CIESC Journal ›› 2020, Vol. 71 ›› Issue (12): 5842-5853.DOI: 10.11949/0438-1157.20200627

• Material science and engineering, nanotechnology • Previous Articles Next Articles

LI Zihui1( ),JIANG Jing2(

),JIANG Jing2( ),JIN Zhangyong2,CAI Bozhi3,CAO Yongjun3,LI Qian1

),JIN Zhangyong2,CAI Bozhi3,CAO Yongjun3,LI Qian1

Received:2020-05-21

Revised:2020-06-30

Online:2020-12-05

Published:2020-12-05

Contact:

JIANG Jing

李子辉1( ),蒋晶2(

),蒋晶2( ),金章勇2,蔡泊志3,曹永俊3,李倩1

),金章勇2,蔡泊志3,曹永俊3,李倩1

通讯作者:

蒋晶

作者简介:李子辉(1995—),男,硕士研究生,基金资助:CLC Number:

LI Zihui,JIANG Jing,JIN Zhangyong,CAI Bozhi,CAO Yongjun,LI Qian. Preparation and oil absorption performance of biodegradable PCL/PLA open-cell foam material[J]. CIESC Journal, 2020, 71(12): 5842-5853.

李子辉,蒋晶,金章勇,蔡泊志,曹永俊,李倩. 生物可降解PCL/PLA开孔发泡材料制备及吸油性能[J]. 化工学报, 2020, 71(12): 5842-5853.

Add to citation manager EndNote|Ris|BibTeX

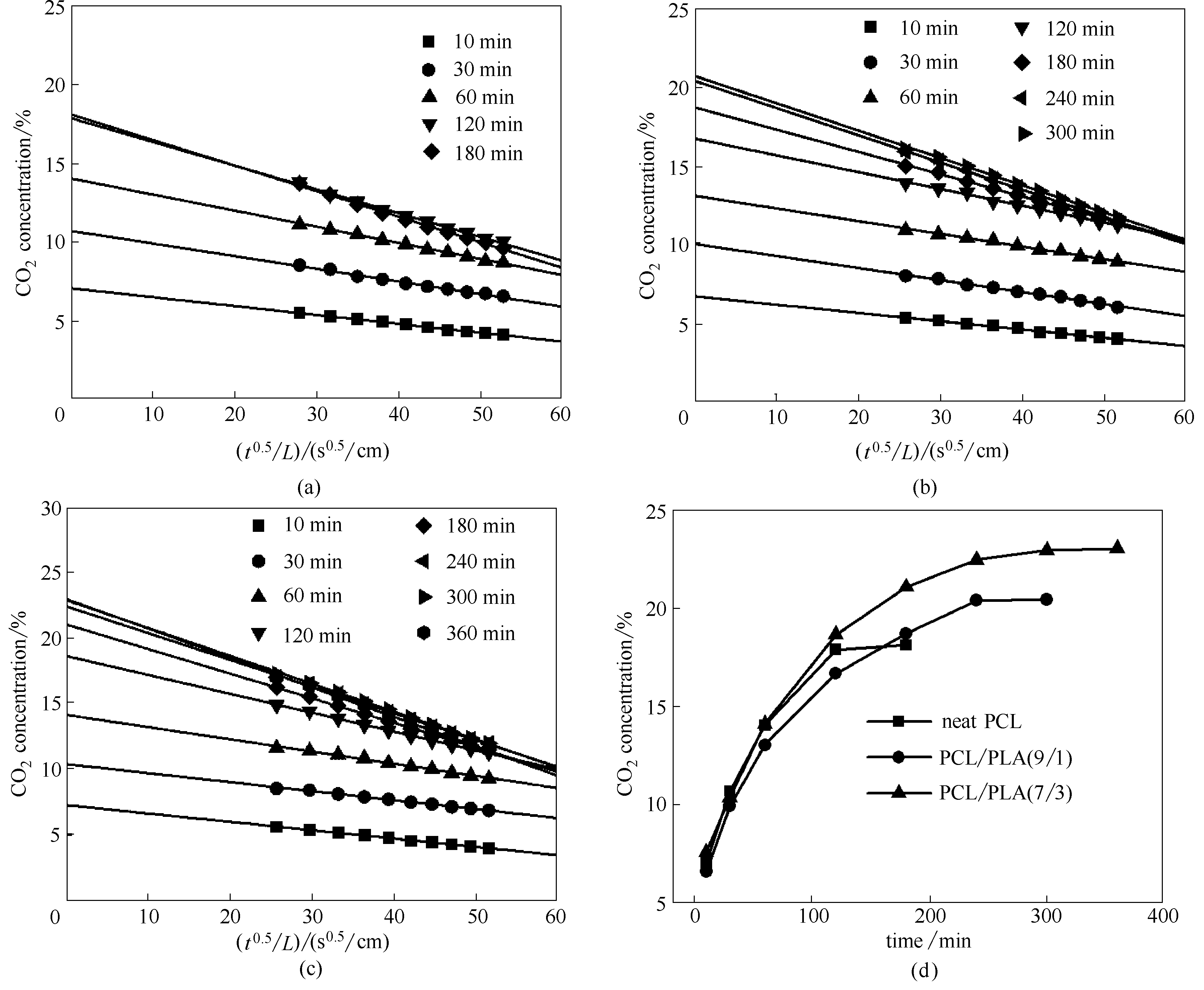

Fig.4 Desorption CO2 from neat PCL(a), PCL/PLA(9/1) (b), PCL/PLA(7/3) (c) after being fully saturated at 25℃, 12.41 MPa( linear fit line is drawn to show the extrapolated value at t=0) and CO2 uptake as a function of time at various PCL/PLA blends

Fig.9 Water contact angle results of foamed samples (a) and test for hydrophobic and lipophilic property of water (b), peanut oil (c), silicone oil (d)

| 1 | 张泽霆, 陈英, 陈东, 等. 化学洗涤法修复石油污染土壤研究现状[J]. 油气储运, 2019, 38(1): 20-25. |

| Zhang Z T, Chen Y, Chen D, et al. Research status on the remediation of petroleum contaminated soil by chemical cleaning [J]. Oil & Gas Storage and Transportation, 2019, 38(1): 20-25. | |

| 2 | Sun L, Ruan J, Lu M, et al. Combined effects of ocean acidification and crude oil pollution on tissue damage and lipid metabolism in embryo–larval development of marine medaka (Oryzias melastigma)[J]. Environmental Geochemistry and Health, 2019, 41(4): 1847-1860. |

| 3 | Koshlaf E, Shahsavari E, Aburto-Medina A, et al. Bioremediation potential of diesel-contaminated Libyan soil[J]. Ecotoxicology & Environmental Safety, 2016, 133: 297-305. |

| 4 | Guan Y, Cheng F, Pan Z. Superwetting polymeric three dimensional (3D) porous materials for oil/water separation: a review[J]. Polymers, 2019, 11(5): 806. |

| 5 | Li Z T, Lin B, Jiang L W, et al. Effective preparation of magnetic superhydrophobic Fe3O4/PU sponge for oil-water separation[J]. Applied Surface Science, 2018, 427: 56-64. |

| 6 | Zhang H, Zhen Q, Yan Y, et al. Polypropylene/polyester composite micro/nano-fabrics with linear valley-like surface structure for high oil absorption[J]. Materials Letters, 2020, 261: 127009. |

| 7 | Thakur K, Rajhans A, Kandasubramanian B. Starch/PVA hydrogels for oil/water separation[J]. Environmental Science and Pollution Research, 2019, 26(31): 32013-32028. |

| 8 | Fang, Y W, Bao J B, Yan H K, et al. Preparation of open‐cell foams from polymer blends by supercritical CO2 and their efficient oil‐absorbing performance [J]. AIChE Journal, 2016, 62(12): 4182-4185. |

| 9 | Li J J, Zhou Y N, Luo Z H. Polymeric materials with switchable superwettability for controllable oil/water separation: a comprehensive review[J]. Progress in Polymer Science, 2018, 87: 1-33. |

| 10 | Mi H Y, Jing X, Politowicz A L, et al. Highly compressible ultra-light anisotropic cellulose/graphene aerogel fabricated by bidirectional freeze drying for selective oil absorption[J]. Carbon, 2018, 132: 199-209. |

| 11 | Huang A, Jiang Y, Napiwocki B, et al. Fabrication of poly (ε-caprolactone) tissue engineering scaffolds with fibrillated and interconnected pores utilizing microcellular injection molding and polymer leaching[J]. RSC Advances, 2017, 7 (69): 43432-43444. |

| 12 | Kabir M E, Saha M C, Jeelani S. Effect of ultrasound sonication in carbon nanofibers/polyurethane foam composite[J]. Materials Science and Engineering: A, 2007, 459(1/2): 111-116. |

| 13 | Wang X, Pan Y, Shen C, et al. Facile thermally impacted water‐induced phase separation approach for the fabrication of skin-free thermoplastic polyurethane foam and its recyclable counterpart for oil–water separation[J]. Macromolecular Rapid Communications, 2018, 39(23): 1800635. |

| 14 | Hou J, Jiang J, Guo H, et al. Fabrication of fibrillated and interconnected porous poly(ε-caprolactone) vascular tissue engineering scaffolds by microcellular foaming and polymer leaching[J]. RSC Advances, 2020, 10(17): 10055-10066. |

| 15 | Zhang K, Wang Y, Jiang J, et al. Fabrication of highly interconnected porous poly(e-caprolactone) scaffolds with supercritical CO2 foaming and polymer leaching[J]. Journal of Materials Science, 2019, 54(6): 5112-5126. |

| 16 | Kong W, Bao J B, Wang J, et al. Preparation of open-cell polymer foams by CO2 assisted foaming of polymer blends[J]. Polymer, 2016, 90: 331-341. |

| 17 | 张义盛, 吴德峰, 张明. 聚己内酯/聚乳酸共混体系的相形态及其流变行为[J]. 化工学报, 2008, 59(10): 2644-2649. |

| Zhang Y S, Wu D F, Zhang M. Phase morphology and rheological behavior of poly (ε-caprolactone)/polylactide blend [J]. Journal of Chemical Industry and Engineering(China), 2008, 59(10): 2644-2649. | |

| 18 | Bartnikowski M, Dargaville T R, Ivanovski S, et al. Degradation mechanisms of polycaprolactone in the context of chemistry, geometry and environment[J]. Progress in Polymer Science, 2019, 96: 1-20. |

| 19 | Sun S, Li Q, Zhao N, et al. Preparation of highly interconnected porous poly (ε‐caprolactone)/poly (lactic acid) scaffolds via supercritical foaming[J]. Polymers for Advanced Technologies, 2018, 29(12): 3065-3074. |

| 20 | Zhang J, Yang S, Yang X, et al. Novel fabricating process for porous polyglycolic acid scaffolds by melt-foaming using supercritical carbon dioxide[J]. ACS Biomaterials Science & Engineering, 2018, 4(2): 694-706. |

| 21 | 蒋瑞, 胡冬冬, 刘涛, 等. 热塑性聚醚酯弹性体硬段含量对其超临界CO2发泡行为的影响[J]. 化工学报, 2020, 71(2): 871-878. |

| Jiang R, Hu D D, Liu T, et al. Effect of hard segment content on microcellular foaming process of thermoplastic polyether ester elastomer using supercritical CO2 as blowing agent [J]. CIESC Journal, 2020, 71(2): 871-878. | |

| 22 | Guo H, Kumar V. Some thermodynamic and kinetic low-temperature properties of the PC-CO2 system and morphological characteristics of solid-state PC nanofoams produced with liquid CO2[J]. Polymer, 2015, 56: 46-56. |

| 23 | Li Y, Mi J, Fu H, et al. Nanocellular foaming behaviors of chain-extended Poly(lactic acid) induced by isothermal crystallization[J]. ACS omega, 2019, 4(7): 12512-12523. |

| 24 | Shi D, Hu G H, Ke Z, et al. Relaxation behavior of polymer blends with complex morphologies: Palierne emulsion model for uncompatibilized and compatibilized PP/PA6 blends[J]. Polymer, 2006, 47(13): 4659-4666. |

| 25 | Zhou H, Zhao M, Qu Z, et al. Thermal and rheological properties of poly (lactic acid)/low-density polyethylene blends and their supercritical CO2 foaming behavior[J]. Journal of Polymers and the Environment, 2018, 26(9): 3564-3573. |

| 26 | Guo H, Jiang J, Li Z, et al. Solid-state supercritical CO2 foaming of PCL/PLGA blends: cell opening and compression behavior[J]. Journal of Polymers and the Environment, 2020, 28: 1880-1892. |

| 27 | Huang Y, Huo L, Zhang S, et al. Sulfonyl: a new application of electron-withdrawing substituent in highly efficient photovoltaic polymer[J]. Chemical Communications, 2011, 47(31): 8904-8906. |

| 28 | Yin D, Mi J, Zhou H, et al. Simple and feasible strategy to fabricate microcellular poly (butylene succinate) foams by chain extension and isothermal crystallization induction[J]. Journal of Applied Polymer Science, 2020, 137(26): 48850. |

| 29 | Ye J, Liao X, Xiao W, et al. The effects of molecular weight and supercritical CO2 on the phase morphology of organic solvent free porous scaffolds[J]. The Journal of Supercritical Fluids, 2018, 140: 279-289. |

| 30 | Qu Z, Yin D, Zhou H, et al. Cellular morphology evolution in nanocellular poly (lactic acid)/thermoplastic polyurethane blending foams in the presence of supercritical N2[J]. European Polymer Journal, 2019, 116: 291-301. |

| 31 | Arisetty S, Prasad A K, Advani S G. Metal foams as flow field and gas diffusion layer in direct methanol fuel cells[J]. Journal of Power Sources, 2007, 165(1): 49-57. |

| 32 | 王小峰, 蒋晶, 侯建华, 等. 化学物理联合微孔发泡成型制备聚己内酯多孔材料[J]. 化工学报, 2014, 65(6): 2386-2392. |

| Wang X F, Jiang J, Hou J H, et al. Fabrication of porous structure of poly(ε-caprolactone) via microcellular injection molding combined with chemical foaming [J]. CIESC Journal, 2014, 65(6): 2386-2392. | |

| 33 | 王明, 李星. 超临界二氧化碳技术制备的聚丙烯/三元乙丙橡胶开孔发泡材料的吸油行为[J]. 材料导报, 2018, 32(8): 1236-1240. |

| Wang M, Li X. Oil-absorbing behavior of PP/EPDM rubber blend open-cell foams prepared using supercritical CO2 technique [J]. Materials Reports, 2018, 32(8): 1236-1240. |

| [1] | Yifei ZHANG, Fangchen LIU, Shuangxing ZHANG, Wenjing DU. Performance analysis of printed circuit heat exchanger for supercritical carbon dioxide [J]. CIESC Journal, 2023, 74(S1): 183-190. |

| [2] | Rui HONG, Baoqiang YUAN, Wenjing DU. Analysis on mechanism of heat transfer deterioration of supercritical carbon dioxide in vertical upward tube [J]. CIESC Journal, 2023, 74(8): 3309-3319. |

| [3] | Bingguo ZHU, Jixiang HE, Jinliang XU, Bin PENG. Heat transfer characteristics of supercritical pressure CO2 in diverging/converging tube under cooling conditions [J]. CIESC Journal, 2023, 74(3): 1062-1072. |

| [4] | Senlin WANG, Zhaozhi LI, Yingjuan SHAO, Wenqi ZHONG. Numerical simulation on heat transfer deterioration of supercritical carbon dioxide in vertical tube [J]. CIESC Journal, 2022, 73(3): 1072-1082. |

| [5] | Jianguo YAN, Shumin ZHENG, Pengcheng GUO, Bo ZHANG, Zhenkai MAO. Prediction of heat transfer characteristics for supercritical CO2 based on GA-BP neural network [J]. CIESC Journal, 2021, 72(9): 4649-4657. |

| [6] | Ruqi YAN, Xuexing DING, Jie XU, Xianzhi HONG, Xin BAO. Flow field and steady performance of supercritical carbon dioxide dry gas seal based on turbulence model [J]. CIESC Journal, 2021, 72(8): 4292-4303. |

| [7] | Peng JIANG, Jinbo JIANG, Xudong PENG, Xiangkai MENG, Yi MA. Influence of heat transfer model on temperature and pressure distribution and steady state performance of CO2 dry gas seal under near critical condition [J]. CIESC Journal, 2021, 72(8): 4239-4254. |

| [8] | HONG Yanzhen, WANG Di, LI Zhuoyu, XU Yanan, WANG Hongtao, SU Yuzhong, PENG Li, LI Jun. Catalytic isomerization of α-terpineol to 1,8-cineole in supercritical carbon dioxide [J]. CIESC Journal, 2021, 72(7): 3680-3685. |

| [9] | JIANG Jinbo, TENG Liming, MENG Xiangkai, LI Jiyun, PENG Xudong. Dynamic characteristics of supercritical CO2 dry gas seal based on multi variables perturbation [J]. CIESC Journal, 2021, 72(4): 2190-2202. |

| [10] | Yigao LYU, Qing LI, Zhexi WEN. Thermal-hydraulic performance of sinusoidal channel printed circuit heat exchanger [J]. CIESC Journal, 2020, 71(S2): 142-151. |

| [11] | Qingdi KE, Jie YANG, Qiankun LI, Yaming TIAN. Structure analysis for refrigerator molding layer door based on polymer foaming simulation [J]. CIESC Journal, 2020, 71(S2): 273-280. |

| [12] | Ruqi YAN, Xianzhi HONG, Xin BAO, Jie XU, Xuexing DING. Phase-distribution regularity and sealing performance of supercritical carbon dioxide dry gas seal [J]. CIESC Journal, 2020, 71(8): 3681-3690. |

| [13] | Yu WAN, Min ZHANG, Yunxuan WENG, Chengtao LI. Effect of porogenic of yeast on adsorption and degradation of PVA/CMC hydrogel [J]. CIESC Journal, 2020, 71(4): 1828-1835. |

| [14] | Rui JIANG, Dongdong HU, Tao LIU, Ling ZHAO. Effect of hard segment content on microcellular foaming process of thermoplastic polyether ester elastomer using supercritical CO 2 as blowing agent [J]. CIESC Journal, 2020, 71(2): 871-878. |

| [15] | GUO Xiaolu,YU Jianliang,YAN Xingqing,XU Peng,XU Shuangqing. Research progress on leakage characteristics of supercritical CO2 pipeline [J]. CIESC Journal, 2020, 71(12): 5430-5442. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||