化工学报 ›› 2019, Vol. 70 ›› Issue (12): 4635-4644.DOI: 10.11949/0438-1157.20190690

收稿日期:2019-06-19

修回日期:2019-09-30

出版日期:2019-12-05

发布日期:2019-12-05

通讯作者:

王翠苹

作者简介:王金玉(1994—),男,硕士研究生,基金资助:

Jinyu WANG( ),Huaizhi ZHU,Zewen AN,Jian GONG,Cuiping WANG(

),Huaizhi ZHU,Zewen AN,Jian GONG,Cuiping WANG( )

)

Received:2019-06-19

Revised:2019-09-30

Online:2019-12-05

Published:2019-12-05

Contact:

Cuiping WANG

摘要:

为考察ZSM-5分子筛作载体和Ce掺杂对催化剂低温脱硝活性及抗水抗硫性的影响,通过分子动力学模拟和实验研究的手段研究了载体类型、掺杂Ce对催化剂性能的影响。分子动力学模拟发现,ZSM-5分子筛作载体较γ-Al2O3明显抑制H2O在其表面的吸附,在活性组分中添加Ce既抑制H2O在其表面的吸附,又减轻SO2对催化剂的毒化作用。实验研究发现,Mn-Fe-Ce/ZSM-5催化剂性能更优,Ce的添加对提高催化剂的低温脱硝活性和抗水抗硫性能具有明显的积极作用,ZSM-5分子筛作为载体也对提高催化剂抗水性能起到重要作用。通过SEM、XRD、BET、TG-DTG等表征手段和BaCl2鼓泡实验对Mn-Fe-Ce/ZSM-5催化剂抗硫性提高的原因分析发现,添加Ce使催化剂储氧释氧能力提高,将烟气中的SO2氧化为SO3并被烟气携带,避免了SO2与催化剂活性组分的反应,则催化剂表面的活性组分不被破坏,保证了催化剂的催化反应性能。

中图分类号:

王金玉, 朱怀志, 安泽文, 巩建, 王翠苹. Mn基脱硝催化剂抗水抗硫改性的模拟与实验研究[J]. 化工学报, 2019, 70(12): 4635-4644.

Jinyu WANG, Huaizhi ZHU, Zewen AN, Jian GONG, Cuiping WANG. Simulation and experimental study on modification of water and sulfur resistance by Mn-based denitration catalyst[J]. CIESC Journal, 2019, 70(12): 4635-4644.

| 载体 | 吸附能/(kcal/mol) | 吸附后H—O键长/nm | 吸附后原子间距/nm |

|---|---|---|---|

| ZSM-5分子筛 | -9.743 | 0.1076 | 0.3789 |

| γ-Al2O3 | -11.610 | 0.1022 | 0.3026 |

表1 H2O分子在不同载体模型上的吸附能、键长和原子间距

Table 1 Adsorption energy, bond length and atomic spacing of H2O molecules on different carrier models

| 载体 | 吸附能/(kcal/mol) | 吸附后H—O键长/nm | 吸附后原子间距/nm |

|---|---|---|---|

| ZSM-5分子筛 | -9.743 | 0.1076 | 0.3789 |

| γ-Al2O3 | -11.610 | 0.1022 | 0.3026 |

| 吸附构型 | H2O分子在β-MnO2(0 0 1)上的吸附能/(kcal/mol) | H2O分子在β-MnO2(+Ce)上的吸附能/(kcal/mol) |

|---|---|---|

| H2O分子中H吸附到β-MnO2的Mn | -6.577 | -3.857 |

| H2O分子中H吸附到β-MnO2的O | -7.943 | -5.335 |

| H2O分子中O吸附到β-MnO2的Mn | -10.982 | -7.396 |

| H2O分子中O吸附到β-MnO2的O | -6.044 | -4.769 |

表2 H2O分子在不同活性组分表面上不同吸附构型的吸附能

Table 2 Adsorption energy of different adsorption configurations of H2O molecules on surface of different active components

| 吸附构型 | H2O分子在β-MnO2(0 0 1)上的吸附能/(kcal/mol) | H2O分子在β-MnO2(+Ce)上的吸附能/(kcal/mol) |

|---|---|---|

| H2O分子中H吸附到β-MnO2的Mn | -6.577 | -3.857 |

| H2O分子中H吸附到β-MnO2的O | -7.943 | -5.335 |

| H2O分子中O吸附到β-MnO2的Mn | -10.982 | -7.396 |

| H2O分子中O吸附到β-MnO2的O | -6.044 | -4.769 |

| 活性组分类型 | 反应活化能/(kcal/mol) |

|---|---|

| β-MnO2(0 0 1) | 15.473 |

| β-MnO2(+Ce) | 33.581 |

表3 SO2分子与不同活性组分的反应活化能

Table 3 Reaction activation energy of SO2 molecule and different active components

| 活性组分类型 | 反应活化能/(kcal/mol) |

|---|---|

| β-MnO2(0 0 1) | 15.473 |

| β-MnO2(+Ce) | 33.581 |

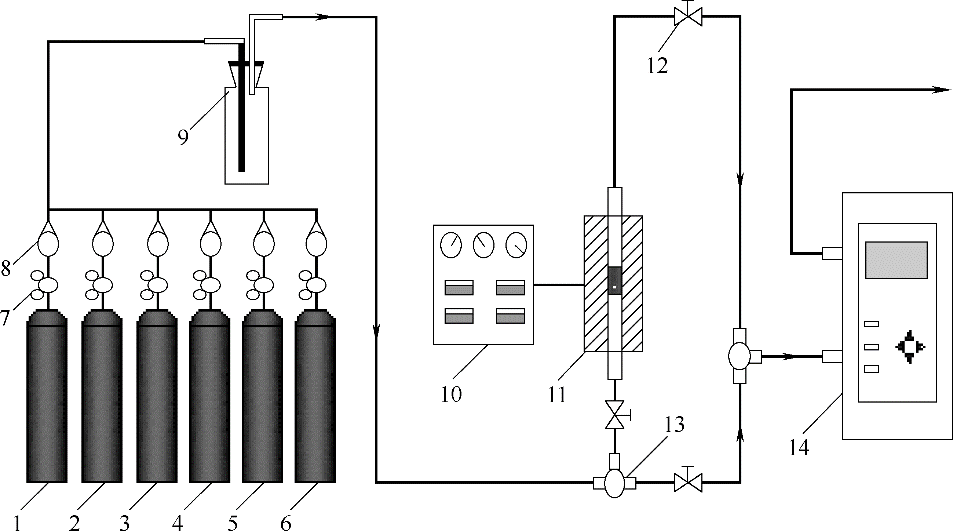

图4 烟气脱硝实验装置 1—氮气气瓶;2—二氧化硫气瓶;3—一氧化氮气瓶;4—氨气气瓶;5—氧气气瓶;6—蒸汽发生器;7—减压阀;8—质量流量计;9—气体缓冲瓶;10—温控箱;11—管式炉;12—阀门;13—三通;14—烟气分析仪

Fig.4 Schematic diagram of flue gas denitration experimental device

图7 不同H2O体积分数下Mn-Fe-Ce/ZSM-5和Mn-Fe/γ-Al2O3催化剂的脱硝效率

Fig.7 Denitration efficiency of Mn-Fe-Ce/ZSM-5 and Mn-Fe/γ-Al2O3 catalysts with different H2O volume fractions

图8 不同SO2浓度下Mn-Fe-Ce/ZSM-5和Mn-Fe/γ-Al2O3催化剂的脱硝效率

Fig.8 Denitration efficiency of Mn-Fe-Ce/ZSM-5 and Mn-Fe/γ-Al2O3 catalysts at different SO2 concentrations

| 催化剂类型 | 比表面积/ (m2/g) | 孔容×102/ (cm3/g) | 平均孔径 /nm |

|---|---|---|---|

| Mn-Fe/γ-Al2O3(反应前) | 129 | 20 | 6.9 |

| Mn-Fe/γ-Al2O3(反应后) | 115 | 18.1 | 5.8 |

| Mn-Fe-Ce/ZSM-5(反应前) | 308 | 10 | 5 |

| Mn-Fe-Ce/ZSM-5(反应后) | 303 | 9.4 | 4.7 |

表4 反应前后Mn-Fe-Ce/ZSM-5和Mn-Fe/γ-Al2O3催化剂物理性质变化

Table 4 Physical properties of Mn-Fe-Ce/ZSM-5 and Mn-Fe/γ-Al2O3 catalysts before and after reaction

| 催化剂类型 | 比表面积/ (m2/g) | 孔容×102/ (cm3/g) | 平均孔径 /nm |

|---|---|---|---|

| Mn-Fe/γ-Al2O3(反应前) | 129 | 20 | 6.9 |

| Mn-Fe/γ-Al2O3(反应后) | 115 | 18.1 | 5.8 |

| Mn-Fe-Ce/ZSM-5(反应前) | 308 | 10 | 5 |

| Mn-Fe-Ce/ZSM-5(反应后) | 303 | 9.4 | 4.7 |

| 1 | Miroslav R . Reduction of nitrogen oxides in flue gases[J]. Environmental Pollution, 1998, 102(1): 685-689. |

| 2 | 张楚莹, 王书肖, 邢佳, 等 . 中国能源相关的氮氧化物排放现状与发展趋势分析[J]. 环境科学学报, 2015, 28(12): 2470-2479. |

| Zhang C Y , Wang S X , Xing J , et al . Current status and future projections of NO x emissions from energy related in dustries in China[J]. Acta Scientiae Circumstantiae, 2015, 28(12): 2470-2479. | |

| 3 | Xue Y , Tian H , Yan J , et al . Temporal trends and spatial variation characteristics of primary air pollutants emissions from coal-fired industrial boilers in Beijing, China[J]. Environmental Pollution, 2016, 213: 717-726. |

| 4 | Chiu C H , Hsi, H C, Lin H P , et al . Effects of properties of manganese oxide-impregnated catalysts and flue gas condition on multipollutant control of HgO and NO[J]. Journal of Hazardous Materials, 2015, 291: 1-8. |

| 5 | Wang X , Li Y J , Shi J W , et al . Simultaneous SO2/NO removal performance of carbide slag pellets by bagasse templating in a bubbling fluidized bed reactor[J]. Fuel Processing Technology, 2018, 180: 75-86. |

| 6 | Liu Z , Woo S I . Recent advances in catalytic DeNO x science and technology[J]. Catalysis Reviews, 2006, 48(1): 43-89. |

| 7 | 黄海凤, 张峰, 卢晗锋, 等 . 制备方法对低温NH3-SCR脱硝催化剂MnO x /TiO2结构与性能的影响[J]. 化工学报, 2010, 61(1): 80-85. |

| Huang H F , Zhang F , Lu H F , et al . Effect of preparation methods on structures and performance of MnO x /TiO2 catalyst for low-temperature NH3-SCR[J]. CIESC Journal, 2010, 61(1): 80-85. | |

| 8 | Qi G , Yang R T . Performance and kinetics study for low-temperature SCR of NO with NH3 over MnO x -CeO2 catalyst[J]. Journal of Catalysis, 2003, 217(2): 434-441. |

| 9 | Muniz J , Marban G , Fuertes A B . Low temperature selective catalytic reduction of NO over modified activated carbon fibers[J]. Applied Catalysis B: Environmental, 2000, 27: 27-36. |

| 10 | Lei Z , Liu X , Jia M . Modeling of selective catalytic reduction (SCR) for NO removal using monolithic honeycomb catalys[J]. Energy & Fuels, 2009, 23: 6146-6151. |

| 11 | Shi J , Zhang Z H , Chen M X , et al . Promotion effect of tungsten and iron co-addition on the catalytic performance of MnO x /TiO2 for NH3-SCR of NO x [J]. Fuel, 2017, 210(15): 783-789. |

| 12 | Nam K B , Kwon D W , Hong S C . DRIFT study on promotion effects of tungsten-modified Mn/Ce/Ti catalysts for the SCR reaction at low-temperature[J]. Applied Catalysis A: General, 2017, 542: 55-62. |

| 13 | 廖永进, 张亚平, 余岳溪, 等 . MnO x /WO3/TiO2低温选择性催化还原NO x 机理的原位红外研究[J]. 化工学报, 2016, 67(12): 5031-5039. |

| Liao Y J , Zhang Y P , Yu Y X , et al . In situ FT-IR studies on low temperature NH3-SCR mechanism of NO x over MnO x /WO3/TiO2 catalyst[J]. CIESC Journal, 2016, 67(12): 5031-5039. | |

| 14 | Wu Z B , Jiang B Q , Liu Y , et al . Experimental study on a low-temperature SCR catalyst based on MnO x /TiO2 prepared by sol-gel method[J]. Journal of Hazardous Materials, 2007, 145: 488-94. |

| 15 | Jiang S Y , Zhou R X . Ce doping effect on performance of the Fe/β catalyst for NO x , reduction by NH3 [J]. Fuel Processing Technology, 2015, 133: 220-226. |

| 16 | Huang T J , Zhang Y P , Zhuang K , et al . Preparation of honeycombed holmium-modified Fe-Mn/TiO2 catalyst and its performance in the low temperature selective catalytic reduction of NO x [J]. Journal of Fuel Chemistry & Technology, 2018, 46(3): 319-327. |

| 17 | Chen X , Wang P , Fang P , et al . Tuning the property of Mn-Ce composite oxides by titanate nanotubes to improve the activity selectivity and SO2/H2O tolerance in middle temperature NH3-SCR reaction[J]. Fuel Processing Technology, 2017, 167: 221-228. |

| 18 | Jiang B Q , Wu Z B , Liu Y , et al . DRIFT Study of the SO2 effect on low-temperature SCR reaction over Fe-Mn/TiO2 [J]. Journal of Physical Chemistry C, 2010, 114(11): 4961-4965. |

| 19 | Shen B X , Liu T . Deactivation of MnO x -CeO x /ACF catalysts for low temperature NH3-SCR in the presence of SO2 [J]. Acta Physico-Chimica Sinica, 2010, 26(11): 3009-3016. |

| 20 | Phil H H , Reddy M P , Kumar P A , et al . SO2 resistant antimony promoted V2O5/TiO2 catalyst for NH3-SCR of NO x at low temperatures[J]. Applied Catalysis B: Environmental, 2008, 78(3): 301-308. |

| 21 | Li Y , Han X , et al . Role of CTAB in the improved H2O resistance for selective catalytic reduction of NO with NH3 over iron titanium catalyst[J]. Chemical Engineering Journal, 2018, 347(1): 313-321. |

| 22 | Park T S , Jeong S K , Hong S H , et al . Selective catalytic reduction of nitrogen oxides with NH3 over natural manganese ore at low temperature[J]. Ind. Eng. Chem. Res., 2001, 40(21): 4491-4495. |

| 23 | 刘亭 . 锰铈基低温选择性催化还原(SCR)脱硝催化剂的研究[D]. 天津: 南开大学, 2011. |

| Liu T . Study on manganese sulfhydryl group low temperature selective catalytic reduction (SCR) denitration catalyst[D]. Tianjin: Nankai University, 2011. | |

| 24 | Kijlstra W S , Biervliet M , Poels E K , et al . Deactivation by SO2 of MnO x /Al2O3 catalysts used for the selective catalytic reduction of NO with NH3 at low temperatures[J]. Applied Catalysis B: Environmental, 1998, 16(4): 327-337. |

| 25 | 孙克勤, 钟秦, 黄丽娜 . SCR钒基催化剂吸附氨和水的密度泛函研究[J]. 环境化学, 2008, 27(1): 33-38. |

| Sun K Q , Zhong Q , Huang L N . DFT Study of ammonia and water adsorption on vanadia-based catalysts catalysts for SCR reaction[J]. Environmental Chemistry, 2008, 27(1): 33-38. | |

| 26 | 程浩 . 铈掺杂对铜基氧载体释氧性能以及CO化学链燃烧影响的研究[D]. 武汉: 华中科技大学, 2016. |

| Cheng H . Study of the influence of Ce-doping on the oxygen releasing properties of copper based oxygen carrier and CO chemical looping combustion[D].Wuhan: Huazhong University of Science and Technology, 2016. | |

| 27 | 王雪冲 . 碱土金属对Ce基催化剂SCR烟气脱硝性能的影响研究[D]. 北京: 中国石油大学, 2016. |

| Wang X C . The effect of alkaline earth metals on Ce based catalyst for selective catalytic reduction of NO[D]. Beijing: China University of Petroleum, 2016. | |

| 28 | Reddy B M , Lakshmanan P , Khan A , et al . Structural characterization of CeO2-ZrO2/TiO2 and V2O5/CeO2-ZrO2/TiO2 mixed oxide catalysts by XRD, Raman spectroscopy, HREM, and other techniques[J]. Journal of Physical Chemistry B, 2005, 109(5): 1781. |

| 29 | Luo M , Chen J , Chen L , et al . Structure and redox properties of Ce x Ti1- x O2 solid solution[J]. Chem. Mater., 2001, 13(1): 197-202. |

| 30 | Chen L , Weng D , Wang J , et al . Low-temperature activity and mechanism of WO3-modified CeO2-TiO2 catalyst under NH3-NO/NO2 SCR conditions[J]. Chinese Journal of Catalysis, 2018, 39(11): 1804-1813. |

| [1] | 宋明昊, 赵霏, 刘淑晴, 李国选, 杨声, 雷志刚. 离子液体脱除模拟油中挥发酚的多尺度模拟与研究[J]. 化工学报, 2023, 74(9): 3654-3664. |

| [2] | 胡建波, 刘洪超, 胡齐, 黄美英, 宋先雨, 赵双良. 有机笼跨细胞膜易位行为的分子动力学模拟研究[J]. 化工学报, 2023, 74(9): 3756-3765. |

| [3] | 赵佳佳, 田世祥, 李鹏, 谢洪高. SiO2-H2O纳米流体强化煤尘润湿性的微观机理研究[J]. 化工学报, 2023, 74(9): 3931-3945. |

| [4] | 汪林正, 陆俞冰, 张睿智, 罗永浩. 基于分子动力学模拟的VOCs热氧化特性分析[J]. 化工学报, 2023, 74(8): 3242-3255. |

| [5] | 陈吉, 洪泽, 雷昭, 凌强, 赵志刚, 彭陈辉, 崔平. 基于分子动力学的焦炭溶损反应及其机理研究[J]. 化工学报, 2023, 74(7): 2935-2946. |

| [6] | 董明, 徐进良, 刘广林. 超临界水非均质特性分子动力学研究[J]. 化工学报, 2023, 74(7): 2836-2847. |

| [7] | 刘远超, 蒋旭浩, 邵钶, 徐一帆, 钟建斌, 李耑. 几何尺寸及缺陷对石墨炔纳米带热输运特性的影响[J]. 化工学报, 2023, 74(6): 2708-2716. |

| [8] | 顾浩, 张福建, 刘珍, 周文轩, 张鹏, 张忠强. 力电耦合作用下多孔石墨烯膜时间维度的脱盐性能及机理研究[J]. 化工学报, 2023, 74(5): 2067-2074. |

| [9] | 李辰鑫, 潘艳秋, 何流, 牛亚宾, 俞路. 基于碳微晶结构的炭膜模型及其气体分离模拟[J]. 化工学报, 2023, 74(5): 2057-2066. |

| [10] | 杨松涛, 李东洋, 牛玉清, 李鑫钢, 康绍辉, 李洪, 叶开凯, 周志全, 高鑫. 氟化物势能函数和热力学性质的分子模拟研究进展[J]. 化工学报, 2022, 73(9): 3828-3840. |

| [11] | 廖艺, 牛亚宾, 潘艳秋, 俞路. 复配表面活性剂对油水界面行为和性质影响的模拟研究[J]. 化工学报, 2022, 73(9): 4003-4014. |

| [12] | 郑默, 李晓霞. ReaxFF MD模拟揭示的煤热解挥发分自由基反应的竞争与协调[J]. 化工学报, 2022, 73(6): 2732-2741. |

| [13] | 李春晖, 何辉, 何明键, 张萌, 高杨, 矫彩山. 离子液体萃取硝酸中Ce(Ⅳ)的动力学研究[J]. 化工学报, 2022, 73(4): 1606-1614. |

| [14] | 王瑞, 任瑛, 陈卫, 韩永生. 冰水界面动态结构的分子动力学模拟研究[J]. 化工学报, 2022, 73(3): 1315-1323. |

| [15] | 张瑾渊, 徐娜, 贺文云, 吕耀东, 刘子璐, 张兴芳. 消防用PEO/OTAC/NaSal减阻体系的介观分子动力学分析[J]. 化工学报, 2022, 73(3): 1157-1165. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号