化工学报 ›› 2022, Vol. 73 ›› Issue (5): 2242-2250.DOI: 10.11949/0438-1157.20211775

徐劲松1( ),林敏2,陈晓平1(

),林敏2,陈晓平1( ),马吉亮1,耿鹏飞1,鲍学兵1,刘道银1,梁财1

),马吉亮1,耿鹏飞1,鲍学兵1,刘道银1,梁财1

收稿日期:2021-12-16

修回日期:2022-03-30

出版日期:2022-05-05

发布日期:2022-05-24

通讯作者:

陈晓平

作者简介:徐劲松(1996—),男,硕士研究生,

Jinsong XU1( ),Min LIN2,Xiaoping CHEN1(

),Min LIN2,Xiaoping CHEN1( ),Jiliang MA1,Pengfei GENG1,Xuebing BAO1,Daoyin LIU1,Cai LIANG1

),Jiliang MA1,Pengfei GENG1,Xuebing BAO1,Daoyin LIU1,Cai LIANG1

Received:2021-12-16

Revised:2022-03-30

Online:2022-05-05

Published:2022-05-24

Contact:

Xiaoping CHEN

摘要:

废酸流化床法再生技术可高效回收酸和金属离子,具有广阔的应用前景。利用自行搭建的流化床热态实验装置,并结合SEM、离子色谱和XPS等表征手段研究了密相区温度、初始床料粒径对废混酸(HNO3+HF)中酸与金属离子再生回收特性的影响规律。结果表明:流化床法可有效实现废混酸中酸和金属元素再生回收,金属氧化物在床料表面附着量随流化床密相区温度的升高而增加,850℃时达到峰值,继续升温后附着量小幅降低,同时增大床料初始粒径,金属氧化物在床料表面附着量将大幅提高;NO x 、HF生成量随流化床密相区温度的升高而增加,750℃时达到峰值,继续升温后大幅回落,同时随着床料初始粒径增大,NO x 生成量将小幅降低,而HF生成量峰值对应的密相区温度变化到800℃。

中图分类号:

徐劲松, 林敏, 陈晓平, 马吉亮, 耿鹏飞, 鲍学兵, 刘道银, 梁财. 不锈钢酸洗废混酸流化床焙烧再生特性的实验研究[J]. 化工学报, 2022, 73(5): 2242-2250.

Jinsong XU, Min LIN, Xiaoping CHEN, Jiliang MA, Pengfei GENG, Xuebing BAO, Daoyin LIU, Cai LIANG. Experimental study on regeneration characteristics of stainless steel pickling waste mixed acid by fluidized bed roaster[J]. CIESC Journal, 2022, 73(5): 2242-2250.

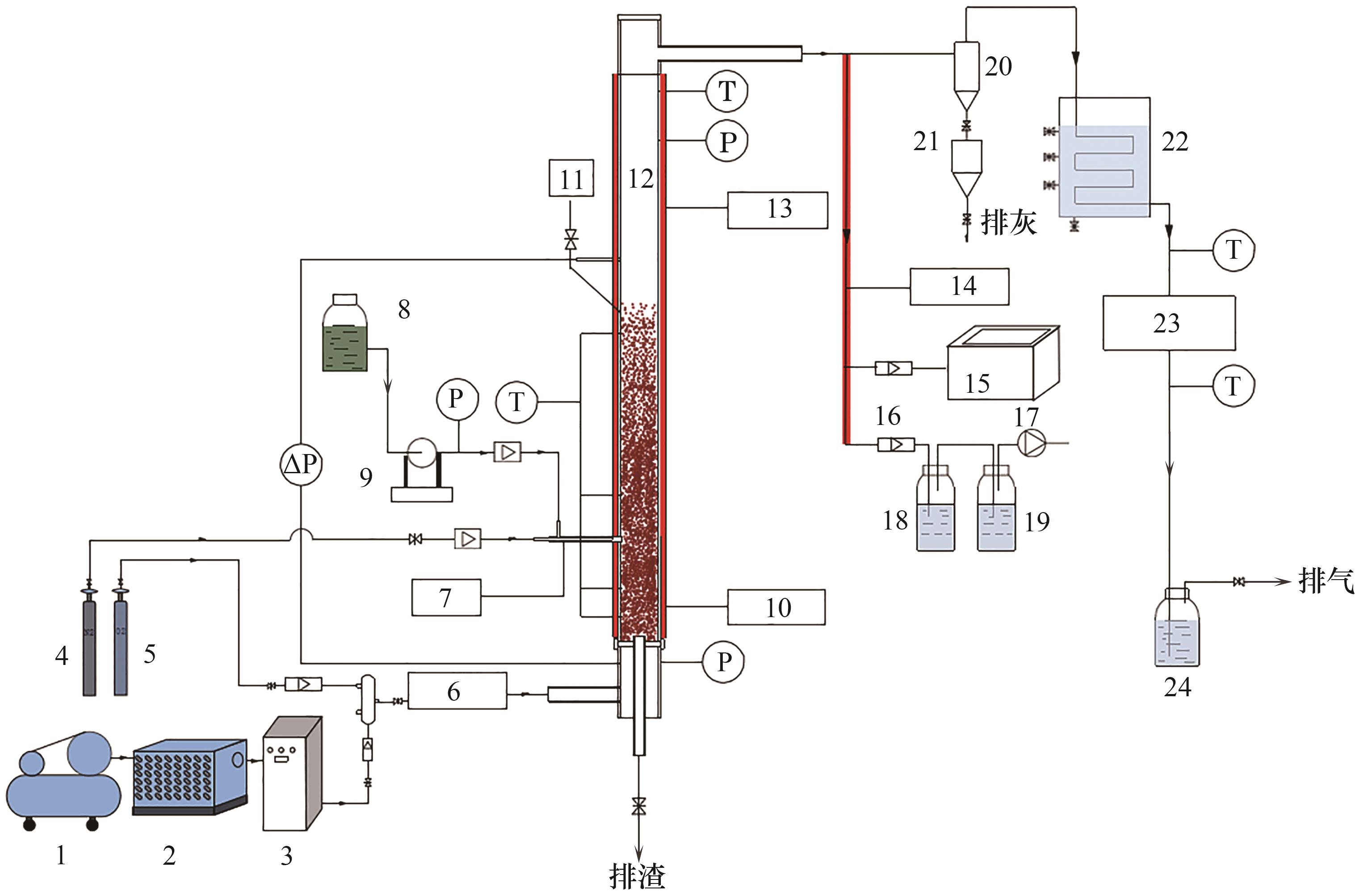

图1 废混酸流化床焙烧法再生实验系统示意图1—空气压缩机;2—冷干机;3—制氮机;4—氮气钢瓶;5—氧气钢瓶;6—预热器;7—喷枪;8—废混酸罐;9—电磁泵;10—密相区电加热器;11—料罐;12—流化床反应炉;13—稀相区电加热器;14—电加热带;15—烟气分析仪;16—流量计;17—真空泵;18—去离子水;19—NaOH溶液;20—旋风分离器;21—灰斗;22—冷却器;23—布袋除尘器;24—碱洗装置

Fig.1 Schematic diagram of the experimental system for regeneration of waste mixed acid by fluidized bed method1—air compressor;2—cold dryer;3—nitrogen generator;4—nitrogen cylinder;5—oxygen cylinder;6—preheater;7—spray gun;8—waste mixed acid tank;9—electromagnetic pump;10—electric heater in the dense phase zone;11—canister;12—fluidized bed reactor;13—electric heaters in the thin phase zone;14—electric heating belt;15—flue gas analyser;16—flow meter;17—vacuum pump;18—deionised water;19—NaOH solution;20—cyclone separator;21—grey bucket;22—cooler;23—bag filter;24—alkaline washing unit

| 化学组成/(g/L) | 密度/ (g/ml) | pH | |||||||

|---|---|---|---|---|---|---|---|---|---|

| F- | NO | H+ | Cr | Ni | Fe | Mn | Ca | ||

| 28.8 | 55.5 | 2.66 | 4.13 | 3.26 | 50.75 | 0.78 | 0.0436 | 1.1141 | 0.68 |

表1 废混酸理化特性和成分分析

Table 1 Physicochemical characteristics and composition analysis of waste mixed acid

| 化学组成/(g/L) | 密度/ (g/ml) | pH | |||||||

|---|---|---|---|---|---|---|---|---|---|

| F- | NO | H+ | Cr | Ni | Fe | Mn | Ca | ||

| 28.8 | 55.5 | 2.66 | 4.13 | 3.26 | 50.75 | 0.78 | 0.0436 | 1.1141 | 0.68 |

| 样品 | 元素分析/%(质量) | |||||||

|---|---|---|---|---|---|---|---|---|

| Fe | Al | Cu | Ni | Ca | Zn | Cr | Mn | |

| 床料 | 92.61 | 3.59 | 1.06 | 0.71 | 0.59 | 0.50 | 0.47 | 0.47 |

表2 氧化铁床料元素分析

Table 2 Elemental analysis of iron oxide bed material

| 样品 | 元素分析/%(质量) | |||||||

|---|---|---|---|---|---|---|---|---|

| Fe | Al | Cu | Ni | Ca | Zn | Cr | Mn | |

| 床料 | 92.61 | 3.59 | 1.06 | 0.71 | 0.59 | 0.50 | 0.47 | 0.47 |

| 1 | 程玲俐. 不锈钢冷带退火酸洗的工艺及设备的研究[D]. 上海: 上海交通大学, 2008. |

| Cheng L L. Study on process and equipment of annealing and pickling for cold-rolled stainless strip[D]. Shanghai: Shanghai Jiao Tong University, 2008. | |

| 2 | 刘鹏. 基于生命周期评价的废盐酸再生工艺比较研究[D]. 大连: 大连理工大学, 2015. |

| Liu P. Comparison of waste hydrochloric acid regeneration technologies based on LCA[D]. Dalian: Dalian University of Technology, 2015. | |

| 3 | 代秀芝. 不锈钢酸洗废混酸回收工艺[J]. 冶金设备, 2013(S1):69-71. |

| Dai X Z. Technology of waste mixed acid recovery in stainless steel pickling[J]. Metallurgical Equipment, 2013(S1): 69-71. | |

| 4 | 朱冰. 不锈钢酸洗废水中金属离子的资源化分离回收工艺研究[D]. 重庆: 重庆大学, 2018. |

| Zhu B. Recycling and recovery of metal ions from spent steel pickling wastewater[D]. Chongqing: Chongqing University, 2018. | |

| 5 | 曹明义, 何国凯, 刘万涛. 钢铁酸洗废水资源化处理技术综述[J]. 冶金动力, 2020, 39(10): 55-56, 71. |

| Cao M Y, He G K, Liu W T. Review on resource treatment technology of steel pickling wastewater[J]. Metallurgical Power, 2020, 39(10): 55-56, 71. | |

| 6 | 于丹. 盐酸废液流化床法再生工艺的应用[J]. 天津冶金, 2014(S1):141-144. |

| Yu D. Application of the process of hydrochloric acid regeneration with fluidized bed method[J]. Tianjin Metallurgy, 2014(S1): 141-144. | |

| 7 | Negro C, Blanco M A, López-Mateos F, et al. Free acids and chemicals recovery from stainless steel pickling baths[J]. Separation Science and Technology, 2001, 36(7): 1543-1556. |

| 8 | 别如山, 李炳熙, 陆慧林, 等. 处理高浓度有机废水流化床焚烧炉[J]. 锅炉制造, 2000(1): 40-44. |

| Bie R S, Li B X, Lu H L,et al. CFB boiler for handling high consistency organic waste water[J]. Boiler Manufacturing, 2000(1):40-44. | |

| 9 | 王超. 不锈钢酸洗废酸回收[J]. 天津冶金, 2016(1): 56-59. |

| Wang C. Recovery of waste acid for stainless steel pickling[J]. Tianjin Metallurgy, 2016(1): 56-59. | |

| 10 | 王贵喜, 任艳平, 何宗健. 不锈钢酸洗混合废酸(HNO3-HF)的回收以及离子交换法在其纯化中的应用[J]. 江西化工, 2010(1):138-141. |

| Wang G X, Ren Y P, He Z J. Recovery of stainless steel pickling mixed waste acid (HNO3-HF) and the application of ion exchange in its purification[J]. Jiangxi Chemical Industry, 2010(1): 138-141. | |

| 11 | 高健. 探讨离子交换树脂在水处理中的应用[J]. 皮革制作与环保科技, 2022, 3(2): 10-12. |

| Gao J. Discuss the application of ion exchange resin in water treatment[J]. Leather Manufacture and Environmental Technology, 2022, 3(2): 10-12. | |

| 12 | 李菲, 赵俊学, 马红周, 等. 用强酸性阳离子交换树脂从不锈钢酸洗废水中富集铬[J]. 湿法冶金, 2011, 30(1): 71-73. |

| Li F, Zhao J X, Ma H Z, et al. Enrichment of chromium from stainless steel pickling wastewater by strong acidic cation ion-exchange resin[J]. Hydrometallurgy of China, 2011, 30(1): 71-73. | |

| 13 | 李菲, 赵俊学, 马红周, 等. 用强酸性阳离子交换树脂分离不锈钢酸洗废水中的铁[J]. 湿法冶金, 2011, 30(2): 155-158. |

| Li F, Zhao J X, Ma H Z, et al. Separation of iron from stainless steel pickling wastewater by strong acidic cation ion-exchange resin[J]. Hydrometallurgy of China, 2011, 30(2): 155-158. | |

| 14 | 李小明, 李文锋, 王尚杰, 等. 不锈钢酸洗废液的处理与回收技术综述[J]. 化工环保, 2012, 32(6): 511-515. |

| Li X M, Li W F, Wang S J, et al. Review of treatment and recovery technologies of waste stainless steel pickling liquor[J]. Environmental Protection of Chemical Industry, 2012, 32(6): 511-515. | |

| 15 | 曾彬. 不锈钢蚀刻废液的综合回收利用[J]. 低碳世界, 2021, 11(3): 6-7. |

| Zeng B. Comprehensive recycling of stainless steel etching waste liquor[J]. Low Carbon World, 2021, 11(3): 6-7. | |

| 16 | 赫红超. 钢铁酸洗废液处理技术研究[D]. 上海: 上海应用技术大学, 2021. |

| He H C.Study on treatment technology of steel pickling waste liquid [D]. Shanghai: Shanghai Institute of Technology, 2021. | |

| 17 | 戴丽萍,朱汉权,柯雄,等. 双极膜电渗析法去除水溶液中Cr(Ⅵ)[J]. 环境工程, 2021, 39(11): 89-95. |

| Dai L P, Zhu H Q, Ke X,et al. Removal of hexavalent chromium from aqueous solution using bipolar membrane electrodialysis technique[J].Environmental Engineering, 2021, 39(11): 89-95. | |

| 18 | 朱桂平, 郭合理, 周兵. 流化床法废盐酸再生技术在钢丝绳行业的应用[J]. 金属制品, 2013, 39(4): 47-50. |

| Zhu G P, Guo H L, Zhou B. Application of fluidized bed waste hydrochloric acid regeneration technology in wire rope industry[J]. Metal Products, 2013, 39(4): 47-50. | |

| 19 | Nandy T, Vyas R D, Kaul S N, et al. Recovery of value-added chemicals from hazardous waste pickle liquor through application of full-scale fluidized bed reactor system[J]. Environmental Engineering Science, 2001, 18(6): 329-336. |

| 20 | Regel-Rosocka M. A review on methods of regeneration of spent pickling solutions from steel processing[J]. Journal of Hazardous Materials, 2010, 177(1/2/3): 57-69. |

| 21 | 徐向东, 蔡恒君, 杨伟. 鞍钢联众不锈钢混酸再生技术改进[J]. 鞍钢技术, 2017(6): 58-61. |

| Xu X D, Cai H J, Yang W. Improvement of recycling technology for waste mixed acid produced by manufacturing stainless steel in ansteel LISCO steel[J]. Angang Technology, 2017(6): 58-61. | |

| 22 | Melnikov P, Nascimento V A, Arkhangelsky I V, et al. Thermolysis mechanism of chromium nitrate nonahydrate and computerized modeling of intermediate products[J]. Journal of Thermal Analysis and Calorimetry, 2013, 114(3): 1021-1027. |

| 23 | Yuvaraj S, Lin F Y, Tsong-Huei C, et al. Thermal decomposition of metal nitrates in air and hydrogen environments[J]. The Journal of Physical Chemistry B, 2003, 107(4): 1044-1047. |

| 24 | Ge Y, Fan L S. Droplet-particle collision mechanics with film-boiling evaporation[J]. Journal of Fluid Mechanics, 2007, 573: 311-337. |

| 25 | Hatta N, Fujimoto H, Kinoshita K, et al. Experimental study of deformation mechanism of a water droplet impinging on hot metallic surfaces above the leidenfrost temperature[J]. Journal of Fluids Engineering, 1997, 119(3): 692-699. |

| 26 | Christoph L K, Schlünder E U. Fluidized bed spray granulation: investigation of the coating process on a single sphere[J]. Chemical Engineering and Processing: Process Intensification, 1997, 36(6): 443-457. |

| 27 | 段然. 大颗粒流化床水泥熟料煅烧工艺热模试验研究[D]. 西安: 西安建筑科技大学, 2008. |

| Duan R. An investigation into the calcination of cement clinker by coarse particles fluidization-thermo dynamics of the calcination process[D]. Xi'an: Xi'an University of Architecture and Technology, 2008. | |

| 28 | 齐庆杰, 刘建忠, 曹欣玉, 等. 燃煤过程中CaO对氟析出的固定作用[J]. 燃料化学学报, 2002, 30(3): 204-208. |

| Qi Q J, Liu J Z, Cao X Y, et al. Restraining of fluoride emission by blending CaO or lime with coal during coal combustion[J]. Journal of Fuel Chemistry and Technology, 2002, 30(3): 204-208. | |

| 29 | 齐庆杰, 刘建忠, 周俊虎, 等. 燃煤过程中CaO及钙基固氟剂对氟析出的控制[J]. 化工学报, 2003, 54(2): 226-231. |

| Qi Q J, Liu J Z, Zhou J H, et al.Fluoride emission control by blending and injecting CaO and calcium-based sorbents during coal combustion[J]. Journal of Chemical Industry and Engineering (China), 2003, 54(2): 226-231. | |

| 30 | Li W H, Ma Z Y, Yan J H, et al. Evolution and distribution characteristics of fluorine during the incineration of fluorine-containing waste in a hazardous waste incinerator[J]. Journal of Zhejiang University-SCIENCE A, 2019, 20(8): 564-576. |

| 31 | 李文瀚. 危险废物焚烧过程中重金属与氟的迁移转化及污染控制机理研究[D]. 杭州: 浙江大学, 2020. |

| Li W H. Mechanism study on the transfer and pollution control of heavy metals and fluorine in the incineration of hazardous wastes[D]. Hangzhou: Zhejiang University, 2020. | |

| 32 | 高强. MgO和Al2O3基固氟剂的制备及NF3分解反应[D]. 烟台: 烟台大学, 2021. |

| Gao Q. The preparation of MgO- and Al2O3-based fluorine-fixed reagents for NF3 decomposition[D]. Yantai: Yantai University, 2021. | |

| 33 | 李舒伶, 齐庆杰, 刘建忠, 等. 煤燃烧固氟剂及固氟效果研究[J]. 环境科学, 2004, 25(2): 174-176. |

| Li S L, Qi Q J, Liu J Z, et al. Study on the calcium-based sorbent for removal fluorine during coal combustion[J]. Environmental Science, 2004, 25(2): 174-176. | |

| 34 | 刘建忠, 齐庆杰, 盛军杰, 等. 燃煤高温固氟工艺和添加剂的实验研究[J]. 中国电机工程学报, 2004, 24(7): 227-230. |

| Liu J Z, Qi Q J, Sheng J J, et al. Experimental study on fluorine retention process and additive under high temperation during coal combustion[J]. Proceedings of the CSEE, 2004, 24(7): 227-230. | |

| 35 | 刘静, 向轶, 刘建忠. 有机钙燃煤固氟剂的固氟效果和表面形态研究[J]. 热力发电, 2020, 49(2): 65-70. |

| Liu J, Xiang Y, Liu J Z. Study on fluorine removal efficiency and surface morphology of organic calcium fluorine removal additive for coal combustion[J]. Thermal Power Generation, 2020, 49(2): 65-70. |

| [1] | 车睿敏, 郑文秋, 王小宇, 李鑫, 许凤. 基于离子液体的纤维素均相加工研究进展[J]. 化工学报, 2023, 74(9): 3615-3627. |

| [2] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [3] | 杨峥豪, 何臻, 常玉龙, 靳紫恒, 江霞. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| [4] | 陈巨辉, 张谦, 舒崚峰, 李丹, 徐鑫, 刘晓刚, 赵晨希, 曹希峰. 基于DEM方法的旋转流化床纳米颗粒流动特性研究[J]. 化工学报, 2023, 74(6): 2374-2381. |

| [5] | 张媛媛, 曲江源, 苏欣欣, 杨静, 张锴. 循环流化床燃煤机组SNCR脱硝过程气液传质和反应特性[J]. 化工学报, 2023, 74(6): 2404-2415. |

| [6] | 卫雪岩, 钱勇. 微米级铁粉燃料中低温氧化反应特性及其动力学研究[J]. 化工学报, 2023, 74(6): 2624-2638. |

| [7] | 袁子涵, 王淑彦, 邵宝力, 谢磊, 陈曦, 马一玫. 基于幂律液固曳力模型流化床内湿颗粒流动特性的研究[J]. 化工学报, 2023, 74(5): 2000-2012. |

| [8] | 潘煜, 王子航, 王佳韵, 王如竹, 张华. 基于可得然-氯化锂复合吸附剂的除湿换热器热湿性能研究[J]. 化工学报, 2023, 74(3): 1352-1359. |

| [9] | 陈瑞哲, 程磊磊, 顾菁, 袁浩然, 陈勇. 纤维增强树脂复合材料化学回收技术研究进展[J]. 化工学报, 2023, 74(3): 981-994. |

| [10] | 黄宽, 马永德, 蔡镇平, 曹彦宁, 江莉龙. 油脂催化加氢转化制备第二代生物柴油研究进展[J]. 化工学报, 2023, 74(1): 380-396. |

| [11] | 鲁文静, 李先锋. 液流电池多孔离子传导膜研究进展[J]. 化工学报, 2023, 74(1): 192-204. |

| [12] | 朱莲峰, 王超, 张梦娟, 刘方正, 贾鑫, 安萍, 许光文, 韩振南. 水蒸气/氧流化床两段煤气化制备低焦油合成气工艺实验[J]. 化工学报, 2022, 73(8): 3720-3730. |

| [13] | 张东旺, 杨海瑞, 周托, 黄中, 李诗媛, 张缦. 生物质锅炉对流受热面积灰冷态模拟实验研究[J]. 化工学报, 2022, 73(8): 3731-3738. |

| [14] | 刘新华, 韩振南, 韩健, 梁斌, 张楠, 胡善伟, 白丁荣, 许光文. 基于热解与燃烧反应重构的低NO x 解耦燃烧原理与技术[J]. 化工学报, 2022, 73(8): 3355-3368. |

| [15] | 王刚, 夏志豪, 李希艳, 张虹, 韩振南, 宋兴飞, 许光文. 不同气氛下流化床菱镁矿轻烧产物特性研究[J]. 化工学报, 2022, 73(8): 3699-3707. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号