化工学报 ›› 2022, Vol. 73 ›› Issue (10): 4551-4564.DOI: 10.11949/0438-1157.20220753

收稿日期:2022-05-27

修回日期:2022-06-27

出版日期:2022-10-05

发布日期:2022-11-02

通讯作者:

罗雄麟

作者简介:王峥(1996—),男,硕士研究生,wangzheng_pcx@163.com

基金资助:

Zheng WANG( ), Feng XU, Xionglin LUO(

), Feng XU, Xionglin LUO( )

)

Received:2022-05-27

Revised:2022-06-27

Online:2022-10-05

Published:2022-11-02

Contact:

Xionglin LUO

摘要:

在乙炔加氢反应器的实际生产运行过程中,乙炔加氢反应大部分在第一床层,加氢反应放出的大量热量使得床层内温度高于最佳反应温度范围,致使乙烯选择性降低,乙烯产量下降,而在进行全周期操作优化时并未考虑到此问题。因此,首先考虑温度对绿油累积的影响,修正了催化剂失活动力学方程;其次,为保证反应器各床层内温度都在最佳反应温度范围,从化学反应工程理论和实际生产过程中的安全性两个角度出发,给出两种反应器各床层乙炔转化率分配方案;最后,在常规全周期操作优化模型中添加乙炔转化率约束,建立全周期乙炔转化率分配操作优化模型,并对两种乙炔转化率分配方案进行全周期操作优化。优化结果表明,两种乙炔转化率分配方案操作优化的乙烯产量要远远高于常规操作优化,且乙炔转化率方案为33∶33∶33时,乙烯产量最高,而考虑实际生产过程中的安全性,乙炔转化率分配方案为43∶47∶10时具有更好的效果。

中图分类号:

王峥, 许锋, 罗雄麟. 乙炔加氢串联反应器全周期乙炔转化率最优分配研究[J]. 化工学报, 2022, 73(10): 4551-4564.

Zheng WANG, Feng XU, Xionglin LUO. Full-cycle optimization of acetylene conversion distribution for acetylene hydrogenation beds-in-series reactor[J]. CIESC Journal, 2022, 73(10): 4551-4564.

| 床层 | 操作方案 | 乙炔转化率/% | 操作点 | 入口温度/℃ | 入口氢气流量/(kg·h-1) |

|---|---|---|---|---|---|

| 床层1 | 当前生产方案 | 68.0 | A | 47.65 | 29.40 |

| 方案Ⅰ(平均) | 33.3 | A′ | 保持 | ↓↓ | |

| 方案Ⅱ(安全) | 45.0 | A″ | 保持 | ↓ | |

| 床层2 | 当前生产方案 | 28.0 | B | 48.65 | 13.92 |

| 方案Ⅰ(平均) | 33.3 | B′ | 保持 | ↓ | |

| 方案Ⅱ(安全) | 45.0 | B″ | 保持 | ↑ | |

| 床层3 | 当前生产方案 | 4.0 | C | 49.65 | 0.78 |

| 方案Ⅰ(平均) | 33.4 | C′ | 保持 | ↑↑ | |

| 方案Ⅱ(安全) | 10.0 | C″ | 保持 | ↑ |

表1 反应器的入口操作条件调整

Table 1 Adjustment of reactor inlet operating conditions

| 床层 | 操作方案 | 乙炔转化率/% | 操作点 | 入口温度/℃ | 入口氢气流量/(kg·h-1) |

|---|---|---|---|---|---|

| 床层1 | 当前生产方案 | 68.0 | A | 47.65 | 29.40 |

| 方案Ⅰ(平均) | 33.3 | A′ | 保持 | ↓↓ | |

| 方案Ⅱ(安全) | 45.0 | A″ | 保持 | ↓ | |

| 床层2 | 当前生产方案 | 28.0 | B | 48.65 | 13.92 |

| 方案Ⅰ(平均) | 33.3 | B′ | 保持 | ↓ | |

| 方案Ⅱ(安全) | 45.0 | B″ | 保持 | ↑ | |

| 床层3 | 当前生产方案 | 4.0 | C | 49.65 | 0.78 |

| 方案Ⅰ(平均) | 33.4 | C′ | 保持 | ↑↑ | |

| 方案Ⅱ(安全) | 10.0 | C″ | 保持 | ↑ |

| 项目 | 操作变量 | 符号及单位 | 数值 |

|---|---|---|---|

| 床层1 | 入口氢气分压 | 29.55 | |

| 入口温度 | 320.8 | ||

| 入口乙炔分压 | 29.55 | ||

| 入口乙烯分压 | 1684.35 | ||

| 床层2 | 入口氢气分压 | 14.00 | |

| 入口温度 | 321.8 | ||

| 床层3 | 入口氢气分压 | 0.79 | |

| 入口温度 | 322.8 | ||

| 运行周期 | 时间 | Γ/d | 180 |

表2 模拟运行的操作条件

Table 2 Operational conditions for the simulation run

| 项目 | 操作变量 | 符号及单位 | 数值 |

|---|---|---|---|

| 床层1 | 入口氢气分压 | 29.55 | |

| 入口温度 | 320.8 | ||

| 入口乙炔分压 | 29.55 | ||

| 入口乙烯分压 | 1684.35 | ||

| 床层2 | 入口氢气分压 | 14.00 | |

| 入口温度 | 321.8 | ||

| 床层3 | 入口氢气分压 | 0.79 | |

| 入口温度 | 322.8 | ||

| 运行周期 | 时间 | Γ/d | 180 |

| 项目 | ||

|---|---|---|

| 模拟1 | 29.55 | 320.8 |

| 模拟2 | 保持 | 321.8 |

| 模拟3 | 保持 | 322.8 |

表3 反应器第一床层入口温度变化

Table 3 Inlet temperature change of the first reactor bed

| 项目 | ||

|---|---|---|

| 模拟1 | 29.55 | 320.8 |

| 模拟2 | 保持 | 321.8 |

| 模拟3 | 保持 | 322.8 |

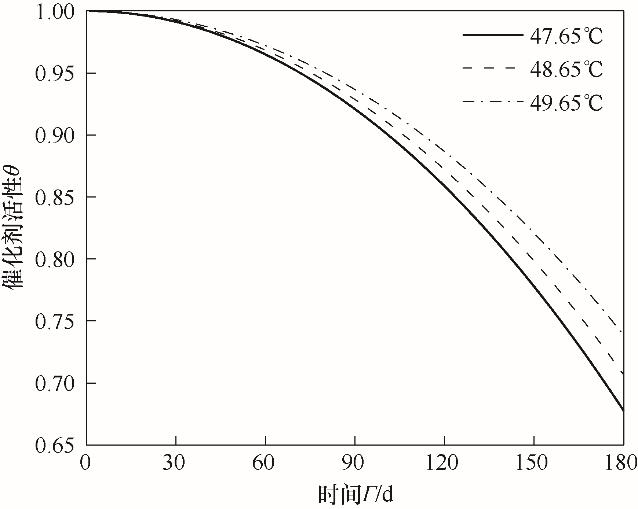

图4 原失活模型入口温度变化系统运行180 d的第一床层催化剂活性

Fig.4 First bed catalyst activity of the inlet temperature change system running for 180 days of original deactivated model

| 项目 | ||

|---|---|---|

| 模拟4 | 320.8 | 27.55 |

| 模拟5 | 保持 | 28.55 |

| 模拟6 | 保持 | 29.55 |

表4 反应器第一床层入口加氢量变化

Table 4 Inlet hydrogen change of the first reactor bed

| 项目 | ||

|---|---|---|

| 模拟4 | 320.8 | 27.55 |

| 模拟5 | 保持 | 28.55 |

| 模拟6 | 保持 | 29.55 |

| 符号 | 说明 | |

|---|---|---|

| 优化目标(J) | 全周期乙烯产品累积产量 | |

| 乙烯产品产量(MC) | 单日乙烯产品产量 | |

| 周期(Γf) | 优化运行180 d | |

| 反应过程模型f(·) | 操作优化应用的模型,表达式见式(6)~式(12) | |

| 操作优化约束g(·) | 操作优化约束见 | |

| 催化剂活性(θ) | 操作优化考虑催化剂活性变化,表达式见式(18) | |

| 出口乙炔摩尔分数(α) | α为乙炔摩尔分数,αlb=1×10-6,αub=1×10-5 | |

| 状态变量(x) | 各床层入口乙炔分压 | 各床层出口乙烯分压 |

| 各床层入口乙烯分压 | 各床层出口氢气分压 | |

| 各床层出口乙炔分压 | 各床层出口温度 | |

表5 全周期操作优化模型符号说明

Table 5 Symbolic description of full-cycle operation optimization model

| 符号 | 说明 | |

|---|---|---|

| 优化目标(J) | 全周期乙烯产品累积产量 | |

| 乙烯产品产量(MC) | 单日乙烯产品产量 | |

| 周期(Γf) | 优化运行180 d | |

| 反应过程模型f(·) | 操作优化应用的模型,表达式见式(6)~式(12) | |

| 操作优化约束g(·) | 操作优化约束见 | |

| 催化剂活性(θ) | 操作优化考虑催化剂活性变化,表达式见式(18) | |

| 出口乙炔摩尔分数(α) | α为乙炔摩尔分数,αlb=1×10-6,αub=1×10-5 | |

| 状态变量(x) | 各床层入口乙炔分压 | 各床层出口乙烯分压 |

| 各床层入口乙烯分压 | 各床层出口氢气分压 | |

| 各床层出口乙炔分压 | 各床层出口温度 | |

| 床层 | 优化变量(u) | 符号及单位 | 优化约束 | 初值 |

|---|---|---|---|---|

| 床层1 | 入口温度 | 320.8 | ||

| 入口氢气分压 | 29.55 | |||

| 床层2 | 入口温度 | 321.8 | ||

| 入口氢气分压 | 14.00 | |||

| 床层3 | 入口温度 | 322.8 | ||

| 入口氢气分压 | 0.79 |

表6 操作优化约束

Table 6 Constraints of operation optimization

| 床层 | 优化变量(u) | 符号及单位 | 优化约束 | 初值 |

|---|---|---|---|---|

| 床层1 | 入口温度 | 320.8 | ||

| 入口氢气分压 | 29.55 | |||

| 床层2 | 入口温度 | 321.8 | ||

| 入口氢气分压 | 14.00 | |||

| 床层3 | 入口温度 | 322.8 | ||

| 入口氢气分压 | 0.79 |

| 床层 | 优化变量(u) | Ⅰ | Ⅱ-A | Ⅱ-B | Ⅱ-C |

|---|---|---|---|---|---|

| 床层1 | 入口温度/K | 320.8 | 320.8 | 320.8 | 320.8 |

| 入口氢气流量/(kg·h-1) | 13.67 | 18.41 | 19.60 | 20.10 | |

| 床层2 | 入口温度/K | 321.8 | 321.8 | 321.8 | 321.8 |

| 入口氢气流量/(kg·h-1) | 13.63 | 20.25 | 19.30 | 18.90 | |

| 床层3 | 入口温度/K | 322.8 | 322.8 | 322.8 | 322.8 |

| 入口氢气流量/(kg·h-1) | 13.63 | 2.54 | 2.54 | 2.54 |

表7 乙炔转化率分配方案入口初值

Table 7 Inlet initial value of acetylene conversion rate distribution scheme

| 床层 | 优化变量(u) | Ⅰ | Ⅱ-A | Ⅱ-B | Ⅱ-C |

|---|---|---|---|---|---|

| 床层1 | 入口温度/K | 320.8 | 320.8 | 320.8 | 320.8 |

| 入口氢气流量/(kg·h-1) | 13.67 | 18.41 | 19.60 | 20.10 | |

| 床层2 | 入口温度/K | 321.8 | 321.8 | 321.8 | 321.8 |

| 入口氢气流量/(kg·h-1) | 13.63 | 20.25 | 19.30 | 18.90 | |

| 床层3 | 入口温度/K | 322.8 | 322.8 | 322.8 | 322.8 |

| 入口氢气流量/(kg·h-1) | 13.63 | 2.54 | 2.54 | 2.54 |

| 项目 | 乙炔转化率平均分配 | 乙炔转化率安全分配 | ||

|---|---|---|---|---|

| Ⅰ(33∶33∶33) | Ⅱ-A(43∶47∶10) | Ⅱ-B(45∶45∶10) | Ⅱ-C(47∶43∶10) | |

| 乙炔转化率分配附加约束 | 0.32≤y[ | 0.40≤y[ | 0.42≤y[ | 0.44≤y[ |

| 0.32≤y[ | 0.44≤y[ | 0.42≤y[ | 0.40≤y[ | |

| 0.32≤y[ | 0.05≤y[ | 0.05≤y[ | 0.05≤y[ | |

表8 乙炔转化率分配方案

Table 8 Distribution scheme of acetylene conversion rate

| 项目 | 乙炔转化率平均分配 | 乙炔转化率安全分配 | ||

|---|---|---|---|---|

| Ⅰ(33∶33∶33) | Ⅱ-A(43∶47∶10) | Ⅱ-B(45∶45∶10) | Ⅱ-C(47∶43∶10) | |

| 乙炔转化率分配附加约束 | 0.32≤y[ | 0.40≤y[ | 0.42≤y[ | 0.44≤y[ |

| 0.32≤y[ | 0.44≤y[ | 0.42≤y[ | 0.40≤y[ | |

| 0.32≤y[ | 0.05≤y[ | 0.05≤y[ | 0.05≤y[ | |

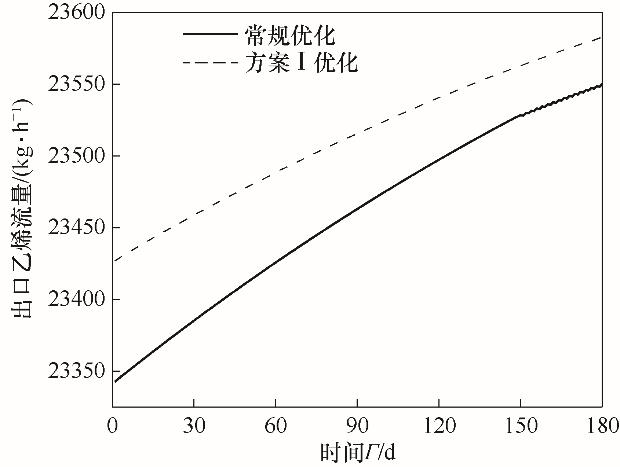

图7 常规优化和乙炔转化率平均分配方案优化的反应器出口乙烯质量流量

Fig.7 Ethylene mass flow at reactor outlet optimized by conventional optimization and acetylene conversion average distribution scheme

| 优化方案 | 乙炔转化率分配 | 180 d乙烯产品累积产量/t | 180 d乙烯产品累积增量/t |

|---|---|---|---|

| 当前生产方案(未优化) | 无 | 100831.04 | 251.16 |

| 当前生产方案(常规优化) | 无 | 101339.92 | 713.90 |

| 方案Ⅰ | 33∶33∶33 | 101573.55 | 844.68 |

| 方案Ⅱ-A | 43∶47∶10 | 101521.03 | 816.23 |

| 方案Ⅱ-B | 45∶45∶10 | 101511.91 | 812.62 |

| 方案Ⅱ-C | 47∶43∶10 | 101505.81 | 808.25 |

表9 系统运行180 d乙烯累积产品产量

Table 9 Cumulative product yield of ethylene on system at 180 days operation

| 优化方案 | 乙炔转化率分配 | 180 d乙烯产品累积产量/t | 180 d乙烯产品累积增量/t |

|---|---|---|---|

| 当前生产方案(未优化) | 无 | 100831.04 | 251.16 |

| 当前生产方案(常规优化) | 无 | 101339.92 | 713.90 |

| 方案Ⅰ | 33∶33∶33 | 101573.55 | 844.68 |

| 方案Ⅱ-A | 43∶47∶10 | 101521.03 | 816.23 |

| 方案Ⅱ-B | 45∶45∶10 | 101511.91 | 812.62 |

| 方案Ⅱ-C | 47∶43∶10 | 101505.81 | 808.25 |

| 1 | 杜文莉, 鲍春瑜, 陈旭. 串联型乙炔加氢反应过程的动态优化[J]. 信息与控制, 2017, 46(1): 83-89. |

| Du W L, Bao C Y, Chen X. Dynamic optimization of tandem acetylene hydrogenation process[J]. Information and Control, 2017, 46(1): 83-89. | |

| 2 | McCue A J, Anderson J A. Recent advances in selective acetylene hydrogenation using palladium containing catalysts[J]. Frontiers of Chemical Science and Engineering, 2015, 9(2): 142-153. |

| 3 | 张健, 黄邦印, 隋志军, 等. 不同Pd/Ag配比Pd-Ag/Al2O3催化乙炔加氢微观反应动力学分析[J]. 化工学报, 2018, 69(2): 674-681. |

| Zhang J, Huang B Y, Sui Z J, et al. Microkinetic analysis of acetylene hydrogenation over Pd-Ag/Al2O3 catalyst with different Pd/Ag ratios[J]. CIESC Journal, 2018, 69(2): 674-681. | |

| 4 | Abakumov A A, Bychko I B, Selyshchev O V, et al. Highly selective hydrogenation of acetylene over reduced graphene oxide carbocatalyst[J]. Materialia, 2021, 18: 101163. |

| 5 | Park Y, Lee S, Hyun K, et al. Breaking the inverse relationship between catalytic activity and selectivity in acetylene partial hydrogenation using dynamic metal-polymer interaction[J]. Journal of Catalysis, 2021, 404: 716-725. |

| 6 | 杨方明, 张亮, 谢春丽. 碳二加氢反应器优化操作分析[J]. 当代化工, 2011, 40(10): 1007-1012. |

| Yang F M, Zhang L, Xie C L. Analysis on optimized operation of acetylene converter[J]. Contemporary Chemical Industry, 2011, 40(10): 1007-1012. | |

| 7 | 罗雄麟. 化工过程动态学[M]. 北京: 化学工业出版社, 2005. |

| Luo X L. Chemical Process Dynamics[M]. Beijing: Chemical Industry Press, 2005. | |

| 8 | 谢府命, 许锋, 罗雄麟. 工艺调度对乙炔加氢反应器优化运行策略的影响分析[J]. 化工学报, 2021, 72(5): 2718-2726. |

| Xie F M, Xu F, Luo X L. Influence analysis of process scheduling on optimized operation strategy of acetylene hydrogenation reactor[J]. CIESC Journal, 2021, 72(5): 2718-2726. | |

| 9 | 张东平, 王功华. 乙炔加氢反应器的模拟与分析[J]. 石油化工, 2003, 32(5): 414-417. |

| Zhang D P, Wang G H. Simulating and analysis of reactor for selective hydrogenation of acetylene[J]. Petrochemical Technology, 2003, 32(5): 414-417. | |

| 10 | 涂飞, 青红英, 罗雄麟, 等. 乙炔加氢反应器的先进控制(Ⅰ): 动态机理模型的建立[J]. 化工自动化及仪表, 2003, 30(1): 20-24. |

| Tu F, Qing H Y, Luo X L, et al. Advanced control of acetylene hydrogenation reactor(Ⅰ): Dynamic mechanism model[J]. Control and Instruments in Chemical Industry, 2003, 30(1): 20-24. | |

| 11 | Weiss G. Modelling and control of an acetylene converter[J]. Journal of Process Control, 1996, 6(1): 7-15. |

| 12 | Gobbo R, Soares R P, Lansarin M A, et al. Modeling, simulation, and optimization of a front-end system for acetylene hydrogenation reactors[J]. Brazilian Journal of Chemical Engineering, 2004, 21(4): 545-556. |

| 13 | Szukiewicz M, Kaczmarski K, Petrus R. Modelling of fixed-bed reactor: two models of industrial reactor for selective hydrogenation of acetylene[J]. Chemical Engineering Science, 1998, 53(1): 149-155. |

| 14 | 谢府命, 许锋, 梁志珊, 等. 乙炔加氢反应器全周期操作优化[J]. 化工学报, 2018, 69(3): 1081-1091. |

| Xie F M, Xu F, Liang Z S, et al. Full-cycle operation optimization of acetylene hydrogenation reactor[J]. CIESC Journal, 2018, 69(3): 1081-1091. | |

| 15 | Houzvicka J, Pestman R, Ponec V. The role of carbonaceous deposits and support impurities in the selective hydrogenation of ethyne[J]. Catalysis Letters, 1994, 30(1/2/3/4): 289-296. |

| 16 | Asplund S. Coke formation and its effect on internal mass transfer and selectivity in Pd-catalysed acetylene hydrogenation[J]. Journal of Catalysis, 1996, 158(1): 267-278. |

| 17 | Takht R M, Sahebdelfar S. Pd-Ag/Al2O3 catalyst: stages of deactivation in tail-end acetylene selective hydrogenation[J]. Applied Catalysis A: General, 2016, 525: 197-203. |

| 18 | Kuhn M, Lucas M, Claus P. Precise recognition of catalyst deactivation during acetylene hydrogenation studied with the advanced TEMKIN reactor[J]. Catalysis Communications, 2015, 72: 170-173. |

| 19 | Rahimpour M R, Dehghani O, Gholipour M R, et al. A novel configuration for P d / A g / α - A l 2 O 3 catalyst regeneration in the acetylene hydrogenation reactor of a multi feed cracker[J]. Chemical Engineering Journal, 2012, 198/199: 491-502. |

| 20 | 田亮, 蒋达, 钱锋. 催化剂失活条件下的碳二加氢反应器模拟与优化[J]. 化工学报, 2012, 63(1): 185-192. |

| Tian L, Jiang D, Qian F. Simulation and optimization of acetylene converter with decreasing catalyst activity[J]. CIESC Journal, 2012, 63(1): 185-192. | |

| 21 | Samavati M, Ebrahim H A, Dorj Y. Effect of the operating parameters on the simulation of acetylene hydrogenation reactor with catalyst deactivation[J]. Applied Catalysis A: General, 2018, 567: 45-55. |

| 22 | Brown M W, Penlidis A, Sullivan G R. Control policies for an industrial acetylene hydrogenation reactor[J]. The Canadian Journal of Chemical Engineering, 1991, 69(1): 152-164. |

| 23 | Lesieur M, Sharma S, Nath R. Advanced process control and optimization of acetylene hydrogenation reactors[C]// AIChE Spring National Meeting 15th Annual Ethylene Producers' Conference Session T9a05-Ethylene Plant Process Control. Petromont Varennes, Canada, 2003: 815-827. |

| 24 | Aeowjaroenlap H, Chotiwiriyakun K, Tiensai N, et al. Dynamic modelling and optimization of acetylene hydrogenation reactor to improve overall economics of ethylene plant[M]//Computer Aided Chemical Engineering. Amsterdam: Elsevier, 2017: 847-852. |

| 25 | 戴伟, 朱警, 万文举. C2馏分选择加氢工艺和催化剂研究进展[J]. 石油化工, 2000, 29(7): 535-540. |

| Dai W, Zhu J, Wan W J. Advances in process and catalysts for selective hydrogenation of acetylene[J]. Petrochemical Technology, 2000, 29(7): 535-540. | |

| 26 | 朱炳辰. 化学反应工程[M]. 3版. 北京: 化学工业出版社, 2001. |

| Zhu B C. Chemical Reaction Engineering[M]. 3rd ed. Beijing: Chemical Industry Press, 2001. | |

| 27 | 任超, 孙琳, 罗雄麟. 换热器因应结垢慢时变的控制系统重构分析[J]. 化工学报, 2021, 72(10): 5273-5283. |

| Ren C, Sun L, Luo X L. Analysis on the reconfiguration of the control system of the heat exchanger in response to the slow and time-varying fouling[J]. CIESC Journal, 2021, 72(10): 5273-5283. | |

| 28 | Borodziński A, Cybulski A. The kinetic model of hydrogenation of acetylene-ethylene mixtures over palladium surface covered by carbonaceous deposits[J]. Applied Catalysis A: General, 2000, 198(1/2): 51-66. |

| 29 | 罗雄麟, 涂飞, 杜殿林, 等. 乙炔加氢反应器的先进控制(Ⅲ): 控制策略及其工程应用[J]. 化工自动化及仪表, 2003, 30(3): 10-15. |

| Luo X L, Tu F, Du D L, et al. Advanced control of acetylene hydrogenation reactor (Ⅲ): Control strategy and its application[J]. Control and Instruments in Chemical Industry, 2003, 30(3): 10-15. |

| [1] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [2] | 郑玉圆, 葛志伟, 韩翔宇, 王亮, 陈海生. 中高温钙基材料热化学储热的研究进展与展望[J]. 化工学报, 2023, 74(8): 3171-3192. |

| [3] | 李贵贤, 曹阿波, 孟文亮, 王东亮, 杨勇, 周怀荣. 耦合固体氧化物电解槽的CO2制甲醇过程设计与评价研究[J]. 化工学报, 2023, 74(7): 2999-3009. |

| [4] | 邵远哲, 赵忠盖, 刘飞. 基于共同趋势模型的非平稳过程质量相关故障检测方法[J]. 化工学报, 2023, 74(6): 2522-2537. |

| [5] | 贠程, 王倩琳, 陈锋, 张鑫, 窦站, 颜廷俊. 基于社团结构的化工过程风险演化路径深度挖掘[J]. 化工学报, 2023, 74(4): 1639-1650. |

| [6] | 王子宗, 索寒生, 赵学良. 数字孪生智能乙烯工厂研究与构建[J]. 化工学报, 2023, 74(3): 1175-1186. |

| [7] | 王雅琳, 潘雨晴, 刘晨亮. 基于GSA-LSTM动态结构特征提取的间歇过程监测方法[J]. 化工学报, 2022, 73(9): 3994-4002. |

| [8] | 王琨, 侍洪波, 谭帅, 宋冰, 陶阳. 局部时差约束邻域保持嵌入算法在故障检测中的应用[J]. 化工学报, 2022, 73(7): 3109-3119. |

| [9] | 杨岭, 崔国民, 周志强, 肖媛. 精细搜索策略应用于质量交换网络综合[J]. 化工学报, 2022, 73(7): 3145-3155. |

| [10] | 孟文亮, 李贵贤, 周怀荣, 李婧玮, 王健, 王可, 范学英, 王东亮. 绿氢重构的粉煤气化煤制甲醇近零碳排放工艺研究[J]. 化工学报, 2022, 73(4): 1714-1723. |

| [11] | 张欣, 周利, 王诗慧, 吉旭, 毕可鑫. 考虑原油性质波动的炼厂氢气网络集成优化[J]. 化工学报, 2022, 73(4): 1631-1646. |

| [12] | 张淑君, 王诗慧, 张欣, 吉旭, 戴一阳, 党亚固, 周利. 集成轻烃回收单元代理模型的氢气网络多目标优化[J]. 化工学报, 2022, 73(4): 1658-1672. |

| [13] | 张建飞, 林嘉奖, 罗雄麟, 许锋. 重油催化裂化装置产品分布调控与优化模拟分析[J]. 化工学报, 2022, 73(3): 1232-1245. |

| [14] | 陈耀明,许锋,罗雄麟. 基于相对增益和优先级的化工过程协调优化裕量设计[J]. 化工学报, 2022, 73(3): 1280-1290. |

| [15] | 曹森山, 许锋, 罗雄麟. 基于稳定性的循环物流系统流程模拟——以催化裂化反应-再生系统为例[J]. 化工学报, 2022, 73(3): 1256-1269. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号