CIESC Journal ›› 2024, Vol. 75 ›› Issue (9): 3133-3151.DOI: 10.11949/0438-1157.20240358

• Catalysis, kinetics and reactors • Previous Articles Next Articles

Shuyue LI1( ), Huan WANG1,2, Shaoqiang ZHOU2, Zhihong MAO1, Yongmin ZHANG1(

), Huan WANG1,2, Shaoqiang ZHOU2, Zhihong MAO1, Yongmin ZHANG1( ), Junwu WANG1, Xiuhua WU2

), Junwu WANG1, Xiuhua WU2

Received:2024-04-02

Revised:2024-05-07

Online:2024-10-10

Published:2024-09-25

Contact:

Yongmin ZHANG

李舒月1( ), 王欢1,2, 周少强2, 毛志宏1, 张永民1(

), 王欢1,2, 周少强2, 毛志宏1, 张永民1( ), 王军武1, 吴秀花2

), 王军武1, 吴秀花2

通讯作者:

张永民

作者简介:李舒月(1992—),女,博士,讲师,shuyue.li@cup.edu.cn

基金资助:CLC Number:

Shuyue LI, Huan WANG, Shaoqiang ZHOU, Zhihong MAO, Yongmin ZHANG, Junwu WANG, Xiuhua WU. Numerical simulation of hydrogen reduction of U3O8 in fluidized bed reactors using CPFD method[J]. CIESC Journal, 2024, 75(9): 3133-3151.

李舒月, 王欢, 周少强, 毛志宏, 张永民, 王军武, 吴秀花. 基于CPFD方法的U3O8氢还原流化床反应器数值模拟[J]. 化工学报, 2024, 75(9): 3133-3151.

Add to citation manager EndNote|Ris|BibTeX

| 操作参数 | 数值 |

|---|---|

| U3O8进料 | |

| 进料量 | |

| 进料温度 | 866 K |

| 密度 | 6690 kg/m3 |

| 气体进料 | |

| 进气量(H2过量80%) | 氢气量:3025.21 mol/h 氮气量:1008 mol/h 折算气速:0.064 m/s |

| 固体产物出口 | |

| 温度 | 866 K |

| 压力 | 400 kPa |

| 出料量 | 707.56 kg/h |

| UO2密度 | 6870 kg/m3 |

| 壁面条件 | 绝热壁面 |

Table 1 Main operating parameters of U3O8 reduction fluidized bed reactor

| 操作参数 | 数值 |

|---|---|

| U3O8进料 | |

| 进料量 | |

| 进料温度 | 866 K |

| 密度 | 6690 kg/m3 |

| 气体进料 | |

| 进气量(H2过量80%) | 氢气量:3025.21 mol/h 氮气量:1008 mol/h 折算气速:0.064 m/s |

| 固体产物出口 | |

| 温度 | 866 K |

| 压力 | 400 kPa |

| 出料量 | 707.56 kg/h |

| UO2密度 | 6870 kg/m3 |

| 壁面条件 | 绝热壁面 |

| 参数 | 数值 |

|---|---|

| 颗粒堆积体积分数 | 0.56 |

| 最大碰撞动量再定向系数/% | 40 |

| 切向颗粒-壁面碰撞恢复系数 | 0.99 |

| 法向颗粒-壁面碰撞恢复系数 | 0.3 |

| 回弹系数 | 0 |

| 颗粒应力模型的压力常数ps/Pa | 10 |

| 颗粒应力模型的无量纲常数β | 3 |

| 计算颗粒代表的实际颗粒数 | 125 |

| 颗粒应力模型的无量纲常数 α | 10-7 |

| 湍流模型 | LES |

Table 2 Simulation parameters and initial boundary conditions

| 参数 | 数值 |

|---|---|

| 颗粒堆积体积分数 | 0.56 |

| 最大碰撞动量再定向系数/% | 40 |

| 切向颗粒-壁面碰撞恢复系数 | 0.99 |

| 法向颗粒-壁面碰撞恢复系数 | 0.3 |

| 回弹系数 | 0 |

| 颗粒应力模型的压力常数ps/Pa | 10 |

| 颗粒应力模型的无量纲常数β | 3 |

| 计算颗粒代表的实际颗粒数 | 125 |

| 颗粒应力模型的无量纲常数 α | 10-7 |

| 湍流模型 | LES |

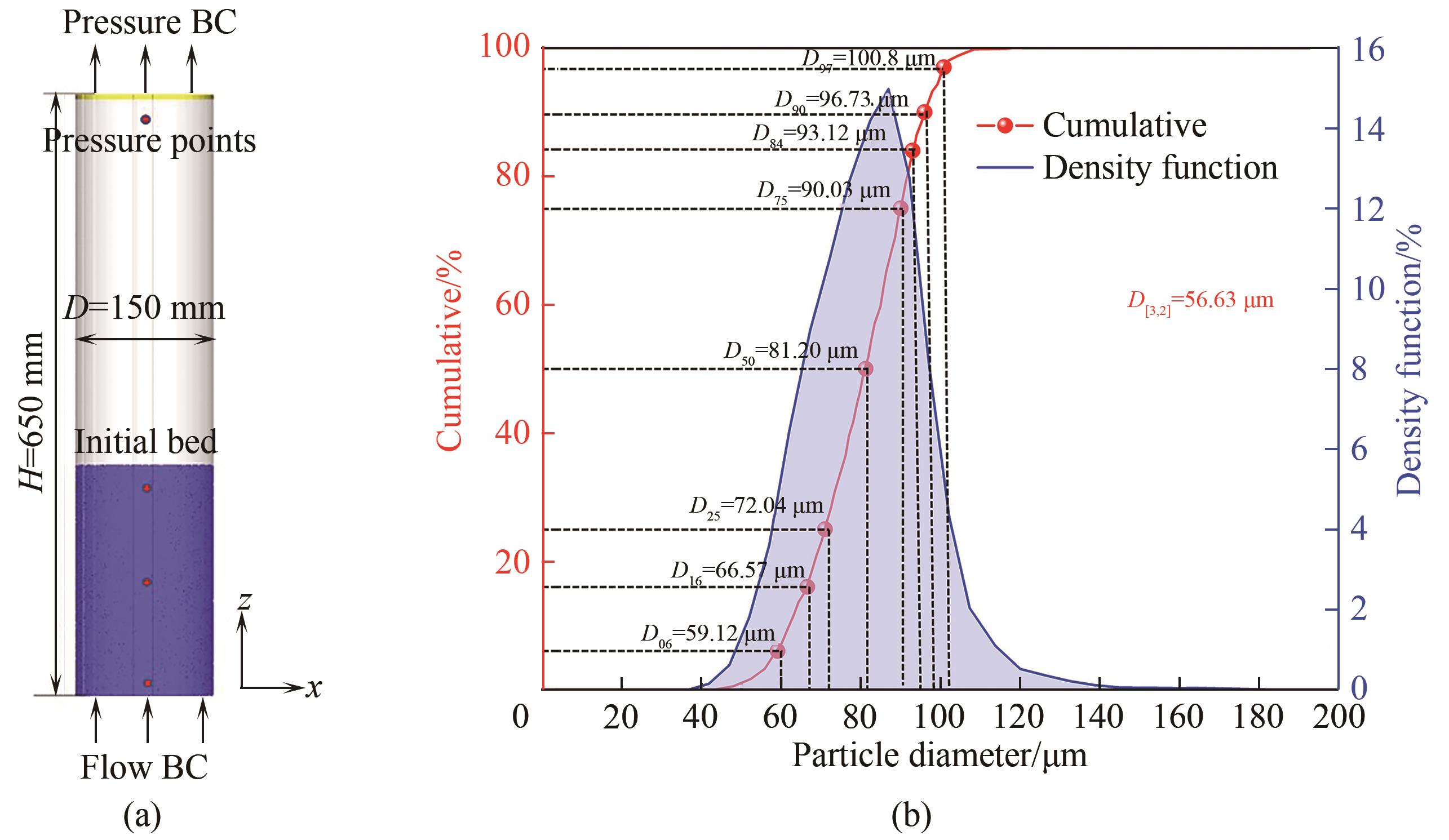

Fig.5 (a) Three-dimensional model of a bubbling fluidized bed constructed based on laboratory apparatus; (b) particle size distribution of iron oxide particles

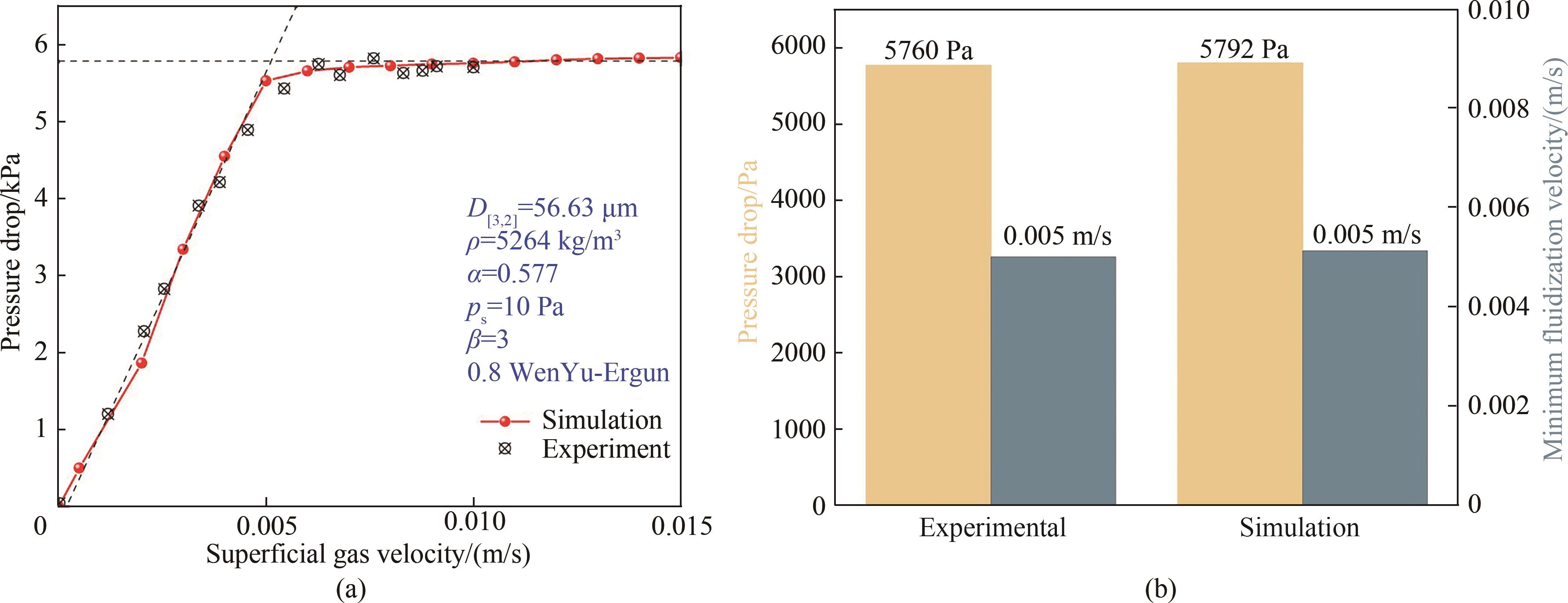

Fig.6 (a) Characteristics of bed pressure drop under different fluidization velocities; (b) comparison between experimental and simulation results for maximum bed pressure drop and predicted values of minimum fluidization velocity

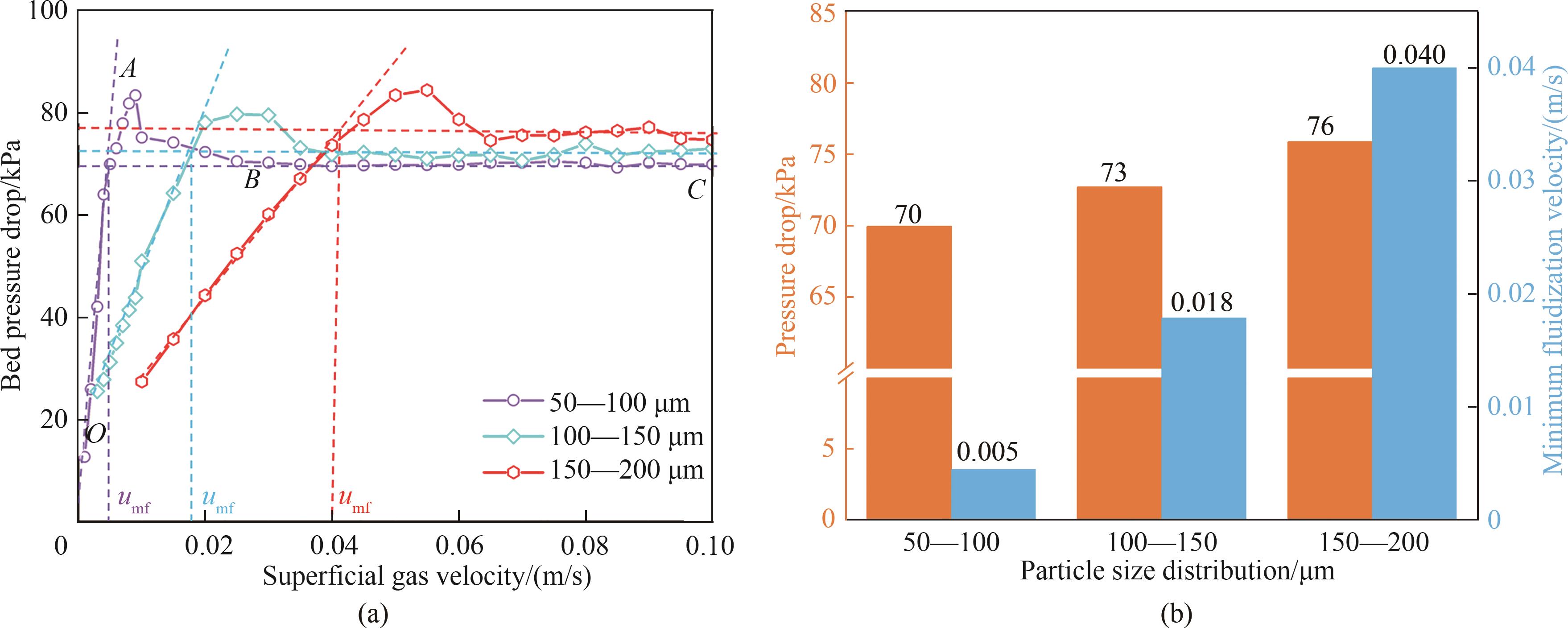

Fig.7 Thermal U3O8 reduction reactor with different particle sizes: (a) bed pressure varying with fluidization velocity and flow pattern classification; (b) comparison of bed pressure drop under the fully fluidized state and minimum fluidization velocity

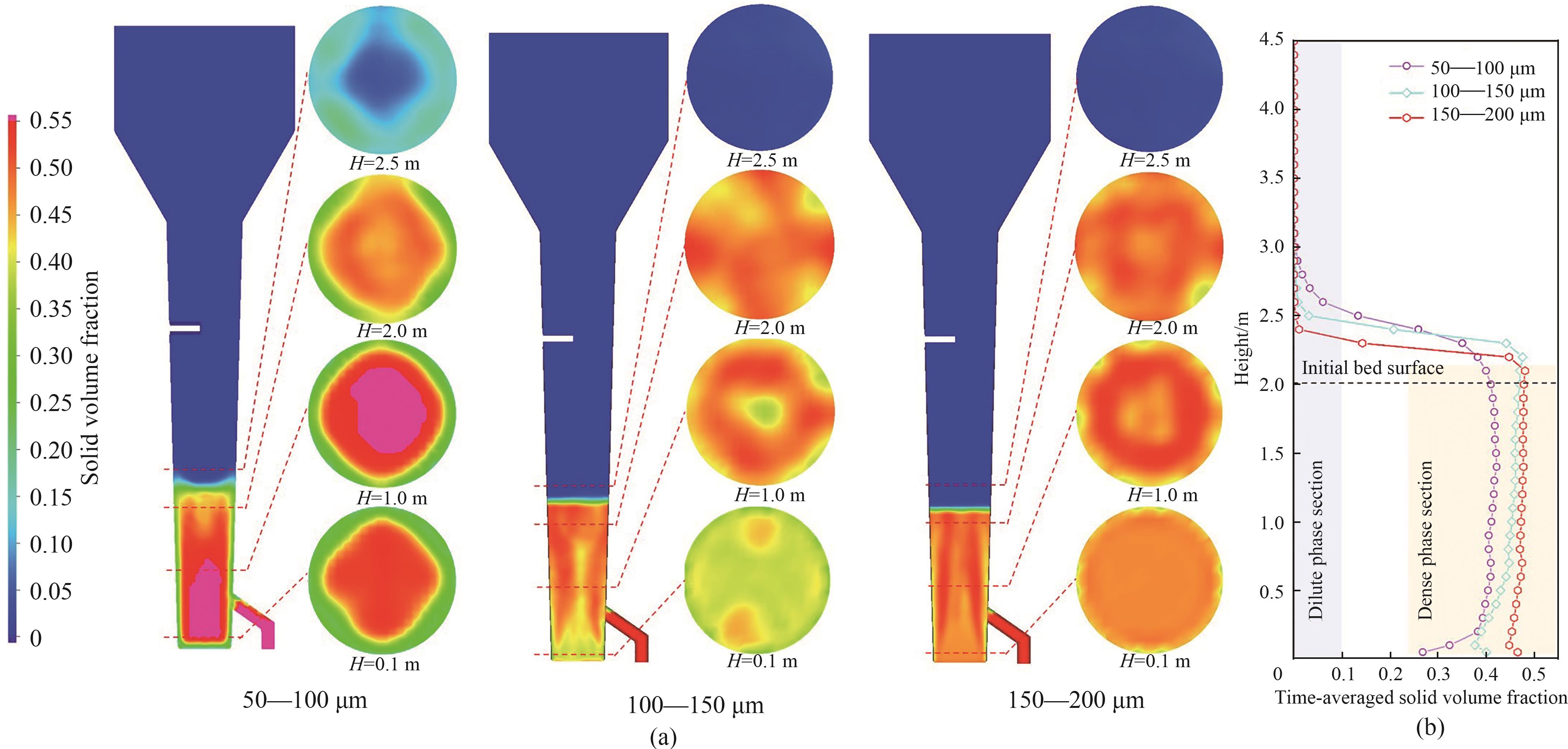

Fig.10 (a) Time-averaged particle distribution in steady flow state; (b) time-averaged distribution of particle concentration at different heights in reactor

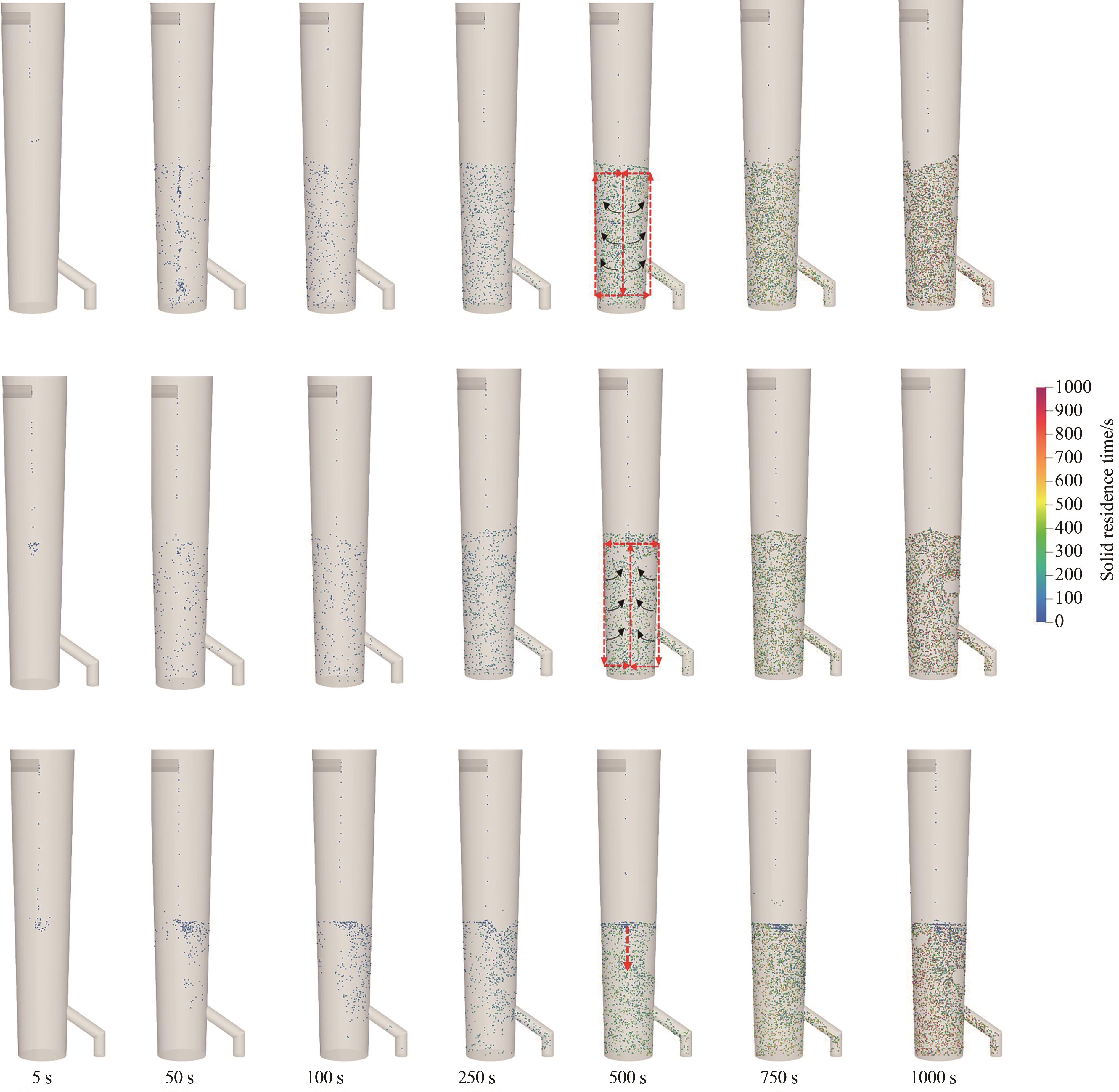

Fig.12 Evolution of instantaneous distribution of fresh feeding particles with different sizes inside reactor (coloring based on particle residence time)

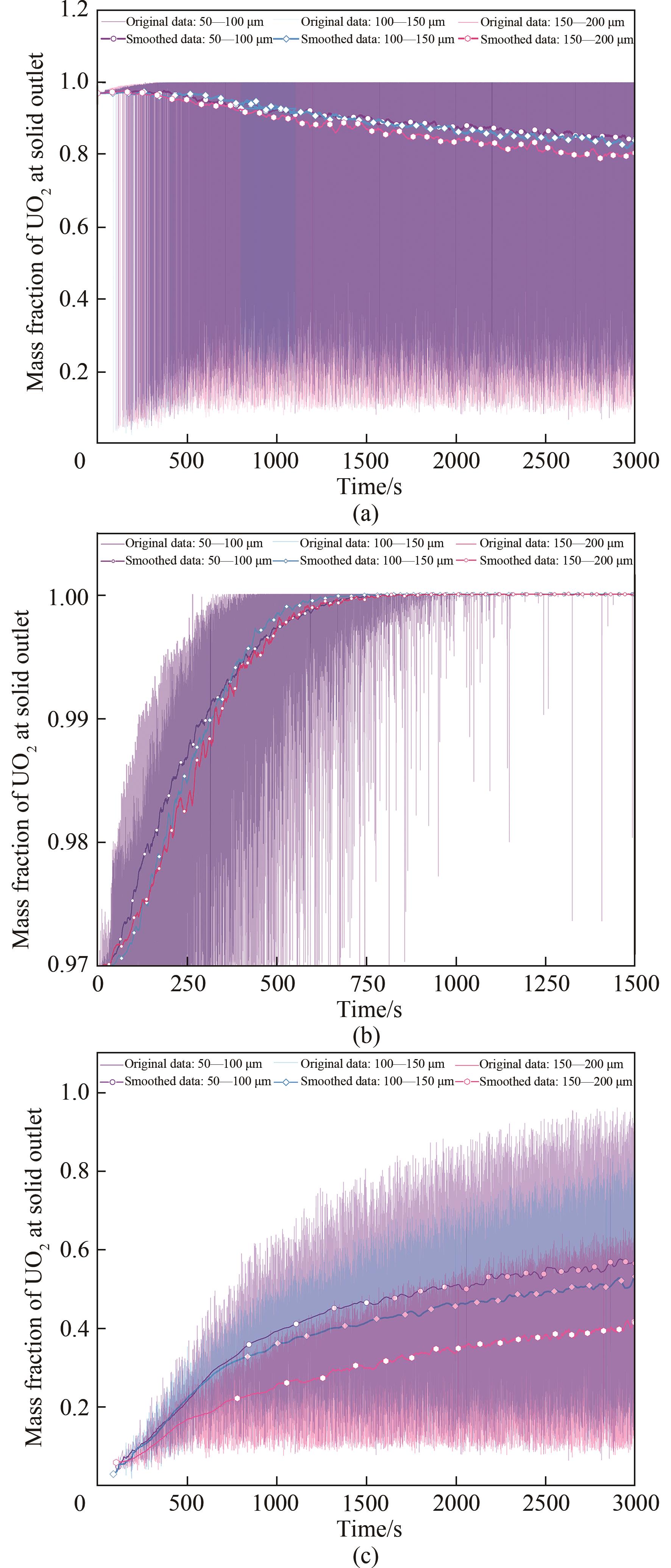

Fig.15 Time variation with UO2 mass fraction of different particle sizes at solid outlet: (a) particle mixture; (b) initial packing particles; (c) fresh feeding particles

| 1 | Murchie M P, Reid S J. Uranium conversion and enrichment[C]//Piro M H A. Advances in Nuclear Fuel Chemistry. Cambridge: Woodhead Publishing, 2020: 331-370. |

| 2 | 吴俊德, 徐乐昌, 牛洁, 等. 天然铀纯化与转化废物最小化对策建议[J]. 中国辐射卫生, 2022, 31(1): 74-78, 84. |

| Wu J D, Xu L C, Niu J, et al. A recommendation on minimization of wastes from natural uranium purification and conversion[J]. Chinese Journal of Radiological Health, 2022, 31(1): 74-78, 84. | |

| 3 | 刘马林. 化工流化床技术在铀燃料循环工业中的应用[J]. 化工进展, 2013, 32(3): 508-514, 548. |

| Liu M L. Review on application of fluidized bed technology in industry of uranium fuel cycle[J]. Chemical Industry and Engineering Progress, 2013, 32(3): 508-514, 548. | |

| 4 | 刘荣正, 刘马林, 邵友林, 等. 流化床-化学气相沉积技术的应用及研究进展[J]. 化工进展, 2016, 35(5): 1263-1272. |

| Liu R Z, Liu M L, Shao Y L, et al. Application and research progress of fluidized bed-chemical vapor deposition technology[J]. Chemical Industry and Engineering Progress, 2016, 35(5): 1263-1272. | |

| 5 | Oliver A J, Özberk E. Conversion of natural uranium[C]// Hore-Lacy I. Uranium for Nuclear Power. Amsterdam: Elsevier, 2016: 299-319. |

| 6 | Raffo-Caiado A C, Begovich J M, Ferrada J J, et al. Model of a generic natural uranium conversion plant—Suggested measures to strengthen international safeguards[R]. Oak Ridge National Laboratory, Tennessee, 2009. |

| 7 | Gupta C K, Sathiyamoorthy D. Fluid Bed Technology in Materials Processing[M]. Boca Raton, Fla: CRC Press, 1999. |

| 8 | Cappia F, Cullison M, Chen T, et al. Grain subdivision and structural modifications by high-energy heavy ions in UO2 with different initial grain size[J]. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 2022, 515: 48-60. |

| 9 | Lindroos M, Vajragupta N, Heikinheimo J, et al. Micromechanical modeling of single crystal and polycrystalline UO2 at elevated temperatures[J]. Journal of Nuclear Materials, 2023, 573: 154127. |

| 10 | Qiu M F, Chen Z, Jiang L, et al. Numerical simulation of uranium tetrafluoride fluorination in a multistage spouted bed using the improved CFD-DEM chemical reaction model[J]. Particuology, 2023, 75: 119-136. |

| 11 | Du Z, Liu J Y, Liu F, et al. Relationship of particle size, reaction and sticking behavior of iron ore fines toward efficient fluidized bed reduction[J]. Chemical Engineering Journal, 2022, 447: 137588. |

| 12 | de Vos W, Nicol W, du Toit E. Entrainment behaviour of high-density Geldart A powders with different shapes[J]. Powder Technology, 2009, 190(3): 297-303. |

| 13 | Bischi A, Langørgen Ø, Morin J X, et al. Performance analysis of the cold flow model of a second generation chemical looping combustion reactor system[J]. Energy Procedia, 2011, 4: 449-456. |

| 14 | Pierson H O. Handbook of Chemical Vapor Deposition (CVD): Principles, Technology, and Applications[M]. 2nd ed. Norwich, N.Y.: Noyes Publications, 1999. |

| 15 | Grace J R, Bi X T, Ellis N. Essentials of Fluidization Technology[M]. Weinheim: John Wiley & Sons, 2020. |

| 16 | 王荘, 吕潇, 邵媛媛, 等. 流态化的往昔寻觅及未来启示[J]. 化工学报, 2021, 72(12): 5904-5927. |

| Wang Z, Lyu X, Shao Y Y, et al. Early exploration of fluidization theory and its inspiration to the future[J]. CIESC Journal, 2021, 72(12): 5904-5927. | |

| 17 | Zhong Y, Gao J, Guo Z, et al. Mechanism and prevention of agglomeration/defluidization during fluidized-bed reduction of iron ore [C]//Shatokha V. Iron Ores and Iron Oxide Materials. Rijeka: IntechOpen, 2018: 105. |

| 18 | Rodriguez P, Caussat B, Ablitzer C, et al. Fluidization and coating of very dense powders by fluidized bed chemical vapour deposition[J]. Chemical Engineering Research and Design, 2013, 91(12): 2477-2483. |

| 19 | Zhong Y W, Wang Z, Guo Z C, et al. Defluidization behavior of iron powders at elevated temperature: influence of fluidizing gas and particle adhesion[J]. Powder Technology, 2012, 230: 225-231. |

| 20 | Vanni F, Caussat B, Ablitzer C, et al. Effects of reducing the reactor diameter on the fluidization of a very dense powder[J]. Powder Technology, 2015, 277: 268-274. |

| 21 | Saayman J, Ellis N, Nicol W. Fluidization of high-density particles: the influence of fines on reactor performance[J]. Powder Technology, 2013, 245: 48-55. |

| 22 | Bournival G, Ata S, Wanless E J. Behavior of bubble interfaces stabilized by particles of different densities[J]. Langmuir, 2016, 32(25): 6226-6238. |

| 23 | Liu M L, Wen Y Y, Liu R Z, et al. Investigation of fluidization behavior of high density particle in spouted bed using CFD-DEM coupling method[J]. Powder Technology, 2015, 280: 72-82. |

| 24 | Jiang L, Qiu M F, Liu R Z, et al. CFD-DEM simulation of high density particles fluidization behaviors in 3D conical spouted beds[J]. Particuology, 2024, 88: 266-281. |

| 25 | Li S Y, Zhang Y M, Wang W J, et al. Multi-scale simulation of particle density effects on hydrodynamics in dense gas-solid fluidized beds[J]. Powder Technology, 2024, 435: 119394. |

| 26 | Li S Y, Zhang Y M, Wang W J, et al. Comparative analysis of particle density effects on initial fluidization in gas-solid fluidized beds[J]. Chemical Engineering Journal, 2023, 477: 146966. |

| 27 | Lan B, Xu J, Lu S, et al. Direct reduction of iron-ore with hydrogen in fluidized beds: a coarse-grained CFD-DEM-IBM study[J]. Powder Technology, 2024, 438: 119624. |

| 28 | Smagorinsky J. General circulation experiments with the primitive equations (Ⅰ): The basic experiment[J]. Monthly Weather Review, 1963, 91(3): 99-164. |

| 29 | Gan J Q, Zhou Z Y, Yu A B. Particle scale study of heat transfer in packed and fluidized beds of ellipsoidal particles[J]. Chemical Engineering Science, 2016, 144: 201-215. |

| 30 | Kuang S B, Yu A B. Micromechanic modeling and analysis of the flow regimes in horizontal pneumatic conveying[J]. AIChE Journal, 2011, 57(10): 2708-2725. |

| 31 | Snider D M. An incompressible three-dimensional multiphase particle-in-cell model for dense particle flows[J]. Journal of Computational Physics, 2001, 170(2): 523-549. |

| 32 | Harris S E, Crighton D G. Solitons, solitary waves, and voidage disturbances in gas-fluidized beds[J]. Journal of Fluid Mechanics, 1994, 266: 243-276. |

| 33 | Wen C Y. Mechanics of fluidization[J]. Fluid Particle Technology, Chemical Engineering Progress Symposium Series, 1966, 62:100-111. |

| 34 | Hamilton M A, Reinking Z, Whitty K J, et al. Application of MP-PIC on dual interconnected chemical looping cold flow system: validation process with hydrodynamic experiments[R]. Salt Lake City, UT: Univ of Utah, 2018. |

| 35 | Adkins B D, Kapur N, Dudley T, et al. Experimental validation of CFD hydrodynamic models for catalytic fast pyrolysis[J]. Powder Technology, 2017, 316: 725-739. |

| 36 | Reinking Z, Shim H S, Whitty K J, et al. Computational simulation of a 100 kW dual circulating fluidized bed reactor processing coal by chemical looping with oxygen uncoupling[J]. International Journal of Greenhouse Gas Control, 2019, 90: 102795. |

| 37 | Zafiryadis F, Jensen A D, Laxminarayan Y, et al. Predicting cold gas-solid flow in a pilot-scale dual-circulating fluidized bed: validation of computational particle fluid dynamics model[J]. Powder Technology, 2021, 381: 25-43. |

| 38 | Wheeler V J. The diffusion and solubility of hydrogen in uranium dioxide single crystals[J]. Journal of Nuclear Materials, 1971, 40(2): 189-194. |

| 39 | Le Page A H, Fane A G. The kinetics of hydrogen reduction of UO3 and U3O8 derived from ammonium diuranate[J]. Journal of Inorganic and Nuclear Chemistry, 1974, 36(1): 87-92. |

| 40 | 王俊峰. 铀转化工艺学[M]. 北京: 中国原子能出版社, 2012. |

| Wang J F. Uranium Conversion Technology [M]. Beijing: China Atomic Energy Press, 2012. | |

| 41 | 许贺卿. 铀化合物转化工艺学[M]. 北京: 原子能出版社, 1994. |

| Xu H Q. Uranium Compound Conversion Technology[M]. Beijing: Atomic Press, 1994. | |

| 42 | Dell R M, Wheeler V J. Chemical reactivity of uranium trioxide Part 1—Conversion to U3O8, UO2 and UF4 [J]. Transactions of the Faraday Society, 1962, 58: 1590-1607. |

| 43 | Kavazauri R, Pokrovskiy S A, Baranov V G, et al. Thermal properties of nonstoichiometry uranium dioxide[J]. IOP Conference Series: Materials Science and Engineering, 2016, 130(1): 012025. |

| 44 | Niksiar A, Rahimi A. Design of a moving bed reactor for the production of uranium tetrafluoride based on mathematical modeling[J]. Chemical Engineering Science, 2010, 65(10): 3147-3157. |

| 45 | Park J Y, Levenspiel O. The crackling core model for the reaction of solid particles[J]. Chemical Engineering Science, 1975, 30(10): 1207-1214. |

| 46 | 闫树仁, 梁咏诗, 张永民. 深层鼓泡床内偏涌现象的实验研究与数值模拟[J]. 化工学报, 2014, 65(12): 4775-4784. |

| Yan S R, Liang Y S, Zhang Y M. Experimental study and numerical simulation on jet streaming in deep bubbling fluidized-bed[J]. CIESC Journal, 2014, 65(12): 4775-4784. | |

| 47 | Issangya A S, Knowlton T, Karri S. Detection of gas bypassing due to jet streaming in deep fluidized beds of group A particles[C]//Berruti F, Bi X, Pugsley T. The 12th International Conference on Fluidization-New Horizons in Fluidization Engineering. ECI Symposium Series. Vancouver, Canada: ECI Digital Archives, 2007:775-782. |

| 48 | Sau D C, Mohanty S, Biswal K C. Minimum fluidization velocities and maximum bed pressure drops for gas-solid tapered fluidized beds[J]. Chemical Engineering Journal, 2007, 132(1/2/3): 151-157. |

| 49 | Schaafsma S H, Marx T, Hoffmann A C. Investigation of the particle flowpattern and segregation in tapered fluidized bed granulators[J]. Chemical Engineering Science, 2006, 61(14): 4467-4475. |

| 50 | Hua L N, Zhao H, Li J, et al. Eulerian–Eulerian simulation of irregular particles in dense gas–solid fluidized beds[J]. Powder Technology, 2015, 284: 299-311. |

| 51 | Reuge N, Cadoret L, Coufort-Saudejaud C, et al. Multifluid Eulerian modeling of dense gas-solids fluidized bed hydrodynamics: influence of the dissipation parameters[J]. Chemical Engineering Science, 2008, 63(22): 5540-5551. |

| 52 | Sau D C, Mohanty S, Biswal K C. Experimental studies and empirical models for the prediction of bed expansion in gas–solid tapered fluidized beds[J]. Chemical Engineering and Processing: Process Intensification, 2010, 49(4): 418-424. |

| 53 | Li D D, Zhao B D, Lu S, et al. Physics-informed dynamic mode decomposition for short-term and long-term prediction of gas-solid flows[J]. Chemical Engineering Science, 2024, 289: 119849. |

| 54 | Xie Z Z, Gu X Y, Shen Y S. A machine learning study of predicting mixing and segregation behaviors in a bidisperse solid-liquid fluidized bed[J]. Industrial & Engineering Chemistry Research, 2022, 61(24): 8551-8565. |

| [1] | Juhui CHEN, Tong SU, Dan LI, Liwei CHEN, Wensheng LYU, Fanqi MENG. Study on the heat transfer characteristics of microchannels under the action of fin-shaped spoilers [J]. CIESC Journal, 2024, 75(9): 3122-3132. |

| [2] | Xiaoyu QIAN, Xuan RUAN, Shuiqing LI. Structural reconstruction and levitation of dielectric particle layers in electric fields [J]. CIESC Journal, 2024, 75(8): 2756-2762. |

| [3] | Ziliang ZHU, Shuang WANG, Yu'ang JIANG, Mei LIN, Qiuwang WANG. Solid-liquid phase change algorithm with Euler-Lagrange iteration [J]. CIESC Journal, 2024, 75(8): 2763-2776. |

| [4] | Aiming DENG, Yurong HE, Tianqi TANG, Yanwei HU. Simulation of effect of draft plate on particle growth process in spray fluidized beds [J]. CIESC Journal, 2024, 75(8): 2787-2799. |

| [5] | Hu JIN, Fan YANG, Mengyao DAI. The motion process of a droplet on a circular cylinder based on the lattice Boltzmann method [J]. CIESC Journal, 2024, 75(8): 2897-2908. |

| [6] | Yongqi TONG, Jie CHENG, Hai LIN, Xi CHEN, Haibo ZHAO. CPFD simulation of a 10 MWth chemical looping combustion reactor [J]. CIESC Journal, 2024, 75(8): 2949-2959. |

| [7] | Shaojun DOU, Liang HAO. Mesoscale simulation of coupled gas charge transfer process in PEMFC catalyst layer [J]. CIESC Journal, 2024, 75(8): 3002-3010. |

| [8] | Zhimin HAN, Jiang LI, Zeqi CHEN, Wei LIU, Zhiming XU. Particulate fouling characteristics of different longitudinal vortex generators in pulsating flow channel [J]. CIESC Journal, 2024, 75(7): 2486-2496. |

| [9] | Lichang FANG, Zilong LI, Bo CHEN, Zheng SU, Lisi JIA, Zhibin WANG, Ying CHEN. Study on cooling characteristics of chip array based on microencapsulated phase change material slurry [J]. CIESC Journal, 2024, 75(7): 2455-2464. |

| [10] | Fei LU, Bona LU, Guangwen XU. Analysis of criteria for ideal flow patterns in gas-solid micro fluidized bed reaction analyzer [J]. CIESC Journal, 2024, 75(6): 2201-2213. |

| [11] | Bin HUANG, Shengjie FENG, Cheng FU, Wei ZHANG. Numerical study on spreading characteristics of droplet impact on single fiber [J]. CIESC Journal, 2024, 75(6): 2233-2242. |

| [12] | Jing LI, Fangfang ZHANG, Shuaishuai WANG, Jianhua XU, Pengyuan ZHANG. Effect of cavity structure on flammability limit of n-butane partially premixed flame [J]. CIESC Journal, 2024, 75(5): 2081-2090. |

| [13] | Lei XIE, Yongsheng XU, Mei LIN. Comparative study on single-phase flow and heat transfer of different cross-section rib-soft tail structures [J]. CIESC Journal, 2024, 75(5): 1787-1801. |

| [14] | Wenya WANG, Wei ZHANG, Xiaoling LOU, Ruofei ZHONG, Bingbing CHEN, Junxian YUN. Multi-microtubes formation and simulation of nanocellulose-embedded cryogel microspheres [J]. CIESC Journal, 2024, 75(5): 2060-2071. |

| [15] | Juan LI, Yaowen CAO, Zhangyu ZHU, Lei SHI, Jia LI. Numerical study and structural optimization of microchannel flow and heat transfer characteristics of bionic homocercal fin microchannels [J]. CIESC Journal, 2024, 75(5): 1802-1815. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||