗析电堆内质量传递的影响[J]. 化工学报, 2018, 69(10): 4206-4215. |

| Xu S M, Zhang K, Wu X, et al. Influence of current density and concentration difference between solutions on mass transfer in reverse electro-dialysis stack[J]. CIESC Journal, 2018, 69(10): 4206-4215. | |

| 14 | 吴德兵, 徐士鸣, 吴曦, 等. 不同单价电解质水溶液对逆电渗析电堆工作特性的影响[J]. 化工进展, 2019, 38(6): 2738-2744. |

| Wu D B, Xu S M, Wu X, et al. Influences of different monovalent electrolyte aqueous solution on the performance characteristics of reverse electrodialysis stack[J]. Chemical Industry and Engineering Progress, 2019, 38(6): 2738-2744. | |

| 15 | 徐士鸣, 何其琛, 吴曦, 等. 顺、逆流串联电路逆电渗析电堆发电系统能量转换效率研究[J]. 大连理工大学学报, 2019, 59(1): 20-27. |

| Xu S M, He Q C, Wu X, et al. Investigation on energy conversion efficiency of series RED stacks power generation system in solution co-flow or counter-flow[J]. Journal of Dalian University of Technology, 2019, 59(1): 20-27. | |

| 16 | 何其琛, 徐士鸣, 吴曦, 等. 顺流串联逆电渗析电堆数对能量转换效率的影响研究[J]. 膜科学与技术, 2018, 38(5): 23-30. |

| He Q C, Xu S M, Wu X, et al. Study on the influence of series RED stack numbers on energy conversion efficiency in co-flow RED system[J]. Membrane Science and Technology, 2018, 38(5): 23-30. | |

| 17 | Hu J Y, Xu S M, Wu X, et al. Theoretical simulation and evaluation for the performance of the hybrid multi-effect distillation—reverse electrodialysis power generation system[J]. Desalination, 2018, 443: 172-183. |

| 18 | 徐士鸣, 徐志杰, 吴曦, 等. 溶液浓差能驱动的逆电渗析有机废水氧化降解机理研究[J]. 环境科学学报, 2018, 38(12): 4642-4651. |

| Xu S M, Xu Z J, Wu X, et al. Study on the mechanism of organic wastewater oxidation degradation with reverse electrodialysis powered by concentration gradient energy of solutions[J]. Acta Scientiae Circumstantiae, 2018, 38(12): 4642-4651. | |

| 19 | 徐士鸣, 冷强, 吴曦, 等. 逆电渗析反应器阴、阳极联合降解酸性橙Ⅱ实验研究[J]. 环境科学学报, 2019, 39(7): 2163-2171. |

| Xu S M, Leng Q, Wu X, et al. Experimental investigate on the joint degradation for acid Orange 7 by anode and cathode in RED reactor[J]. Acta Scientiae Circumstantiae, 2019, 39(7): 2163-2171. | |

| 20 | Vermaas D A, Veerman J, Yip N Y, et al. High efficiency in energy generation from salinity gradients with reverse electrodialysis[J]. ACS Sustainable Chemistry & Engineering, 2013, 1(10): 1295-1302. |

| 21 | Post J W, Hamelers H V M, Buisman C J N. Energy recovery from controlled mixing salt and fresh water with a reverse electrodialysis system[J]. Environmental Science & Technology, 2008, 42(15): 5785-5790. |

| 22 | Tufa R A, Rugiero E, Chanda D, et al. Salinity gradient power-reverse electrodialysis and alkaline polymer electrolyte water electrolysis for hydrogen production[J]. Journal of Membrane Science, 2016, 514: 155-164. |

| 23 | Kim Y, Logan B E. Hydrogen production from inexhaustible supplies of fresh and salt water using microbial reverse-electrodialysis electrolysis cells[J]. Proc. Natl. Acad. Sci. USA, 2011, 108: 16176-16181. |

| 24 | Hatzell M C, Ivanov I, Cusick R D, et al. Comparison of hydrogen production and electrical power generation for energy capture in closed-loop ammonium bicarbonate reverse electrodialysis systems[J]. Physical Chemistry Chemical Physics, 2014, 16(4): 1632-1638. |

| 25 | Millet P, Grigoriev S. Water electrolysis technologies[M]//Renewable Hydrogen Technologies: Production, Purification, Storage, Applications and Safety. Elsevier, 2013: 19-41. |

| 26 | Nam J Y, Cusick R D, Kim Y, et al. Hydrogen generation in microbial reverse-electrodialysis electrolysis cells using a heat-regenerated salt solution[J]. Environmental Science and Technology, 2012, 46(9): 5240-5246. |

| 27 | Veerman J, Saakes M, Metz S J, et al. Reverse electrodialysis: a validated process model for design and optimization[J]. Chemical Engineering Journal, 2011, 166(1): 256-268. |

| 28 | Hong S K, Kim C S, Hwang K S, et al. Experimental and numerical studies on pressure drop in reverse electrodialysis: effect of unit cell configuration[J]. Journal of Mechanical Science and Technology, 2016, 30(11): 5287-5292. |

| 29 | Hu J Y, Xu S M, Wu X, et al. Exergy analysis for the multi-effect distillation - reverse electrodialysis heat engine[J]. Desalination, 2019, 467: 158-169. |

| 30 | Hu J Y, Xu S M, Wu X, et al. Multi-stage reverse electrodialysis: strategies to harvest salinity gradient energy[J]. Energy Conversion and Management, 2019, 183: 803-815. |

| 31 | Schiebahn S, Grube T, Robinius M, et al. Power to gas: technological overview, systems analysis and economic assessment for a case study in Germany[J]. International Journal of Hydrogen Energy, 2015, 40(12): 4285-4294. |

| [1] | Congqi HUANG, Yimei WU, Jianye CHEN, Shuangquan SHAO. Simulation study of thermal management system of alkaline water electrolysis device for hydrogen production [J]. CIESC Journal, 2023, 74(S1): 320-328. |

| [2] | Jiaqi YUAN, Zheng LIU, Rui HUANG, Lefu ZHANG, Denghui HE. Investigation on energy conversion characteristics of vortex pump under bubble inflow [J]. CIESC Journal, 2023, 74(9): 3807-3820. |

| [3] | Yaxin ZHAO, Xueqin ZHANG, Rongzhu WANG, Guo SUN, Shanjing YAO, Dongqiang LIN. Removal of monoclonal antibody aggregates with ion exchange chromatography by flow-through mode [J]. CIESC Journal, 2023, 74(9): 3879-3887. |

| [4] | Yan GAO, Peng WU, Chao SHANG, Zejun HU, Xiaodong CHEN. Preparation of magnetic agarose microspheres based on a two-fluid nozzle and their protein adsorption properties [J]. CIESC Journal, 2023, 74(8): 3457-3471. |

| [5] | Yali HU, Junyong HU, Suxia MA, Yukun SUN, Xueyi TAN, Jiaxin HUANG, Fengyuan YANG. Development of novel working fluid and study on electrochemical characteristics of reverse electrodialysis heat engine [J]. CIESC Journal, 2023, 74(8): 3513-3521. |

| [6] | Zhaoguang CHEN, Yuxiang JIA, Meng WANG. Modeling neutralization dialysis desalination driven by low concentration waste acid and its validation [J]. CIESC Journal, 2023, 74(6): 2486-2494. |

| [7] | Xiaowen ZHOU, Jie DU, Zhanguo ZHANG, Guangwen XU. Study on the methane-pulsing reduction characteristics of Fe2O3-Al2O3 oxygen carrier [J]. CIESC Journal, 2023, 74(6): 2611-2623. |

| [8] | Kuikui HAN, Xianglong TAN, Jinzhi LI, Ting YANG, Chun ZHANG, Yongfen ZHANG, Hongquan LIU, Zhongwei YU, Xuehong GU. Four-channel hollow fiber MFI zeolite membrane for the separation of xylene isomers [J]. CIESC Journal, 2023, 74(6): 2468-2476. |

| [9] | Yong LI, Jiaqi GAO, Chao DU, Yali ZHAO, Boqiong LI, Qianqian SHEN, Husheng JIA, Jinbo XUE. Construction of Ni@C@TiO2 core-shell dual-heterojunctions for advanced photo-thermal catalytic hydrogen generation [J]. CIESC Journal, 2023, 74(6): 2458-2467. |

| [10] | Caihong LIN, Li WANG, Yu WU, Peng LIU, Jiangfeng YANG, Jinping LI. Effect of alkali cations in zeolites on adsorption and separation of CO2/N2O [J]. CIESC Journal, 2023, 74(5): 2013-2021. |

| [11] | Rong WANG, Yonghong WANG, Xinru ZHANG, Jinping LI. Construction of 6FDA-based polyimide carbon molecular sieve membranes for gas separation and its application [J]. CIESC Journal, 2023, 74(4): 1433-1445. |

| [12] | Xiaoxuan WANG, Xiaohong HU, Yunan LU, Shiyong WANG, Fengxian FAN. Numerical simulation of flow characteristics in a rotating membrane filter [J]. CIESC Journal, 2023, 74(4): 1489-1498. |

| [13] | Xiangshang CHEN, Zhenjie MA, Xihua REN, Yue JIA, Xiaolong LYU, Huayan CHEN. Preparation and mass transfer efficiency of three-dimensional network extraction membrane [J]. CIESC Journal, 2023, 74(3): 1126-1133. |

| [14] | Sheng’an ZHANG, Guilian LIU. Multi-objective optimization of high-efficiency solar water electrolysis hydrogen production system and its performance [J]. CIESC Journal, 2023, 74(3): 1260-1274. |

| [15] | Min LI, Xueru YAN, Xinlei LIU. Advances in benzimidazole-linked polymer adsorbents and membranes [J]. CIESC Journal, 2023, 74(2): 599-616. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||