化工学报 ›› 2021, Vol. 72 ›› Issue (7): 3706-3715.DOI: 10.11949/0438-1157.20201914

叶凯1( ),刘香华2(

),刘香华2( ),姜月2,于颖2,赵亚飞1,庄烨1,郑进保2(

),姜月2,于颖2,赵亚飞1,庄烨1,郑进保2( ),陈秉辉2

),陈秉辉2

收稿日期:2020-12-25

修回日期:2021-03-31

出版日期:2021-07-05

发布日期:2021-07-05

通讯作者:

郑进保

作者简介:叶凯(1988—),男,硕士,

YE Kai1( ),LIU Xianghua2(

),LIU Xianghua2( ),JIANG Yue2,YU Ying2,ZHAO Yafei1,ZHUANG Ye1,ZHENG Jinbao2(

),JIANG Yue2,YU Ying2,ZHAO Yafei1,ZHUANG Ye1,ZHENG Jinbao2( ),CHEN Binghui2

),CHEN Binghui2

Received:2020-12-25

Revised:2021-03-31

Online:2021-07-05

Published:2021-07-05

Contact:

ZHENG Jinbao

摘要:

低温等离子体协同催化剂技术(NTP-CAT)由于操作方便、能耗低等特点,特别适合用于工业非连续或连续消除低浓度VOCs过程。本研究发现NTP-CAT体系中CeO2基催化剂更适合负载于13X载体以降解甲苯,并进一步考察CeO2负载量对VOCs消除效果的影响。结果发现,NTP-CAT 体系中30% CeO2/13X表现出最优性能,其可降解约85%的甲苯,CO2产物选择性可达55%。表征结果也表明,Ce组分在30% CeO2/13X表面仍可较好分散,而且表面的Ce3+物种含量最高。O2-TPD实验结果证实表面Ce3+物种来源于Ce4+物种的等离子体处理。而且,表面Ce3+含量越高,有利于产生更多的氧物种,随后将与其周边13X吸附活化的甲苯反应。因此,甲苯降解在NTP-CAT体系中应存在分工协同机制。

中图分类号:

叶凯, 刘香华, 姜月, 于颖, 赵亚飞, 庄烨, 郑进保, 陈秉辉. 低温等离子体协同CeO2/13X催化降解甲苯[J]. 化工学报, 2021, 72(7): 3706-3715.

YE Kai, LIU Xianghua, JIANG Yue, YU Ying, ZHAO Yafei, ZHUANG Ye, ZHENG Jinbao, CHEN Binghui. Combing low-temperature plasma with CeO2/13X for toluene degradation[J]. CIESC Journal, 2021, 72(7): 3706-3715.

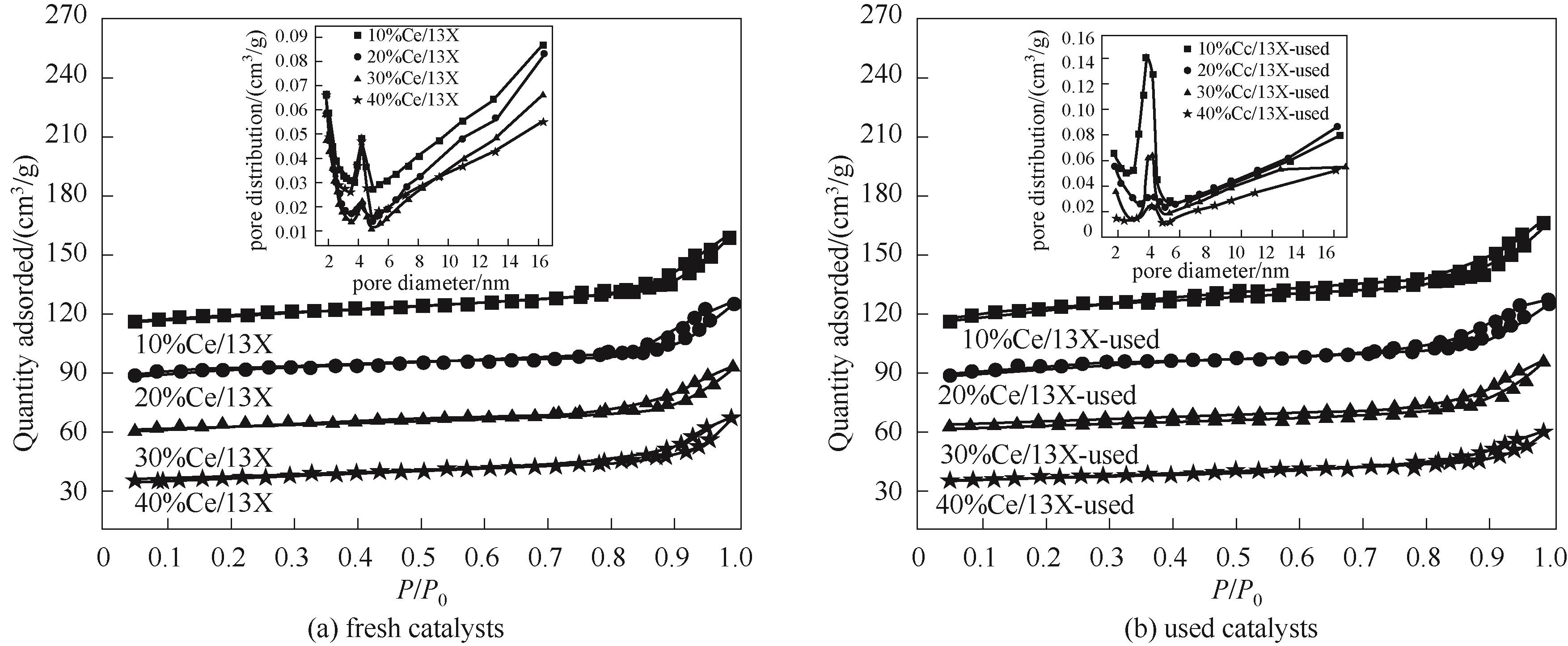

图6 不同催化剂反应前后的N2-等温吸脱附曲线和孔径分布

Fig.6 Nitrogen adsorption-desorption isotherms and corresponding pore size distribution curves (inset) of different CeO2-based catalysts

| Catalyst | SBET/(m2/g) | Vpore/(cm3/g) | Pore size/nm |

|---|---|---|---|

| fresh 10%Ce/13X | 379.4 | 0.052 | 5.0 |

| used 10%Ce/13X | 313.0 | 0.063 | 4.5 |

| fresh 20%Ce/13X | 346.7 | 0.042 | 5.1 |

| used 20%Ce/13X | 342.6 | 0.046 | 5.0 |

| fresh 30%Ce/13X | 286.1 | 0.035 | 5.0 |

| used 30%Ce/13X | 173.9 | 0.032 | 6.5 |

| fresh 40%Ce/13X | 200.7 | 0.027 | 4.7 |

| used 40%Ce/13X | 179.2 | 0.030 | 5.2 |

表1 CeO2基催化剂的比表面积、孔容和孔径

Table 1 Textural properties of CeO2-based catalysts

| Catalyst | SBET/(m2/g) | Vpore/(cm3/g) | Pore size/nm |

|---|---|---|---|

| fresh 10%Ce/13X | 379.4 | 0.052 | 5.0 |

| used 10%Ce/13X | 313.0 | 0.063 | 4.5 |

| fresh 20%Ce/13X | 346.7 | 0.042 | 5.1 |

| used 20%Ce/13X | 342.6 | 0.046 | 5.0 |

| fresh 30%Ce/13X | 286.1 | 0.035 | 5.0 |

| used 30%Ce/13X | 173.9 | 0.032 | 6.5 |

| fresh 40%Ce/13X | 200.7 | 0.027 | 4.7 |

| used 40%Ce/13X | 179.2 | 0.030 | 5.2 |

| Catalysts | CeO2 loading/% | Ce3+/Ce4+ | Ce/ (Si+Al) | Ce3+/ (Si+Al) | Osur/O | Osur/ (Si+Al) |

|---|---|---|---|---|---|---|

| 10%Ce/13X | ||||||

| fresh | 13.5 | 0.39 | 2.38 | 0.93 | 0.44 | 1.67 |

| used | — | 0.41 | 2.25 | 0.92 | 0.42 | 1.42 |

| 20%Ce/13X | ||||||

| fresh | 20.7 | 0.28 | 2.87 | 0.80 | 0.4 | 2.63 |

| used | — | 0.37 | 2.90 | 1.07 | 0.44 | 2.86 |

| 30%Ce/13X | ||||||

| fresh | 27.7 | 0.23 | 6.74 | 1.55 | 0.57 | 4.11 |

| used | — | 0.31 | 8.13 | 2.52 | 0.61 | 4.57 |

| 40%Ce/13X | ||||||

| fresh | 35.1 | 0.12 | 10.8 | 1.30 | 0.55 | 3.11 |

| used | — | 0.19 | 9.3 | 1.77 | 0.58 | 3.42 |

表2 不同催化剂元素的表面组成

Table 2 The surface composition of different CeO2-based catalysts

| Catalysts | CeO2 loading/% | Ce3+/Ce4+ | Ce/ (Si+Al) | Ce3+/ (Si+Al) | Osur/O | Osur/ (Si+Al) |

|---|---|---|---|---|---|---|

| 10%Ce/13X | ||||||

| fresh | 13.5 | 0.39 | 2.38 | 0.93 | 0.44 | 1.67 |

| used | — | 0.41 | 2.25 | 0.92 | 0.42 | 1.42 |

| 20%Ce/13X | ||||||

| fresh | 20.7 | 0.28 | 2.87 | 0.80 | 0.4 | 2.63 |

| used | — | 0.37 | 2.90 | 1.07 | 0.44 | 2.86 |

| 30%Ce/13X | ||||||

| fresh | 27.7 | 0.23 | 6.74 | 1.55 | 0.57 | 4.11 |

| used | — | 0.31 | 8.13 | 2.52 | 0.61 | 4.57 |

| 40%Ce/13X | ||||||

| fresh | 35.1 | 0.12 | 10.8 | 1.30 | 0.55 | 3.11 |

| used | — | 0.19 | 9.3 | 1.77 | 0.58 | 3.42 |

| 1 | 梁文俊, 郭书清, 武红梅, 等. 非热等离子体协同Mn-Ce/La/γ-Al2O3催化剂去除甲苯[J]. 化工学报, 2017, 68(7): 2755-2762. |

| Liang W J, Guo S Q, Wu H M, et al. Removal of toluene using non-thermal plasma coupled with Mn-Ce/La/γ-Al2O3 catalysts[J]. CIESC Journal, 2017, 68(7): 2755-2762. | |

| 2 | 尚超, 韦献革, 白敏冬, 等. 低温等离子体催化降解烟气中甲苯的研究[J]. 中国环境科学, 2020, 40(9): 3714-3720. |

| Shang C, Wei X G, Bai M D, et al. Degradation of toluene in flue gas by low temperature plasma catalysis[J]. China Environmental Science, 2020, 40(9): 3714-3720. | |

| 3 | 梁文俊, 孙慧频, 朱玉雪, 等. 流向变换等离子体催化系统去除甲苯[J]. 中国环境科学, 2019, 39(12): 4974-4981. |

| Liang W J, Sun H P, Zhu Y X, et al. Removal of toluene with a reverse flow non-thermal plasma-catalytic reaction system[J]. China Environmental Science, 2019, 39(12): 4974-4981. | |

| 4 | Fan H Y, Shi C, Li X S, et al. High-efficiency plasma catalytic removal of dilute benzene from air[J]. Journal of Physics D: Applied Physics, 2009, 42(22): 225105. |

| 5 | 刘文正, 赵帅, 柴茂林, 等. 采用辉光放电等离子体的烟气处理技术研究[J]. 中国环境科学, 2017, 37(8): 2905-2914. |

| Liu W Z, Zhao S, Chai M L, et al. Technology of flue gas treatment with glow discharge plasma[J]. China Environmental Science, 2017, 37(8): 2905-2914. | |

| 6 | 竹涛, 梁文俊, 李坚, 等. 等离子体联合纳米技术降解甲苯废气的研究[J]. 中国环境科学, 2008, 28(8): 699-703. |

| Zhu T, Liang W J, Li J, et al. Degradation of toluene in exhaust gas with plasma and nano-materials[J]. China Environmental Science, 2008, 28(8): 699-703. | |

| 7 | 赵军杰, 党小庆, 秦彩虹, 等. 分子筛吸附: 低温等离子体氧化去除甲苯[J]. 环境污染与防治, 2018, 40(5): 562-565. |

| Zhao J J, Dang X Q, Qin C H, et al. Removal of toluene by molecular sieve adsorption-nonthermal plasma oxidation[J]. Environmental Pollution & Control, 2018, 40(5): 562-565. | |

| 8 | Youn J S, Bae J, Park S, et al. Plasma-assisted oxidation of toluene over Fe/zeolite catalyst in DBD reactor using adsorption/desorption system[J]. Catalysis Communications, 2018, 113: 36-40. |

| 9 | 滕晶晶, 党小庆, 秦彩虹, 等. Mn-Ag/13X的焙烧温度对等离子体催化氧化吸附态甲苯的影响[J]. 环境工程学报, 2017, 11(6): 3666-3670. |

| Teng J J, Dang X Q, Qin C H, et al. Effect of calcination temperature on Mn-Ag/13X for plasma catalytic oxidation of adsorbed toluene[J]. Chinese Journal of Environmental Engineering, 2017, 11(6): 3666-3670. | |

| 10 | Kim H H, Teramoto Y, Negishi N, et al. A mul- tidisciplinary approach to understand the interactions of nonthermal plasma and catalyst: a review[J]. Catalysis Today, 2015, 256: 13-22. |

| 11 | 康忠利, 党小庆, 秦彩虹, 等. 锰银复合催化剂对NTP降解吸附态甲苯的影响[J]. 环境工程, 2017, 35(2): 72-77, 99. |

| Kang Z L, Dang X Q, Qin C H, et al. Influence of manganese-silver catalyst on adsorbed toluene decomposition with non-thermal plasma[J]. Environmental Engineering, 2017, 35(2): 72-77, 99. | |

| 12 | Yi H H, Yang X, Tang X L, et al. Removal of toluene from industrial gas over 13X zeolite supported catalysts by adsorption-plasma catalytic process[J]. Journal of Chemical Technology & Biotechnology, 2017, 92(9): 2276-2286. |

| 13 | Yi H H, Yang X, Tang X L, et al. Performance and pathways of toluene degradation over Co/13X by different processes based on nonthermal plasma[J]. Energy & Fuels, 2017, 31(10): 11217-11224. |

| 14 | Trinh Q H, Gandhi M S, Mok Y S. Adsorption and plasma-catalytic oxidation of acetone over zeolite-supported silver catalyst[J]. Japanese Journal of Applied Physics, 2015, 54(1S): 01AG04. |

| 15 | Lu M J, Huang R, Wu J L, et al. On the performance and mechanisms of toluene removal by FeOx/SBA-15-assisted non-thermal plasma at atmospheric pressure and room temperature[J]. Catalysis Today, 2015, 242: 274-286. |

| 16 | Okumura K, Kobayashi T, Tanaka H, et al. Toluene combustion over palladium supported on various metal oxide supports[J]. Applied Catalysis B: Environmental, 2003, 44(4): 325-331. |

| 17 | Ordóñez S, Bello L, Sastre H, et al. Kinetics of the deep oxidation of benzene, toluene, n-hexane and their binary mixtures over a platinum on γ-alumina catalyst[J]. Applied Catalysis B: Environmental, 2002, 38(2): 139-149. |

| 18 | 樊国栋, 王丽娜. 热处理温度对Ce掺杂TiO2光催化剂结构与性能的影响[J]. 陕西科技大学学报(自然科学版), 2015, 33(5): 46-49, 75. |

| Fan G D, Wang L N. Annealing temperature on the influence of the structure and photocatalytic performance of Ce doped TiO2[J]. Journal of Shaanxi University of Science & Technology (Natural Science Edition), 2015, 33(5): 46-49, 75. | |

| 19 | Lawrence N J, Brewer J R, Wang L, et al. De- fect engineering in cubic cerium oxide nanostructures for catalytic oxidation[J]. Nano Letters, 2011, 11(7): 2666-2671. |

| 20 | Wu Z L, Mann A K P, Li M J, et al. Spectro- scopic investigation of surface-dependent acid–base property of ceria nanoshapes[J]. The Journal of Physical Chemistry C, 2015, 119(13): 7340-7350. |

| 21 | Liu X, Zhou K, Wang L, et al. Oxygen vacancy clusters promoting reducibility and activity of ceria nanorods[J]. Journal of the American Chemical Society, 2009, 131(9): 3140-3141. |

| 22 | Jiang L Y, Nie G F, Zhu R Y, et al. Efficient degradation of chlorobenzene in a non-thermal plasma catalytic reactor supported on CeO2/HZSM-5 catalysts[J]. Journal of Environmental Sciences, 2017, 55: 266-273. |

| 23 | Asgari N, Haghighi M, Shafiei S. Synthesis and physicochemical characterization of nanostructured CeO2/clinoptilolite for catalytic total oxidation of xylene at low temperature[J]. Environmental Progress & Sustainable Energy, 2013, 32(3): 587-597. |

| 24 | Abbasi Z, Haghighi M, Fatehifar E, et al. Syn- thesis and physicochemical characterizations of nanostructured Pt/Al2O3-CeO2 catalysts for total oxidation of VOCs[J]. Journal of Hazardous Materials, 2011, 186(2/3): 1445-1454. |

| 25 | Tang X L, Gao F Y, Wang J G, et al. Comparative study between single- and double-dielectric barrier discharge reactor for nitric oxide removal[J]. Industrial & Engineering Chemistry Research, 2014, 53(14): 6197-6203. |

| 26 | 于欣, 党小庆, 李世杰, 等. 单介质和双介质阻挡放电低温等离子体降解甲苯的比较[J]. 环境工程学报, 2020, 14(4): 1033-1041. |

| Yu X, Dang X Q, Li S J, et al. Comparison of single and double dielectric barrier discharge non-thermal plasma for toluene removal[J]. Chinese Journal of Environmental Engineering, 2020, 14(4): 1033-1041. | |

| 27 | Kim H H, Kim J H, Ogata A. Microscopic observation of discharge plasma on the surface of zeolites supported metal nanoparticles[J]. Journal of Physics D: Applied Physics, 2009, 42(13): 135210. |

| 28 | Yao X M, Jiang N, Li J, et al. An improved corona discharge ignited by oxide cathodes with high secondary electron emission for toluene degradation[J]. Chemical Engineering Journal, 2019, 362: 339-348. |

| 29 | Xiao G, Xu W P, Wu R B, et al. Non-thermal plasmas for VOCs abatement[J]. Plasma Chemistry and Plasma Processing, 2014, 34(5): 1033-1065. |

| 30 | Zhang Z P, Chen L Q, Li Z B, et al. Activity and SO2 resistance of amorphous CeaTiOx catalysts for the selective catalytic reduction of NO with NH3: in situ DRIFT studies[J]. Catalysis Science & Technology, 2016, 6(19): 7151-7162. |

| 31 | Li Y Z, Sun Q, Kong M, et al. Coupling oxy- gen ion conduction to photocatalysis in mesoporous nanorod-like ceria significantly improves photocatalytic efficiency[J]. The Journal of Physical Chemistry C, 2011, 115(29): 14050-14057. |

| 32 | Zhang S, Guo Y Y, Li X Y, et al. Effects of cerium doping position on physicochemical properties and catalytic performance in methanol total oxidation[J]. Journal of Rare Earths, 2018, 36(8): 811-818. |

| 33 | Li J J, Yu E Q, Cai S C, et al. Noble metal free, CeO2/LaMnO3 hybrid achieving efficient photo-thermal catalytic decomposition of volatile organic compounds under IR light[J]. Applied Catalysis B: Environmental, 2019, 240: 141-152. |

| 34 | Trovarelli A. Structural properties and non- stoichiometric behavior of CeO2[M]//Catalysis by Ceria and Related Materials. London: Imperial College Press, 2002: 15-50. |

| 35 | Wang B F, Chen B X, Sun Y H, et al. Effects of dielectric barrier discharge plasma on the catalytic activity of Pt/CeO2 catalysts[J]. Applied Catalysis B: Environmental, 2018, 238: 328-338. |

| 36 | Liu C J, Yu K L, Zhang Y P, et al. Characterization of plasma treated Pd/HZSM-5 catalyst for methane combustion[J]. Applied Catalysis B: Environmental, 2004, 47(2): 95-100. |

| 37 | Chen L, Zhang X W, Huang L, et al. Application of in-plasma catalysis and post-plasma catalysis for methane partial oxidation to methanol over a Fe2O3-CuO/γ-Al2O3 catalyst[J]. Journal of Natural Gas Chemistry, 2010, 19(6): 628-637. |

| 38 | Huang H B, Ye D Q, Leung D Y C, et al. By products and pathways of toluene destruction via plasma-catalysis[J]. Journal of Molecular Catalysis A: Chemical, 2011, 336(1/2): 87-93. |

| 39 | Li S J, Dang X Q, Yu X, et al. The application of dielectric barrier discharge non-thermal plasma in VOCs abatement: a review[J]. Chemical Engineering Journal, 2020, 388: 124275. |

| 40 | Feng X X, Liu H X, He C, et al. Synergistic effects and mechanism of a non-thermal plasma catalysis system in volatile organic compound removal: a review[J]. Catalysis Science & Technology, 2018, 8(4): 936-954. |

| [1] | 涂玉明, 邵高燕, 陈健杰, 刘凤, 田世超, 周智勇, 任钟旗. 钙基催化剂的设计合成及应用研究进展[J]. 化工学报, 2023, 74(7): 2717-2734. |

| [2] | 李盼, 马俊洋, 陈志豪, 王丽, 郭耘. Ru/α-MnO2催化剂形貌对NH3-SCO反应性能的影响[J]. 化工学报, 2023, 74(7): 2908-2918. |

| [3] | 韩奎奎, 谭湘龙, 李金芝, 杨婷, 张春, 张永汾, 刘洪全, 于中伟, 顾学红. 四通道中空纤维MFI分子筛膜用于二甲苯异构体分离[J]. 化工学报, 2023, 74(6): 2468-2476. |

| [4] | 王辰, 史秀锋, 武鲜凤, 魏方佳, 张昊虹, 车寅, 吴旭. 氧化还原法制备Mn3O4催化剂及其甲苯催化氧化性能与机理研究[J]. 化工学报, 2023, 74(6): 2447-2457. |

| [5] | 蹇建, 张嘉明, 佘祥, 周虎, 游奎一, 罗和安. V4+和V5+比例对钒磷氧催化NO2氧化环己烷性能的影响[J]. 化工学报, 2023, 74(4): 1570-1577. |

| [6] | 赵涛岩, 曹江涛, 李平, 冯琳, 商瑀. 区间二型模糊免疫PID在环己烷无催化氧化温度控制系统中的应用[J]. 化工学报, 2022, 73(7): 3166-3173. |

| [7] | 钱庆玲, 朱晴, 杨正金, 徐铜文. 微孔Noria聚合物用于二甲苯异构体吸附分离研究[J]. 化工学报, 2022, 73(12): 5438-5448. |

| [8] | 石秀娟, 梁文俊, 尹国彬, 王金柱. 低温等离子体协同Mn基催化剂降解氯苯研究[J]. 化工学报, 2022, 73(10): 4472-4483. |

| [9] | 王乾浩, 赵璐, 孙付琳, 房克功. ZSM-5催化剂与低温等离子体协同转化H2S-CO2制合成气[J]. 化工学报, 2022, 73(1): 255-265. |

| [10] | 徐健元, 吴艳阳, 徐菊美, 彭阳峰. 2 kPa下均三甲苯-偏三甲苯与均三甲苯-邻甲乙苯体系二元汽液相平衡数据研究及精馏模拟[J]. 化工学报, 2021, 72(9): 4504-4510. |

| [11] | 孙静, 董一霖, 李法齐, 李文翔, 马晓玲, 王文龙. Co3O4改性USY分子筛吸附和催化氧化甲苯特性研究[J]. 化工学报, 2021, 72(6): 3306-3315. |

| [12] | 朱倩倩, 靳海波, 郭晓燕, 何广湘, 马磊, 张荣月, 谷庆阳, 杨索和. H2O2/乙腈体系下MgO催化环己酮Baeyer-Villiger绿色氧化合成ε-己内酯的研究[J]. 化工学报, 2021, 72(5): 2638-2646. |

| [13] | 王琴, 徐会金, 韩兴超, 赵长颖. MgO/Mg(OH)2热化学储热反应的第一性原理研究[J]. 化工学报, 2021, 72(3): 1242-1252. |

| [14] | 吕全明, 孙伟振, 赵玲. 连四甲苯液相氧化过程热力学分析及动力学模拟[J]. 化工学报, 2021, 72(2): 1009-1017. |

| [15] | 殷梦凡, 唐政, 张睿, 刘植昌, 刘海燕, 徐春明, 孟祥海. 离子液体液液萃取分离正辛烷/邻二甲苯[J]. 化工学报, 2021, 72(12): 6282-6290. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号