化工学报 ›› 2020, Vol. 71 ›› Issue (9): 4177-4188.DOI: 10.11949/0438-1157.20200529

史大昕1( ),李爱如1(

),李爱如1( ),方祝青2,李继娟1,矫庆泽1,3,吴芹1,冯彩虹1,赵芸1,黎汉生1(

),方祝青2,李继娟1,矫庆泽1,3,吴芹1,冯彩虹1,赵芸1,黎汉生1( )

)

收稿日期:2020-05-08

修回日期:2020-07-18

出版日期:2020-09-05

发布日期:2020-09-05

通讯作者:

黎汉生

作者简介:史大昕(1974—),男,博士,讲师,基金资助:

Daxin SHI1( ),Airu LI1(

),Airu LI1( ),Zhuqing FANG2,Jijuan LI1,Qingze JIAO1,3,Qin WU1,Caihong FENG1,Yun ZHAO1,Hansheng LI1(

),Zhuqing FANG2,Jijuan LI1,Qingze JIAO1,3,Qin WU1,Caihong FENG1,Yun ZHAO1,Hansheng LI1( )

)

Received:2020-05-08

Revised:2020-07-18

Online:2020-09-05

Published:2020-09-05

Contact:

Hansheng LI

摘要:

研究了钼元素及其添加量对镍基催化剂在双环戊二烯(DCPD)加氢反应中耐硫特性的影响规律。催化 剂∶DCPD =1∶10,反应温度150℃,压力3.5 MPa,转速600 r/min,噻吩浓度为:500 mg/L时,Ni/γ-Al2O3催化剂的双环戊二烯8、9位双键的加氢速率显著降低,3、4位双键的加氢活性完全抑制; 而NiMo0.2/γ-Al2O3催化剂,在4 h内完成加氢反应,四氢双环戊二烯(endo-THDCPD)收率达到98%,抗硫特性显著提高。不同镍钼比的系列催化剂中,NiMo0.2/γ-Al2O3具有最好的加氢活性与耐硫特性。0~2000 mg/L噻吩浓度内,低浓度条件下,NiMo0.2/γ-Al2O3催化剂对双环戊二烯的加氢活性高,选择性好;随着噻吩浓度增加,催化性能有所下降,2000 mg/L时,加氢反应延长至6 h,endo-THDCPD收率降至95%。

中图分类号:

史大昕, 李爱如, 方祝青, 李继娟, 矫庆泽, 吴芹, 冯彩虹, 赵芸, 黎汉生. 双环戊二烯加氢NiMox/γ-Al2O3催化剂耐硫特性的研究[J]. 化工学报, 2020, 71(9): 4177-4188.

Daxin SHI, Airu LI, Zhuqing FANG, Jijuan LI, Qingze JIAO, Qin WU, Caihong FENG, Yun ZHAO, Hansheng LI. Study on sulfur tolerance of NiMox/γ-Al2O3 catalyst for dicyclopentadiene hydrogenation[J]. CIESC Journal, 2020, 71(9): 4177-4188.

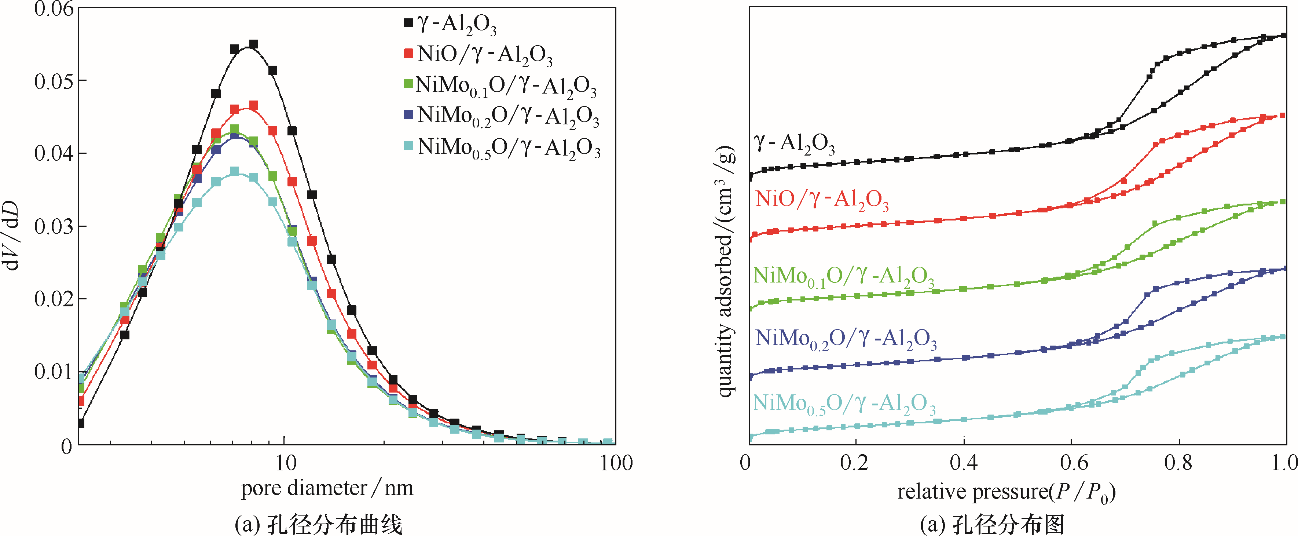

图4 前体NiO/γ-Al2O3、NiMoxO/γ-Al2O3(x=0.1,0.2和0.5)以及载体γ-Al2O3的N2吸附-脱附实验结果

Fig.4 N2 adsorption-desorption isotherms (a) and pore size distributions (b) of the precursors NiMoxO/γ-Al2O3(x=0.1,0.2 and 0.5), NiO/γ-Al2O3 and γ-Al2O3

| 样品 | Vp/(cm3/g) | MPD/nm | SBET/(m2/g) |

|---|---|---|---|

| γ-Al2O3 | 0.64 | 10.9 | 236 |

| NiO/γ-Al2O3 | 0.56 | 10.5 | 213 |

| NiMo0.1O/γ-Al2O3 | 0.49 | 9.7 | 201 |

| NiMo0.2O/γ-Al2O3 | 0.49 | 9.4 | 209 |

| NiMo0.5O/γ-Al2O3 | 0.46 | 9.2 | 198 |

表1 前体和载体的孔体积(Vp)、比表面积(SBET)和平均孔径(MPD)

Table 1 Symbols and several characteristics of the precursors [specific pore volume(Vp), specific surface area (SBET) and mean pore diameter (MPD)]

| 样品 | Vp/(cm3/g) | MPD/nm | SBET/(m2/g) |

|---|---|---|---|

| γ-Al2O3 | 0.64 | 10.9 | 236 |

| NiO/γ-Al2O3 | 0.56 | 10.5 | 213 |

| NiMo0.1O/γ-Al2O3 | 0.49 | 9.7 | 201 |

| NiMo0.2O/γ-Al2O3 | 0.49 | 9.4 | 209 |

| NiMo0.5O/γ-Al2O3 | 0.46 | 9.2 | 198 |

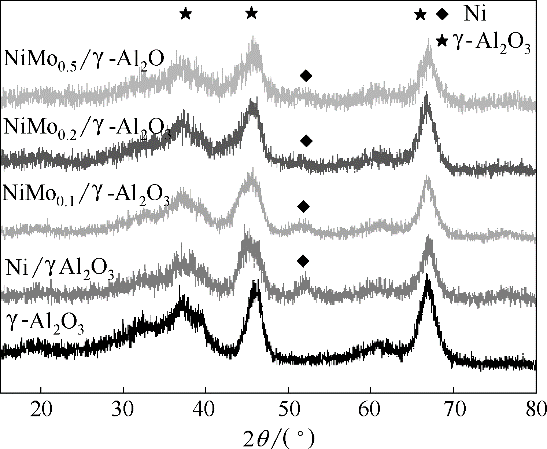

图5 NiMox/γ-Al2O3 (x=0.1,0.2,0.5), Ni/γ-Al2O3及载体γ-Al2O3的XRD谱图

Fig.5 XRD patterns of fresh catalysts NiMox/γ-Al2O3 (x= 0.1, 0.2, 0.5), Ni/γ-Al2O3 and γ-Al2O3

图7 Ni/γ-Al2O3和NiMo0.2 /γ-Al2O3催化DCPD加氢性能图(催化剂∶DCPD∶环己烷=1∶10∶100;150℃,3.5 MPa,600 r/min)

Fig.7 Results of DCPD hydrogenation reaction (Cata∶DCPD∶cyclohexane=1∶10∶100;150℃,3.5 MPa,600 r/min)

图8 噻吩对催化剂Ni/γ-Al2O3和NiMo0.2 /γ-Al2O3催化DCPD加氢的影响(催化剂∶DCPD∶环己烷=1∶10∶100,噻吩浓度500 mg/L,150℃,3.5 MPa,600 r/min)

Fig.8 The effect of thiophene on DCPD hydrogenation (Cata∶DCPD∶cyclohexane=1∶10∶100,thiophene 500 mg/L,150℃,3.5 MPa,600 r/min)

图9 Mo含量对NiMox/γ-Al2O3(x=0.1、0.2、0.5)催化DCPD加氢耐硫性能的影响(催化剂∶DCPD∶环己烷=1∶10∶100,噻吩浓度500 mg/L,150℃,3.5 MPa,600 r/min)

Fig.9 Effect of molybdenum content on NiMox/γ-Al2O3(x=0.1,0.2,0.5) sulfur resistance (Cata∶DCPD∶cyclohexane=1∶10∶100,thiophene 500 mg/L,150℃,3.5 MPa,600 r/min)

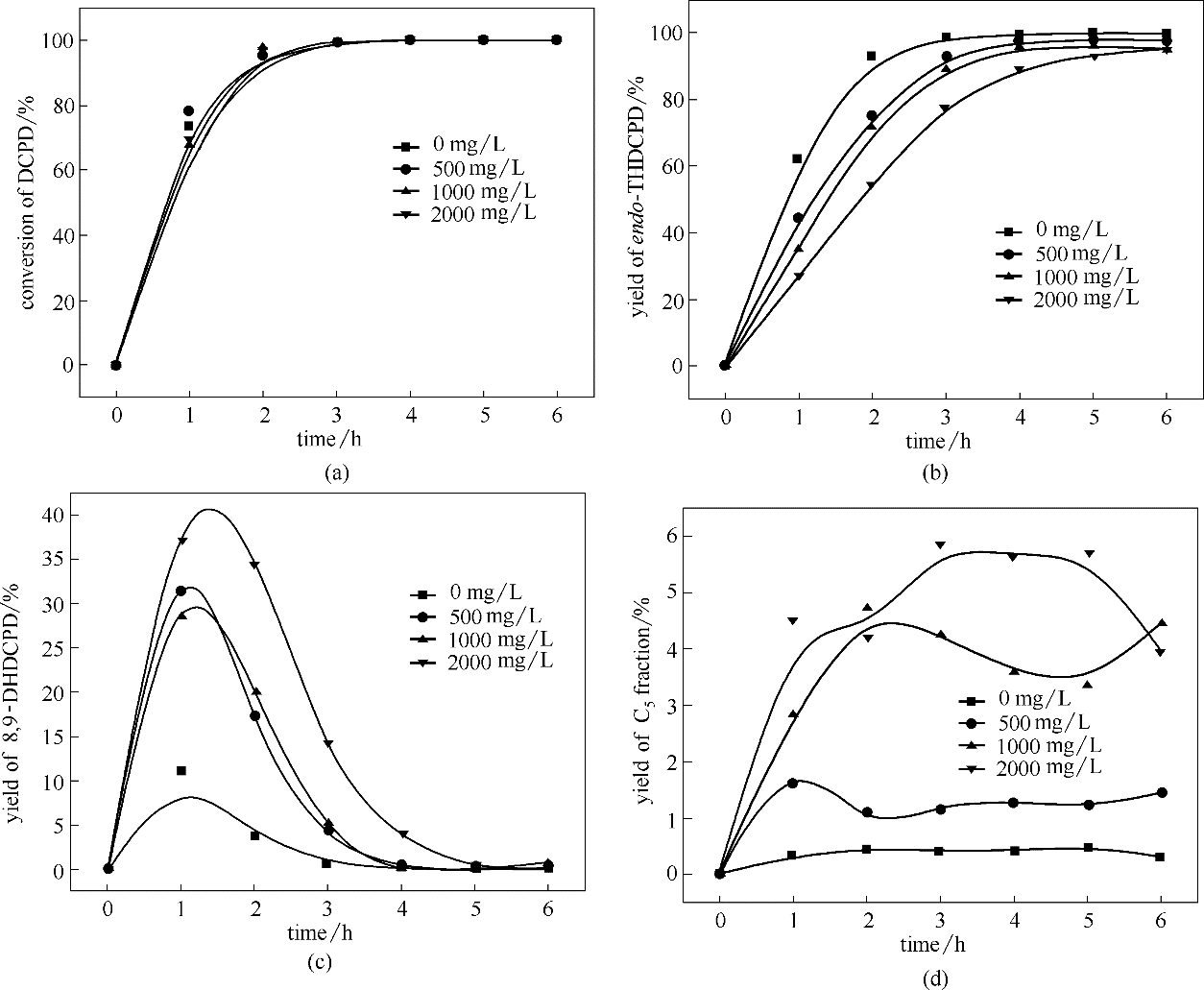

图10 噻吩浓度对NiMo0.2 /γ-Al2O3催化DCPD加氢性能的影响(催化剂∶DCPD∶环己烷=1∶10∶100,噻吩浓度0、500、1000、2000 mg/L,150℃,3.5 MPa,600 r/min)

Fig.10 Effect of thiophene content on NiMo0.2 /γ-Al2O3 catalytic hydrogenation characteristics (Cata∶DCPD∶cyclohexane=1∶10∶100,thiophene 0,500,1000,2000 mg/L,150℃,3.5 MPa,600 r/min)

| 1 | 邹吉军, 郭成, 张香文, 等. 航天推进用高密度液体碳氢燃料: 合成与应用[J]. 推进技术, 2014, 35(10): 1419-1425. |

| Zou J J, Guo C, Zhang X W, et al. High-density liquid hydrocarbon fuels for aerospace propulsion: synthesis and application[J]. Journal of Propulsion Technology, 2014, 35(10): 1419-1425. | |

| 2 | Chung H S, Chen C S H, Kremer R A, et al. Recent developments in high-energy density liquid hydrocarbon fuels[J]. Energy & Fuels, 1999, 13(3): 641-649. |

| 3 | Huang M Y, Wu J C. Preparation of high energy fuel JP-10 by acidity-adjustable chloroaluminate ionic liquid catalyst[J]. Fuel, 2011, 90(3): 1012-1017. |

| 4 | Xing E H, Mi Z T, Xin C W, et al. Endo- to exo-isomerization of tetrahydrodicyclopentadiene catalyzed by commercially available zeolites[J]. Journal of Molecular Catalysis A Chemical, 2005, 231(1/2): 161-167. |

| 5 | Sun C M, Li G. Vapor-phase isomerization of endo-tetrahydrodicyclopentadiene to its exo-isomer over zeolite catalysts[J]. Applied Catalysis A General, 2011, 402(1/2): 196-200. |

| 6 | 杜咏梅, 李春迎, 吕剑. 高密度烃燃料挂式四氢双环戊二烯的研究进展[J]. 火炸药学报, 2005, 28(4): 58-60. |

| Du Y M, Li C Y, Lyu J. Progress of the high density hydrocarbon fuel of exo-tetrahydrodicyclopentadiene[J]. Chin. J. Expl. Propell., 2005, 28(4): 58-60. | |

| 7 | Liu G, Mi Z, Wang L, et al. Kinetics of dicyclopentadiene hydrogenation over Pd/Al2O3 catalyst[J]. Industrial & Engineering Chemistry Research, 2005, 44(11): 3846-3851. |

| 8 | Hao M, Yang B, Wang H, et al. Kinetics of liquid phase catalytic hydrogenation of dicyclopentadiene over Pd/C catalyst[J]. Journal of Physical Chemistry A, 2010, 114(11): 3811-3817. |

| 9 | 陈华祥, 黎汉生, 史大昕, 等. 液相连续制备挂式四氢双环戊二烯[J]. 含能材料, 2015, 23(10): 964-970. |

| Chen H X, Li H S, Shi D X, et al. Liquid-phase continuous-flow preparation of high energy fuel exo-THDCPD[J]. Chinese Journal of Energetic Materials, 2015, 23(10): 964-970. | |

| 10 | 张月红, 邱迎昕. 双环戊二烯的生产与应用[J]. 广东化工, 2014, 41(9): 119-120. |

| Zhang Y H, Qiu Y X. Production and application of dicyclopentadiene[J]. Guangdong Chemical Industry, 2014, 41(9): 119-120. | |

| 11 | 张香文, 熊中强, 米镇涛. SRNA-4 非晶态合金催化双环戊二烯液相加氢反应研究[J]. 高校化学工程学报, 2006, 20(4): 604-609. |

| Zhang X W, Xiong Z Q, Mi Z T. Liquid-phase hydrogenation of dicyclopentadiene by using SRNA-4 amorphous catalyst[J]. Journal of Chemical Engineering of Chinese Universities, 2006, 20(4): 604-609. | |

| 12 | Wang Y, Luo G, Xu X, et al. Preparation of supported skeletal Ni catalyst and its catalytic performance on dicyclopentadiene hydrogenation[J]. Catalysis Communications, 2014, 53(30): 15-20. |

| 13 | 杜咏梅, 李春迎, 寇联岗, 等. 双环戊二烯加氢催化体系研究[J]. 精细石油化工, 2011, 28(2): 21-24. |

| Du Y M, Li C Y, Kou L G, et al. Studies on shape-selectivity of alkylation of toluene with dimethyl carbonate over MgO/HZSM-5 catalysts[J]. Speciality Petrochemicals, 2011, 28(2): 21-24. | |

| 14 | 孙聪明, 厉刚. Ni/HY 催化剂上双环戊二烯液相催化加氢[J]. 石油学报(石油加工), 2012, 28(2): 296-302. |

| Sun C M, Li G. Liquid-phase hydrogenation of dicyclopentadiene on Ni/HY catalysts[J]. Acta Petrolei Sinica(Petroleum Processing Section), 2012, 28(2): 296-302. | |

| 15 | Fang Z Q, Shi D X, Lin N, et al. Probing the synergistic effect of Mo on Ni-based catalyst in the hydrogenation of dicyclopentadiene[J]. Applied Catalysis A General, 2019, 574: 60-70. |

| 16 | 李松军, 罗来涛. Ni/sepiolite催化剂的改性研究(Ⅰ): 助剂的改性[J]. 南昌大学学报(理科版), 2001, (3): 88-93. |

| Li S J, Luo L T. Study on the modification of Ni/sepiolite catalyst(Ⅰ): The modification of promoters[J]. Journal of Nanchang University (Natural Science), 2001, (3): 88-93. | |

| 17 | 黄华, 尹笃林, 文建军, 等. Ni含量对镍催化剂芳烃加氢抗硫性能的影响[J]. 工业催化, 2005, (1): 13-16. |

| Huang H, Yin D L, Wen J J, et al. Effect of nickel content on sulfur tolerance of nickel-based catalysts for aromatic hydrogenation [J]. Industrial Catalysts, 2005, (1): 13-16. | |

| 18 | 黄华, 尹笃林, 文建军, 等. 镍基芳烃加氢金属催化剂抗硫性的研究进展[J]. 工业催化, 2004, (7): 12-16. |

| Huang H, Yin D L, Wen J J, et al. Advances in the researches in sulfur tolerance of nickel-based catalysts for aromatics hydrogenation[J]. Industrial Catalysts, 2004, (7): 12-16. | |

| 19 | 黄华, 尹笃林, 文建军, 等. 制备方法对镍基芳烃加氢催化剂抗硫性能的影响[J]. 工业催化, 2004, (5): 16-19. |

| Huang H, Yin D L, Wen J J, et al. Influence of preparation methods of nickel-based aromatic hydrogenation catalysts on their tolerances to sulfur[J]. Industrial Catalysts, 2004, (5): 16-19. | |

| 20 | 史立杰, 张永泽, 李晨佳, 等. 耐硫甲烷化催化剂研究进展[J]. 工业催化, 2018, 26(11): 23-28. |

| Shi L J, Zhang Y Z, Li C J, et al. Research progress of sulfur-resistant methanation catalyst[J]. Industrial Catalysts, 2018, 26(11): 23-28. | |

| 21 | Li Z, Liu J, Wang H, et al. Effect of sulfidation temperature on the catalytic behavior of unsupported MoS2 catalysts for synthetic natural gas production from syngas[J]. Journal of Molecular Catalysis A: Chemical, 2013, 378(9): 99-108. |

| 22 | 王昱涵, 白思雨, 崔丽杰, 等. Ni-Mo双金属催化剂的甲烷化性能与耐硫稳定性[J]. 化工学报, 2018, 69(5): 2063-2072. |

| Wang Y H, Bai S Y, Cui L J, et al. Catalytic activity and sulfur-resistance stability of Ni-Mo-based catalysts for syngas methanation[J]. CIESC Journal, 2018, 69(5): 2063-2072. | |

| 23 | 钟小文. 镍钼比对Ni-Mo-N催化剂结构及苯/噻吩加氢性能的影响[J]. 现代化工, 2018, 38(5): 66-69+71. |

| Zhong X W. Effects of Ni/Mo molar ratio on Ni-Mo-N catalyst's structure and catalytic performance in benzene hydrogenation with presence of thiophene[J]. Modern Chemical Industry, 2018, 38(5): 66-69+71. | |

| 24 | 陈炳琳, 刘阳, 梁国强, 等. 裂解C9馏份高纯双环戊二烯的生产和应用[J].广东化工, 2018, 45(6): 126-130. |

| Chen B L, Liu Y, Liang G Q, et al. The production and application of cracking C9 fraction and high-purity dicyclopentadiene[J].Guangdong Chemical Industry, 2018, 45(6): 126-130. | |

| 25 | 梅刘勋, 章小林, 辛雄威, 等. Ni-Mo系双活性组分耐硫甲烷化催化剂活性研究[J]. 煤化工, 2013, 46(3): 45-48. |

| Mei L X, Zhang X L, Xin X W, et al. Activity study on Ni-Mo based double active ingredient sulfur-tolerant methanation catalyst[J]. Coal Chemical Industry, 2013, 46(3): 45-48. | |

| 26 | Youn M H, Seo J G, Kim P, et al. Role and effect of molybdenum on the performance of NiMo/γ-Al2O3 catalysts in the hydrogen production by auto-thermal reforming of ethanol[J]. Journal of Molecular Catalysis A Chemical, 2007, 261(2): 276-281. |

| 27 | Kordouli E, Sygellou L, Kordulis C, et al. Probing the synergistic ratio of the NiMo/γ-Al2O3 reduced catalysts for the transformation of natural triglycerides into green diesel[J]. Applied Catalysis B Environmental, 2017, (209): 12-22. |

| 28 | Li Z, Liu J, Wang H, et al. Effect of sulfidation temperature on the catalytic behavior of unsupported MoS2 catalysts for synthetic natural gas production from syngas[J]. Journal of Molecular Catalysis A: Chemical, 2013, 378(9): 99-108. |

| 29 | 李振花, 王强, 王玮涵, 等. 钼基耐硫甲烷化催化剂放大制备[J]. 工业催化, 2018, 26(10): 64-70. |

| Li Z H, Wang Q, Wang W H, et al. Scale-up production of Mo-based catalysts for sulfur-resistant methanation[J]. Industrial Catalysts, 2018, 26(10): 64-70. | |

| 30 | Asier M P, Dj I G, Teichner S J. Nickel-molydennm catalysts prepared by reduction of ammonium triammine tetranickel pentamolybdate[J] . Appl. Catal., 1991, 72: 321. |

| 31 | Tsurov M A, Afanasiev P V, Lunin V V. Composition and catalytic properties of products from the reduction of NiMoO4[J]. App.l Catal., 1993, 106: 205. |

| 32 | 牛雪平, 江雅新, 石玉, 等. Mo-Ni/γ-Al2O3甲烷化催化剂MoNi4合金的生成及其作用[J]. 内蒙古大学学报(自然科学版), 1999, 30(6): 709-714. |

| Niu X P, Jiang Y X, Shi Y, et al. Producing and effect of MoNi4 alloy in Mo-Ni/γ-Al2O3 methanation catalysts[J]. Acta Scientiarum Naturalium Universitatis Neimongol, 1999, 30(6): 709-714. | |

| 33 | Rahbar S F, Rezaei M, Meshkani F. The influence of Ni loading on the activity and coke formation of ultrasound-assisted co-precipitated Ni-Al2O3, nanocatalyst in dry reforming of methane[J]. International Journal of Hydrogen Energy, 2017, 42(7): 4155-4164. |

| 34 | Leofanti G, Padovan M, Tozzola G, et al. Surface area and pore texture of catalysts[J]. Catalysis Today, 1998, 41(1): 207-219. |

| [1] | 杨欣, 王文, 徐凯, 马凡华. 高压氢气加注过程中温度特征仿真分析[J]. 化工学报, 2023, 74(S1): 280-286. |

| [2] | 曹跃, 余冲, 李智, 杨明磊. 工业数据驱动的加氢裂化装置多工况切换过渡状态检测[J]. 化工学报, 2023, 74(9): 3841-3854. |

| [3] | 杨绍旗, 赵淑蘅, 陈伦刚, 王晨光, 胡建军, 周清, 马隆龙. Raney镍-质子型离子液体体系催化木质素平台分子加氢脱氧制备烷烃[J]. 化工学报, 2023, 74(9): 3697-3707. |

| [4] | 杨菲菲, 赵世熙, 周维, 倪中海. Sn掺杂的In2O3催化CO2选择性加氢制甲醇[J]. 化工学报, 2023, 74(8): 3366-3374. |

| [5] | 张江淮, 赵众. 碳三加氢装置鲁棒最小协方差约束控制及应用[J]. 化工学报, 2023, 74(3): 1216-1227. |

| [6] | 梁梦欣, 郭艳, 王世栋, 张宏伟, 袁珮, 鲍晓军. 氮化碳负载钯催化剂的制备及对SBS选择性催化加氢性能的研究[J]. 化工学报, 2023, 74(2): 766-775. |

| [7] | 沈辰阳, 孙楷航, 张月萍, 刘昌俊. 二氧化碳加氢合成甲醇氧化铟及其负载金属催化剂研究进展[J]. 化工学报, 2023, 74(1): 145-156. |

| [8] | 黄宽, 马永德, 蔡镇平, 曹彦宁, 江莉龙. 油脂催化加氢转化制备第二代生物柴油研究进展[J]. 化工学报, 2023, 74(1): 380-396. |

| [9] | 杜峰, 尹思琦, 罗辉, 邓文安, 李传, 黄振薇, 王文静. H2在Mo x S y 团簇上吸附解离的尺寸效应研究[J]. 化工学报, 2022, 73(9): 3895-3903. |

| [10] | 彭琳, 牛明鑫, 白羽, 孙克宁. 中空硫球-MoS2/rGO材料的制备及其在锂硫电池中的应用[J]. 化工学报, 2022, 73(8): 3688-3698. |

| [11] | 张军, 胡升, 顾菁, 袁浩然, 陈勇. 甲醇体系电镀污泥衍生磁性多金属材料催化糠醛加氢转化[J]. 化工学报, 2022, 73(7): 2996-3006. |

| [12] | 金科, 王晨光, 马隆龙, 张琦. 核壳纳米材料制备及其在CO/CO2热催化加氢中的应用[J]. 化工学报, 2022, 73(3): 990-1007. |

| [13] | 王吴玉, 史玉竹, 严龙, 张兴华, 马隆龙, 张琦. 负载型Co基双功能催化剂上戊酸酯生物燃料的制备[J]. 化工学报, 2022, 73(2): 689-698. |

| [14] | 王峥, 许锋, 罗雄麟. 乙炔加氢串联反应器全周期乙炔转化率最优分配研究[J]. 化工学报, 2022, 73(10): 4551-4564. |

| [15] | 尤红运, 林景骏, 黄凯越, 舒日洋, 田志鹏, 王超, 陈颖. 溶剂效应对木质素酚类化合物加氢反应的影响机理[J]. 化工学报, 2022, 73(10): 4498-4506. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号