化工学报 ›› 2021, Vol. 72 ›› Issue (6): 3041-3052.DOI: 10.11949/0438-1157.20201731

收稿日期:2020-12-01

修回日期:2021-03-08

出版日期:2021-06-05

发布日期:2021-06-05

通讯作者:

程芳琴

作者简介:周冬冬(1993—),男,博士研究生,201814001005 @email.sxu.edu.cn

基金资助:

ZHOU Dongdong1,FANG Li1,2,YANG Qiaozhen2,QIU Ruifang1,CHENG Fangqin1( )

)

Received:2020-12-01

Revised:2021-03-08

Online:2021-06-05

Published:2021-06-05

Contact:

CHENG Fangqin

摘要:

针对青海盐湖地区弃置堆积的水氯镁石难以规模化消纳问题,制备了碱式硫酸镁(BMS)水泥基多孔吸声材料,研究了原料硫酸镁、引气剂十四烷基甜菜碱(C14BE)和矿物掺合料粉煤灰(FA)等对材料的微观孔结构和性能的影响。结果表明,硫酸镁和C14BE的浓度对溶液的起泡性能和泡沫稳定性影响显著,当二者浓度分别为2.4 mol/L(水灰比为1.1)和9.8 mmol/L时,所制得的BMS多孔材料的孔径大、开孔率高,抗压强度为2.0 MPa,降噪系数(NRC)可达0.70;FA掺杂使材料的孔壁增厚、力学性能提升,同时开孔率下降、吸声性能降低,但即使FA掺量增至40%,其NRC值仍然可达0.51。BMS多孔吸声材料的研制不仅为噪声控制领域提供了一种新型无机非金属材料,而且为盐湖镁资源的有效利用提供了一条新途径。

中图分类号:

周冬冬, 方莉, 杨巧珍, 邱瑞芳, 程芳琴. 碱式硫酸镁多孔吸声材料的制备及性能研究[J]. 化工学报, 2021, 72(6): 3041-3052.

ZHOU Dongdong, FANG Li, YANG Qiaozhen, QIU Ruifang, CHENG Fangqin. Preparation and performance of base magnesium sulfate porous sound absorbing materials[J]. CIESC Journal, 2021, 72(6): 3041-3052.

| 化学组成 (质量分数)/ % | 柠檬酸活性值/s | |||||

|---|---|---|---|---|---|---|

| MgO | α-MgO① | SO3 | Cl | SiO2 | 烧失量 | |

| 96.30 | 93.37 | 1.23 | 0.39 | 0.10 | 1.98 | 234 |

表1 氧化镁的化学组成及反应活性

Table 1 Chemical composition and reactivity of the used MgO

| 化学组成 (质量分数)/ % | 柠檬酸活性值/s | |||||

|---|---|---|---|---|---|---|

| MgO | α-MgO① | SO3 | Cl | SiO2 | 烧失量 | |

| 96.30 | 93.37 | 1.23 | 0.39 | 0.10 | 1.98 | 234 |

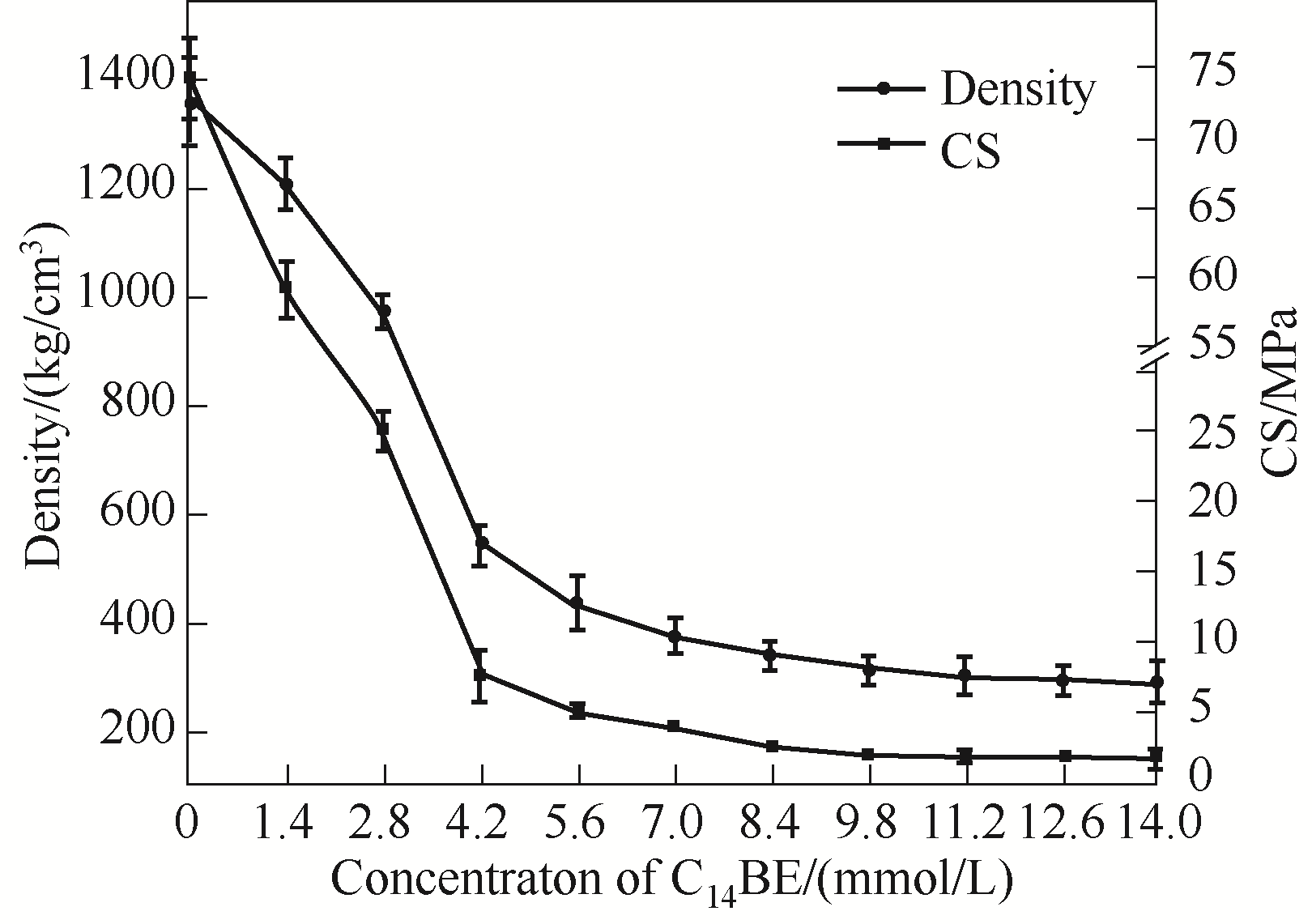

图7 不同C14BE浓度下BMS多孔吸声材料的干密度和抗压强度(水灰比为 1.1)

Fig.7 Density and compressive strength of porous BMS sound-absorbing materials at different C14BE concentrations

图10 不同水灰比下BMS多孔吸声材料的干密度和抗压强度(C14BE浓度为9.8 mmol/L)

Fig.10 Density and compressive strength of porous BMS sound-absorbing materials at different w/c ratios

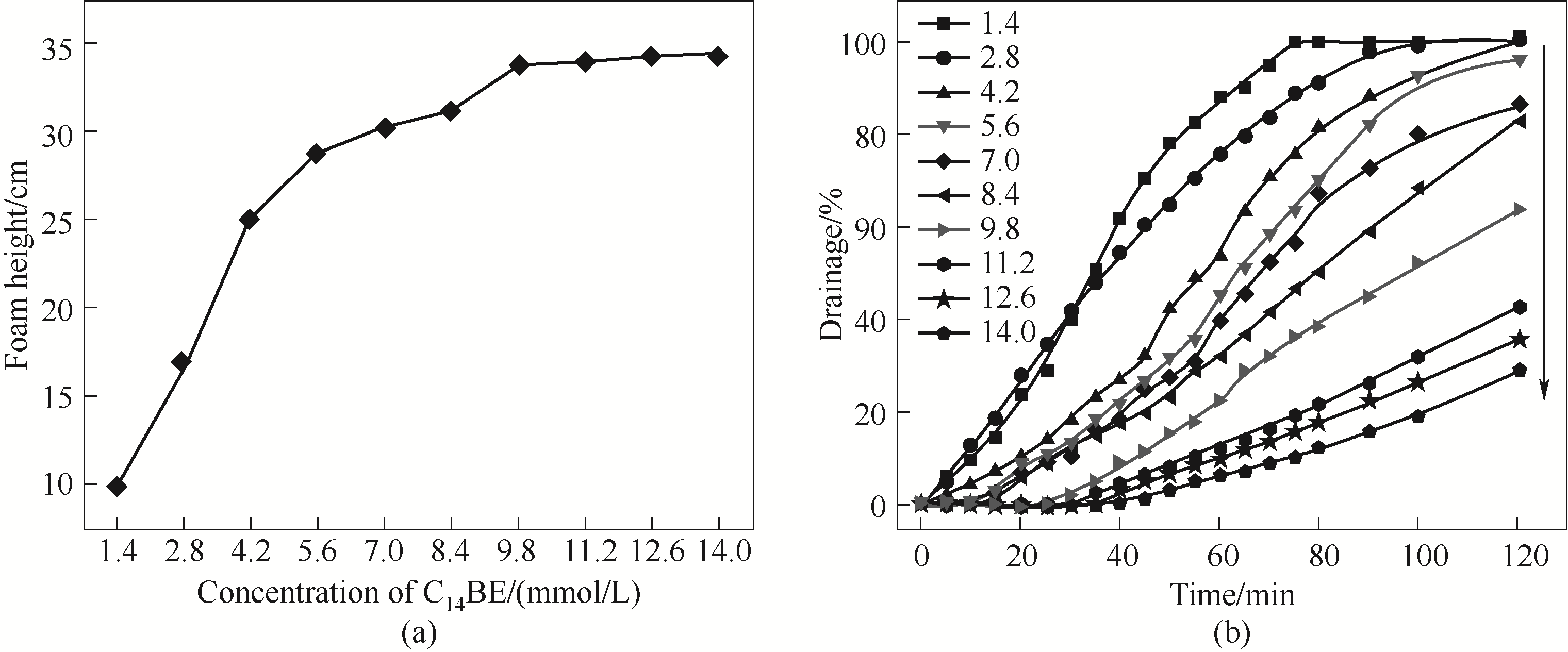

图11 不同C14BE浓度下硫酸镁溶液的发泡高度(a)和排液量(b)[MgSO4溶液的浓度为2.4 mol/L;图(b)中箭头方向为C14BE浓度由1.4增大至14.0 mmol/L]

Fig.11 Foam height (a) and drainage (b) of MgSO4 solutions at different C14BE concentrations

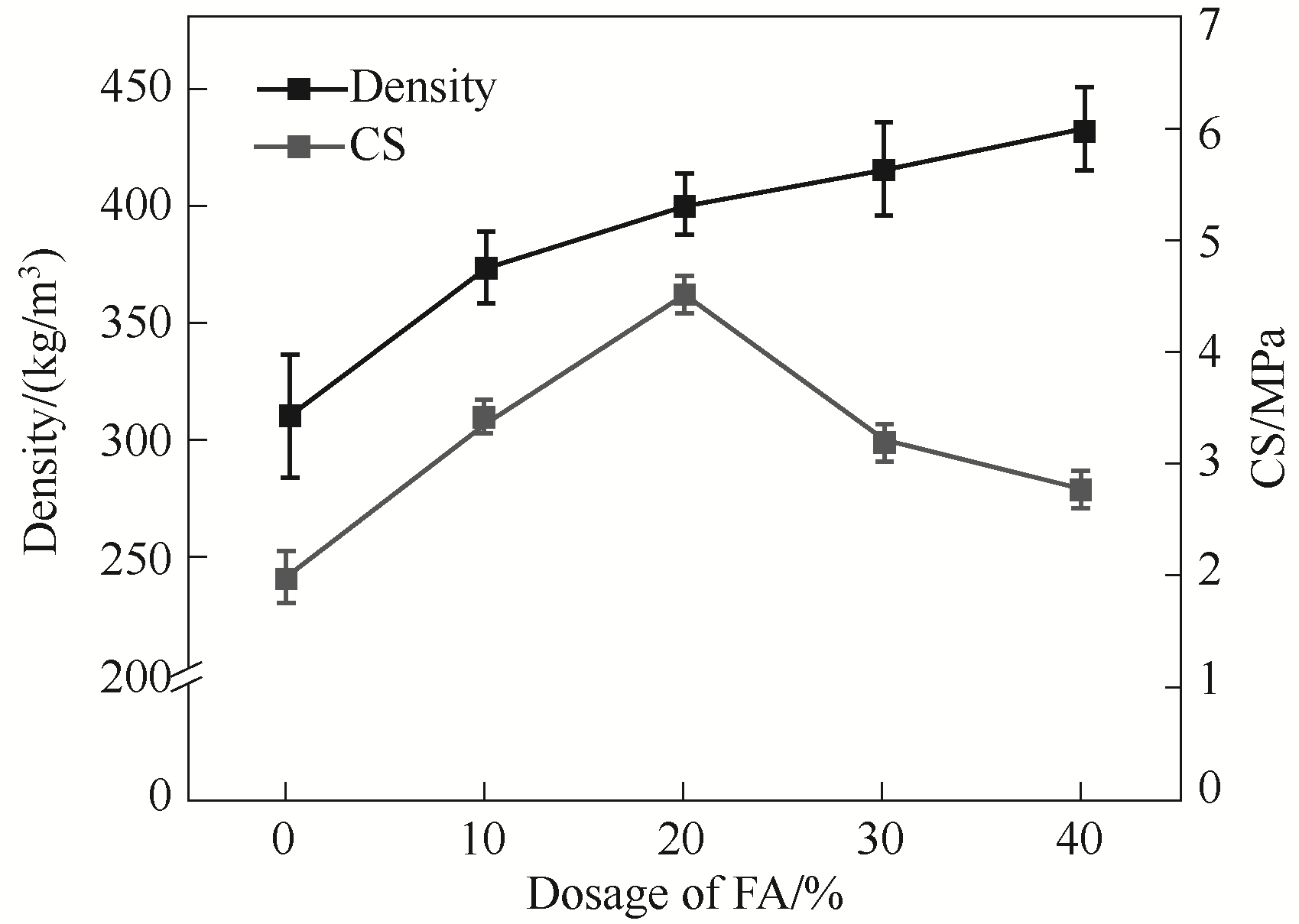

图13 不同FA掺量BMS多孔吸声材料的干密度和抗压强度(水灰比为 1.1,C14BE浓度为9.8 mmol/L)

Fig.13 Density and compressive strength of porous BMS sound-absorbing material at different FA dosages

| 1 | 孙朋. 钢渣多孔吸声材料的制备及吸声性能研究[D]. 北京: 北京科技大学, 2016. |

| Sun P. Preparation of porous sound-absorbing material using steel slag and its sound absorption properties[D]. Beijing: University of Science and Technology Beijing, 2016. | |

| 2 | Arenas J P, Crocker M J. Recent trends in porous sound-absorbing materials[J]. Sound and Vibration, 2010, 44(7): 12-17. |

| 3 | Guo H W, Gong Y X, Gao S Y. Preparation of high strength foam glass-ceramics from waste cathode ray tube[J]. Materials Letters, 2010, 64(8): 997-999. |

| 4 | 钟祥璋. 吸声泡沫玻璃的材料特性及其吸声性能的提高[J]. 电声技术, 2010, 34(8): 4-8. |

| Zhong X Z. Material characters of foamglass and improvement of its properties for sound absorption[J]. Audio Engineering, 2010, 34(8): 4-8. | |

| 5 | 李阳. 轻质泡沫玻璃吸声材料的制备及性能研究[D]. 太原: 中北大学, 2016. |

| Li Y. Preparation of lightweight foam glass sound absorbing material[D]. Taiyuan: North University of China, 2016. | |

| 6 | Choy Y S, Huang L X, Wang C Q. Sound propagation in and low frequency noise absorption by helium-filled porous material[J]. The Journal of the Acoustical Society of America, 2009, 126(6): 3008-3019. |

| 7 | 孙进兴, 刘培生. 多孔吸声陶瓷的研究进展[J]. 陶瓷学报, 2015, 36(4): 347-352. |

| Sun J X, Liu P S. The research progress of porous sound absorption ceramics[J]. Journal of Ceramics, 2015, 36(4): 347-352. | |

| 8 | 祝日新, 李晶, 毕万利, 等. 无机多孔吸声材料的研究与发展[J]. 辽宁科技大学学报, 2017, 40(3): 194-199. |

| Zhu R X, Li J, Bi W L, et al. Study on inorganic porous sound absorption materials[J]. Journal of University of Science and Technology Liaoning, 2017, 40(3): 194-199. | |

| 9 | Sun F G, Chen H L, Wu J H, et al. Sound absorbing characteristics of fibrous metal materials at high temperatures[J]. Applied Acoustics, 2010, 71(3): 221-235. |

| 10 | Zhang Y, Li H, Abdelhady A, et al. Effect of different factors on sound absorption property of porous concrete[J]. Transportation Research Part D: Transport and Environment, 2020, 87: 102532. |

| 11 | Luo X, Xu J Y, Bai E L, et al. Study on the effect of basalt fiber on the energy absorption characteristics of porous material[J]. Construction and Building Materials, 2014, 68: 384-390. |

| 12 | Arenas C, Leiva C, Vilches L F, et al. Use of co-combustion bottom ash to design an acoustic absorbing material for highway noise barriers[J]. Waste Management, 2013, 33(11): 2316-2321. |

| 13 | Yilmazer S, Ozdeniz M B. The effect of moisture content on sound absorption of expanded perlite plates[J]. Building and Environment, 2005, 40(3): 311-318. |

| 14 | Zhang Z H, Provis J L, Reid A, et al. Mechanical, thermal insulation, thermal resistance and acoustic absorption properties of geopolymer foam concrete[J]. Cement and Concrete Composites, 2015, 62: 97-105. |

| 15 | Qin L, Gao X J, Li W G, et al. Modification of magnesium oxysulfate cement by incorporating weak acids[J]. Journal of Materials in Civil Engineering, 2018, 30(9): 04018209. |

| 16 | Li X, Qiu R F, Xue F B, et al. Effects of unreactive MgO and impurities in light burned MgO on the hydration process and performance of base magnesium sulfate cement[J]. Construction and Building Materials, 2020, 240: 117854. |

| 17 | Wang N, Yu H F, Bi W L, et al. Effects of sodium citrate and citric acid on the properties of magnesium oxysulfate cement[J]. Construction and Building Materials, 2018, 169: 697-704. |

| 18 | Qin L, Gao X J, Chen T F. Recycling of raw rice husk to manufacture magnesium oxysulfate cement based lightweight building materials[J]. Journal of Cleaner Production, 2018, 191: 220-232. |

| 19 | Wang R, Qin L, Gao X J. Mechanical strength and water resistance of magnesium oxysulfate cement based lightweight materials[J]. Cement and Concrete Composites, 2020, 109: 103554. |

| 20 | 陈聪. 利用盐湖提取碳酸锂副产镁渣制备镁质胶凝材料[D]. 西宁: 青海大学, 2019. |

| Chen C. Preparation of magnesia cement using magnesium-rich byproducts from the production of lithium carbonate from salt lakes[D]. Xining: Qinghai University, 2019. | |

| 21 | 刘博. 碱式硫酸镁水泥泡沫混凝土的制备及性能研究[D]. 哈尔滨: 哈尔滨理工大学, 2019. |

| Liu B. Preparation and performance investigation of basic magnesium sulfate cement foamed concrete[D]. Harbin: Harbin University of Science and Technology, 2019. | |

| 22 | 赵祥, 李嘉华. 改性氯氧镁水泥吸声保温板在建筑节能中的应用[J]. 新型建筑材料, 2004, 31(3): 56-57. |

| Zhao X, Li J H. Application of modified magnesium oxychloride cement sound-absorbing insulation board in building energy saving [J]. New Building Materials, 2004, 31(3): 56-57. | |

| 23 | 李晶, 毕万利, 孙明晶, 等. 一种具有吸声降噪功效的硫氧镁胶凝材料及其制备方法: 110282950A[P]. 2019-09-27. |

| Li J, Bi W L, Sun M J, et al. Magnesium oxysulfate cementing material with sound absorption and noise reduction effects and preparation method thereof: 110282950A[P]. 2019-09-27. | |

| 24 | 吴成友. 碱式硫酸镁水泥的基本理论及其在土木工程中的应用技术研究[D]. 西宁: 中国科学院研究生院(青海盐湖研究所), 2014. |

| Wu C Y. Fundamental theory and civil engineering application of basic magnesium sulfate cement[D]. Xining: Qinghai Institute of Salt Lakes, Chinese Academy of Sciences, 2014. | |

| 25 | Hajimohammadi A, Ngo T, Mendis P. Enhancing the strength of pre-made foams for foam concrete applications[J]. Cement and Concrete Composites, 2018, 87: 164-171. |

| 26 | Yao X, Zhao G, Dai C L, et al. Interfacial characteristics and the stability mechanism of a dispersed particle gel (DPG) three-phase foam[J]. Journal of Molecular Liquids, 2020, 301: 112425. |

| 27 | Wang J Z, Ao Q B, Ma J, et al. Sound absorption performance of porous metal fiber materials with different structures[J]. Applied Acoustics, 2019, 145: 431-438. |

| 28 | Shao N N, Zhang Y B, Liu Z, et al. Fabrication of hollow microspheres filled fly ash based foam geopolymers with ultra-low thermal conductivity and relative high strength[J]. Construction and Building Materials, 2018, 185: 567-573. |

| 29 | Xu F, Gu G H, Zhang W, et al. Pore structure analysis and properties evaluations of fly ash-based geopolymer foams by chemical foaming method[J]. Ceramics International, 2018, 44(16): 19989-19997. |

| 30 | 周栋梁, 潘志华. 新型水泥基泡沫吸声材料的研制[J]. 噪声与振动控制, 2010, 30(4): 58-60. |

| Zhou D L, Pan Z H. Research and development of a new type cellular concrete based sound absorption material[J]. Noise and Vibration Control, 2010, 30(4): 58-60. | |

| 31 | Doutres O, Salissou Y, Atalla N, et al. Evaluation of the acoustic and non-acoustic properties of sound absorbing materials using a three-microphone impedance tube[J]. Applied Acoustics, 2010, 71(6): 506-509. |

| 32 | Li T, Wang Z, Zhou T T, et al. Preparation and properties of magnesium phosphate cement foam concrete with H2O2 as foaming agent[J]. Construction and Building Materials, 2019, 205: 566-573. |

| 33 | 龚良发, 李汝雄, 徐新, 等. 无机盐及其与表面活性剂混合物溶液的表面张力[J]. 北京石油化工学院学报, 2000, 8(1): 42-46. |

| Gong L F, Li R X, Xu X, et al. Surface tension of aqueous solutions of inorganic salts and those+surfactant[J]. Journal of Beijing Institute of Petrochemical Technology, 2000, 8(1): 42-46. | |

| 34 | 吴刚. 无机盐对表面活性剂及其复合体系泡沫稳定性影响的机理研究[D]. 东营: 中国石油大学(华东), 2017. |

| Wu G. Effect of inorganic salts on foam stability of surfactant and its composite systems[D]. Dongying: ChinaUniversity of Petroleum, 2017. | |

| 35 | Wang A Q, Zhang C Z, Sun W. Fly ash effects(Ⅲ): The microaggregate effect of fly ash[J]. Cement and Concrete Research, 2004, 34(11): 2061-2066. |

| 36 | Guo T, Wang H F, Yang H J, et al. The mechanical properties of magnesium oxysulfate cement enhanced with 517 phase magnesium oxysulfate whiskers[J]. Construction and Building Materials, 2017, 150: 844-850. |

| [1] | 吴延鹏, 李晓宇, 钟乔洋. 静电纺丝纳米纤维双疏膜油性细颗粒物过滤性能实验分析[J]. 化工学报, 2023, 74(S1): 259-264. |

| [2] | 杨天阳, 邹慧明, 周晖, 王春磊, 田长青. -30℃电动汽车补气式CO2热泵制热性能实验研究[J]. 化工学报, 2023, 74(S1): 272-279. |

| [3] | 常明慧, 王林, 苑佳佳, 曹艺飞. 盐溶液蓄能型热泵循环特性研究[J]. 化工学报, 2023, 74(S1): 329-337. |

| [4] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [5] | 王阳, 戴永强, 曾炜. 2,5-二羟基苯磺酸增强离子水凝胶材料热电性能的研究[J]. 化工学报, 2023, 74(9): 3946-3955. |

| [6] | 徐文杰, 贾献峰, 王际童, 乔文明, 凌立成, 王任平, 余子舰, 张寅旭. 有机硅/酚醛杂化气凝胶的制备和性能研究[J]. 化工学报, 2023, 74(8): 3572-3583. |

| [7] | 陈国泽, 卫东, 郭倩, 向志平. 负载跟踪状态下的铝空气电池堆最优功率点优化方法[J]. 化工学报, 2023, 74(8): 3533-3542. |

| [8] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [9] | 史方哲, 甘云华. 超薄热管启动特性和传热性能数值模拟[J]. 化工学报, 2023, 74(7): 2814-2823. |

| [10] | 吴文涛, 褚良永, 张玲洁, 谭伟民, 沈丽明, 暴宁钟. 腰果酚生物基自愈合微胶囊的高效制备工艺研究[J]. 化工学报, 2023, 74(7): 3103-3115. |

| [11] | 邢美波, 张中天, 景栋梁, 张洪发. 磁调控水基碳纳米管协同多孔材料强化相变储/释能特性[J]. 化工学报, 2023, 74(7): 3093-3102. |

| [12] | 王志龙, 杨烨, 赵真真, 田涛, 赵桐, 崔亚辉. 搅拌时间和混合顺序对锂离子电池正极浆料分散特性的影响[J]. 化工学报, 2023, 74(7): 3127-3138. |

| [13] | 刘杰, 吴立盛, 李锦锦, 罗正鸿, 周寅宁. 含乙烯基胺酯键聚醚类可逆交联聚合物的制备及性能研究[J]. 化工学报, 2023, 74(7): 3051-3057. |

| [14] | 张谭, 刘光, 李晋平, 孙予罕. Ru基氮还原电催化剂性能调控策略[J]. 化工学报, 2023, 74(6): 2264-2280. |

| [15] | 朱风, 陈凯琳, 黄小凤, 鲍银珠, 李文斌, 刘嘉鑫, 吴玮强, 高王伟. KOH改性电石渣脱除羰基硫的性能研究[J]. 化工学报, 2023, 74(6): 2668-2679. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号