化工学报 ›› 2020, Vol. 71 ›› Issue (12): 5620-5627.DOI: 10.11949/0438-1157.20200535

刘应书1( ),孙宁起1,李子宜1(

),孙宁起1,李子宜1( ),杨雄1,魏进超2,杨本涛2,吴倩倩1,刘佳欣1

),杨雄1,魏进超2,杨本涛2,吴倩倩1,刘佳欣1

收稿日期:2020-05-08

修回日期:2020-07-19

出版日期:2020-12-05

发布日期:2020-12-05

通讯作者:

李子宜

作者简介:刘应书(1960—),男,博士,教授,基金资助:

LIU Yingshu1( ),SUN Ningqi1,LI Ziyi1(

),SUN Ningqi1,LI Ziyi1( ),YANG Xiong1,WEI Jinchao2,YANG Bentao2,WU Qianqian1,LIU Jiaxin1

),YANG Xiong1,WEI Jinchao2,YANG Bentao2,WU Qianqian1,LIU Jiaxin1

Received:2020-05-08

Revised:2020-07-19

Online:2020-12-05

Published:2020-12-05

Contact:

LI Ziyi

摘要:

烟气中SO2具有高回收价值,在吸附法净化烟气过程中,可采用冷凝法对解吸气中SO2提纯为高纯度液态产品。基于邯钢烧结机烟气活性炭吸附脱硫工艺中的富硫解吸气,进行了冷凝法回收SO2的实验研究。重点考察了SO2气源浓度、压力和冷凝温度等工艺参数对回收率和冷凝排出气SO2浓度的影响。结果显示,回收率随气源浓度、压力的升高和冷凝温度的减小而升高;排出气SO2浓度是压力的-1次幂函数,并随冷凝温度的降低而呈指数型函数降低;设计冷凝器时要以可能出现的最高浓度为设计依据,实际生产时应结合预期回收率确定合理的压力上限,尽量采用以低压策略为基础降低温度的措施提升回收率。研究结果可为烟气吸附脱硫过程中SO2的资源化提供参考。

中图分类号:

刘应书,孙宁起,李子宜,杨雄,魏进超,杨本涛,吴倩倩,刘佳欣. 冷凝法回收烟气吸附脱硫解吸气中SO2工艺参数的影响规律研究[J]. 化工学报, 2020, 71(12): 5620-5627.

LIU Yingshu,SUN Ningqi,LI Ziyi,YANG Xiong,WEI Jinchao,YANG Bentao,WU Qianqian,LIU Jiaxin. Influence of process parameters of condensation on the recovery of SO2 in desorption gas from flue gas adsorption desulfurization[J]. CIESC Journal, 2020, 71(12): 5620-5627.

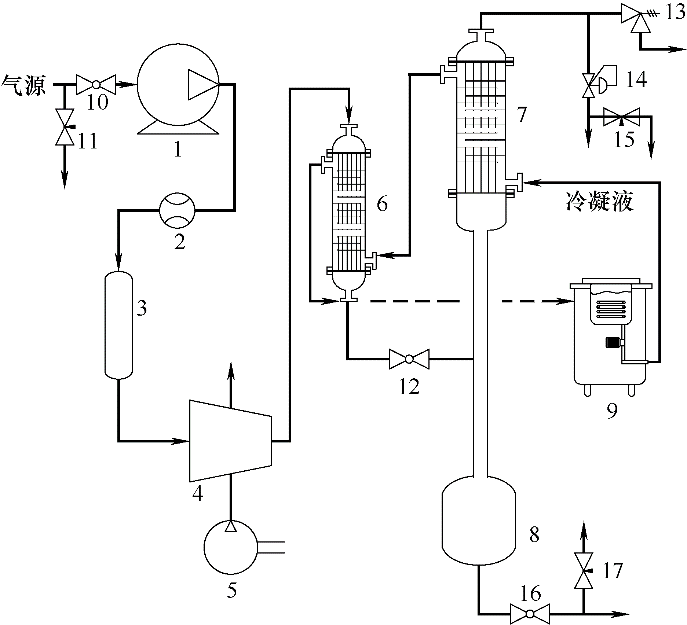

图1 冷凝法回收解吸气SO2实验流程示意图1—气源引风机;2—金属转子流量计;3—缓冲罐;4—增压装置;5—空气压缩机;6—冷却器;7—冷凝器;8—液态SO2储罐;9—低温冷阱;10,12,16—球阀;11,15,17—针阀;13—安全阀;14—背压阀

Fig.1 Schematic diagram of the experimental process of SO2 recovery from desorbed gases by condensation method

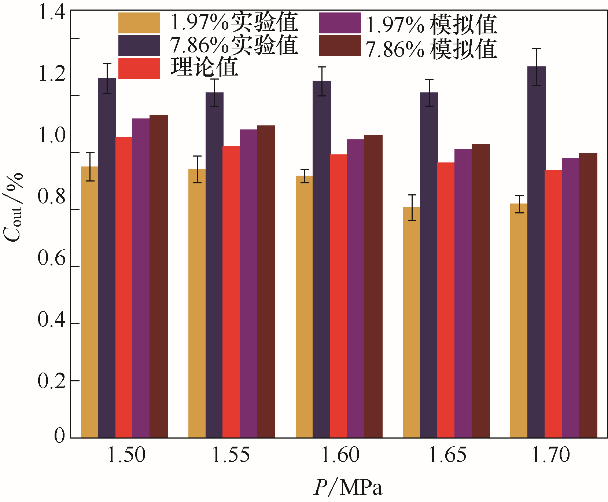

图3 排出气SO2浓度随气源浓度的变化(冷凝温度为-44℃)

Fig.3 Variations of purified SO2 concentration in the exhaust gas with source gas concentrations (condensation temperature is -44℃)

| 温度/K | A | B | C |

|---|---|---|---|

| 177.7~263.0 | 3.48586 | 668.225 | -72.252 |

| 263.0~414.9 | 4.37798 | 966.575 | -42.071 |

表1 计算SO2饱和蒸气压的Antoine方程参数[23-24]

Table 1 Antoine equation parameters for calculating the saturated vapor pressure of SO2[23-24]

| 温度/K | A | B | C |

|---|---|---|---|

| 177.7~263.0 | 3.48586 | 668.225 | -72.252 |

| 263.0~414.9 | 4.37798 | 966.575 | -42.071 |

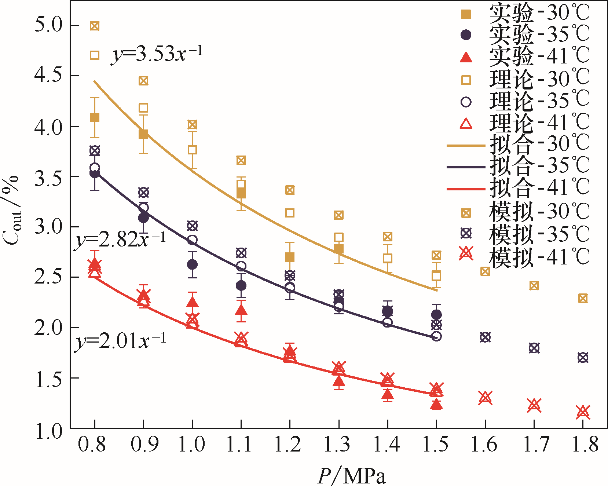

图5 排出气SO2浓度随压力的变化(冷凝温度为-30、-35、-41℃)

Fig.5 Variations of purified SO2 concentration in the exhaust gas with pressure (condensation temperature is -30,-35,-41℃)

| 温度/℃ | 压力/MPa | |||||||

|---|---|---|---|---|---|---|---|---|

| 0.8 | 0.9 | 1.0 | 1.1 | 1.2 | 1.3 | 1.4 | 1.5 | |

| -35 | 8.13% | 8.62% | 7.56% | 7.65% | 7.61% | 7.12% | 7.17% | 7.32% |

| -41 | 8.98% | 9.05% | 9.07% | 8.93% | 9.05% | 9.94% | 9.01% | 8.97% |

表2 不同温度和压力下的SO2气源浓度

Table 2 SO2 concentrations in the source gases at different temperatures and pressures

| 温度/℃ | 压力/MPa | |||||||

|---|---|---|---|---|---|---|---|---|

| 0.8 | 0.9 | 1.0 | 1.1 | 1.2 | 1.3 | 1.4 | 1.5 | |

| -35 | 8.13% | 8.62% | 7.56% | 7.65% | 7.61% | 7.12% | 7.17% | 7.32% |

| -41 | 8.98% | 9.05% | 9.07% | 8.93% | 9.05% | 9.94% | 9.01% | 8.97% |

| 1 | Li C, Mclinden C, Fioletov V, et al. India is overtaking China as the worlds largest emitter of anthropogenic sulfur dioxide[J]. Scientific Reports, 2017, 7(1): 1-7. |

| 2 | Yang X, Zhang W, Fan J, et al. The temporal variation of SO2 emissions embodied in Chinese supply chains, 2002—2012[J]. Environmental Pollution, 2018, 241(2018): 172-181. |

| 3 | 唐强, 曹子栋, 王盛, 等. 活性炭吸附法脱硫实验研究和工业性应用[J]. 现代化工, 2003, 23(3): 37-40. |

| Tang Q, Cao Z D, Wang S, et al. Experimental study on removal of SO2 over granular activated carbon and its industrial-scale application[J]. Modern Chemical Industry, 2003, 23(3): 37-40. | |

| 4 | 刘静, 翟尚鹏, 岑祖望, 等. 活性焦吸附法硫酸尾气脱硫装置的设计与运行[J]. 硫酸工业, 2010, (3): 28-31. |

| Liu J, Zhai S P, Cen Z W, et al. Design and operation of sulphuric acid tail gas desulphurization plant using active coke adsorption process[J]. Sulphuric Acid Industry, 2010, (3): 28-31. | |

| 5 | 张力, 刘伟. 活性炭吸附烟气脱硫的展望[J]. 辽宁化工, 1996, (5): 16-18. |

| Zhang L, Liu W. Prospect of flue gas desulfurization by activated carbon adsorption[J]. Liaoning Chemical Industry, 1996, (5): 16-18. | |

| 6 | 段丽. 活性炭吸附法联合脱硫脱硝技术分析[J]. 云南电力技术, 2009, 37(4): 58-59. |

| Duan L. Analysis of activated carbon adsorption combined with desulfurization and denitration[J]. Yunnan Electric Power, 2009, 37(4): 58-59. | |

| 7 | 高泽磊, 邵志超, 王政, 等. 活性焦脱硫系统低耗能解吸技术研究及应用[J]. 硫酸工业, 2017, (10): 38-40. |

| Gao Z L, Shao Z C, Wang Z, et al. Research and application of low power consumption active coke desorption technology in desulphurization system[J]. Sulphuric Acid Industry, 2017, (10): 38-40. | |

| 8 | Olson D G, Tsuji K, Shiraishi I. The reduction of gas phase air toxics from combustion and incineration sources using the MET-Mitsui-BF activated coke process[J]. Fuel Processing Technology, 2000, 65: 393-405. |

| 9 | Tsuji K, Shiraishi I. Combined desulfurization, denitrification and reduction of air toxics using activated coke(1): Activity of activated coke[J]. Fuel, 1997, 76(6): 549-553. |

| 10 | 中商产业研究院. 中国二氧化硫行业市场前景及投资策略研究报告(2016~2021年)[R]. 深圳: 中商产业研究院, 2016. |

| China Business Industry Research Institute. China sulfur dioxide industry market prospects and investment strategy research report (2016—2021)[R]. Shenzhen: China Business Industry Research Institute, 2016. | |

| 11 | Emmett E J, Willis M C. The development and application of sulfur dioxide surrogates in synthetic organic chemistry[J]. Asian J. Org. Chem., 2015, 4(7): 602-611. |

| 12 | 任翔宇, 金奇超, 袁伊娟. 活性炭-冷凝回收治理有机废气工程应用研究[J]. 环境与发展, 2019, 31(8): 86-87. |

| Ren X Y, Jin Q C, Yuan Y J. Study on the application of activated carbon-condensate recovery in the treatment of organic waste gas engineering[J]. Environment Development, 2019, 31(8): 86-87. | |

| 13 | 陆晓春, 宋娟, 孔德香, 等. 二氯甲烷废气净化与冷凝回收量的计算[J]. 南昌大学学报(工科版), 2019, 41(3): 228-233. |

| Lu X C, Song J, Kong D X, et al. Purification and calculation of condensation recovery quantity from waste gas flow containing dichloromethane[J]. Journal of Nanchang University (Engineering & Technology), 2019, 41(3): 228-233. | |

| 14 | 甘露, 徐绯然, 田波, 等. 某航天发射场四氧化二氮废气冷凝回收方法设计[C]//第十三届全国信号和智能信息处理与应用学术会议. 北京: 中国高科技产业化研究会, 2019: 215-219. |

| Gan L, Xu F R, Tian B, et al. Design of the method of condensing and reclaiming N2O4 exhaust[C]// Proceedings of the 13th National Conference on Signal and Intelligent Information Processing and Application. Beijing: China High-tech Industrialization Research Association, 2019: 215-219. | |

| 15 | Zhang L, Hou Z, Huang L, et al. Simulation and practice of condensation recovery of nitrogen tetroxide based on HYSYS[C]//IOP Conference Series: Earth and Environmental Science. Shanghai: IOP Publishing Ltd., 2019, 281(1): 012003. |

| 16 | 彭万旺, 王乃计, 戢绪国, 等. 气流床烟气干法脱硫技术的初步试验研究[J]. 洁净煤技术, 1999, (4): 22-26. |

| Peng W W, Wang N J, Ji X G, et al. Primary test results of dry flue gas desulfurization with entrained bed[J]. Clean Coal Technology, 1999, (4): 22-26. | |

| 17 | 彭万旺, 王乃计. 烟气脱硫再生尾气中二氧化硫的液化分离[J]. 煤气与热力, 2000, (2): 3-7. |

| Peng W W, Wang N J. Basic analysis for recovery of liquid SO2 from regeneration tail gas of flue gas desulfurization[J]. Gas & Heat, 2000, (2): 3-7. | |

| 18 | 杨化震. 二氧化硫烟气深冷液化分离工艺实验及模拟研究[D]. 淄博: 山东理工大学, 2019. |

| Yang H Z. Experiments and simulations of cryogenic sulfur dioxide flue gas desulfurization process[D]. Zibo: Shandong University of Technology, 2019. | |

| 19 | 卢建光, 阎占海, 邵久刚, 等. 逆流式活性炭净化烟气工艺在邯钢烧结机的应用[J]. 中国钢铁业, 2019, (3): 52-54. |

| Lu J G, Yan Z H, Shao J G, et al. Application of countercurrent activated carbon purification technology in sintering machine of Handan steel [J]. China Steel, 2019, (3): 52-54. | |

| 20 | 韩健, 阎占海, 邵久刚. 逆流式活性炭烟气脱硫脱硝技术特点及应用[J]. 烧结球团, 2018, 43(6): 13-18. |

| Han J, Yan Z H, Shao J G. Technical characteristics of counter flow active carbon-flue gas desulphurization and denitrification process and its application[J]. Sintering and Pelletizing, 2018, 43(6): 13-18. | |

| 21 | Grebenev I V, Lebedeva O V, Polushkina S V. A demonstration experiment for studying the properties of saturated vapor[J]. Physics Education, 2017, 52(6): 063001. |

| 22 | Roedel W. The sulfuric acid saturation vapor pressure: measurement and implications for aerosol condensation[J]. Pergamon, 1980, 11(3): 267-268. |

| 23 | National Institute of Standards and Technology. Sulfur dioxide: phase change data[DB/OL]. [2020-04-29]. https://webbook.nist.gov/cgi/cbook.cgi?ID=C7446095&Units=SI&Mask=4#Thermo-Phase. |

| 24 | Stull D R. Vapor pressure of pure substances: organic and inorganic compounds[J]. Ind. Eng. Chem., 1947, 39(4): 517-540. |

| 25 | 沈维道. 能源技术基础理论讲座——应用传热学[J]. 能源技术, 1988, (3): 48-53+46. |

| Shen W D. Lectures on basic theories of energy technology: applied heat transfer[J]. Energy Technology, 1988, (3): 48-53+46. | |

| 26 | Huang J, Zhang J, Wang L. Review of vapor condensation heat and mass transfer in the presence of non-condensable gas[J]. Appl. Therm. Eng., 2015, 89: 469-484. |

| 27 | Al-Shammari S B, Webb D R, Heggs P. Condensation of steam with and without the presence of non-condensable gases in a vertical tube[J]. Desalination, 2003, 169(2): 151-160. |

| 28 | Knacke O, Stranski I N. The mechanism of evaporation[J]. Prog. Met. Phys., 1956, (6): 181-235. |

| 29 | Collier J G, Thome J R. Convective Boiling and Condensation[M]. London: Clarendon Press, 1994: 430-434. |

| 30 | Ge M, Zhao J, Wang S. Experimental investigation of steam condensation with high concentration CO2 on a horizontal tube[J]. Applied Thermal Engineering, 2013, 61(2): 334-343. |

| [1] | 黄琮琪, 吴一梅, 陈建业, 邵双全. 碱性电解水制氢装置热管理系统仿真研究[J]. 化工学报, 2023, 74(S1): 320-328. |

| [2] | 苏伟, 马东旭, 金旭, 刘忠彦, 张小松. 表面润湿性对霜层传递特性影响可视化实验研究[J]. 化工学报, 2023, 74(S1): 122-131. |

| [3] | 赵亚欣, 张雪芹, 王荣柱, 孙国, 姚善泾, 林东强. 流穿模式离子交换层析去除单抗聚集体[J]. 化工学报, 2023, 74(9): 3879-3887. |

| [4] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [5] | 张佳怡, 何佳莉, 谢江鹏, 王健, 赵鹬, 张栋强. 渗透汽化技术用于锂电池生产中N-甲基吡咯烷酮回收的研究进展[J]. 化工学报, 2023, 74(8): 3203-3215. |

| [6] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [7] | 刘爽, 张霖宙, 许志明, 赵锁奇. 渣油及其组分黏度的分子层次组成关联研究[J]. 化工学报, 2023, 74(8): 3226-3241. |

| [8] | 张缘良, 栾昕奇, 苏伟格, 李畅浩, 赵钟兴, 周利琴, 陈健民, 黄艳, 赵祯霞. 离子液体复合萃取剂选择性萃取尼古丁的研究及DFT计算[J]. 化工学报, 2023, 74(7): 2947-2956. |

| [9] | 高金明, 郭玉娇, 鄂承林, 卢春喜. 一种封闭罩内顺流多旋臂气液分离器的分离特性研究[J]. 化工学报, 2023, 74(7): 2957-2966. |

| [10] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [11] | 韩奎奎, 谭湘龙, 李金芝, 杨婷, 张春, 张永汾, 刘洪全, 于中伟, 顾学红. 四通道中空纤维MFI分子筛膜用于二甲苯异构体分离[J]. 化工学报, 2023, 74(6): 2468-2476. |

| [12] | 朱兴驰, 郭志远, 纪志永, 汪婧, 张盼盼, 刘杰, 赵颖颖, 袁俊生. 选择性电渗析镁锂分离过程模拟优化[J]. 化工学报, 2023, 74(6): 2477-2485. |

| [13] | 蔺彩虹, 王丽, 吴瑜, 刘鹏, 杨江峰, 李晋平. 沸石中碱金属阳离子对CO2/N2O吸附分离性能的影响[J]. 化工学报, 2023, 74(5): 2013-2021. |

| [14] | 孙永尧, 高秋英, 曾文广, 王佳铭, 陈艺飞, 周永哲, 贺高红, 阮雪华. 面向含氮油田伴生气提质利用的膜耦合分离工艺设计优化[J]. 化工学报, 2023, 74(5): 2034-2045. |

| [15] | 张正, 何永平, 孙海东, 张荣子, 孙正平, 陈金兰, 郑一璇, 杜晓, 郝晓刚. 蛇形流场电控离子交换装置用于选择性提锂[J]. 化工学报, 2023, 74(5): 2022-2033. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号