CIESC Journal ›› 2021, Vol. 72 ›› Issue (11): 5590-5597.DOI: 10.11949/0438-1157.20210721

• Catalysis, kinetics and reactors • Previous Articles Next Articles

Ding DING( ),Wenduo LU,Lu HOU,Anhui LU(

),Wenduo LU,Lu HOU,Anhui LU( )

)

Received:2021-05-27

Revised:2021-09-10

Online:2021-11-12

Published:2021-11-05

Contact:

Anhui LU

通讯作者:

陆安慧

作者简介:丁鼎(1996—),男,硕士研究生,基金资助:CLC Number:

Ding DING, Wenduo LU, Lu HOU, Anhui LU. Preparation of fibrous BPO4/SiO2 catalyst for oxidative dehydrogenation of propane[J]. CIESC Journal, 2021, 72(11): 5590-5597.

丁鼎, 陆文多, 侯璐, 陆安慧. 纤维状BPO4/SiO2催化剂的制备及其丙烷氧化脱氢性能[J]. 化工学报, 2021, 72(11): 5590-5597.

Add to citation manager EndNote|Ris|BibTeX

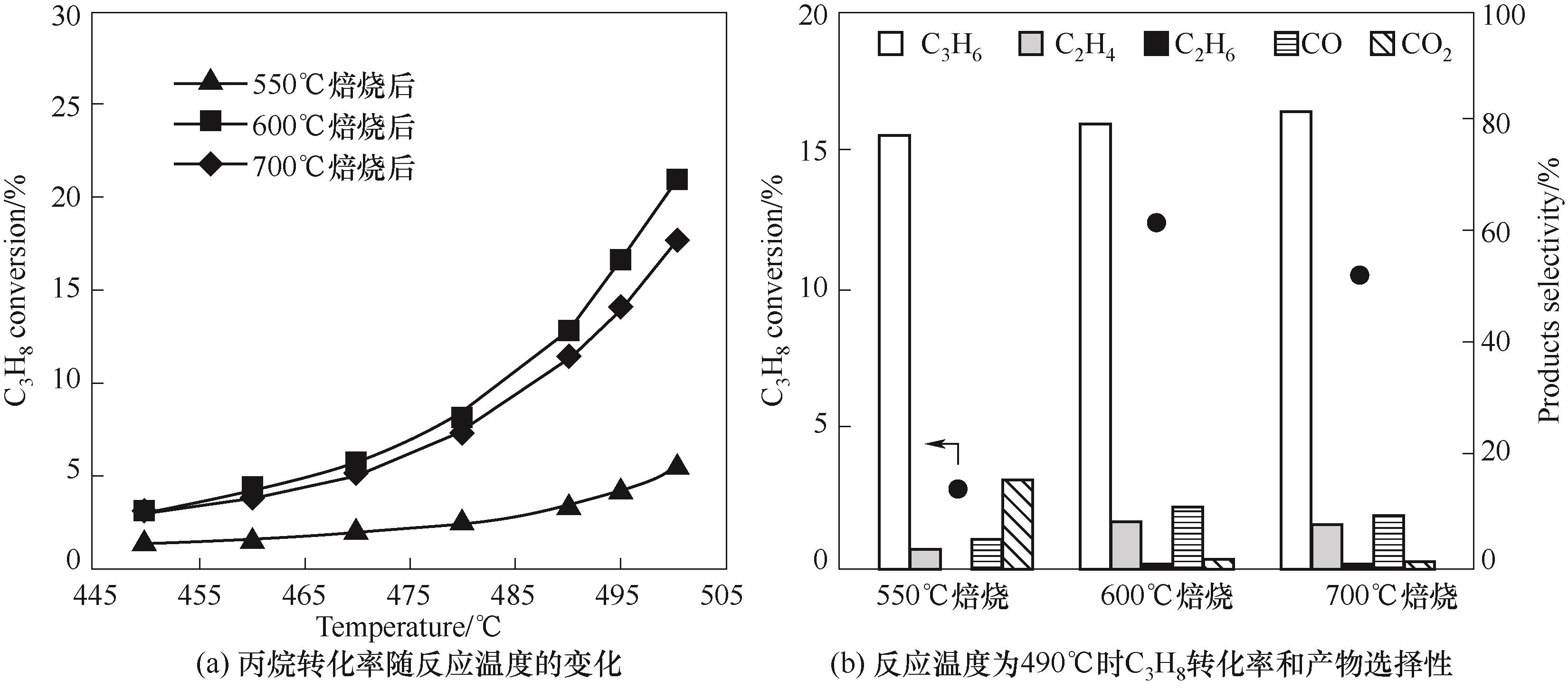

Fig.5 Catalytic performance of BPO4(3%)/SiO2 nanofibrous catalysts calcined at different temperatures (reaction conditions: 16.7%(vol) C3H8, 25.0%(vol) O2, 58.3%(vol) N2; total flow rate 12 ml·min-1)

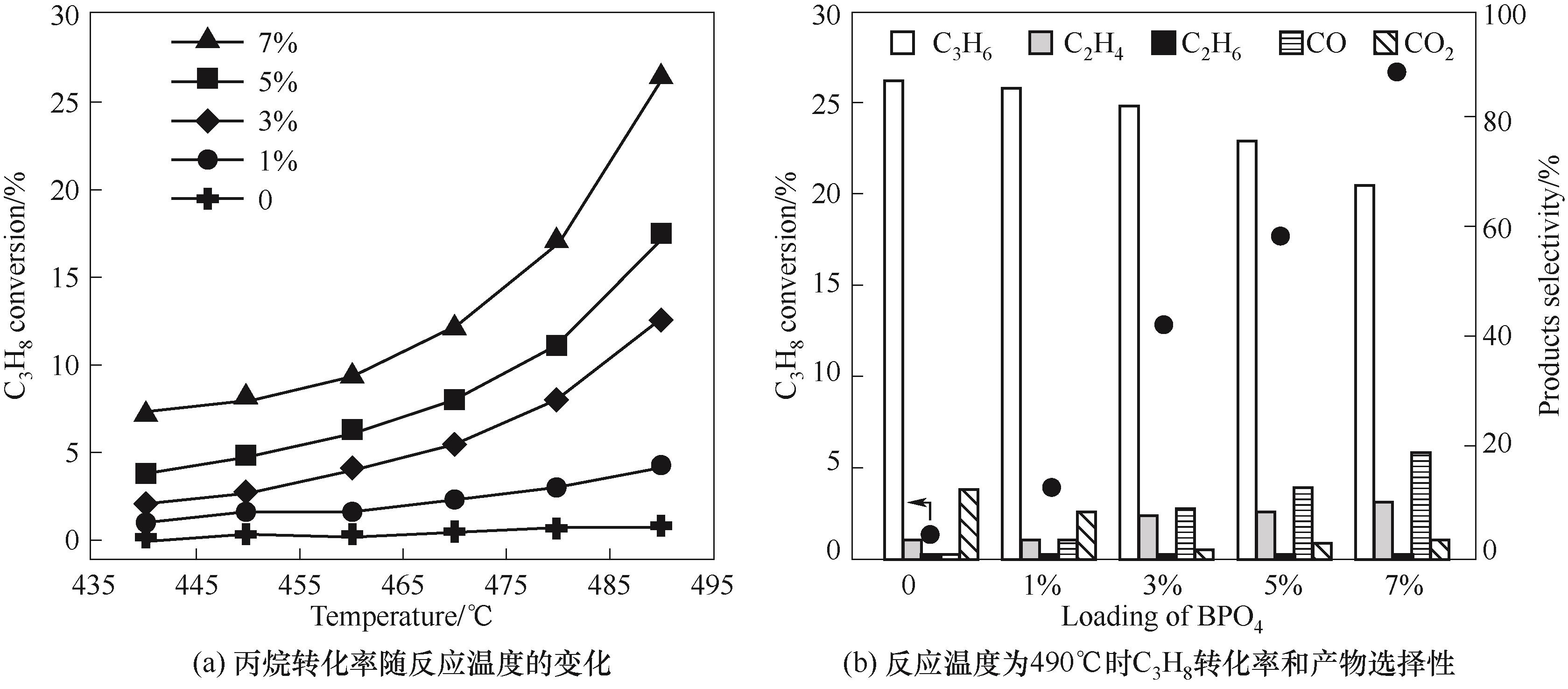

Fig.6 Catalytic performance of BPO4/SiO2 nanofibrous catalysts with different BPO4 loadings (reaction conditions: 16.7%(vol) C3H8, 25.0%(vol) O2, 58.3%(vol) N2; total flow rate 12 ml·min-1)

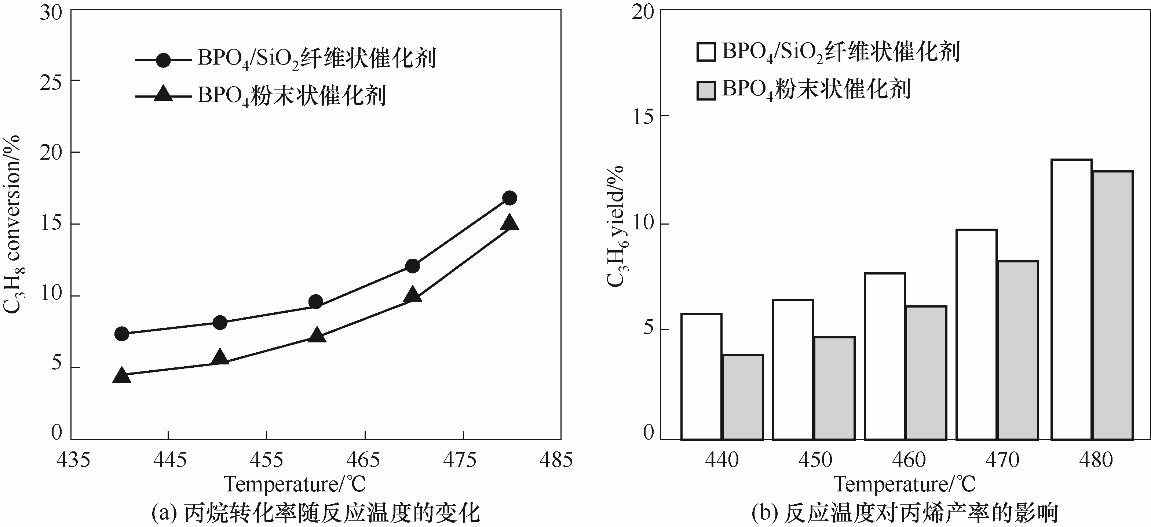

Fig.7 Comparison of the catalytic property of BPO4/SiO2 nanofibrous catalyst and the bulk BPO4 catalyst (reaction conditions: 16.7% C3H8, 25.0% O2, 58.3% N2; total flow rate 12 ml·min-1)

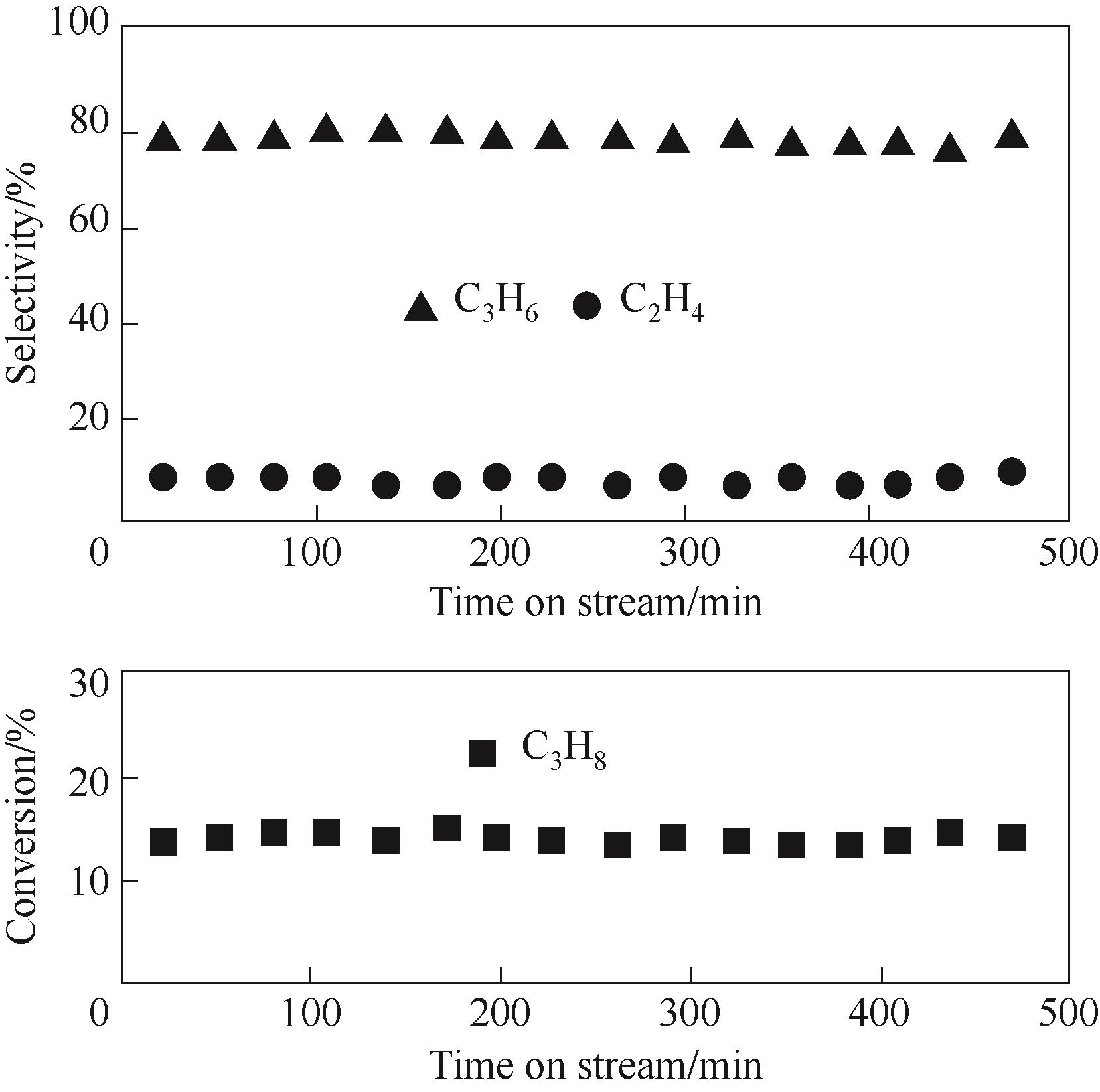

Fig.8 Catalytic stability tests over BPO4(7%)/SiO2 nanofibrous catalyst at 480℃ (reaction conditions: gas feed, 16.7% C3H8, 25.0% O2, 58.3% N2; total flow rate 12 ml·min-1)

| 1 | Sattler J J, Ruiz-Martinez J, Santillan-Jimenez E, et al. Catalytic dehydrogenation of light alkanes on metals and metal oxides[J]. Chemical Reviews, 2014, 114(20): 10613-10653. |

| 2 | Sheng J, Yan B, Lu W D, et al. Oxidative dehydrogenation of light alkanes to olefins on metal-free catalysts[J]. Chemical Society Reviews, 2021, 50(2): 1438-1468. |

| 3 | 戴伟, 罗晴, 王定博. 烯烃转化生产丙烯的研究进展[J]. 石油化工, 2008, 37(5): 425-433. |

| Dai W, Luo Q, Wang D B. Review of propylene production through olefins conversion[J]. Petrochemical Technology, 2008, 37(5): 425-433. | |

| 4 | 林少波, 单玉领, 隋志军, 等. 氧对丙烷脱氢反应体系影响的热力学分析[J]. 化工进展, 2015, 34(4): 970-975, 1006. |

| Lin S B, Shan Y L, Sui Z J, et al. Thermodynamic analysis of effects of oxygen addition on dehydrogenation of propane[J]. Chemical Industry and Engineering Progress, 2015, 34(4): 970-975, 1006. | |

| 5 | Shi L, Wang Y, Yan B, et al. Progress in selective oxidative dehydrogenation of light alkanes to olefins promoted by boron nitride catalysts[J]. Chemical Communications (Cambridge, England), 2018, 54(78): 10936-10946. |

| 6 | 张海娟, 高杰, 张浩楠, 等. 低碳烷烃深加工制烯烃技术的研究进展[J]. 石油化工, 2016, 45(12): 1411-1419. |

| Zhang H J, Gao J, Zhang H N, et al. Progresses in processes and catalysts for dehydrogenation of light paraffins to olefins[J]. Petrochemical Technology, 2016, 45(12): 1411-1419. | |

| 7 | Cavani F, Ballarini N, Cericola A. Oxidative dehydrogenation of ethane and propane: how far from commercial implementation? [J]. Catalysis Today, 2007, 127(1/2/3/4): 113-131. |

| 8 | De León M A, De Los Santos C, Latrónica L, et al. High catalytic activity at low temperature in oxidative dehydrogenation of propane with Cr-Al pillared clay[J]. Chemical Engineering Journal, 2014, 241: 336-343. |

| 9 | Grant J T, Carrero C A, Goeltl F, et al. Selective oxidative dehydrogenation of propane to propene using boron nitride catalysts[J]. Science, 2016, 354(6319): 1570-1573. |

| 10 | Tian J S, Tan J Q, Xu M L, et al. Propane oxidative dehydrogenation over highly selective hexagonal boron nitride catalysts: the role of oxidative coupling of methyl[J]. Science Advances, 2019, 5(3): eaav8063. |

| 11 | Zhang X Y, You R, Wei Z Y, et al. Radical chemistry and reaction mechanisms of propane oxidative dehydrogenation over hexagonal boron nitride catalysts[J]. Angewandte Chemie International Edition, 2020, 59(21): 8042-8046. |

| 12 | Venegas J M, Zhang Z S, Agbi T O, et al. Why boron nitride is such a selective catalyst for the oxidative dehydrogenation of propane[J]. Angewandte Chemie International Edition, 2020, 59(38): 16527-16535. |

| 13 | Shi L, Yan B, Shao D, et al. Selective oxidative dehydrogenation of ethane to ethylene over a hydroxylated boron nitride catalyst[J]. Chinese Journal of Catalysis, 2017, 38(2): 389-395. |

| 14 | Zhou Y L, Lin J, Li L, et al. Enhanced performance of boron nitride catalysts with induction period for the oxidative dehydrogenation of ethane to ethylene[J]. Journal of Catalysis, 2018, 365: 14-23. |

| 15 | Si C W, Lian Z, Olanrele S O, et al. Revealing the origin of the reactivity of metal-free boron nitride catalysts in oxidative dehydrogenation of propane[J]. Applied Surface Science, 2020, 519: 146241. |

| 16 | Lu W D, Gao X Q, Wang Q G, et al. Ordered macroporous boron phosphate crystals as metal-free catalysts for the oxidative dehydrogenation of propane[J]. Chinese Journal of Catalysis, 2020, 41(12): 1837-1845. |

| 17 | Xue J J, Wu T, Dai Y Q, et al. Electrospinning and electrospun nanofibers: methods, materials, and applications[J]. Chemical Reviews, 2019, 119(8): 5298-5415. |

| 18 | Dai Y Q, Liu W Y, Formo E, et al. Ceramic nanofibers fabricated by electrospinning and their applications in catalysis, environmental science, and energy technology[J]. Polymers for Advanced Technologies, 2011, 22(3): 326-338. |

| 19 | Yang G, Li X L, He Y, et al. From nano to micro to macro: Electrospun hierarchically structured polymeric fibers for biomedical applications[J]. Progress in Polymer Science, 2018, 81: 80-113. |

| 20 | 丁春立, 林帝出, 王德武, 等. 电纺及疏水改性制备CA/SiNPs-FAS超疏水复合膜及膜蒸馏脱盐研究[J]. 化工学报, 2018, 69(4): 1774-1782. |

| Ding C L, Lin D C, Wang D W, et al. Preparation of superhydrophobic CA/SiNPs-FAS electrospun nanofibrous membranes for direct contact membrane distillation[J]. CIESC Journal, 2018, 69(4): 1774-1782. | |

| 21 | 何璐铭, 辛忠, 高文莉, 等. 静电纺丝法制备高活性多孔Ni/SiO2甲烷化催化剂[J]. 化工学报, 2020, 71(11): 5007-5015. |

| He L M, Xin Z, Gao W L, et al. Highly efficient porous Ni/SiO2 catalysts prepared by electrospinning method for CO methanation[J]. CIESC Journal, 2020, 71(11): 5007-5015. | |

| 22 | Liu G, Zhang T D, Feng Y, et al. Sandwich-structured polymers with electrospun boron nitrides layers as high-temperature energy storage dielectrics[J]. Chemical Engineering Journal, 2020, 389: 124443. |

| 23 | Li S, Cui Z M, Li D M, et al. Hierarchically structured electrospinning nanofibers for catalysis and energy storage[J]. Composites Communications, 2019, 13: 1-11. |

| 24 | Kang H G, Zhu Y H, Yang X L, et al. A novel catalyst based on electrospun silver-doped silica fibers with ribbon morphology[J]. Journal of Colloid and Interface Science, 2010, 341(2): 303-310. |

| 25 | Zhu Y F, Ikoma T, Hanagata N, et al. Rattle-type Fe3O4@SiO2 hollow mesoporous spheres as carriers for drug delivery[J]. Small, 2010, 6(3): 471-478. |

| 26 | Yan B, Lu W D, Sheng J, et al. Electrospinning synthesis of porous boron-doped silica nanofibers for oxidative dehydrogenation of light alkanes[J]. Chinese Journal of Catalysis, 2021, 42(10): 1782-1789. |

| 27 | Ishigami M, Chen J H, Cullen W G, et al. Atomic structure of graphene on SiO2[J]. Nano Letters, 2007, 7(6): 1643-1648. |

| 28 | Li X, Zhi C Y, Hanagata N, et al. Boron nitride nanotubes functionalized with mesoporous silica for intracellular delivery of chemotherapy drugs[J]. Chemical Communications, 2013, 49(66): 7337-7339. |

| 29 | Feng S N, Zhang H J, Xu S, et al. Folate-conjugated, mesoporous silica functionalized boron nitride nanospheres for targeted delivery of doxorubicin[J]. Materials Science and Engineering: C, 2019, 96: 552-560. |

| 30 | Lu W D, Wang D Q, Zhao Z C, et al. Supported boron oxide catalysts for selective and low-temperature oxidative dehydrogenation of propane[J]. ACS Catalysis, 2019, 9(9): 8263-8270. |

| 31 | Wang Y, Li W C, Zhou Y X, et al. Boron nitride wash-coated cordierite monolithic catalyst showing high selectivity and productivity for oxidative dehydrogenation of propane[J]. Catalysis Today, 2020, 339: 62-66. |

| 32 | Zhou Y X, Wang Y, Lu W D, et al. A high propylene productivity over B2O3/SiO2@honeycomb cordierite catalyst for oxidative dehydrogenation of propane[J]. Chinese Journal of Chemical Engineering, 2020, 28(11): 2778-2784. |

| 33 | Sun G X, Bi J Q, Wang W L, et al. Enhancing mechanical properties of fused silica composites by introducing well-dispersed boron nitride nanosheets[J]. Ceramics International, 2018, 44(5): 5002-5009. |

| 34 | Li D, Zhang C R, Li B, et al. Preparation and mechanical properties of unidirectional boron nitride fibre reinforced silica matrix composites[J]. Materials & Design, 2012, 34: 401-405. |

| 35 | Namba S, Takagaki A, Jimura K, et al. Effects of ball-milling treatment on physicochemical properties and solid base activity of hexagonal boron nitrides[J]. Catalysis Science & Technology, 2019, 9(2): 302-309. |

| 36 | Lee D, Lee B, Park K H, et al. Scalable exfoliation process for highly soluble boron nitride nanoplatelets by hydroxide-assisted ball milling[J]. Nano Letters, 2015, 15(2): 1238-1244. |

| 37 | Chang M J, Cui W N, Liu J. Facile preparation of porous inorganic SiO2 nanofibrous membrane by electrospinning method[J]. Journal of Nanomaterials, 2017, 2017: 1-8. |

| 38 | Otomo R, Yamaguchi C, Iwaisako D, et al. Selective dehydration of 1, 2-propanediol to propanal over boron phosphate catalyst in the presence of steam[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(3): 3027-3033. |

| 39 | Wu Y J, Xu Y Z, Wang D J, et al. FT-IR spectroscopic investigation on the interaction between nylon 66 and lithium salts[J]. Journal of Applied Polymer Science, 2004, 91(5): 2869-2875. |

| 40 | Wu F, He L, Li W C, et al. Highly dispersed boron-nitride/CuOx-supported Au nanoparticles for catalytic CO oxidation at low temperatures[J]. Chinese Journal of Catalysis, 2021, 42(3): 388-395. |

| 41 | Qiu B, Jiang F, Lu W D, et al. Oxidative dehydrogenation of propane using layered borosilicate zeolite as the active and selective catalyst[J]. Journal of Catalysis, 2020, 385: 176-182. |

| 42 | Shi L, Wang D Q, Song W, et al. Edge-hydroxylated boron nitride for oxidative dehydrogenation of propane to propylene[J]. ChemCatChem, 2017, 9(10): 1720. |

| 43 | Belgamwar R, Rankin A G M, Maity A, et al. Boron nitride and oxide supported on dendritic fibrous nanosilica for catalytic oxidative dehydrogenation of propane[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(43): 16124-16135. |

| [1] | Yanpeng WU, Xiaoyu LI, Qiaoyang ZHONG. Experimental analysis on filtration performance of electrospun nanofibers with amphiphobic membrane of oily fine particles [J]. CIESC Journal, 2023, 74(S1): 259-264. |

| [2] | Xuejin YANG, Jintao YANG, Ping NING, Fang WANG, Xiaoshuang SONG, Lijuan JIA, Jiayu FENG. Research progress in dry purification technology of highly toxic gas PH3 [J]. CIESC Journal, 2023, 74(9): 3742-3755. |

| [3] | Shaoqi YANG, Shuheng ZHAO, Lungang CHEN, Chenguang WANG, Jianjun HU, Qing ZHOU, Longlong MA. Hydrodeoxygenation of lignin-derived compounds to alkanes in Raney Ni-protic ionic liquid system [J]. CIESC Journal, 2023, 74(9): 3697-3707. |

| [4] | Jie CHEN, Yongsheng LIN, Kai XIAO, Chen YANG, Ting QIU. Study on catalytic synthesis of sec-butanol by tunable choline-based basic ionic liquids [J]. CIESC Journal, 2023, 74(9): 3716-3730. |

| [5] | Yitong LI, Hang GUO, Hao CHEN, Fang YE. Study on operating conditions of proton exchange membrane fuel cells with non-uniform catalyst distributions [J]. CIESC Journal, 2023, 74(9): 3831-3840. |

| [6] | Xin YANG, Xiao PENG, Kairu XUE, Mengwei SU, Yan WU. Preparation of molecularly imprinted-TiO2 and its properties of photoelectrocatalytic degradation of solubilized PHE [J]. CIESC Journal, 2023, 74(8): 3564-3571. |

| [7] | Tianhua CHEN, Zhaoxuan LIU, Qun HAN, Chengbin ZHANG, Wenming LI. Research progress and influencing factors of the heat transfer enhancement of spray cooling [J]. CIESC Journal, 2023, 74(8): 3149-3170. |

| [8] | Xingzhi HU, Haoyan ZHANG, Jingkun ZHUANG, Yuqing FAN, Kaiyin ZHANG, Jun XIANG. Preparation and microwave absorption properties of carbon nanofibers embedded with ultra-small CeO2 nanoparticles [J]. CIESC Journal, 2023, 74(8): 3584-3596. |

| [9] | Feifei YANG, Shixi ZHAO, Wei ZHOU, Zhonghai NI. Sn doped In2O3 catalyst for selective hydrogenation of CO2 to methanol [J]. CIESC Journal, 2023, 74(8): 3366-3374. |

| [10] | Kaixuan LI, Wei TAN, Manyu ZHANG, Zhihao XU, Xuyu WANG, Hongbing JI. Design of cobalt-nitrogen-carbon/activated carbon rich in zero valent cobalt active site and application of catalytic oxidation of formaldehyde [J]. CIESC Journal, 2023, 74(8): 3342-3352. |

| [11] | Xianheng YI, Wu ZHOU, Xiaoshu CAI, Tianyi CAI. Measurable range of nanoparticle concentration using optical fiber backward dynamic light scattering [J]. CIESC Journal, 2023, 74(8): 3320-3328. |

| [12] | Yuming TU, Gaoyan SHAO, Jianjie CHEN, Feng LIU, Shichao TIAN, Zhiyong ZHOU, Zhongqi REN. Advances in the design, synthesis and application of calcium-based catalysts [J]. CIESC Journal, 2023, 74(7): 2717-2734. |

| [13] | Qiyu ZHANG, Lijun GAO, Yuhang SU, Xiaobo MA, Yicheng WANG, Yating ZHANG, Chao HU. Recent advances in carbon-based catalysts for electrochemical reduction of carbon dioxide [J]. CIESC Journal, 2023, 74(7): 2753-2772. |

| [14] | Pan LI, Junyang MA, Zhihao CHEN, Li WANG, Yun GUO. Effect of the morphology of Ru/α-MnO2 on NH3-SCO performance [J]. CIESC Journal, 2023, 74(7): 2908-2918. |

| [15] | Yajie YU, Jingru LI, Shufeng ZHOU, Qingbiao LI, Guowu ZHAN. Construction of nanomaterial and integrated catalyst based on biological template: a review [J]. CIESC Journal, 2023, 74(7): 2735-2752. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||