化工学报 ›› 2020, Vol. 71 ›› Issue (8): 3789-3796.DOI: 10.11949/0438-1157.20191417

收稿日期:2019-11-25

修回日期:2020-05-22

出版日期:2020-08-05

发布日期:2020-08-05

通讯作者:

吴集迎

作者简介:吴集迎(1964—),男,教授,基金资助:

Jiying WU1,2( ),Yimin MA1,2,Wensheng CAO1,2

),Yimin MA1,2,Wensheng CAO1,2

Received:2019-11-25

Revised:2020-05-22

Online:2020-08-05

Published:2020-08-05

Contact:

Jiying WU

摘要:

为高效利用沼气资源并减轻环境污染,构建了基于沼气机驱动的风冷热泵能源综合利用实验装置,重点研究了蒸发温度、冷却水量、沼气机转速等参数对系统性能的影响。实验测试结果表明:冷凝器总负荷随蒸发温度及冷却水量的增加而增大,但增幅较小;回收的沼气机余热随蒸发温度的升高而降低,但降幅较小,通过增大冷却水量可以提高沼气机余热的回收率,同时也增大了系统总供热量;冷却水量对系统性能系数(COP)的影响不具有单调性,在同一工况下,存在一个最佳冷却水量;冷却水量对系统一次能源利用率(PER)的影响幅度不同,冷却水量大时,PER的增幅反而较小。实验工况下,系统COP最高可达5.15,PER最高可达1.68。

中图分类号:

吴集迎, 马益民, 曹文胜. 沼气机驱动的风冷热泵系统变工况性能[J]. 化工学报, 2020, 71(8): 3789-3796.

Jiying WU, Yimin MA, Wensheng CAO. Performance of biogas engine driven air source heat pump system under variable conditions[J]. CIESC Journal, 2020, 71(8): 3789-3796.

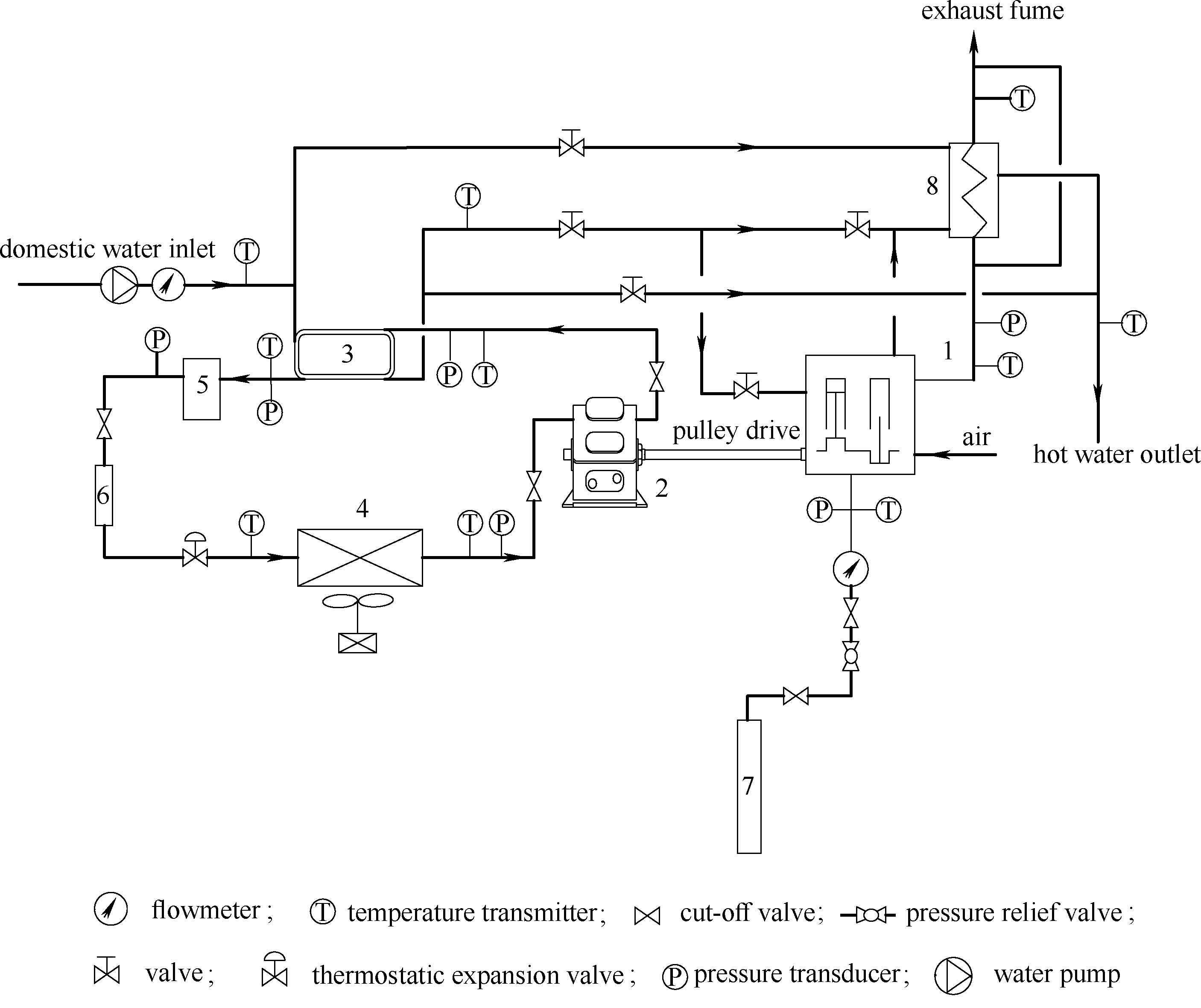

图2 沼气机驱动的风冷热泵实验系统流程图1—biogas engine;2—piston type compressor;3—double-pipe condenser;4—evaporator;5—receiver;6—drier-filter;7—biogas tank; 8—fume-water heat exchanger

Fig.2 Flow diagram of biogas engine driven air source heat pump experimental system

| 1 | Orhan S, Berrin T. Composition and source identification of deposits forming in landfill gas(LFG) engines and effect of activated carbon treatment on deposit composition [J]. Journal of Environment Management, 2013, 128: 300-305. |

| 2 | Orhan S, Berrin T. Effect of persistent trace compounds in landfill gas on engine performance during energy recovery: a case study [J]. Waste Management, 2013, 33: 4-80. |

| 3 | Zhai P M, Li L. Observed atmosphere and surface climate changes in the IPCC Fifth Assessment Report[J]. Progressus Inquisitiones De Mutatione Climatis, 2014, 10(1): 20-24. |

| 4 | 陈业钢, 陈漫漫. 沼气燃烧系统的设计[J]. 中国给水排水, 2002, 18(7): 65-66. |

| Chen Y G, Chen M M. Burning system design of biogas [J]. China Water & Wastewater, 2002, 18(7): 65-66. | |

| 5 | Wang Y W, Cai L, Shao X W, et al. Analysis on energy-saving effect and environmental benefit of a novel hybrid-power gas engine heat pump [J]. International Journal of Refrigeration, 2013, 36(1): 237-246. |

| 6 | Lazzarin R, Noro M. District heating and gas engine heat pump: economic analysis based on a case study [J]. Applied Thermal Engineering, 2006, 26(2/3): 193-199. |

| 7 | 黄剑光, 赵兰萍, 陈汝东. 沼气型燃气热泵的可行性研究 [J]. 流体机械, 2008, 36(2): 80-82. |

| Huang J G, Zhao L P, Chen R D. Feasibility studies about biogas engine driven heat pump [J]. Fluid Machinery, 2008, 36(2): 80-82. | |

| 8 | Wu J Y, Zeng J Q. System construction and economic analysis of heat pump driven by biogas engine [C] // Proceedings of the 22nd International Congress of Refrigeration. Beijing, 2007: 229-238. |

| 9 | 王明涛, 杨昭, 陈轶光. 燃气机热泵的余热回收[J]. 农业机械学报, 2011, 42(1): 35-38. |

| Wang M T, Yang Z, Chen Y G. Recovery of waste heat of gas engine heat pump [J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(1): 35-38. | |

| 10 | Hepbasli A, Erbay Z, Icier F, et al. A review of gas engine driven heat pumps (GEHPs) for residential and industrial applications [J]. Renewable & Sustainable Energy Review, 2009, 13(1): 85-99. |

| 11 | 徐振军, 杨昭. 沼气机热泵复合式空调系统数值计算与能耗分析[J]. 农业机械学报, 2008, 39(9): 118-121. |

| Xu Z J, Yang Z. Numerical calculation and energy consumption analysis for air condition system driven by biogas engine [J]. Transactions of the Chinese Society for Agricultural Machinery, 2008, 39(9): 118-121. | |

| 12 | 徐振军. 复合发电系统的沼气热泵供能特性研究 [J]. 农业机械学报, 2011, 42(7): 144-147. |

| Xu Z J. Energy supply performance for biogas heat pump with generator [J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(7): 144-147. | |

| 13 | Yang Z, Wang W B, Wu X. Thermal modeling and operating tests for a gas-engined driven heat pump working as a water heater in winter [J]. Energy and Buildings, 2013, 58(3): 219-226. |

| 14 | 杨昭, 程珩, 张世钢, 等. 燃气压缩式热泵空调系统的实验研究[J]. 工程热物理学报, 2003, 24(6): 920-922. |

| Yang Z, Cheng H, Zhang S G, et al. Experimental research of a compressive heat pump air-condition system driven by gas engine [J]. Journal of Engineering Thermophysics, 2003, 24(6): 920-922. | |

| 15 | Zhang R R, Lu X S, Li S Z, et al. Analysis on the heating performance of a gas engine driven air to water heat pump based on a steady-state model [J]. Energy Conversion & Management, 2005, 46(11/12): 1714-1730. |

| 16 | Sun Z G, Wang R Z, Sun W Z. Energetic efficiency of a gas engine-driven cooling and heating system [J]. Applied Thermal Engineering, 2004, 24(5/6): 941-947. |

| 17 | Sun Z G. A combined heat and cold system driven by an industrial engine [J]. Energy Conversion and Management, 2007, 48 (2): 366-369. |

| 18 | Elgendy E, Schmidt J, Khalil A, et al. Performance of a gas engine heat pump (GEHP) using R410A for heating and cooling applications [J]. Energy, 2010, 35(12): 4941-4948. |

| 19 | Elgendy E, Schmidt J, Khalil A. Optimum utilization of recovered heat of a gas engine heat pump used for water heating at low air temperature [J]. Energy and Buildings, 2014, 80(1): 375-383. |

| 20 | Elgendy E, Schmidt J, Khalil A, et al.Performance of a gas engine driven heat pump for hot water supply systems [J]. Energy, 2011, 36(5): 2883-2889. |

| 21 | 吴集迎. 沼气发动机驱动的热泵能源利用率计算[J]. 可再生能源, 2007, 25(5): 49-52. |

| Wu J Y. PER calculation of a biogas engine driven heat pump system [J]. Renewable Energy Resources, 2007, 25(5): 49-52. | |

| 22 | 吴集迎. 沼气热泵系统设计及其经济性分析[J]. 农业机械学报, 2006, 37(12): 114-117. |

| Wu J Y. System design and economic analysis of absorption heat pump driven by biogas [J]. Transactions of the Chinese Society for Agricultural Machinery, 2006, 37(12): 114-117. | |

| 23 | Wu J Y, Ma Y M. Experimental study on performance of a biogas engine driven air source heat pump system powered by renewable landfill gas [J].International Journal of Refrigeration, 2016, 62: 19-29. |

| 24 | 吴集迎, 马益民. 空气源沼气机热泵部分负荷性能[J]. 化工学报, 2014, 65(11): 4551-4556. |

| Wu J Y, Ma Y M. Partial load performance of biogas engine driven air source heat pump system [J]. CIESC Journal, 2014, 65(11): 4551-4556. | |

| 25 | 马益民, 吴集迎. 以LFG为燃料的空气源沼气机热泵供热性能实验[J]. 化工学报, 2016, 67: 370-377. |

| Ma Y M, Wu J Y. Heating performance of landfill gas fueled biogas engine driven air source heat pump [J]. CIESC Journal, 2016, 67: 370-377. | |

| 26 | 任勇, 杨昭. 内燃机独立供能系统的性能实验[J]. 天津大学学报, 2011, 4(1): 29-34. |

| Ren Y, Yang Z. Performance experiment of ICEEI system [J]. Journal of Tianjin University, 2011, 4(1): 29-34. | |

| 27 | 刘焕卫, 杨昭, 王明涛. 燃气机热泵部分负荷特性的实验研究 [J]. 热能动力工程, 2011, 26(5): 523-527. |

| Liu H W, Yang Z, Wang M T. Experimental study of the partial load characteristics of a gas-engine-driven heat pump [J]. Journal of Engineering for Thermal Energy and Power, 2011, 26(5): 523-527. | |

| 28 | Chen Y G, Yang Z, Wu X, et al. Theoretical simulation and experimental research on the system of air source energy independence driven by internal-combustion engine[J]. Energy and Buildings, 2011, 43(6): 1351-1358. |

| 29 | Sanaye S, Chahartaghi M. Thermal modeling and operating tests for the gas engine-driven heat pump systems [J]. Energy, 2010, 35(1): 351-363. |

| 30 | Sannye S, Asgari H. Thermal modeling of gas engine driven air to water heat pump systems in heating mode using genetic algorithm and artificial neural network methods [J]. International Journal of Refrigeration, 2013, 36(8): 2262-2277. |

| 31 | Li Y L, Zhang X S. A novel parallel-type hybrid-power biogas engine-driven heat pump system[J]. International Journal of Refrigeration, 2007, 30(7): 1134-1142. |

| 32 | 李应林, 张小松, 殷勇高, 等. 燃气驱动冷热水机组变转速运行实验研究[J]. 东南大学学报, 2005, 35(2): 298-301. |

| Li Y L, Zhang X S, Yin Y G, et al. Experimental research on variable speed operation of cold-hot water unit driven by gas engine[J]. Journal of Southeast University, 2005, 35(2): 298-301. | |

| 33 | 吴集迎, 马益民. 基于LFG的沼气机热泵系统配置与实验研究[J]. 化工学报, 2014, 65: 208-214. |

| Wu J Y, Ma Y M. System configuration and experimental study on LFG based biogas engine driven heat pump [J]. CIESC Journal, 2014, 65: 208-214. | |

| 34 | 侯根富, 段常贵, 马最良. 风冷燃气机驱动压缩式热泵冷热水机组运行特性试验研究[J]. 暖通空调, 2001, 31(3): 5-8. |

| Hou G F, Duan C G, Ma Z L. Experiment of performance characteristics of a compression heat pump unit driven by a gas engine[J]. Heating Ventilating & Air Conditioning, 2001, 31(3): 5-8. |

| [1] | 张化福, 童莉葛, 张振涛, 杨俊玲, 王立, 张俊浩. 机械蒸汽压缩蒸发技术研究现状与发展趋势[J]. 化工学报, 2023, 74(S1): 8-24. |

| [2] | 杨欣, 王文, 徐凯, 马凡华. 高压氢气加注过程中温度特征仿真分析[J]. 化工学报, 2023, 74(S1): 280-286. |

| [3] | 卫雪岩, 钱勇. 微米级铁粉燃料中低温氧化反应特性及其动力学研究[J]. 化工学报, 2023, 74(6): 2624-2638. |

| [4] | 鲁文静, 李先锋. 液流电池多孔离子传导膜研究进展[J]. 化工学报, 2023, 74(1): 192-204. |

| [5] | 黄宽, 马永德, 蔡镇平, 曹彦宁, 江莉龙. 油脂催化加氢转化制备第二代生物柴油研究进展[J]. 化工学报, 2023, 74(1): 380-396. |

| [6] | 李彬, 宋文明, 杨坤龙, 姜爽, 张天永. 水系有机液流电池活性材料的分子工程研究进展[J]. 化工学报, 2022, 73(7): 2806-2818. |

| [7] | 刘庆祎, 肖桐, 孙文杰, 张家豪, 刘昌会. 纳米二氧化钛强化的相变储能研究进展[J]. 化工学报, 2022, 73(5): 1863-1882. |

| [8] | 张殷豪, 詹菲, 李城序, 于畅, 邱介山. 铵钒青铜基浓差流动电池的盐差发电性能研究[J]. 化工学报, 2022, 73(2): 857-864. |

| [9] | 周云龙, 林东尧, 叶校源, 孙博. 常见离子对玉米秸秆为牺牲剂的光催化制氢影响[J]. 化工学报, 2022, 73(2): 722-729. |

| [10] | 王昊成, 杨敬瑶, 董学强, 郭浩, 赵延兴, 公茂琼. 10 t/d级氢液化装置流程热力分析与优化[J]. 化工学报, 2022, 73(11): 5106-5117. |

| [11] | 成珊, 罗睿, 田红, 王振琦, 黄经春, 乔瑜. 水热碳化温度对污泥有机氮固液相迁移转化路径影响研究[J]. 化工学报, 2022, 73(11): 5220-5229. |

| [12] | 张怡洁, 刘星, 陈振武, 张晓春, 周勇, 丘建栋, 顾文波, 马涛. 分布式光伏储能系统的设计方法及运行特性[J]. 化工学报, 2021, 72(S1): 503-511. |

| [13] | 陈建业, 丁月, 吴钊, 禹云星, 邵双全. 带涡流管的新型加氢流程数值研究[J]. 化工学报, 2021, 72(S1): 461-466. |

| [14] | 崔运浩, 乔建新, 王晓涛, 宋斌, 阳朝辉, 戴巍, 李海冰. 普冷温区斯特林制冷机[J]. 化工学报, 2021, 72(S1): 390-397. |

| [15] | 顾潇, 邹慧明, 韩欣欣, 唐明生, 田长青. 基于余热回收的电动客车喷射补气热泵的制热性能[J]. 化工学报, 2021, 72(S1): 326-335. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号