化工学报 ›› 2020, Vol. 71 ›› Issue (9): 4168-4176.DOI: 10.11949/0438-1157.20200518

收稿日期:2020-05-08

修回日期:2020-08-04

出版日期:2020-09-05

发布日期:2020-09-05

通讯作者:

骆广生

作者简介:谢沛(1991—),女,博士研究生,基金资助:

Pei XIE( ),Kai WANG,Jian DENG,Guangsheng LUO(

),Kai WANG,Jian DENG,Guangsheng LUO( )

)

Received:2020-05-08

Revised:2020-08-04

Online:2020-09-05

Published:2020-09-05

Contact:

Guangsheng LUO

摘要:

根据微化工技术发展的主要趋势,针对4-溴-3-甲基苯甲醚间歇非均相合成技术存在的问题,以微筛孔反应器与玻璃微珠填充床为核心功能微设备单元构建了模块化微反应系统,并在此模块化微反应系统内对液-液非均相连续溴化合成4-溴-3-甲基苯甲醚开展研究。通过优化操作条件,在溴浓度(

中图分类号:

谢沛, 王凯, 邓建, 骆广生. 模块化微反应系统内溴化间甲基苯甲醚连续合成[J]. 化工学报, 2020, 71(9): 4168-4176.

Pei XIE, Kai WANG, Jian DENG, Guangsheng LUO. Continuous synthesis of 4-bromo-3-methylanisole in modular microreaction system[J]. CIESC Journal, 2020, 71(9): 4168-4176.

图4 反应起始温度对产物分布的影响(QBr2-HBr=49.1 ml/min, QM=8.7 ml/min, xBr2=17.5%, xHBr=13.2%, nBr2/nM=1.01, T=0, 5.0, 10.0, 15.0, 20.0, 25.0, 30.0℃, τ=0.78 min, GC测量标准偏差小于0.05%)

Fig.4 Effect of initial reaction temperature on the product distribution

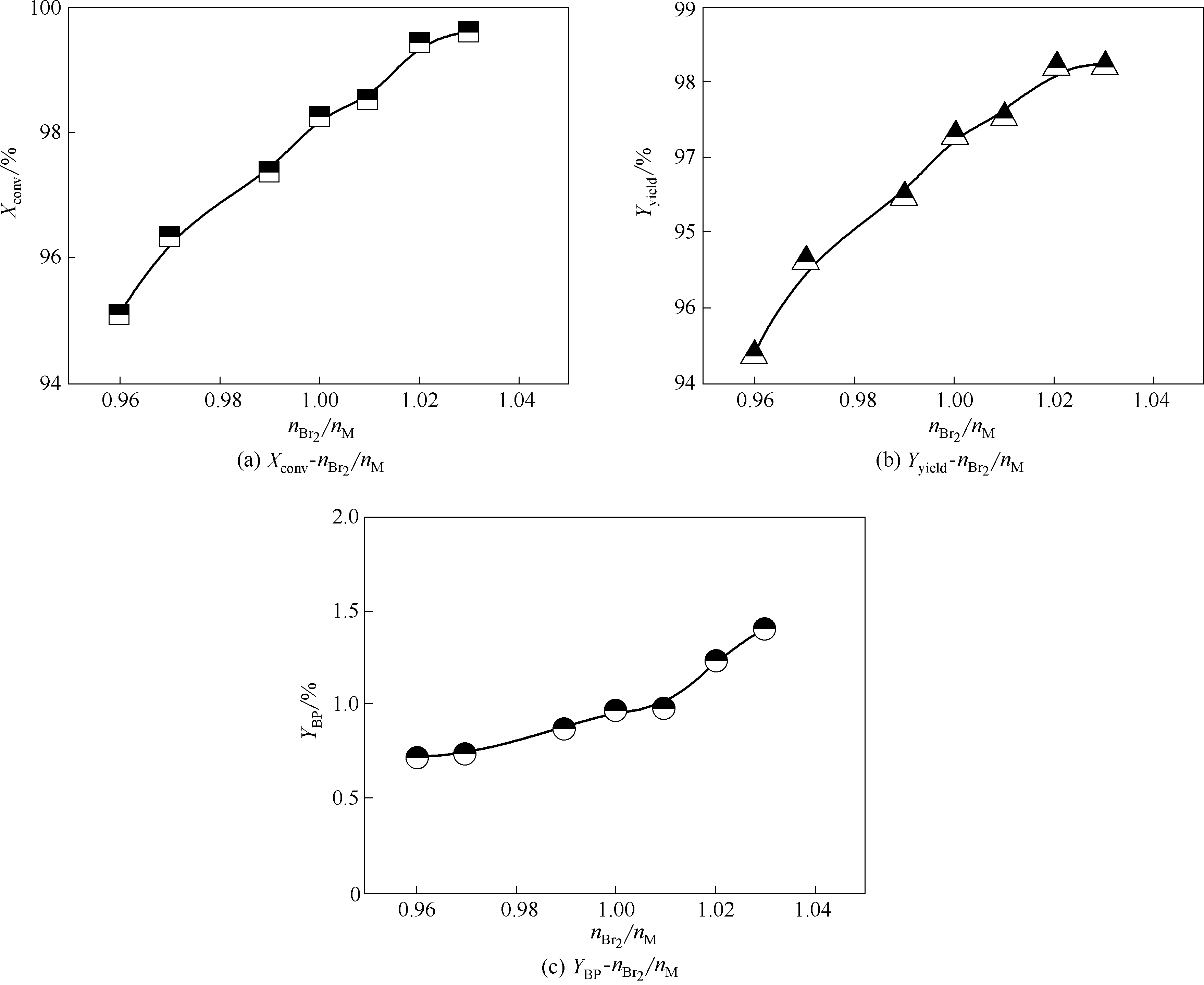

图5 反应物配比对产物分布的影响(QBr2-HBr=49.1 ml/min, QM=8.5 ~ 9.1 ml/min, xBr2=17.5%, xHBr=13.2%, nBr2/nM=0.96, 0.97, 0.99, 1.00, 1.01, 1.02, 1.03, T=0℃, τ=0.78 min, GC测量标准偏差小于0.05%)

Fig.5 Effect of molar ratio of reactants on the product distribution

| 项目 | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| 49.1 | 49.1 | 49.1 | 49.1 | 49.1 | |

| QM/ (ml/min) | 8.5 | 9.1 | 9.4 | 10.2 | 11.2 |

| 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | |

| xHBr/ %(mass) | 10.0 | 15.0 | 20.0 | 25.0 | 33.0 |

| 1.01 | 1.01 | 1.01 | 1.01 | 1.01 | |

| T /℃ | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 |

| τ/min | 0.78 | 0.78 | 0.78 | 0.78 | 0.78 |

| Xconv /% | 97.27 | 98.28 | 99.38 | 98.56 | 98.06 |

| Yyield/% | 96.48 | 97.21 | 97.90 | 97.24 | 95.68 |

| YBP /% | 0.78 | 1.07 | 1.48 | 1.32 | 2.38 |

表1 HBr浓度对产物分布的影响

Table 1 Effect of HBr concentration on the product distribution

| 项目 | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| 49.1 | 49.1 | 49.1 | 49.1 | 49.1 | |

| QM/ (ml/min) | 8.5 | 9.1 | 9.4 | 10.2 | 11.2 |

| 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | |

| xHBr/ %(mass) | 10.0 | 15.0 | 20.0 | 25.0 | 33.0 |

| 1.01 | 1.01 | 1.01 | 1.01 | 1.01 | |

| T /℃ | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 |

| τ/min | 0.78 | 0.78 | 0.78 | 0.78 | 0.78 |

| Xconv /% | 97.27 | 98.28 | 99.38 | 98.56 | 98.06 |

| Yyield/% | 96.48 | 97.21 | 97.90 | 97.24 | 95.68 |

| YBP /% | 0.78 | 1.07 | 1.48 | 1.32 | 2.38 |

| 标号 | QM /(ml/min) | xHBr /%(mass) | T /℃ | τ /min | Xconv/% | Yyield /% | YBP/% | |||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 49.1 | 7.7 | 15.0 | 15.0 | 1.01 | 5.0 | 0.78 | 96.82 | 95.98 | 0.85 |

| 2 | 49.1 | 9.1 | 17.5 | 15.0 | 1.01 | 5.0 | 0.78 | 98.28 | 97.21 | 1.07 |

| 3 | 49.1 | 10.3 | 20.0 | 15.0 | 1.01 | 5.0 | 0.78 | 99.45 | 97.34 | 2.11 |

| 4 | 49.1 | 13.8 | 25.0 | 15.0 | 1.01 | 5.0 | 0.78 | 99.69 | 97.09 | 2.60 |

表2 Br2浓度对产物分布的影响

Table 2 Effect of Br2 concentration on the product distribution

| 标号 | QM /(ml/min) | xHBr /%(mass) | T /℃ | τ /min | Xconv/% | Yyield /% | YBP/% | |||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 49.1 | 7.7 | 15.0 | 15.0 | 1.01 | 5.0 | 0.78 | 96.82 | 95.98 | 0.85 |

| 2 | 49.1 | 9.1 | 17.5 | 15.0 | 1.01 | 5.0 | 0.78 | 98.28 | 97.21 | 1.07 |

| 3 | 49.1 | 10.3 | 20.0 | 15.0 | 1.01 | 5.0 | 0.78 | 99.45 | 97.34 | 2.11 |

| 4 | 49.1 | 13.8 | 25.0 | 15.0 | 1.01 | 5.0 | 0.78 | 99.69 | 97.09 | 2.60 |

| 序号 | 反应装置 | Xconv /% | Yyield /% | YBP/% | YSTY /(kg/m3·h) |

|---|---|---|---|---|---|

| 1 | 搅拌釜 | 99.56 | 97.31 | 2.09 | 45 |

| 2 | 微反应系统 | 99.42 | 98.37 | 1.05 | 6.5×104 |

表3 微反应系统与搅拌釜的溴化结果对比

Table 3 Comparison of bromination results between batch and microreaction system

| 序号 | 反应装置 | Xconv /% | Yyield /% | YBP/% | YSTY /(kg/m3·h) |

|---|---|---|---|---|---|

| 1 | 搅拌釜 | 99.56 | 97.31 | 2.09 | 45 |

| 2 | 微反应系统 | 99.42 | 98.37 | 1.05 | 6.5×104 |

| 1 | Saikia I, Borah A J, Phukan P. Use of bromine and bromo-organic compounds in organic synthesis[J]. Chemical Reviews, 2016, 116(12): 6837-7042. |

| 2 | Deng Q, Shen R, Ding R, et al. Bromination of aromatic compounds using bromine in a microreactor[J]. Chemical Engineering & Technology, 2016, 39(8): 1445-1450. |

| 3 | Löb P, Löwe H, Hessel V. Fluorinations, chlorinations and brominations of organic compounds in micro reactors[J]. Journal of Fluorine Chemistry, 2004, 125(11): 1677-1694. |

| 4 | Mason B P, Price K E, Steinbacher J L, et al. Greener approaches to organic synthesis using microreactor technology[J]. Chemical Reviews, 2007, 107(6): 2300-2318. |

| 5 | Wang W, Zou H, Chu G, et al. Effects of assistant solvents and mixing intensity on the bromination process of butyl rubber[J]. Chinese Journal of Chemical Engineering, 2014, 22(4): 398-404. |

| 6 | Kowalski R C, Davis W M, Newman N F, et al. Extrusion process for preparing improved brominated butyl rubber: US4563506[P]. 1986-01-07. |

| 7 | Butler A, Walker J V. Marine haloperoxidases[J]. Chemical Reviews, 1993, 93: 1937-1944. |

| 8 | 薛明明. 水溶液中芳香醚的溴代反应研究[D]. 天津: 天津大学, 2008. |

| Xue M M. Study on the bromination of aromatic ethers in aqueous solution[D]. Tianjin: Tanjin University, 2008. | |

| 9 | 李华杰. 新的芳环溴化及烯烃溴羟化反应研究[D]. 兰州: 兰州大学, 2012. |

| Li H J. Studies on novel methods for arene bromination and alkene bromohydroxylation[D]. Lanzhou: Lanzhou University, 2012. | |

| 10 | Parent J S, Thom D J, White G, et al. Thermal stability of brominated poly(isobutylene-co-isoprene)[J]. Journal of Polymer Science: Part A: Polyner Chemistry, 2001, 39: 2019-2026. |

| 11 | Abdollahi A, Sharma R N, Vatani A. Fluid flow and heat transfer of liquid-liquid two phase flow in microchannels: a review[J]. International Communications in Heat and Mass Transfer, 2017, 84: 66-74. |

| 12 | Yoshida J I, Kim H, Nagaki A. Green and sustainable chemical synthesis using flow microreactors[J]. ChemSusChem, 2011, 4(3): 331-340. |

| 13 | Deng J, Zhang J, Wang K, et al. Microreaction technology for synthetic chemistry[J]. Chinese Journal of Chemistry, 2019, 37(2): 161-170. |

| 14 | Wang K, Li L, Xie P, et al. Liquid–liquid microflow reaction engineering[J]. Reaction Chemistry & Engineering, 2017, 2(5): 611-627. |

| 15 | 骆广生, 王凯, 徐建鸿, 等. 微化工过程研究进展[J]. 中国科学: 化学, 2014, 44(9): 1404-1412. |

| Luo G S, Wang K, Xu J H, et al. Advances in research of microstructured chemical process [J]. Scientia Sinica Chimica, 2014, 44(9): 1404-1412. | |

| 16 | 骆广生, 王凯, 吕阳成, 等. 微尺度下非均相反应的研究进展[J]. 化工学报, 2013, 64(1): 165-172. |

| Luo G S, Wang K, Lü Y C, et al. Research and development of micro-scale multiphase reaction processes[J]. CIESC Journal, 2013, 64(1): 165-172. | |

| 17 | 骆广生, 王凯, 徐建鸿, 等. 微化工系统内多相流动及其传递反应性能研究进展[J]. 化工学报, 2010, 61(7): 1621-1626. |

| Luo G S, Wang K, Xu J H, et al. Multiphase flow, transport and reaction in micro-structured chemical systems[J]. CIESC Journal, 2010, 61(7): 1621-1626. | |

| 18 | Li G, Pu X, Shang M, et al. Intensification of liquid-liquid two-phase mass transfer in a capillary microreactor system[J]. AIChE Journal, 2019, 65(1): 334-346. |

| 19 | Xie P, Wang K, Wang P, et al. Synthesizing bromobutyl rubber by a microreactor system[J]. AIChE Journal, 2017, 63(3): 1002-1009. |

| 20 | Vukov R. Halogenation of butyl rubber-a model-compound approach[J]. Rubber Chemistry and Technology, 1984, 57(2): 275-283. |

| 21 | Parker P T, Rouge B L, Bryan J, et al. Continuous chlorination and bromination of butyl rubber: US3099644[P]. 1963-07-30. |

| 22 | Baade W, Konigshofen H, Kaszas G. Process for the bromination of alkyl rubbers: US5569723[P]. 1996-10-29. |

| 23 | Chu YC, Vukov R. Determination of the structure of butyl rubber by NMR spectroscopy[J]. Macromolecules, 1985, 18: 1423-1430. |

| 24 | Gardner I J, Fusco J V, Newman N F, et al. Halogenated butyl rubber: US4703091[P]. 1987-10-27. |

| 25 | Gutmann B, Cantillo D, Kappe C O. Continuous-flow technology-a tool for the safe manufacturing of active pharmaceutical ingredients[J]. Angewandte Chemie Internitional Edition, 2015, 54(23): 6688-6728. |

| 26 | Wang W, Zou H K, Chu G W, et al. Bromination of butyl rubber in rotating packed bed reactor[J]. Chemical Engineering Journal, 2014, 240: 503-508. |

| 27 | 王兴刚, 焦宏宇, 刘秀兰, 等. 溴代丁基橡胶的结构控制及其力学性能研究[J]. 弹性体, 2015, 25(3): 24-28. |

| Wang X G, Jiao H Y, Liu X L, et al. Controling structure and mechanical properties of brominated butyl rubber[J]. Elastomer, 2015, 25(3): 24-28. | |

| 28 | Zhang J, Wang K, Teixeira A R, et al. Design and scaling up of microchemical systems: a review[J]. Annual Reviews Chemical and Biomolecular Engineering, 2017, 8: 285-305. |

| 29 | 赵玉潮, 陈光文. 微化工系统的并行放大研究进展[J]. 中国科学: 化学, 2015, 45(1): 16-23. |

| Zhao Y C, Chen G W. Process in research on numbering-up of microchemical system[J]. Cientia Sinica Chimica, 2015, 45(1): 16-23. | |

| 30 | Mawatari K, Kazoe Y, Aota A, et al. Microflow systems for chemical synthesis and analysis: approaches to full integration of chemical process[J]. Journal of Flow Chemistry, 2011, 1(1): 3-12. |

| 31 | Wang K, Lu Y, Luo G. Strategy for scaling-up of a microsieve dispersion reactor[J]. Chemical Engineering & Technology, 2014, 37(12): 2116-2122. |

| 32 | Bhore J B, Dangat V T, Borkar V T, et al. Rapid kinetics of bromination of nitrophenols in aqueous solution by the use of RPE[J]. Research Journal of Chemistry and Environment, 2013, 17(8): 8-10. |

| 33 | Wang K, Lu Y C, Xu J H, et al. Determination of dynamic interfacial tension and its effect on droplet formation in the T-shaped microdispersion process[J]. Langmuir, 2009, 25(4): 2153-2158. |

| 34 | Wang K, Lu Y C, Xu J H, et al. Droplet generation in micro-sieve dispersion device[J]. Microfluidics and Nanofluidics, 2010, 10(5): 1087-1095. |

| [1] | 康飞, 吕伟光, 巨锋, 孙峙. 废锂离子电池放电路径与评价研究[J]. 化工学报, 2023, 74(9): 3903-3911. |

| [2] | 曹跃, 余冲, 李智, 杨明磊. 工业数据驱动的加氢裂化装置多工况切换过渡状态检测[J]. 化工学报, 2023, 74(9): 3841-3854. |

| [3] | 苏晓丹, 朱干宇, 李会泉, 郑光明, 孟子衡, 李防, 杨云瑞, 习本军, 崔玉. 湿法磷酸半水工艺考察与石膏结晶过程研究[J]. 化工学报, 2023, 74(4): 1805-1817. |

| [4] | 张中秋, 李宏光, 石逸林. 基于人工预测调控策略的复杂化工过程多任务学习方法[J]. 化工学报, 2023, 74(3): 1195-1204. |

| [5] | 张江淮, 赵众. 碳三加氢装置鲁棒最小协方差约束控制及应用[J]. 化工学报, 2023, 74(3): 1216-1227. |

| [6] | 杨星宇, 马优, 朱春英, 付涛涛, 马友光. 梳状并行微通道内液液分布规律研究[J]. 化工学报, 2023, 74(2): 698-706. |

| [7] | 付家崴, 陈帅帅, 方凯伦, 蒋新. 微反应器共沉淀反应制备铜锰催化剂[J]. 化工学报, 2023, 74(2): 776-783. |

| [8] | 章承浩, 罗京, 张吉松. 微反应器内基于氮氧自由基催化剂连续氧气/空气氧化反应的研究进展[J]. 化工学报, 2023, 74(2): 511-524. |

| [9] | 谢煜, 张民, 胡卫国, 王玉军, 骆广生. 利用膜分散微反应器高效溶解D-7-ACA的研究[J]. 化工学报, 2023, 74(2): 748-755. |

| [10] | 顾仁杰, 张加威, 靳雪阳, 文利雄. 微撞击流反应器制备镍钴复合氢氧化物超级电容器材料及其性能研究[J]. 化工学报, 2022, 73(8): 3749-3757. |

| [11] | 张经纬, 周弋惟, 陈卓, 徐建鸿. 微反应器内的有机合成前沿进展[J]. 化工学报, 2022, 73(8): 3472-3482. |

| [12] | 侯跃辉, 刘璇, 廉应江, 韩梅, 尧超群, 陈光文. 超声微反应器内三硝基间苯三酚合成工艺研究[J]. 化工学报, 2022, 73(8): 3597-3607. |

| [13] | 禹言芳, 刘桓辰, 孟辉波, 刘励图, 李毓, 吴剑华. Lightnin静态混合器内气泡分散流体动力学特性实验研究[J]. 化工学报, 2022, 73(8): 3565-3575. |

| [14] | 孟辉波, 蒙彤, 禹言芳, 王宗勇, 吴剑华. Ross LPD型静态混合器内湍流传热与混合强化特性[J]. 化工学报, 2022, 73(8): 3541-3552. |

| [15] | 周乐, 沈程凯, 吴超, 侯北平, 宋执环. 深度融合特征提取网络及其在化工过程软测量中的应用[J]. 化工学报, 2022, 73(7): 3156-3165. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号