化工学报 ›› 2022, Vol. 73 ›› Issue (7): 2902-2911.DOI: 10.11949/0438-1157.20220320

解文潇1( ),贾胜坤1,2(

),贾胜坤1,2( ),张会书1,2,罗祎青1,2,袁希钢1,2,3(

),张会书1,2,罗祎青1,2,袁希钢1,2,3( )

)

收稿日期:2022-03-02

修回日期:2022-05-13

出版日期:2022-07-05

发布日期:2022-08-01

通讯作者:

贾胜坤,袁希钢

作者简介:解文潇(1997—),男,硕士研究生,基金资助:

Wenxiao XIE1( ),Shengkun JIA1,2(

),Shengkun JIA1,2( ),Huishu ZHANG1,2,Yiqing LUO1,2,Xigang YUAN1,2,3(

),Huishu ZHANG1,2,Yiqing LUO1,2,Xigang YUAN1,2,3( )

)

Received:2022-03-02

Revised:2022-05-13

Online:2022-07-05

Published:2022-08-01

Contact:

Shengkun JIA,Xigang YUAN

摘要:

采用紫外诱导荧光(UIF)实验方法,研究Hele-Shaw狭缝受限尺度对受限空间内浮升气泡流体力学与气液传质行为的影响。实验中以二苯并[b,e]吡啶作为荧光剂实现了受限空间内CO2溶液浓度分布及其气泡运动速度的定量测量,获得了CO2在受限空间内运动过程中的传质量和气泡动力学参数,并分别计算气泡受限空间内液膜区和自由接触区的传质速率。分析得到受限空间中不同狭缝宽度内CO2的传质行为,分析了受限尺度对CO2-水体系传质过程的影响。

中图分类号:

解文潇, 贾胜坤, 张会书, 罗祎青, 袁希钢. 受限空间内浮升气泡与液体间传质行为实验研究[J]. 化工学报, 2022, 73(7): 2902-2911.

Wenxiao XIE, Shengkun JIA, Huishu ZHANG, Yiqing LUO, Xigang YUAN. Investigation on mass transfer behavior between floating bubbles and liquid in confined space[J]. CIESC Journal, 2022, 73(7): 2902-2911.

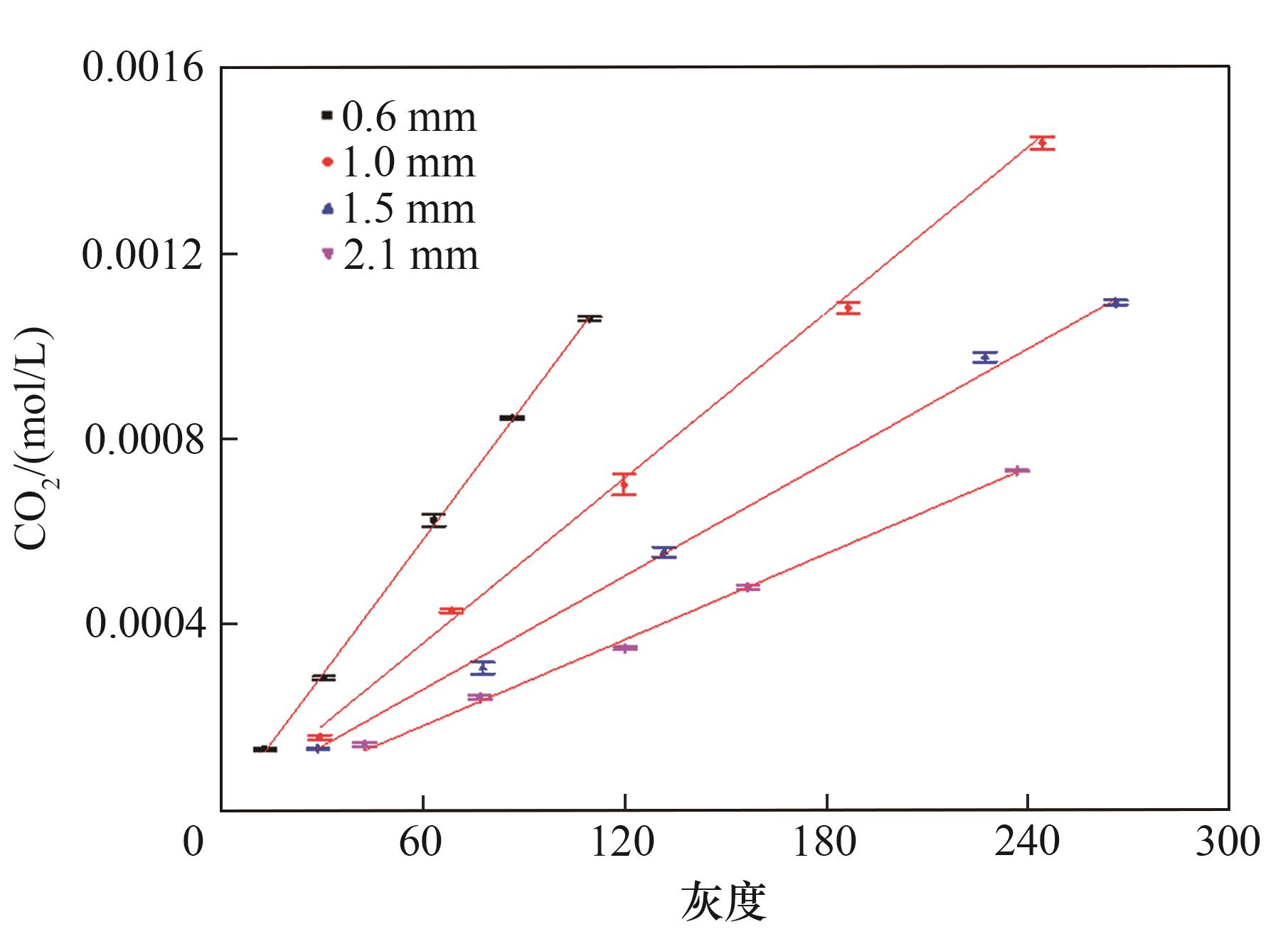

图2 不同狭缝宽度内溶液灰度值与CO2浓度标定曲线

Fig.2 Calibration curves between gray level and dissolved CO2 concentration in standard samples in thin gap with different gap widths

图6 不同狭缝宽度下受限空间内气泡平均浮升终速(a)受限空间内气泡平均浮升终速随de的变化及其与非受限空间浮升速度的比较;(b) de为4 mm气泡质心轨迹的4次测量结果

Fig.6 Average final velocity of bubble buoyancy in confined space under different slit widths(a) variation of average final buoyancy velocity of bubbles in confined space with de and its comparison with that in unrestricted space; (b) four measurement results of bubble centroid trajectory when de is 4 mm

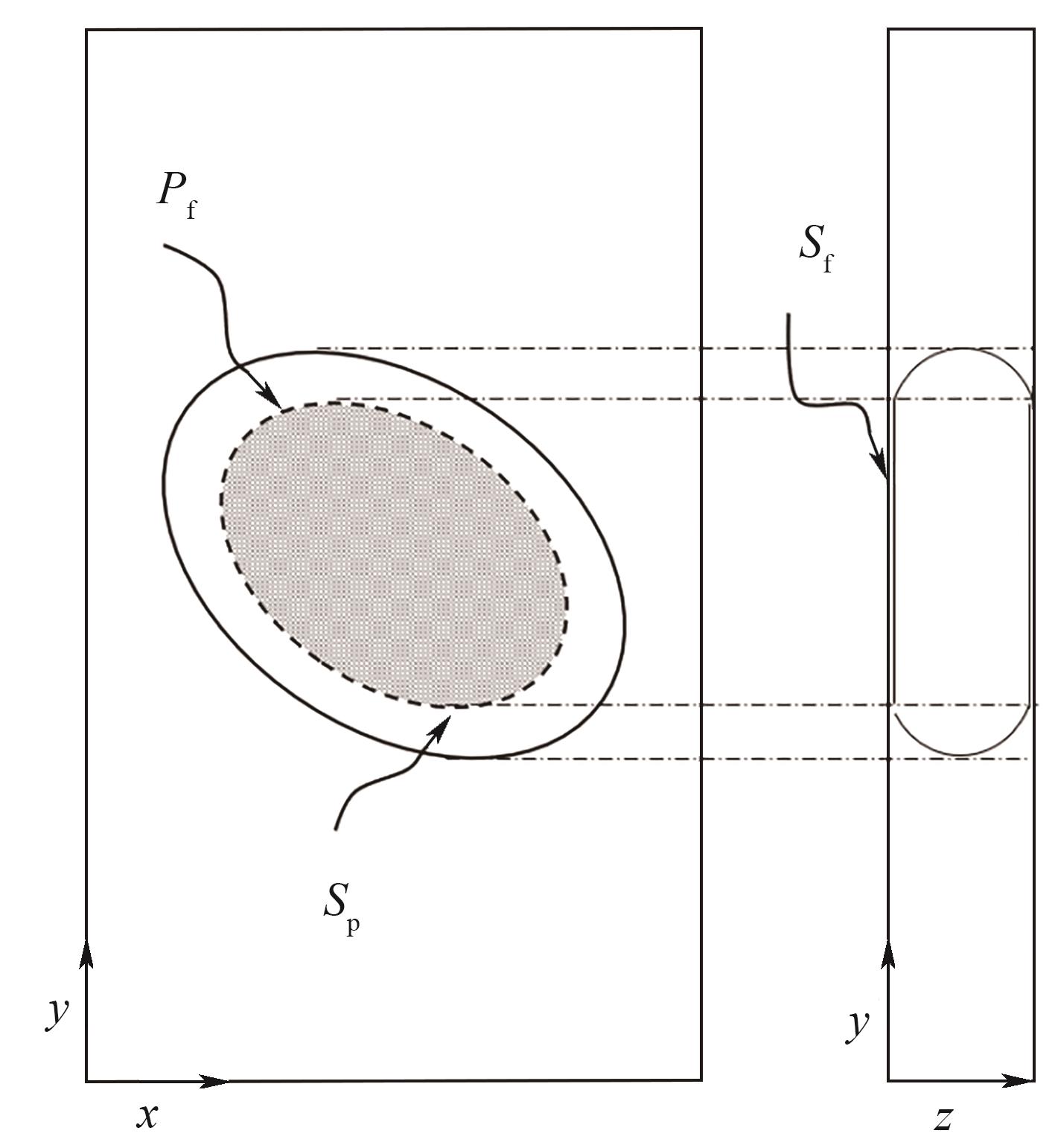

图7 受限空间内液体与浮升气泡传质示意图 (Pf:气泡内轮廓周长;Sp:自由界面区面积;Sf:液膜区面积)

Fig.7 Schematic of mass transfer from a rising CO2 bubble to liquid confined in a gap (Pf:inner contour perimeter of bubble;Sp:free contact area;Sf:liquid film area)

图9 (a)不同受限空间内气液相间传质速率;(b)不同受限空间内气液相间液相侧传质系数

Fig.9 (a) Mass transfer rate from rising CO2 bubble to liquid confined in gaps with different widths; (b) Liquid-side mass transfer coefficient from rising CO2 bubble to liquid confined in gaps with different widths

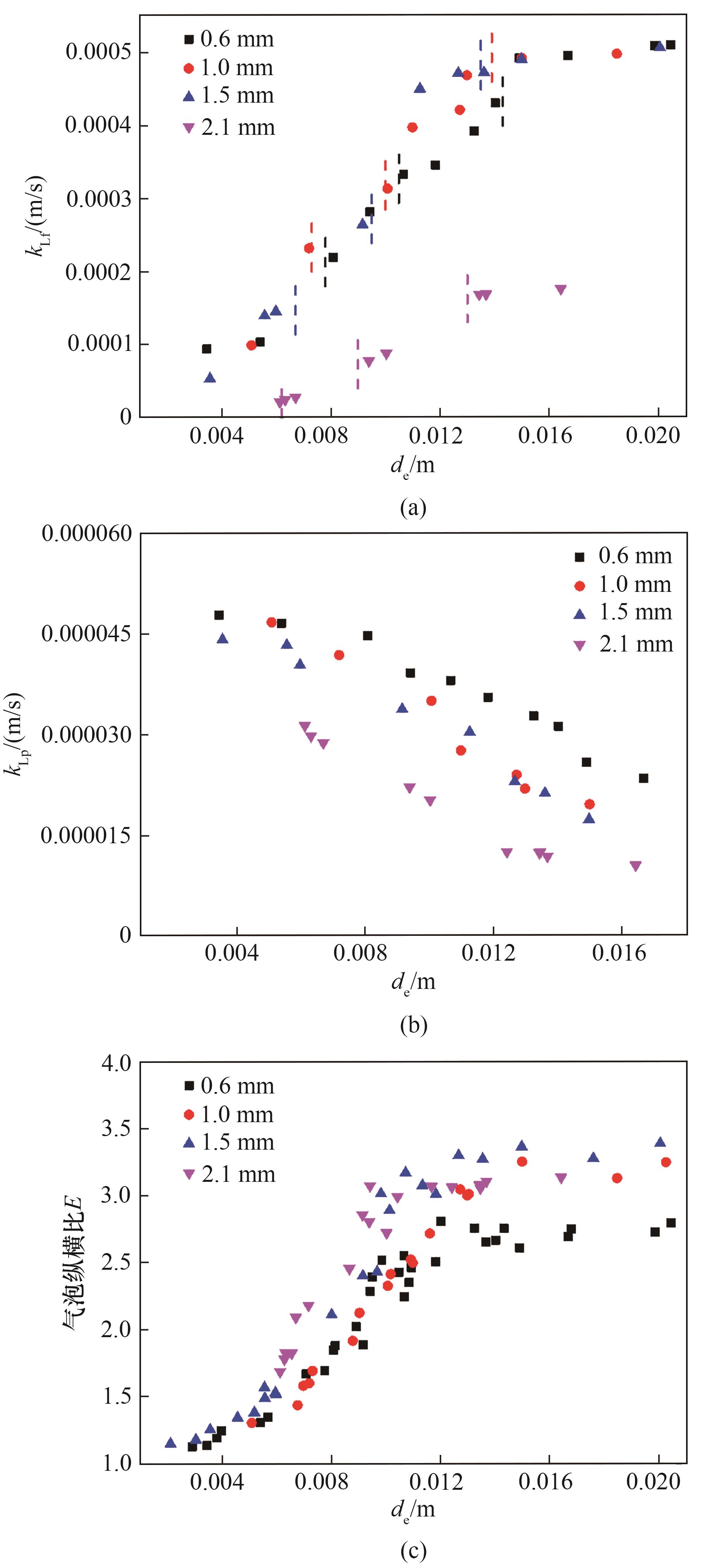

图10 受限空间内液膜区传质系数(a)、自由界面区传质系数(b)和气泡纵横比E(c)随投影面积当量直径变化关系

Fig.10 Mass transfer coefficient of liquid film zone (a), mass transfer coefficient of free interface region (b) and bubble aspect ratio E (c) varied with projected area equivalent diameter in confined space

| 系统类型 | a/(m2/m3) | ||

|---|---|---|---|

| 逆流填料塔[ | 4~20 | 10~350 | 0.04~7.00 |

| 鼓泡塔[ | 10~40 | 50~600 | 0.5~24.0 |

| 浸入式和插入式喷射反应堆[ | 1.5~5.0 | 20~50 | 0.03~0.60 |

| 喷雾柱[ | 12~19 | 75~170 | 1.5~2.2 |

| 微反应器[ | 40 | 3400 | 30 |

| 本研究 | 20~50 | 200~600 | 4~30 |

表1 受限空间与非受限空间内的气液传质系数对比

Table 1 Comparison of gas-liquid mass transfer coefficient between confined space and unrestricted space

| 系统类型 | a/(m2/m3) | ||

|---|---|---|---|

| 逆流填料塔[ | 4~20 | 10~350 | 0.04~7.00 |

| 鼓泡塔[ | 10~40 | 50~600 | 0.5~24.0 |

| 浸入式和插入式喷射反应堆[ | 1.5~5.0 | 20~50 | 0.03~0.60 |

| 喷雾柱[ | 12~19 | 75~170 | 1.5~2.2 |

| 微反应器[ | 40 | 3400 | 30 |

| 本研究 | 20~50 | 200~600 | 4~30 |

| 1 | Ahmed S, Phan A N, Harvey A P. Scale-up of gas-liquid mass transfer in oscillatory multiorifice baffled reactors (OMBRs)[J]. Industrial & Engineering Chemistry Research, 2019, 58(15): 5929-5935. |

| 2 | Zhang C, Yuan X G, Luo Y Q, et al. Prediction of species concentration distribution using a rigorous turbulent mass diffusivity model for bubble column reactor simulation (part Ⅰ): Application to chemisorption process of CO2 into NaOH solution[J]. Chemical Engineering Science, 2018, 184: 161-171. |

| 3 | 傅强, 张会书, 胡楠, 等. 水溶解CO2过程界面对流现象的PIV/LIF测量及传质系数预测[J]. 化工学报, 2018, 69(2): 586-594. |

| Fu Q, Zhang H S, Hu N, et al. Simultaneous PIV/LIF measurements of interfacial convection during CO2 dissolution in water and prediction of mass transfer coefficient[J]. CIESC Journal, 2018, 69(2): 586-594. | |

| 4 | 李陆星, 胡楠, 袁希钢. 水吸收CO2过程界面对流的激光诱导荧光观测[J]. 化工学报, 2016, 67(10): 4055-4063. |

| Li L X, Hu N, Yuan X G. Measurement using laser induced fluorescence technique for interfacial convection during water-CO2 absorption process[J]. CIESC Journal, 2016, 67(10): 4055-4063. | |

| 5 | Vandu C O, Liu H, Krishna R. Mass transfer from Taylor bubbles rising in single capillaries[J]. Chemical Engineering Science, 2005, 60(22): 6430-6437. |

| 6 | Berčič G, Pintar A. The role of gas bubbles and liquid slug lengths on mass transport in the Taylor flow through capillaries[J]. Chemical Engineering Science, 1997, 52(21/22): 3709-3719. |

| 7 | Yue J, Chen G W, Yuan Q, et al. Hydrodynamics and mass transfer characteristics in gas-liquid flow through a rectangular microchannel[J]. Chemical Engineering Science, 2007, 62(7): 2096-2108. |

| 8 | Kashid M N, Renken A, Kiwi-Minsker L. Gas-liquid and liquid-liquid mass transfer in microstructured reactors[J]. Chemical Engineering Science, 2011, 66(17): 3876-3897. |

| 9 | Biswas K G, Das G, Ray S, et al. Mass transfer characteristics of liquid-liquid flow in small diameter conduits[J]. Chemical Engineering Science, 2015, 122: 652-661. |

| 10 | Haase S, Murzin D Y, Salmi T. Review on hydrodynamics and mass transfer in minichannel wall reactors with gas-liquid Taylor flow[J]. Chemical Engineering Research and Design, 2016, 113: 304-329. |

| 11 | Kreutzer M T, Kapteijn F, Moulijn J A. Shouldn't catalysts shape up? Structured reactors in general and gas-liquid monolith reactors in particular[J]. Catalysis Today, 2006, 111(1/2): 111-118. |

| 12 | Wang X, Klaasen B, Degrève J, et al. Experimental and numerical study of buoyancy-driven single bubble dynamics in a vertical Hele-Shaw cell[J]. Physics of Fluids, 2014, 26(12): 123303. |

| 13 | Wang X, Klaasen B, Degrève J, et al. Volume-of-fluid simulations of bubble dynamics in a vertical Hele-Shaw cell[J]. Physics of Fluids, 2016, 28(5): 053304. |

| 14 | Roig V, Roudet M, Risso F, et al. Dynamics of a high-Reynolds-number bubble rising within a thin gap[J]. Journal of Fluid Mechanics, 2012, 707: 444-466. |

| 15 | Bouche E, Roig V, Risso F, et al. Homogeneous swarm of high-Reynolds-number bubbles rising within a thin gap (Part 2): Liquid dynamics[J]. Journal of Fluid Mechanics, 2014, 758: 508-521. |

| 16 | Pavlov L, D'Angelo M V, Cachile M, et al. Kinematics of a bubble freely rising in a thin-gap cell with additional in-plane confinement[J]. Physical Review Fluids, 2021, 6(9): 093605. |

| 17 | Filella A, Ern P, Roig V. Oscillatory motion and wake of a bubble rising in a thin-gap cell[J]. Journal of Fluid Mechanics, 2015, 778: 60-88. |

| 18 | Kherbeche A, Mei M, Thoraval M J, et al. Hydrodynamics and gas-liquid mass transfer around a confined sliding bubble[J]. Chemical Engineering Journal, 2020, 386: 121461. |

| 19 | Felis F, Strassl F, Laurini L, et al. Using a bio-inspired copper complex to investigate reactive mass transfer around an oxygen bubble rising freely in a thin-gap cell[J]. Chemical Engineering Science, 2019, 207: 1256-1269. |

| 20 | Roudet M, Billet A M, Cazin S, et al. Experimental investigation of interfacial mass transfer mechanisms for a confined high-Reynolds-number bubble rising in a thin gap[J]. AIChE Journal, 2017, 63(6): 2394-2408. |

| 21 | 张璠玢, 朱春英, 付涛涛, 等. 微通道内离子液体/乙醇混合溶液吸收CO2的传质特性[J]. 化工学报, 2017, 68(2): 601-611. |

| Zhang F B, Zhu C Y, Fu T T, et al. Mass transfer performance of CO2 absorption into ionic liquid/ethanol mixture in microchannel[J]. CIESC Journal, 2017, 68(2): 601-611. | |

| 22 | 马昱刚, 宋绍富. 微通道反应器内CO2传质反应行为研究[J]. 化学工程, 2020, 48(1): 60-63, 73. |

| Ma Y G, Song S F. Study on mass transfer reaction behavior of CO2 inmicrochannel reactor[J]. Chemical Engineering (China), 2020, 48(1): 60-63, 73. | |

| 23 | Calderbank P H, Lochiel A C. Mass transfer coefficients, velocities and shapes of carbon dioxide bubbles in free rise through distilled water[J]. Chemical Engineering Science, 1964, 19(7): 485-503. |

| 24 | Zhang Z, Zhang H S, Yuan X G, et al. Effective UV-induced fluorescence method for investigating interphase mass transfer of single bubble rising in the Hele-Shaw cell[J]. Industrial & Engineering Chemistry Research, 2020, 59(14): 6729-6740. |

| 25 | Zhang Z, Fu Q, Zhang H S, et al. Experimental and numerical investigation on interfacial mass transfer mechanism for Rayleigh convection in Hele-Shaw cell[J]. Industrial & Engineering Chemistry Research, 2020, 59(21): 10195-10209. |

| 26 | Kong G, Buist K A, Peters E A J F, et al. Dual emission LIF technique for pH and concentration field measurement around a rising bubble[J]. Experimental Thermal and Fluid Science, 2018, 93: 186-194. |

| 27 | Ryan E T, Xiang T, Johnston K P, et al. Absorption and fluorescence studies of acridine in subcritical and supercritical water[J]. The Journal of Physical Chemistry A, 1997, 101(10): 1827-1835. |

| 28 | Bowen E J, Holder N J, Woodger G B. Hydrogen bonding of excited states[J]. The Journal of Physical Chemistry, 1962, 66(12): 2491-2492. |

| 29 | Johnson A I, Besik F, Hamielec A E. Mass transfer from a single rising bubble[J]. The Canadian Journal of Chemical Engineering, 1969, 47(6): 559-564. |

| 30 | Martín M, Montes F J, Galán M A. Mass transfer from oscillating bubbles in bubble column reactors[J]. Chemical Engineering Journal, 2009, 151(1/2/3): 79-88. |

| 31 | Charpentier J C. Mass-transfer rates in gas-liquid absorbers and reactors[M]//Advances in Chemical Engineering: Volume 11. Amsterdam: Elsevier, 1981: 1-133. |

| 32 | Timmermann J, Hoffmann M, Schlüter M. Influence of bubble bouncing on mass transfer and chemical reaction[J]. Chemical Engineering & Technology, 2016, 39(10): 1955-1962. |

| 33 | Kies F K, Benadda B, Otterbein M. Experimental study on mass transfer of a co-current gas-liquid contactor performing under high gas velocities[J]. Chemical Engineering and Processing: Process Intensification, 2004, 43(11): 1389-1395. |

| 34 | Karamanev D G. Equations for calculation of the terminal velocity and drag coefficient of solid spheres and gas bubbles[J]. Chemical Engineering Communications, 1996, 147(1): 75-84. |

| [1] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [2] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [3] | 张媛媛, 曲江源, 苏欣欣, 杨静, 张锴. 循环流化床燃煤机组SNCR脱硝过程气液传质和反应特性[J]. 化工学报, 2023, 74(6): 2404-2415. |

| [4] | 王皓, 唐思扬, 钟山, 梁斌. MEA吸收CO2富液解吸过程中固体颗粒表面的强化作用分析[J]. 化工学报, 2023, 74(4): 1539-1548. |

| [5] | 钱志广, 樊越, 王世学, 岳利可, 王金山, 朱禹. 吹扫条件对PEMFC阻抗弛豫现象和低温启动的影响[J]. 化工学报, 2023, 74(3): 1286-1293. |

| [6] | 何洋, 高森虎, 吴青云, 张明理, 龙涛, 牛佩, 高景辉, 孟颖琪. 析湿工况下平直开缝翅片传热传质特性的数值研究[J]. 化工学报, 2023, 74(3): 1073-1081. |

| [7] | 贾露凡, 王艺颖, 董钰漫, 李沁园, 谢鑫, 苑昊, 孟涛. 微流控双水相贴壁液滴流动强化酶促反应研究[J]. 化工学报, 2023, 74(3): 1239-1246. |

| [8] | 何万媛, 陈一宇, 朱春英, 付涛涛, 高习群, 马友光. 阵列凸起微通道内气液两相传质特性研究[J]. 化工学报, 2023, 74(2): 690-697. |

| [9] | 王煦清, 严圣林, 朱礼涛, 张希宝, 罗正鸿. 填料塔中有机胺吸收CO2气液传质的研究进展[J]. 化工学报, 2023, 74(1): 237-256. |

| [10] | 张浩, 王子悦, 程钰洁, 何晓辉, 纪红兵. 单原子催化剂规模化制备的研究进展[J]. 化工学报, 2023, 74(1): 276-289. |

| [11] | 刘振宇. 煤地下气化低效的化学反应工程根源:滞留层及通道中的传质与反应[J]. 化工学报, 2022, 73(8): 3299-3306. |

| [12] | 王凯玥, 马永丽, 李琛, 刘明言. 气液固微型流化床的气液传质系数[J]. 化工学报, 2022, 73(8): 3529-3540. |

| [13] | 王悦琳, 晁伟, 蓝晓程, 莫志朋, 佟淑环, 王铁峰. 合成气生物发酵法制乙醇的研究进展[J]. 化工学报, 2022, 73(8): 3448-3460. |

| [14] | 魏琳, 郭剑, 廖梓豪, Dafalla Ahmed Mohmed, 蒋方明. 空气流量对空冷燃料电池电堆性能的影响研究[J]. 化工学报, 2022, 73(7): 3222-3231. |

| [15] | 曹健, 叶南南, 蒋管聪, 覃瑶, 王士博, 朱家华, 陆小华. 基于微量热法对多孔碳与双氧水相互作用过程的传质阻力分析[J]. 化工学报, 2022, 73(6): 2543-2551. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号