CIESC Journal ›› 2025, Vol. 76 ›› Issue (S1): 418-425.DOI: 10.11949/0438-1157.20241279

• Energy and environmental engineering • Previous Articles

Ting HE1( ), Kai ZHANG1, Wensheng LIN2, Liqiong CHEN1, Jiafu CHEN1

), Kai ZHANG1, Wensheng LIN2, Liqiong CHEN1, Jiafu CHEN1

Received:2024-11-11

Revised:2024-11-19

Online:2025-06-26

Published:2025-06-25

Contact:

Ting HE

通讯作者:

何婷

作者简介:何婷(1995—),女,博士,副研究员,heting199503@163.com

基金资助:CLC Number:

Ting HE, Kai ZHANG, Wensheng LIN, Liqiong CHEN, Jiafu CHEN. Research on integrated process of cryogenic CO2 removal under supercritical pressure and liquefaction for biogas[J]. CIESC Journal, 2025, 76(S1): 418-425.

何婷, 张开, 林文胜, 陈利琼, 陈家富. 沼气超临界压力低温脱碳-液化耦合流程研究[J]. 化工学报, 2025, 76(S1): 418-425.

Add to citation manager EndNote|Ris|BibTeX

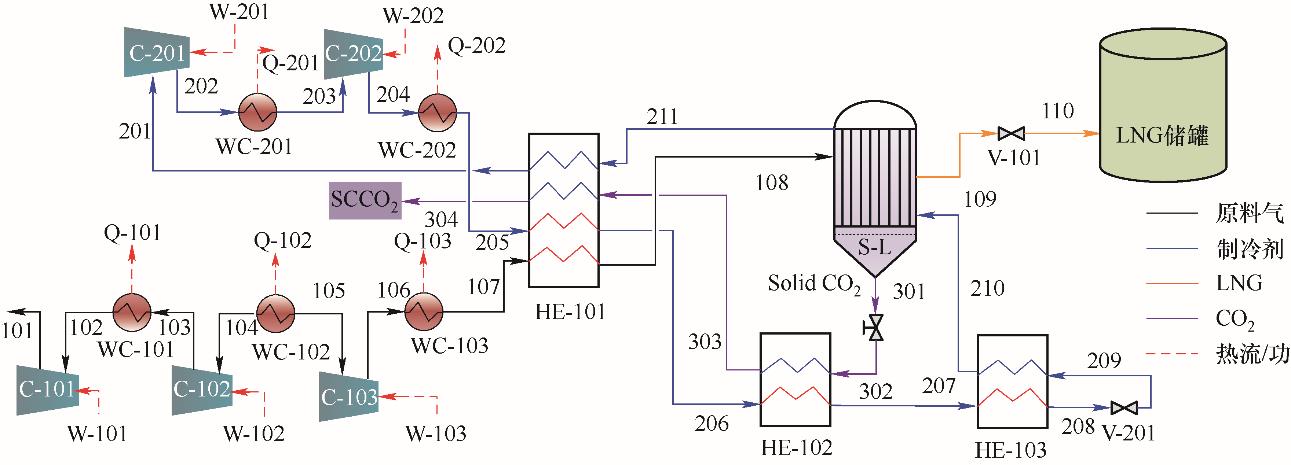

Fig.3 Integrated cryogenic CO2 removal under supercritical pressure and liquefaction process for biogasC—compressor;HE—heat exchanger;Q—heat flow;S-L—solid-liquid separator;V—valve;W—work;WC—water-cooler

| 参数 | 数值 | |

|---|---|---|

| 假设条件 | 水冷器出口温度 | 35℃ |

| 设备压降 | 0 | |

| 最小换热温差 | 3℃ | |

| 压缩机绝热效率 | 85% | |

| 遗传算法参数 | ||

| 交叉概率 | ||

Table 1 Parameter settings for process optimization

| 参数 | 数值 | |

|---|---|---|

| 假设条件 | 水冷器出口温度 | 35℃ |

| 设备压降 | 0 | |

| 最小换热温差 | 3℃ | |

| 压缩机绝热效率 | 85% | |

| 遗传算法参数 | ||

| 交叉概率 | ||

| 优化变量 | 下限 | 上限 |

|---|---|---|

| N201-C1 /(kmol/h) | 0 | 600 |

| N201-C2 /(kmol/h) | 0 | 600 |

| N201-C3 /(kmol/h) | 0 | 600 |

| N201-C4 /(kmol/h) | 0 | 600 |

| P204/kPa | 1800 | 3500 |

| P208/kPa | 110 | 250 |

| T206/℃ | -50 | -10 |

| T208/℃ | -135 | -100 |

Table 2 Upper and lower bounds of parameters to be optimized

| 优化变量 | 下限 | 上限 |

|---|---|---|

| N201-C1 /(kmol/h) | 0 | 600 |

| N201-C2 /(kmol/h) | 0 | 600 |

| N201-C3 /(kmol/h) | 0 | 600 |

| N201-C4 /(kmol/h) | 0 | 600 |

| P204/kPa | 1800 | 3500 |

| P208/kPa | 110 | 250 |

| T206/℃ | -50 | -10 |

| T208/℃ | -135 | -100 |

| 物流 | 温度/℃ | 压力/kPa | 摩尔流量/(kmol/h) | CO2 含量/% | CH4 含量/% | |

|---|---|---|---|---|---|---|

| 原料气侧 | 101 | 35 | 101 | 1000 | 30 | 70 |

| 107 | 35 | 8500 | 1000 | 30 | 70 | |

| 108 | -40 | 8500 | 1000 | 30 | 70 | |

| 109 | -131 | 8500 | 703.5 | 0.05 | 99.95 | |

| 110 | -130 | 1000 | 703.5 | 0.05 | 99.95 | |

| 301 | -131 | 8500 | 296.5 | 100 | 0 | |

| 304 | 30 | 8500 | 296.5 | 100 | 0 | |

| 混合制冷剂 | 201 | 32 | 130 | 1064 | ||

| 205 | 35 | 2560 | 1064 | |||

| 206 | -30 | 2560 | 1064 | |||

| 208 | -130 | 2560 | 1064 | |||

| 209 | -135.9 | 130 | 1064 | |||

| 211 | -43.2 | 130 | 1064 | |||

Table 3 Key process parameters

| 物流 | 温度/℃ | 压力/kPa | 摩尔流量/(kmol/h) | CO2 含量/% | CH4 含量/% | |

|---|---|---|---|---|---|---|

| 原料气侧 | 101 | 35 | 101 | 1000 | 30 | 70 |

| 107 | 35 | 8500 | 1000 | 30 | 70 | |

| 108 | -40 | 8500 | 1000 | 30 | 70 | |

| 109 | -131 | 8500 | 703.5 | 0.05 | 99.95 | |

| 110 | -130 | 1000 | 703.5 | 0.05 | 99.95 | |

| 301 | -131 | 8500 | 296.5 | 100 | 0 | |

| 304 | 30 | 8500 | 296.5 | 100 | 0 | |

| 混合制冷剂 | 201 | 32 | 130 | 1064 | ||

| 205 | 35 | 2560 | 1064 | |||

| 206 | -30 | 2560 | 1064 | |||

| 208 | -130 | 2560 | 1064 | |||

| 209 | -135.9 | 130 | 1064 | |||

| 211 | -43.2 | 130 | 1064 | |||

| 流程 | 比功耗/(kWh/kg LNG) | 比功耗降低幅度/% |

|---|---|---|

| 本研究 | 0.6149 | — |

| 双塔精馏[ | 2.07 | 70.3 |

| 化学吸收[ | 1.54 | 60.1 |

| 低压凝华[ | 1.574 | 60.9 |

Table 4 Comparison between this study and other studies

| 流程 | 比功耗/(kWh/kg LNG) | 比功耗降低幅度/% |

|---|---|---|

| 本研究 | 0.6149 | — |

| 双塔精馏[ | 2.07 | 70.3 |

| 化学吸收[ | 1.54 | 60.1 |

| 低压凝华[ | 1.574 | 60.9 |

| CO2含量/% | 混合制冷剂流量/(kmol/h) | 制冷剂组分含量 | |||

|---|---|---|---|---|---|

| 甲烷 | 乙烷 | 丙烷 | 正丁烷 | ||

| 10 | 1340 | 0.220149 | 0.35597 | 0.10597 | 0.31791 |

| 15 | 1279 | 0.248632 | 0.308835 | 0.111024 | 0.331509 |

| 20 | 1210 | 0.247934 | 0.293388 | 0.123967 | 0.334711 |

| 25 | 1140 | 0.245614 | 0.280702 | 0.131579 | 0.342105 |

| 30 | 1064 | 0.23496241 | 0.28195489 | 0.13345865 | 0.34962406 |

Table 5 Parameters of the refrigeration cycle under different CO2 contents

| CO2含量/% | 混合制冷剂流量/(kmol/h) | 制冷剂组分含量 | |||

|---|---|---|---|---|---|

| 甲烷 | 乙烷 | 丙烷 | 正丁烷 | ||

| 10 | 1340 | 0.220149 | 0.35597 | 0.10597 | 0.31791 |

| 15 | 1279 | 0.248632 | 0.308835 | 0.111024 | 0.331509 |

| 20 | 1210 | 0.247934 | 0.293388 | 0.123967 | 0.334711 |

| 25 | 1140 | 0.245614 | 0.280702 | 0.131579 | 0.342105 |

| 30 | 1064 | 0.23496241 | 0.28195489 | 0.13345865 | 0.34962406 |

| 13 | Baccioli A, Antonelli M, Frigo S, et al. Small scale bio-LNG plant: comparison of different biogas upgrading techniques[J]. Applied Energy, 2018, 217: 328-335. |

| 14 | Ryan J M, Schaffert F W. CO2 recovery by the Ryan/Holmes process[J]. Chemical Engineering Progress, 1984, 80(10): 53-56. |

| 15 | Berstad D, Anantharaman R, Nekså P. Low-temperature CO2 capture technologies — applications and potential[J]. International Journal of Refrigeration, 2013, 36(5): 1403-1416. |

| 16 | Roussanaly S, Anantharaman R, Lindqvist K. Multi-criteria analyses of two solvent and one low-temperature concepts for acid gas removal from natural gas[J]. Journal of Natural Gas Science and Engineering, 2014, 20: 38-49. |

| 17 | Pellegrini L A. Process for the removal of CO2 from acid gas: EP13774252.4[P]. 2015-09-16. |

| 18 | Valencia J A, Denton R D. Method and apparatus for separating carbon dioxide and other acid gases from methane by the use of distillation and a controlled freezing zone: US04533372A[P]. 1985-08-06. |

| 19 | Thomas E R, Denton R D. Conceptual studies for CO2/natural gas separation using the controlled freeze zone (CFZ) process[J]. Gas Separation & Purification, 1988, 2(2): 84-89. |

| 20 | Northrop P S, Valencia J A. The CFZTM process: a cryogenic method for handling high-CO2 and H2S gas reserves and facilitating geosequestration of CO2 and acid gases[J]. Energy Procedia, 2009, 1(1): 171-177. |

| 21 | Hart A, Gnanendran N. Cryogenic CO2 capture in natural gas[J]. Energy Procedia, 2009, 1(1): 697-706. |

| 22 | Babar M, Bustam M A, Maulud A S, et al. Enhanced cryogenic packed bed with optimal CO2 removal from natural gas; a joint computational and experimental approach[J]. Cryogenics, 2020, 105: 103010. |

| 23 | Baccanelli M, Langé S, Rocco M V, et al. Low temperature techniques for natural gas purification and LNG production: an energy and exergy analysis[J]. Applied Energy, 2016, 180: 546-559. |

| 24 | Naquash A, Qyyum M A, Haider J, et al. Renewable LNG production: biogas upgrading through CO2 solidification integrated with single-loop mixed refrigerant biomethane liquefaction process[J]. Energy Conversion Management, 2021, 243: 114363. |

| 1 | 曾金繁. 醇胺和膜分离结合的沼气脱碳工艺流程模拟研究[D]. 上海: 上海交通大学, 2021. |

| Zeng J F. Process simulation and parameter optimization of CO2 removal by alkanolamine and membrane for biogas purification[D]. Shanghai: Shanghai Jiao Tong University, 2021. | |

| 2 | 中国沼气学会. 中国沼气行业“双碳”发展报告[R]. 北京: 中国沼气协会, 2021. |

| China Biogas Society. Report on the “double carbon” development of China's biogas industry[R]. Beijing: China Biogas Society, 2021. | |

| 3 | 尹龙天. 基于MEA-乙醇吸收的旋转床用于沼气中CO2脱除性能与模拟研究[D]. 北京: 北京化工大学, 2021. |

| Yin L T. Study on the performance and simulation of CO2 removal from biogas by a rotating bed based on MEA-ethanol absorption[D]. Beijing: Beijing University of Chemical Technology, 2021. | |

| 4 | 曾金繁, 巨永林. 采用醇胺法的沼气脱碳工艺流程模拟及优化[J]. 现代化工, 2021, 41(8): 224-229. |

| Zeng J F, Ju Y L. Process simulation and parameter optimization of alkanolamine route for removing CO2 from biogas[J]. Modern Chemical Industry, 2021, 41(8): 224-229. | |

| 5 | 周淑霞. 沼气液化制取生物质LNG关键技术研究[D]. 济南: 山东大学, 2012. |

| Zhou S X. Research on key technologies on liquefied production of biomass LNG from biogas[D]. Jinan: Shandong University, 2013. | |

| 6 | He T, Si B, Gundersen T, et al. Integrated ethane recovery and cryogenic carbon capture in a dual mixed refrigerant natural gas liquefaction process [J]. Energy, 2024, 290: 130125. |

| 7 | 洪宗平, 叶楚梅, 吴洪, 等. 天然气脱碳技术研究进展[J]. 化工学报, 2021, 72(12): 6030-6048. |

| Hong Z P, Ye C M, Wu H, et al. Research progress in CO2 removal technology of natural gas[J]. CIESC Journal, 2021, 72(12): 6030-6048. | |

| 8 | He T, Liu Z, Son H, et al. Comparative analysis of cryogenic distillation and chemical absorption for carbon capture in integrated natural gas liquefaction processes[J]. Journal of Cleaner Production, 2024, 383: 135264. |

| 9 | 何婷, 林文胜. 基于余热利用的活化MDEA法脱除CO2的天然气液化系统[J]. 化工学报, 2021, 72(S1): 453-460. |

| He T, Lin W S. Natural gas liquefaction system with activated MDEA method for CO2 removal based on waste heat utilization[J]. CIESC Journal, 2021, 72(S1): 453-460. | |

| 10 | Baena-Moreno F M, Saché E, Pastor-Pérez L, et al. Membrane-based technologies for biogas upgrading: a review[J]. Environmental Chemistry Letters, 2020, 18(5): 1649-1658. |

| 11 | Yusuf N, Almomani F. Recent advances in biogas purifying technologies: process design and economic considerations[J]. Energy, 2023, 265: 126163. |

| 12 | Bi Y J, Ju Y L. Review on cryogenic technologies for CO2 removal from natural gas[J]. Frontiers in Energy, 2022, 16(5): 793-811. |

| 25 | Hashemi S E, Sarker S, Lien K M, et al. Cryogenic vs. absorption biogas upgrading in liquefied biomethane production — an energy efficiency analysis[J]. Fuel, 2019, 245: 294-304. |

| 26 | Pellegrini L A, De Guido G, Langé S. Biogas to liquefied biomethane via cryogenic upgrading technologies[J]. Renewable Energy, 2018, 124: 75-83. |

| 27 | Spitoni M, Pierantozzi M, Comodi G, et al. Theoretical evaluation and optimization of a cryogenic technology for carbon dioxide separation and methane liquefaction from biogas[J]. Journal of Natural Gas Science and Engineering, 2019, 62: 132-143. |

| 28 | Xiong X J, Lin W S, Gu A Z. Integration of CO2 cryogenic removal with a natural gas pressurized liquefaction process using gas expansion refrigeration[J]. Energy, 2015, 93: 1-9. |

| 29 | Babar M, Bustam M A, Ali A, et al. Thermodynamic data for cryogenic carbon dioxide capture from natural gas: a review[J]. Cryogenics, 2019, 102: 85-104. |

| 30 | Peng D Y, Robinson D B. A new two-constant equation of state[J]. Industrial & Engineering Chemistry Fundamentals, 1976, 15: 59-64. |

| 31 | Smith J M, Ness H, Abbott M M. Introduction to Chemical Engineering Thermodynamics[M]. New York: McGraw-Hill, 1975. |

| [1] | Xinquan SHA, Ran HU, Lei DING, Zhenhua JIANG, Yinong WU. Development and testing of an independent two-stage valved linear compressor for space applications [J]. CIESC Journal, 2025, 76(S1): 114-122. |

| [2] |

Jichao GUO, Xiaoxiao XU, Yunlong SUN.

Airflow simulation and optimization based on |

| [3] | Yifan SHI, Gang KE, Hao CHEN, Xiaosheng HUANG, Fang YE, Chengjiao LI, Hang GUO. Simulation of temperature control in large-scale high and low temperature environmental laboratory [J]. CIESC Journal, 2025, 76(S1): 268-280. |

| [4] | Fanchen KONG, Shuo ZHANG, Mingsheng TANG, Huiming ZOU, Zhouhang HU, Changqing TIAN. Simulation of gas bearings in carbon dioxide linear compressors [J]. CIESC Journal, 2025, 76(S1): 281-288. |

| [5] | Ruijie MA, Zixuan HUANG, Xueqian GUAN, Guangjin CHEN, Bei LIU. Efficient ethane and methane separation using ZIF-8/DMPU slurry [J]. CIESC Journal, 2025, 76(5): 2262-2269. |

| [6] | Weijie ZHANG, Jiawen HE, Yiming ZHANG, Deli LI, Guangya HU, Xiao CAI, Jinhua WANG, Zuohua HUANG. Effects of fuel stratification on flow field and flame structure of multi-stage swirling methane combustion [J]. CIESC Journal, 2025, 76(4): 1754-1764. |

| [7] | Zhaoxue ZHANG, Zhengyu LI, Wenhui CUI, Qian WANG, Zhiping WANG, Linghui GONG. Research on cascade recovery and utilization of cold energy in liquid hydrogen energy storage based on liquid neon - liquid nitrogen [J]. CIESC Journal, 2025, 76(4): 1731-1741. |

| [8] | Lu LIU, Kai WAN, Wenyue WANG, Tai WANG, Jiancheng TANG, Shaoheng WANG. Study on orthohydrogen and parahydrogen conversion coupled flow and heat transfer based on helium expansion refrigeration [J]. CIESC Journal, 2025, 76(4): 1513-1522. |

| [9] | Yichen ZHANG, Wenbiao ZHANG, Haoyang LI, Xiaoyang NING. Flow measurement of gas-liquid two-phase CO2 using Venturi tube based on dual differential pressure model [J]. CIESC Journal, 2025, 76(4): 1493-1503. |

| [10] | Zhenglei HE, Dingding HU. Multi-objective optimization of papermaking wastewater based on multi-agent reinforcement learning [J]. CIESC Journal, 2025, 76(4): 1617-1634. |

| [11] | Chengcheng XU, Suola SHAO, Wenjian WEI, Xu ZHENG. Research on heating performance of direct-condensation thermal storage aluminum radiant heating panel under multiple working conditions [J]. CIESC Journal, 2025, 76(4): 1545-1558. |

| [12] | Xiangrui ZHAI, Wei ZHANG, Qianqian ZHANG, Jiuzhe QU, Xufei YANG, Yajun DENG, Bo YU. Active heat transfer enhancement technology for solid-liquid phase change energy storage based on external field disturbance [J]. CIESC Journal, 2025, 76(4): 1432-1446. |

| [13] | Wen CHAN, Wan YU, Gang WANG, Huashan SU, Fenxia HUANG, Tao HU. Thermodynamic and economic analyses and dual-objective optimization of Allam cycle with improved regenerator layout [J]. CIESC Journal, 2025, 76(4): 1680-1692. |

| [14] | Junliang HUO, Zhiguo TANG, Zongjun QIU, Yuhua FENG, Xu JIANG, Leyi WANG, Yu YANG, Fanfan QIAO, Yifan HE, Jianliang YU. Experimental research on risk of freezing and plugging during CO2 pipeline venting under throttling effect [J]. CIESC Journal, 2025, 76(4): 1898-1908. |

| [15] | Luochang WU, Zeyu YANG, Jianguo YAN, Xutao ZHU, Yang CHEN, Zichen WANG. Experimental study on convection heat transfer characteristics of supercritical carbon dioxide flowing in mini square channels [J]. CIESC Journal, 2025, 76(4): 1583-1594. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||