CIESC Journal ›› 2024, Vol. 75 ›› Issue (9): 3198-3209.DOI: 10.11949/0438-1157.20240115

• Catalysis, kinetics and reactors • Previous Articles Next Articles

Ran WANG1( ), Huan WANG2, Xiaoyun XIONG3, Huimin GUAN1, Yunfeng ZHENG3, Cailin CHEN1, Yucai QIN1(

), Huan WANG2, Xiaoyun XIONG3, Huimin GUAN1, Yunfeng ZHENG3, Cailin CHEN1, Yucai QIN1( ), Lijuan SONG1,2

), Lijuan SONG1,2

Received:2024-01-25

Revised:2024-05-19

Online:2024-10-10

Published:2024-09-25

Contact:

Yucai QIN

王冉1( ), 王焕2, 熊晓云3, 关慧敏1, 郑云锋3, 陈彩琳1, 秦玉才1(

), 王焕2, 熊晓云3, 关慧敏1, 郑云锋3, 陈彩琳1, 秦玉才1( ), 宋丽娟1,2

), 宋丽娟1,2

通讯作者:

秦玉才

作者简介:王冉(1998—),女,硕士研究生,2248409310@qq.com

基金资助:CLC Number:

Ran WANG, Huan WANG, Xiaoyun XIONG, Huimin GUAN, Yunfeng ZHENG, Cailin CHEN, Yucai QIN, Lijuan SONG. Visual analysis of mass transfer enhanced active site utilization efficiency of FCC catalyst[J]. CIESC Journal, 2024, 75(9): 3198-3209.

王冉, 王焕, 熊晓云, 关慧敏, 郑云锋, 陈彩琳, 秦玉才, 宋丽娟. FCC催化剂传质强化活性位利用效率的可视化分析[J]. 化工学报, 2024, 75(9): 3198-3209.

Add to citation manager EndNote|Ris|BibTeX

| 样品 | 比表 面积/ (m2·g-1) | 微孔 面积/ (m2·g-1) | 介孔 面积/(m2·g-1) | 总孔 体积/(cm3·g-1) | 微孔 体积/(cm3·g-1) | 介孔 体积/(cm3·g-1) |

|---|---|---|---|---|---|---|

| CAT-1 | 156 | 88 | 68 | 0.167 | 0.046 | 0.121 |

| CAT-2 | 186 | 95 | 91 | 0.198 | 0.050 | 0.148 |

| CAT-3 | 188 | 95 | 93 | 0.202 | 0.050 | 0.152 |

| CAT-4 | 185 | 98 | 87 | 0.218 | 0.056 | 0.162 |

| CAT-5 | 190 | 101 | 89 | 0.229 | 0.059 | 0.170 |

| CAT-6 | 193 | 104 | 88 | 0.248 | 0.061 | 0.187 |

Table 1 Texture property parameters of six catalyst samples

| 样品 | 比表 面积/ (m2·g-1) | 微孔 面积/ (m2·g-1) | 介孔 面积/(m2·g-1) | 总孔 体积/(cm3·g-1) | 微孔 体积/(cm3·g-1) | 介孔 体积/(cm3·g-1) |

|---|---|---|---|---|---|---|

| CAT-1 | 156 | 88 | 68 | 0.167 | 0.046 | 0.121 |

| CAT-2 | 186 | 95 | 91 | 0.198 | 0.050 | 0.148 |

| CAT-3 | 188 | 95 | 93 | 0.202 | 0.050 | 0.152 |

| CAT-4 | 185 | 98 | 87 | 0.218 | 0.056 | 0.162 |

| CAT-5 | 190 | 101 | 89 | 0.229 | 0.059 | 0.170 |

| CAT-6 | 193 | 104 | 88 | 0.248 | 0.061 | 0.187 |

| 样品 | 弱酸量/ (mmol·g-1) | 中强酸量/ (mmol·g-1) | 强酸量/ (mmol·g-1) |

|---|---|---|---|

| CAT1 | 4.07 | 11.55 | 15.70 |

| CAT2 | 4.11 | 12.45 | 15.79 |

| CAT3 | 5.10 | 14.09 | 16.70 |

| CAT-4 | 5.98 | 16.75 | 18.87 |

| CAT-5 | 6.58 | 21.37 | 18.99 |

| CAT-6 | 6.50 | 21.77 | 19.41 |

Table 2 Quantitative data on acid density distribution of six FCC catalysts

| 样品 | 弱酸量/ (mmol·g-1) | 中强酸量/ (mmol·g-1) | 强酸量/ (mmol·g-1) |

|---|---|---|---|

| CAT1 | 4.07 | 11.55 | 15.70 |

| CAT2 | 4.11 | 12.45 | 15.79 |

| CAT3 | 5.10 | 14.09 | 16.70 |

| CAT-4 | 5.98 | 16.75 | 18.87 |

| CAT-5 | 6.58 | 21.37 | 18.99 |

| CAT-6 | 6.50 | 21.77 | 19.41 |

| 样品 | 酸量/(mmol·g-1) | |||

|---|---|---|---|---|

| 150℃ | 400℃ | |||

| B酸 | L酸 | B酸 | L酸 | |

| CAT-1 | 0.065 | 0.064 | 0.043 | 0.010 |

| CAT-2 | 0.069 | 0.070 | 0.047 | 0.014 |

| CAT-3 | 0.087 | 0.071 | 0.067 | 0.010 |

| CAT-4 | 0.072 | 0.082 | 0.056 | 0.009 |

| CAT-5 | 0.086 | 0.135 | 0.057 | 0.005 |

| CAT-6 | 0.089 | 0.137 | 0.061 | 0.010 |

Table 3 Catalyst acidity

| 样品 | 酸量/(mmol·g-1) | |||

|---|---|---|---|---|

| 150℃ | 400℃ | |||

| B酸 | L酸 | B酸 | L酸 | |

| CAT-1 | 0.065 | 0.064 | 0.043 | 0.010 |

| CAT-2 | 0.069 | 0.070 | 0.047 | 0.014 |

| CAT-3 | 0.087 | 0.071 | 0.067 | 0.010 |

| CAT-4 | 0.072 | 0.082 | 0.056 | 0.009 |

| CAT-5 | 0.086 | 0.135 | 0.057 | 0.005 |

| CAT-6 | 0.089 | 0.137 | 0.061 | 0.010 |

| 样品 | 时间/min | 时间/min | ||||

|---|---|---|---|---|---|---|

| 萘穿透 | 菲穿透 | 吖啶穿透 | 萘饱和 | 菲饱和 | 吖啶饱和 | |

| CAT-1 | 1.92 | 3.71 | 10.70 | 6.10 | 9.21 | 43.37 |

| CAT-2 | 2.59 | 4.55 | 13.87 | 7.01 | 11.18 | 50.73 |

| CAT-3 | 2.84 | 4.93 | 18.85 | 7.28 | 12.35 | 54.18 |

| CAT-4 | 3.32 | 5.37 | 20.02 | 8.87 | 14.34 | 59.20 |

| CAT-5 | 3.75 | 6.62 | 21.45 | 9.10 | 16.91 | 66.09 |

| CAT-6 | 3.84 | 6.98 | 23.41 | 9.17 | 18.47 | 73.10 |

Table 4 Adsorption penetration and saturation time of naphthalene, phenanthrene and acridine on six catalyst samples

| 样品 | 时间/min | 时间/min | ||||

|---|---|---|---|---|---|---|

| 萘穿透 | 菲穿透 | 吖啶穿透 | 萘饱和 | 菲饱和 | 吖啶饱和 | |

| CAT-1 | 1.92 | 3.71 | 10.70 | 6.10 | 9.21 | 43.37 |

| CAT-2 | 2.59 | 4.55 | 13.87 | 7.01 | 11.18 | 50.73 |

| CAT-3 | 2.84 | 4.93 | 18.85 | 7.28 | 12.35 | 54.18 |

| CAT-4 | 3.32 | 5.37 | 20.02 | 8.87 | 14.34 | 59.20 |

| CAT-5 | 3.75 | 6.62 | 21.45 | 9.10 | 16.91 | 66.09 |

| CAT-6 | 3.84 | 6.98 | 23.41 | 9.17 | 18.47 | 73.10 |

| 探针分子 | KCAT-1/min-1 | KCAT-2/min-1 | KCAT-3/min-1 | KCAT-4/min-1 | KCAT-5/min-1 | KCAT-6/min-1 |

|---|---|---|---|---|---|---|

| 萘 | 1.3461 | 1.1570 | 1.1327 | 1.1145 | 1.0281 | 0.8897 |

| 菲 | 1.0907 | 0.9867 | 0.9335 | 0.8698 | 0.7798 | 0.7454 |

| 吖啶 | 0.2875 | 0.2562 | 0.2540 | 0.2531 | 0.2260 | 0.1950 |

Table 5 The adsorption rate constants of naphthene, phenanthrene and acridine for six catalyst samples obtained by fitting Yoon-Nelson model

| 探针分子 | KCAT-1/min-1 | KCAT-2/min-1 | KCAT-3/min-1 | KCAT-4/min-1 | KCAT-5/min-1 | KCAT-6/min-1 |

|---|---|---|---|---|---|---|

| 萘 | 1.3461 | 1.1570 | 1.1327 | 1.1145 | 1.0281 | 0.8897 |

| 菲 | 1.0907 | 0.9867 | 0.9335 | 0.8698 | 0.7798 | 0.7454 |

| 吖啶 | 0.2875 | 0.2562 | 0.2540 | 0.2531 | 0.2260 | 0.1950 |

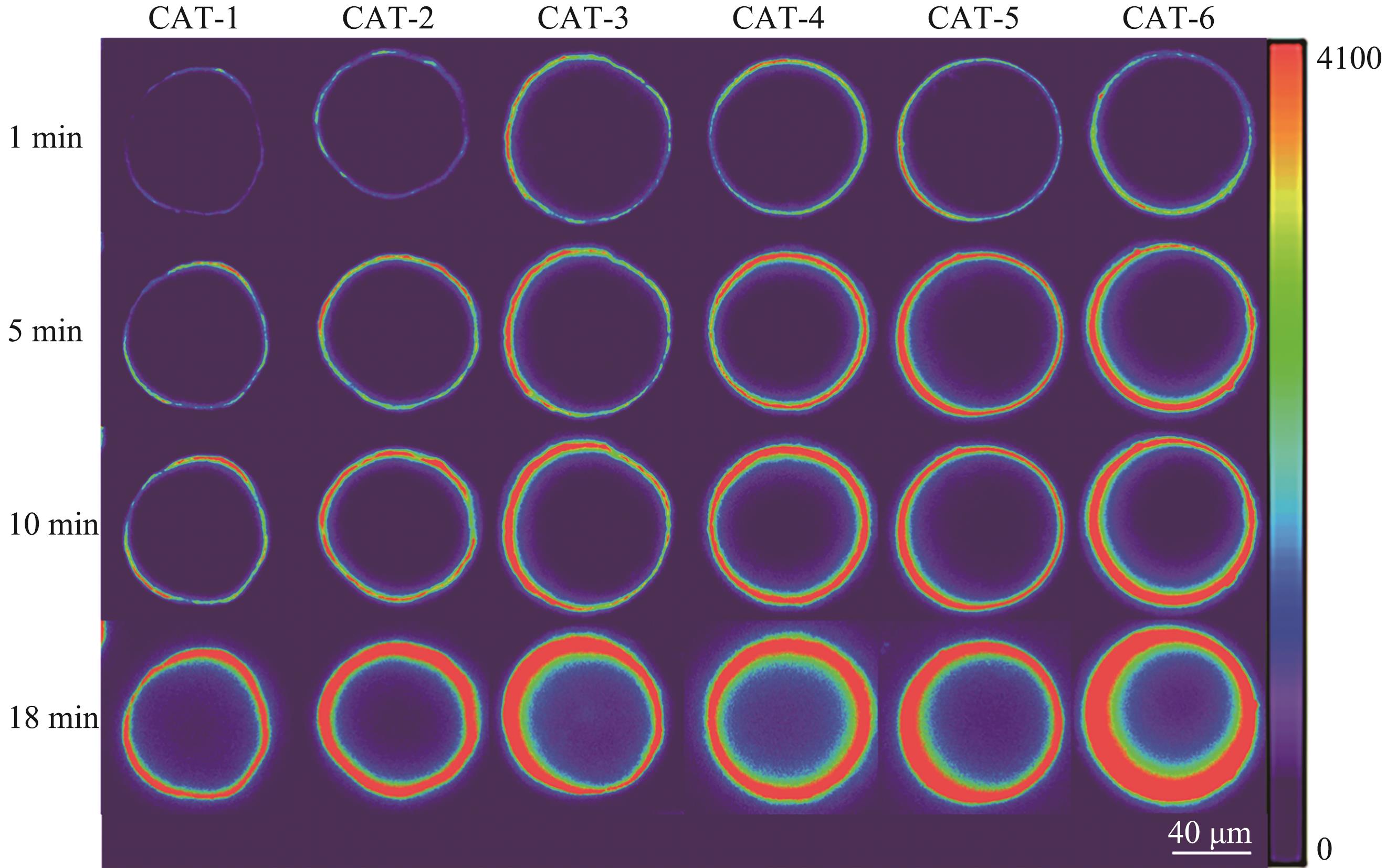

Fig.9 Fluorescence mapping of the maximum section surface of catalyst samples soaked in Rhodamine B probe (color bar displays the fluorescence intensity)

| 催化剂 | L18min/m | Deff/(m2·s-1) |

|---|---|---|

| CAT-1 | 1.76×10-5 | 2.72×10-15 |

| CAT-2 | 2.16×10-5 | 3.63×10-15 |

| CAT-3 | 2.63×10-5 | 6.04×10-15 |

| CAT-4 | 3.01×10-5 | 1.10×10-14 |

| CAT-5 | 3.22×10-5 | 1.65×10-14 |

| CAT-6 | 3.69×10-5 | 6.68×10-14 |

Table 6 The diffusion coefficients of Rhodamine B in six catalyst samples calculated by the Fick’s first law

| 催化剂 | L18min/m | Deff/(m2·s-1) |

|---|---|---|

| CAT-1 | 1.76×10-5 | 2.72×10-15 |

| CAT-2 | 2.16×10-5 | 3.63×10-15 |

| CAT-3 | 2.63×10-5 | 6.04×10-15 |

| CAT-4 | 3.01×10-5 | 1.10×10-14 |

| CAT-5 | 3.22×10-5 | 1.65×10-14 |

| CAT-6 | 3.69×10-5 | 6.68×10-14 |

| 1 | Vogt E T C, Weckhuysen B M. Fluid catalytic cracking: recent developments on the grand old lady of zeolite catalysis[J]. Chemical Society Reviews, 2015, 44(20): 7342-7370. |

| 2 | 王铃. 2030年炼油催化剂市场规模将达到150亿美元[J]. 石油炼制与化工, 2023, 54(11): 33. |

| Wang L. In 2030, the market size of refining catalyst will reach 15 billion US dollars[J]. Petroleum Processing and Petrochemicals, 2023, 54(11): 33. | |

| 3 | 张玉明, 纪德馨, 朱翰文, 等. 微型流化床中萘裂解生成小分子气体的反应动力学研究[J]. 化工学报, 2021, 72(5): 2604-2615. |

| Zhang Y M, Ji D X, Zhu H W, et al. Reaction kinetics of naphthalene cracking into small molecule gas in a micro fluidized bed[J]. CIESC Journal, 2021, 72(5): 2604-2615. | |

| 4 | Fleury M, Pirngruber G, Jolimaitre E. Probing diffusional exchange in mesoporous zeolite by NMR diffusion and relaxation methods[J]. Microporous and Mesoporous Materials, 2023, 355: 112575. |

| 5 | Liu X L, Wang C M, Zhou J, et al. Molecular transport in zeolite catalysts: depicting an integrated picture from macroscopic to microscopic scales[J]. Chemical Society Reviews, 2022, 51(19): 8174-8200. |

| 6 | 周鹏. 基质Lewis酸性调控及其催化轻烃裂化反应性能研究[D]. 徐州: 中国矿业大学, 2023. |

| Zhou P. Lewis acidity regulation of matrix and its effects on the catalytic cracking of light hydrocarbons[D]. Xuzhou: China University of Mining and Technology, 2023. | |

| 7 | 洪梅, 高金强, 李彤, 等. 原位刻蚀调控多级孔分子筛策略及其应用进展[J]. 化学学报, 2023, 81(8): 937-948. |

| Hong M, Gao J Q, Li T, et al. In-situ etching strategy for manipulation of hierarchical zeolite and its application[J]. Acta Chimica Sinica, 2023, 81(8): 937-948. | |

| 8 | 万艳春, 王玉军, 骆广生. 并流滴加法制备大孔容纤维状γ-氧化铝[J]. 化工学报, 2018, 69(11): 4840-4847. |

| Wan Y C, Wang Y J, Luo G S. Preparation of fibrous γ-alumina with large pore volume via co-current dropwise addition method[J]. CIESC Journal, 2018, 69(11): 4840-4847. | |

| 9 | 熊晓云, 曹庚振, 杜学敏, 等. 炭黑模板法制备大孔原位晶化型催化裂化催化剂[J]. 无机盐工业, 2023, 55(9): 134-139. |

| Xiong X Y, Cao G Z, Du X M, et al. Preparation of macroporous in situ crystallized FCC catalyst by carbon black template method[J]. Inorganic Chemicals Industry, 2023, 55(9): 134-139. | |

| 10 | 魏娟, 王玉军, 骆广生. 铝源孔容和焙烧升温过程对碳热还原法制备氮化铝粉体的影响[J]. 化工学报, 2021, 72(2): 1156-1168. |

| Wei J, Wang Y J, Luo G S. Influence of pore volume and heating process on preparation of aluminum nitride powder by carbothermal reduction method[J]. CIESC Journal, 2021, 72(2): 1156-1168. | |

| 11 | 熊晓云, 潘志爽, 胡清勋, 等. 高岭土酸碱复合改性制备多孔材料及其应用[J]. 石油炼制与化工, 2023, 54(7): 46-51. |

| Xiong X Y, Pan Z S, Hu Q X, et al. Preparation and application of porous materials by combining base and acid modification of kaolin[J]. Petroleum Processing and Petrochemicals, 2023, 54(7): 46-51. | |

| 12 | Bondarenko A V, Bondarenko V V, Petukhova, G A, et al. Adsorption properties of kaolinite and montmorillonite activated by thermochemical treatment[J]. Protection of Metals and Physical Chemistry of Surfaces, 2023, 59(5): 828-836. |

| 13 | 张莉, 刘超伟, 胡清勋, 等. 高岭土族矿物原位晶化合成Y型分子筛催化剂的研究进展[J]. 工业催化, 2020, 28(11): 1-8. |

| Zhang L, Liu C W, Hu Q X, et al. Research progress on in situ crystallization of zeolite catalyst from kaolin group minerals for RFCC[J]. Industrial Catalysis, 2020, 28(11): 1-8. | |

| 14 | 黄校亮, 姚文君, 郑云锋, 等. 改性高岭土在催化裂化催化剂中的应用研究[J]. 炼油与化工, 2011, 22(6): 25-27, 63. |

| Huang X L, Yao W J, Zheng Y F, et al. Modification of kaolin and its application in FCC catalyst[J]. Refining and Chemical Industry, 2011, 22(6): 25-27, 63. | |

| 15 | Baker B R, Pearson R M. Water content of pseudoboehmite: a new model for its structure[J]. Journal of Catalysis, 1974, 33(2): 265-278. |

| 16 | 闫涛, 袁程远, 柴军军, 等. 硅改性拟薄水铝石的合成及其在FCC催化剂中的应用[J]. 石油化工, 2021, 50(11): 1115-1120. |

| Yan T, Yuan C Y, Chai J J, et al. Synthesis of silica-modified pseudo boehmite and its application in FCC catalyst[J]. Petrochemical Technology, 2021, 50(11): 1115-1120. | |

| 17 | 郑金玉, 欧阳颖, 罗一斌, 等. 无序介孔硅铝材料的合成、表征及性能研究[J]. 石油炼制与化工, 2015, 46(9): 47-51. |

| Zheng J Y, Ouyang Y, Luo Y B, et al. Synthesis, characterization and catalytic cracking performance of disordered mesoporous silica-alumina material[J]. Petroleum Processing and Petrochemicals, 2015, 46(9): 47-51. | |

| 18 | 熊晓云, 高雄厚, 胡清勋, 等. 富B酸多级孔材料在催化裂化催化剂中的应用[J]. 精细石油化工, 2019, 36(3): 24-27. |

| Xiong X Y, Gao X H, Hu Q X, et al. Application of hierarchical porous material rich in bronsted acid in FCC catalyst[J]. Speciality Petrochemicals, 2019, 36(3): 24-27. | |

| 19 | Kärger J, Freude D, Haase J. Diffusion in nanoporous materials: novel insights by combining MAS and PFG NMR[J]. Processes, 2018, 6(9): 147. |

| 20 | Hernandez-Tamargo C, Silverwood I P, O'Malley A J, et al. Quasielastic neutron scattering and molecular dynamics simulation study on the molecular behaviour of catechol in zeolite beta[J]. Topics in Catalysis, 2021, 64(9): 707-721. |

| 21 | Talmon Y, Shtirberg L, Harneit W, et al. Molecular diffusion in porous media by PGSE ESR[J]. Physical Chemistry Chemical Physics, 2010, 12(23): 5998-6007. |

| 22 | Wessig M, Spitzbarth M, Drescher M, et al. Multiple scale investigation of molecular diffusion inside functionalized porous hosts using a combination of magnetic resonance methods[J]. Physical Chemistry Chemical Physics, 2015, 17(24): 15976-15988. |

| 23 | Ajith V J, Patil S. Translational diffusion of a fluorescent tracer molecule in nanoconfined water[J]. Langmuir, 2022, 38(3): 1034-1044. |

| 24 | Beschieru V, Rathke B, Will S. Particle diffusion in porous media investigated by dynamic light scattering[J]. Microporous and Mesoporous Materials, 2009, 125(1/2): 63-69. |

| 25 | 秦玉才, 高雄厚, 石利飞, 等. 原位晶化FCC催化剂传质性能的频率响应法辨析[J]. 物理化学学报, 2016, 32(2): 527-535. |

| Qin Y C, Gao X H, Shi L F, et al. Discrimination of the mass transfer performance of in situ crystallization FCC catalysts by the frequency response method[J]. Acta Physico-Chimica Sinica, 2016, 32(2): 527-535. | |

| 26 | Yasuda Y. Determination of vapor diffusion coefficients in zeolite by the frequency response method[J]. The Journal of Physical Chemistry, 1982, 86(10): 1913-1917. |

| 27 | Mehlhorn D, Inayat A, Schwieger W, et al. Probing mass transfer in mesoporous faujasite-type zeolite nanosheet assemblies[J]. Chemphyschem: a European Journal of Chemical Physics and Physical Chemistry, 2014, 15(8): 1681-1686. |

| 28 | Vattipalli V, Qi X D, Dauenhauer P J, et al. Long walks in hierarchical porous materials due to combined surface and configurational diffusion[J]. Chemistry of Materials, 2016, 28(21): 7852-7863. |

| 29 | Xiao Y, Xu W L. Single-molecule fluorescence imaging for probing nanocatalytic process[J]. Chem, 2023, 9(1): 16-28. |

| 30 | González R M, Maris J J E, Wagner M, et al. Fluorescent-probe characterization for pore-space mapping with single-particle tracking[J]. Angewandte Chemie International Edition, 2024, 63(4): e202314528. |

| 31 | Lezcano-González I, Oord R, Rovezzi M, et al. Molybdenum speciation and its impact on catalytic activity during methane dehydroaromatization in zeolite ZSM-5 as revealed by operando X-ray methods[J]. Angewandte Chemie International Edition, 2016, 55(17): 5215-5219. |

| 32 | Werny M J, Siebers K B, Friederichs N H, et al. Advancing the compositional analysis of olefin polymerization catalysts with high-throughput fluorescence microscopy[J]. Journal of the American Chemical Society, 2022, 144(46): 21287-21294. |

| 33 | Omori N, Candeo A, Mosca S, et al. Multimodal imaging of autofluorescent sites reveals varied chemical speciation in SSZ-13 crystals[J]. Angewandte Chemie International Edition, 2021, 60(10): 5125-5131. |

| 34 | Lee H, Kim K, Kang C M, et al. In situ confocal fluorescence lifetime imaging of nanopore electrode arrays with redox active fluorogenic amplex red[J]. Analytical Chemistry, 2023, 95(2): 1038-1046. |

| 35 | Buurmans I L C, Ruiz-Martínez J, Knowles W V, et al. Catalytic activity in individual cracking catalyst particles imaged throughout different life stages by selective staining[J]. Nature Chemistry, 2011, 3(11): 862-867. |

| 36 | Kox M H, Mijovilovich A, Sättler J J, et al. The catalytic conversion of thiophenes over large H-ZSM-5 crystals: an X-ray, UV/vis, and fluorescence microspectroscopic study[J]. ChemCatChem, 2010, 2(5): 564-571. |

| 37 | Hendriks F C, Meirer F, Kubarev A V, et al. Single-molecule fluorescence microscopy reveals local diffusion coefficients in the pore network of an individual catalyst particle[J]. Journal of the American Chemical Society, 2017, 139(39): 13632-13635. |

| 38 | 刘现玉, 袁程远, 高雄厚, 等. 拟薄水铝石@高岭土复合材料的合成及其在FCC催化剂中的应用[J]. 石油化工, 2020, 49(3): 219-223. |

| Liu X Y, Yuan C Y, Gao X H, et al. Synthesis of pseudo-boehmite@kaolinite composite and its application in FCC catalyst[J]. Petrochemical Technology, 2020, 49(3): 219-223. | |

| 39 | Thommes M, Kaneko K, Neimark A V, et al. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report)[J]. Pure and Applied Chemistry, 2015, 87(9/10): 1051-1069. |

| [1] | Xinyi LUO, Qiang XU, Yonglu SHE, Tengfei NIE, Liejin GUO. Study on bubble dynamic characteristics and mass transfer mechanism in photoelectrochemical water splitting for hydrogen production [J]. CIESC Journal, 2024, 75(9): 3083-3093. |

| [2] | Zichi YANG, Bingqi XIE, Ruixin SHI, Hong LEI, Chen CHEN, Caijin ZHOU, Jisong ZHANG. Research progress on efficient and safe gas-liquid mass transfer and reaction processes in tube-in-tube reactor [J]. CIESC Journal, 2024, 75(9): 3011-3027. |

| [3] | Jinrui YANG, Hongfei ZHENG, Xinglong MA, Rihui JIN, Shen LIANG. Study on two-stage stacked humidification-dehumidification desalination device [J]. CIESC Journal, 2024, 75(7): 2446-2454. |

| [4] | Jinshan WANG, Shixue WANG, Yu ZHU. Influence of cooling surface temperature difference on the high temperature proton-exchange membrane fuel cell performance [J]. CIESC Journal, 2024, 75(5): 2026-2035. |

| [5] | Binbin FENG, Mingjia LU, Zhihong HUANG, Yiwen CHANG, Zhiming CUI. Application and optimization of carbon supports in proton exchange membrane fuel cells [J]. CIESC Journal, 2024, 75(4): 1469-1484. |

| [6] | Ting CHENG, Weizhou JIAO, Youzhi LIU. Application and research progress of functional packings in high-gravity rotating packed bed [J]. CIESC Journal, 2024, 75(4): 1414-1428. |

| [7] | Fangtao JIANG, Gang QIAN, Xinggui ZHOU, Xuezhi DUAN, Jing ZHANG. Efficient synthesis of fluoroethylene carbonate via phase transfer catalysis using [bmim][BF4] [J]. CIESC Journal, 2024, 75(4): 1543-1551. |

| [8] | Xiao DONG, Zhishan BAI, Xiaoyong YANG, Wei YIN, Ningpu LIU, Qifan YU. Research and industrial application of coupled impurity removal technology in CHPPO process oxidation liquids [J]. CIESC Journal, 2024, 75(4): 1630-1641. |

| [9] | Juan WANG, Xiuming LI, Weitao SHAO, Xu DING, Ying HUO, Lianchao FU, Yunyu BAI, Di LI. Numerical simulation of flow and mass transfer characteristics in porous plate bubbling column reactor [J]. CIESC Journal, 2024, 75(3): 801-814. |

| [10] | Jiaqi WANG, Haoqi WEI, Ajing GOU, Jiaxing LIU, Xinlin ZHOU, Kun GE. Study on the formation mechanism of CO2 hydrate under the action of nanoparticles [J]. CIESC Journal, 2024, 75(3): 956-966. |

| [11] | Wenjun LI, Zhongyang ZHAO, Zhen NI, Can ZHOU, Chenghang ZHENG, Xiang GAO. CFD numerical simulation of wet flue gas desulfurization:performance improvement based on gas-liquid mass transfer enhancement [J]. CIESC Journal, 2024, 75(2): 505-519. |

| [12] | Ruohan ZHAO, Mengmeng HUANG, Chunying ZHU, Taotao FU, Xiqun GAO, Youguang MA. Flow and mass transfer study of CO2 absorption by nanofluid in T-shaped microchannels [J]. CIESC Journal, 2024, 75(1): 221-230. |

| [13] | Yizhou CUI, Chengxiang LI, Linxiao ZHAI, Shuyu LIU, Xiaogang SHI, Jinsen GAO, Xingying LAN. Comparative study on the flow and mass transfer characteristics of sub-millimeter bubbles and conventional bubbles in gas-liquid two-phase flow [J]. CIESC Journal, 2024, 75(1): 197-210. |

| [14] | Jingwei CHAO, Jiaxing XU, Tingxian LI. Investigation on the heating performance of the tube-free-evaporation based sorption thermal battery [J]. CIESC Journal, 2023, 74(S1): 302-310. |

| [15] | Yitong LI, Hang GUO, Hao CHEN, Fang YE. Study on operating conditions of proton exchange membrane fuel cells with non-uniform catalyst distributions [J]. CIESC Journal, 2023, 74(9): 3831-3840. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||