化工学报 ›› 2022, Vol. 73 ›› Issue (8): 3529-3540.DOI: 10.11949/0438-1157.20220166

收稿日期:2022-02-07

修回日期:2022-07-22

出版日期:2022-08-05

发布日期:2022-09-06

通讯作者:

马永丽

作者简介:王凯玥(1997—),女,硕士研究生,wangky97@163.com

基金资助:

Kaiyue WANG1( ), Yongli MA1(

), Yongli MA1( ), Chen LI1, Mingyan LIU1,2

), Chen LI1, Mingyan LIU1,2

Received:2022-02-07

Revised:2022-07-22

Online:2022-08-05

Published:2022-09-06

Contact:

Yongli MA

摘要:

气液固微型流化床兼具微流控系统和宏观流化床的优点,具有潜在的工业应用价值,但是,其应用基础研究十分缺乏。采用床径为1.6、2.0、2.4 mm的微型流化床,平均粒径为160、190、220 μm的玻璃珠,以NaOH水溶液吸收CO2气体为气液传质研究物系,在三相流动研究的基础上,考察了表观气速、表观液速、床径、粒径等对三相微型流化床气液体积传质系数的影响。结果表明:给定其他条件,增加表观气速和表观液速,均使气液体积传质系数增大;表观气速主要改变气含率和气液相界面积,而表观液速主要改变液相传质系数;床径减小,气液相界面积和气液体积传质系数都有所增加;在气液两相微型鼓泡塔中加入固体颗粒,形成三相分散鼓泡流型,当其固含率在0.15~0.30范围内,可显著增强气液传质,其气液体积传质系数是气液微鼓泡塔的1.1~1.5倍;与宏观流化床相比,相同条件下微型床的相界面积为它的5~10倍,是微型流化床具有更大体积传质系数的主要影响因素。

中图分类号:

王凯玥, 马永丽, 李琛, 刘明言. 气液固微型流化床的气液传质系数[J]. 化工学报, 2022, 73(8): 3529-3540.

Kaiyue WANG, Yongli MA, Chen LI, Mingyan LIU. Gas-liquid mass transfer coefficients in the gas-liquid-solid micro-fluidized beds[J]. CIESC Journal, 2022, 73(8): 3529-3540.

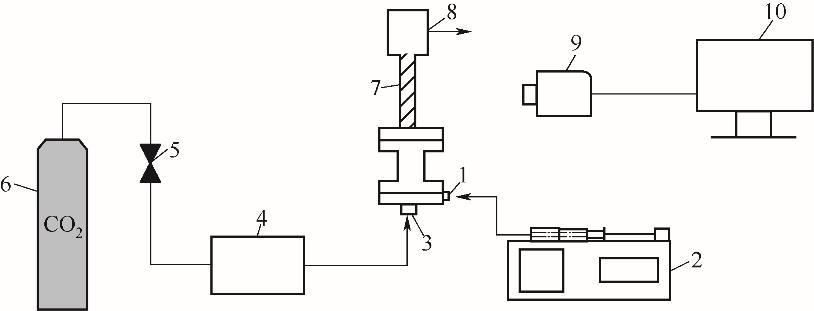

图1 气液固微型流化床传质实验装置及流程1—液体入口; 2—液体泵; 3—气体入口; 4—气体流量计; 5—进气阀; 6—气瓶; 7—微型流化床主体部分; 8—液体出口; 9—高速摄像机; 10—微型计算机

Fig.1 Experimental setup and flowchart of mass transfer in the gas-liquid-solid micro-fluidized bed

图3 气液固微型流化床中体积传质系数随表观气速的变化(dp=190 μm,T=25℃,D=2.0 mm, c(NaOH)=0.1 mol/L)

Fig.3 Variation of volumetric mass transfer coefficient with superficial gas velocity in gas-liquid-solid micro-fluidized bed

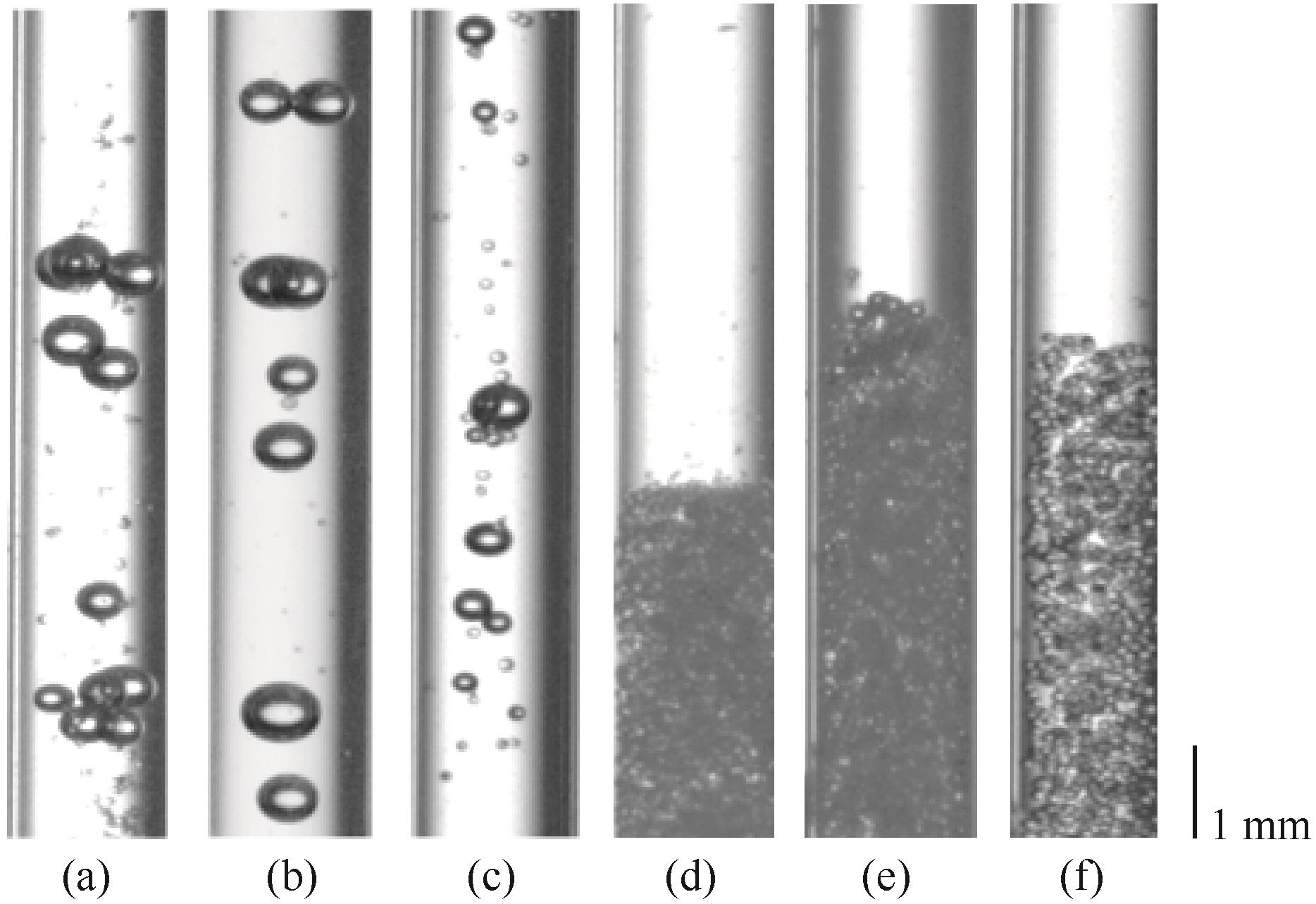

图4 不同表观气速下微型三相流化床内气泡流动状态(a) UG=2.370×10-3 m/s, UL=3.280×10-3 m/s, db=0.53 mm; (b) UG=4.560×10-3 m/s, UL=3.620×10-3 m/s, db=0.55 mm; (c) UG=6.720×10-3 m/s, UL=5.230×10-3 m/s, db=0.68 mm; (d) UG=7.580×10-3m/s, UL=4.870×10-3 m/s, db=0.71 mm

Fig.4 Flow patterns of gas bubbles in gas-liquid-solid micro-fluidized beds at different superficial gas velocities (D=2.0 mm, dp=190 μm)

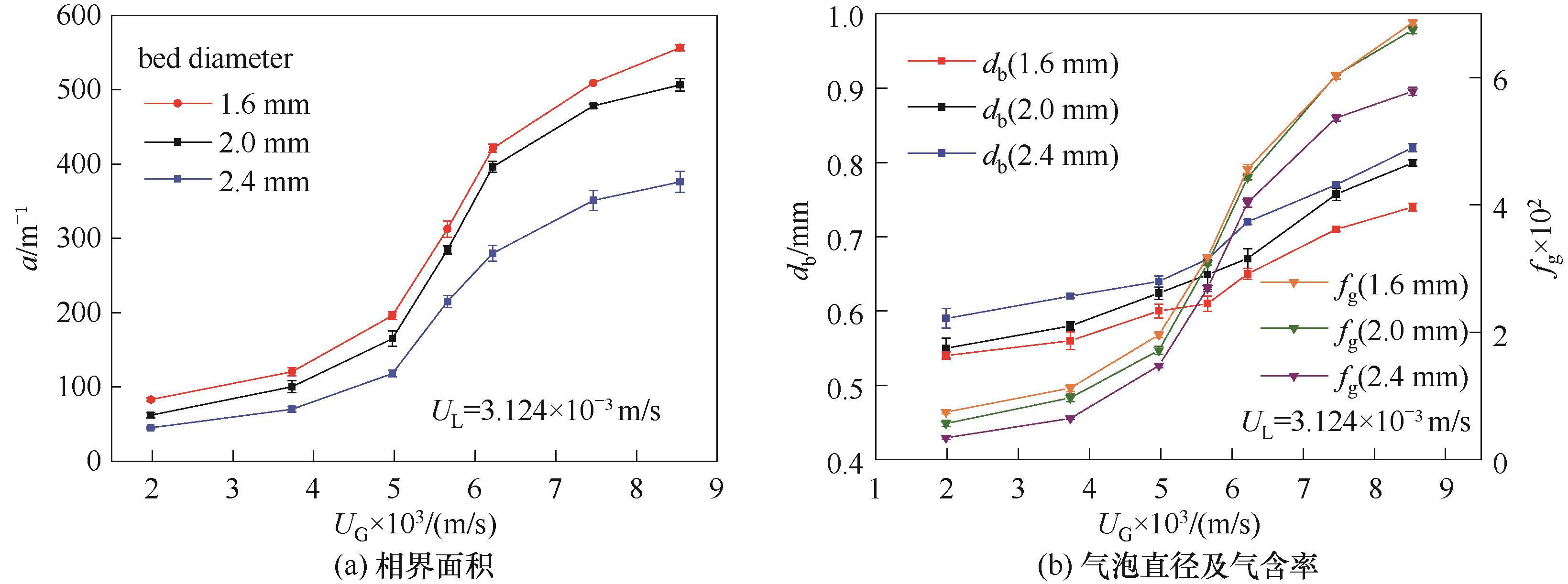

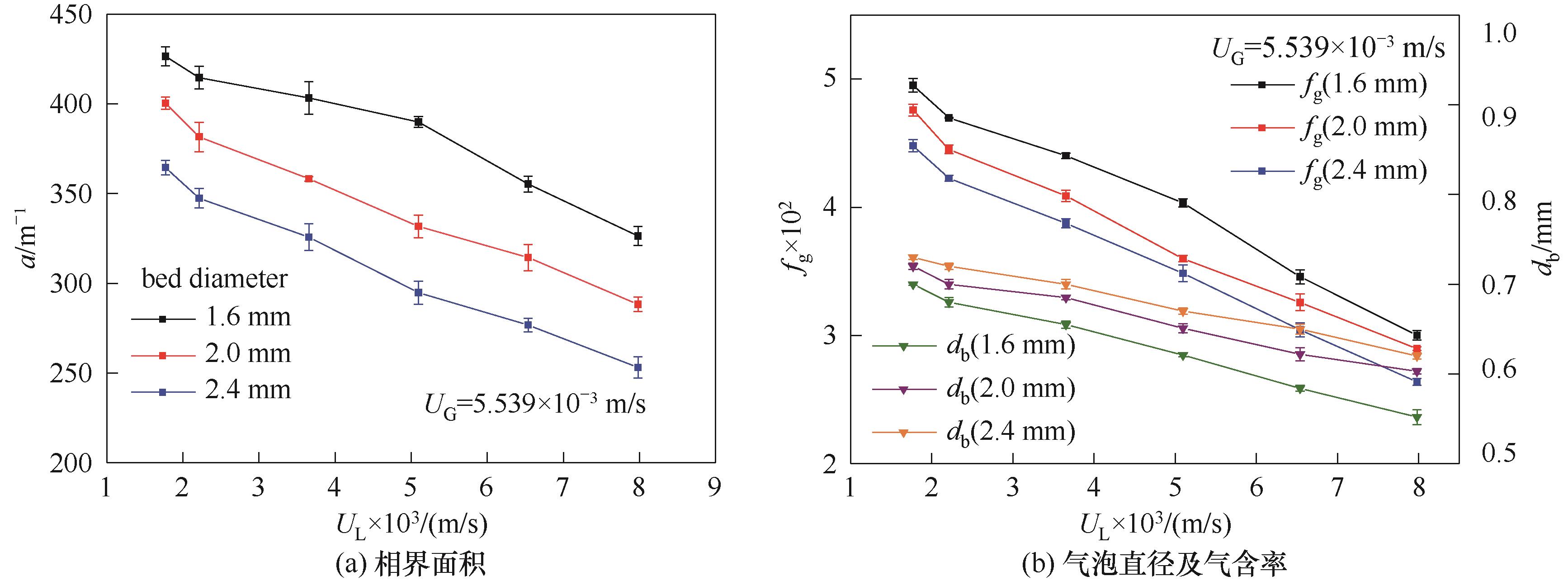

图5 气液固微型流化床中的气液相界面积、气泡直径和气含率随表观气速的变化(dp=190 μm,T=25℃,c(NaOH)=0.1 mol/L)

Fig.5 Changes of gas-liquid phase interface area, bubble diameter and gas holdup with superficial gas velocity in gas-liquid-solid micro-fluidized bed

图6 气液固微型流化床液相传质系数随表观气速的变化(dp=190 μm,T=25℃,c(NaOH)=0.1 mol/L)

Fig.6 Changes of liquid-phase mass transfer coefficient with superficial gas velocity in gas-liquid-solid micro-fluidized bed

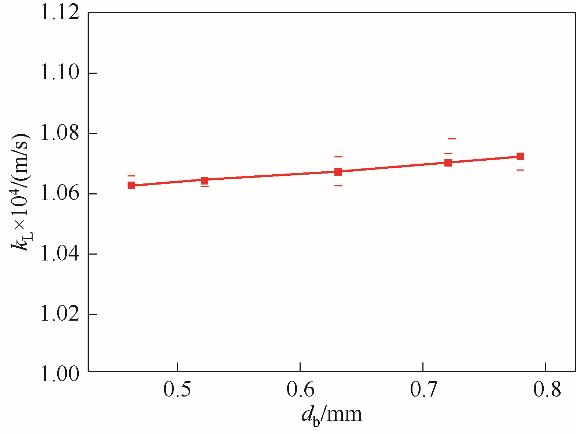

图7 气液固微型流化床液相传质系数随气泡直径的变化(UL=3.076×10-3 m/s,UG=4.587×10-3 m/s, D=2.0 mm,dp=190 μm,T=25℃,c(NaOH)=0.1 mol/L)

Fig.7 Changes of liquid-phase mass transfer coefficient with bubble diameter in gas-liquid-solid micro-fluidized bed

图8 气液固微型流化床中体积传质系数随表观液速的变化(dp=190 μm,T=25℃,c(NaOH)=0.1 mol/L)

Fig.8 Variation of volumetric mass transfer coefficient with superficial liquid velocity in gas-liquid-solid micro-fluidized bed

图9 不同表观液速下三相微型流化床内气泡流动状态(a) UG=5.240×10-3 m/s, UL=3.880×10-3 m/s, dp=190 μm, db=0.69 mm; (b) UG=5.180×10-3 m/s, UL=4.290×10-3 m/s, dp=190 μm, db=0.62 mm; (c) UG=5.760×10-3 m/s, UL=5.020×10-3 m/s, dp=190 μm, db=0.55 mm; (d) UL=4.290×10-3 m/s, dp=190 μm; (e) UL=5.020×10-3 m/s, dp=190 μm; (f) UL=4.290×10-3 m/s, dp=160 μm

Fig.9 Flow patterns of gas bubbles in gas-liquid-solid micro-fluidized beds at different superficial liquid velocities(D=2.0 mm)

图10 气液固微型流化床中的气液相界面积、气泡直径和气含率随表观液速的变化(dp=190 μm,T=25℃,c(NaOH)=0.1 mol/L)

Fig.10 Changes of phase interface area, bubble diameter and gas holdup with superficial liquid velocity in gas-liquid-solid micro-fluidized bed

图11 气液固微型流化床液相传质系数随表观液速的变化(dp=190 μm,T=25℃,c(NaOH)=0.1 mol/L)

Fig.11 Changes of liquid-phase mass transfer coefficient with superficial liquid velocity in gas-liquid-solid micro-fluidized bed

图12 气液固微型流化床体积传质系数随床径的变化(dp=190 μm,T=25℃,c(NaOH)=0.1 mol/L)

Fig.12 Changes of liquid-phase mass transfer coefficient with bed diameter in gas-liquid-solid micro-fluidized bed

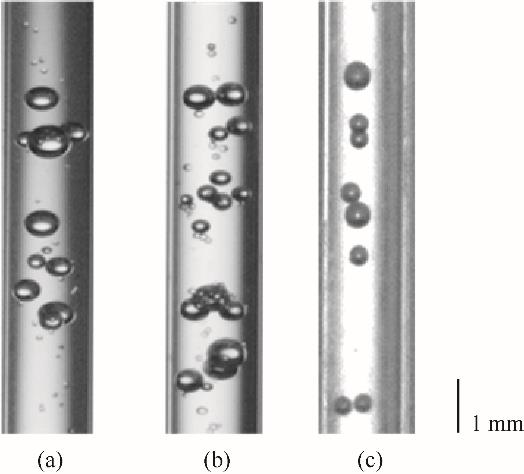

图13 不同床径下三相微型流化床内气泡流动状态(a) UG=5.670 m/s, UL=3.280×10-3 m/s, D=2.4 mm, db=0.64 mm; (b) UG=6.130 m/s, UL=4.250×10-3 m/s, D=2.0 mm, db=0.56 mm; (c) UG=5.280 m/s, UL=4.060×10-3 m/s, D=1.6 mm, db=0.52 mm

Fig.13 Flow patterns of gas bubbles in gas-liquid-solid micro-fluidized beds at different bed sizes(dp=190 μm)

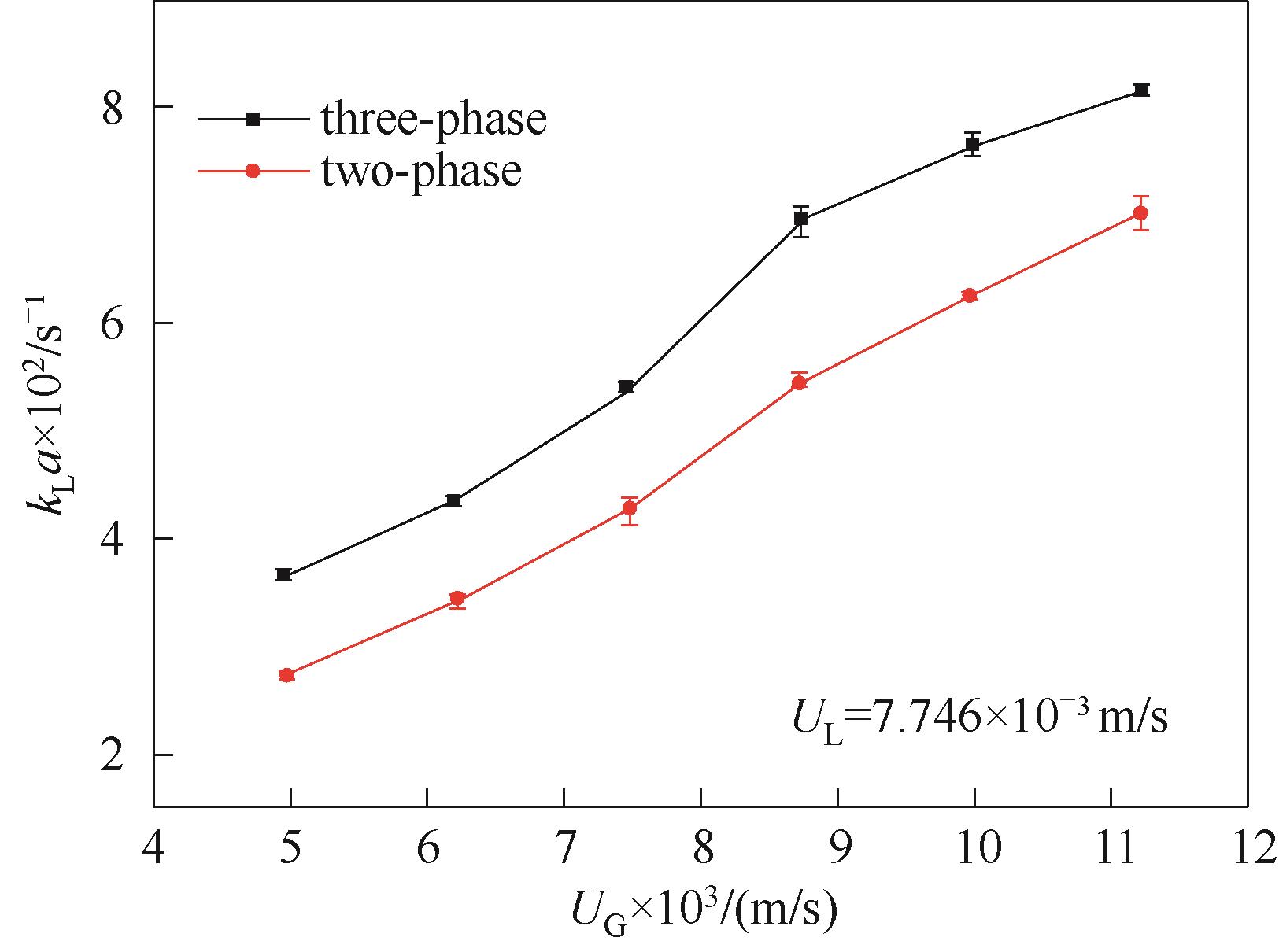

图14 气液微鼓泡塔与三相微型流化床体积传质系数比较(dp=190 μm,T=25℃,c(NaOH)=0.1 mol/L,D=2.0 mm)

Fig.14 Volumetric mass transfer coefficient between gas-liquid bubbling micro-column and gas-liquid-solid

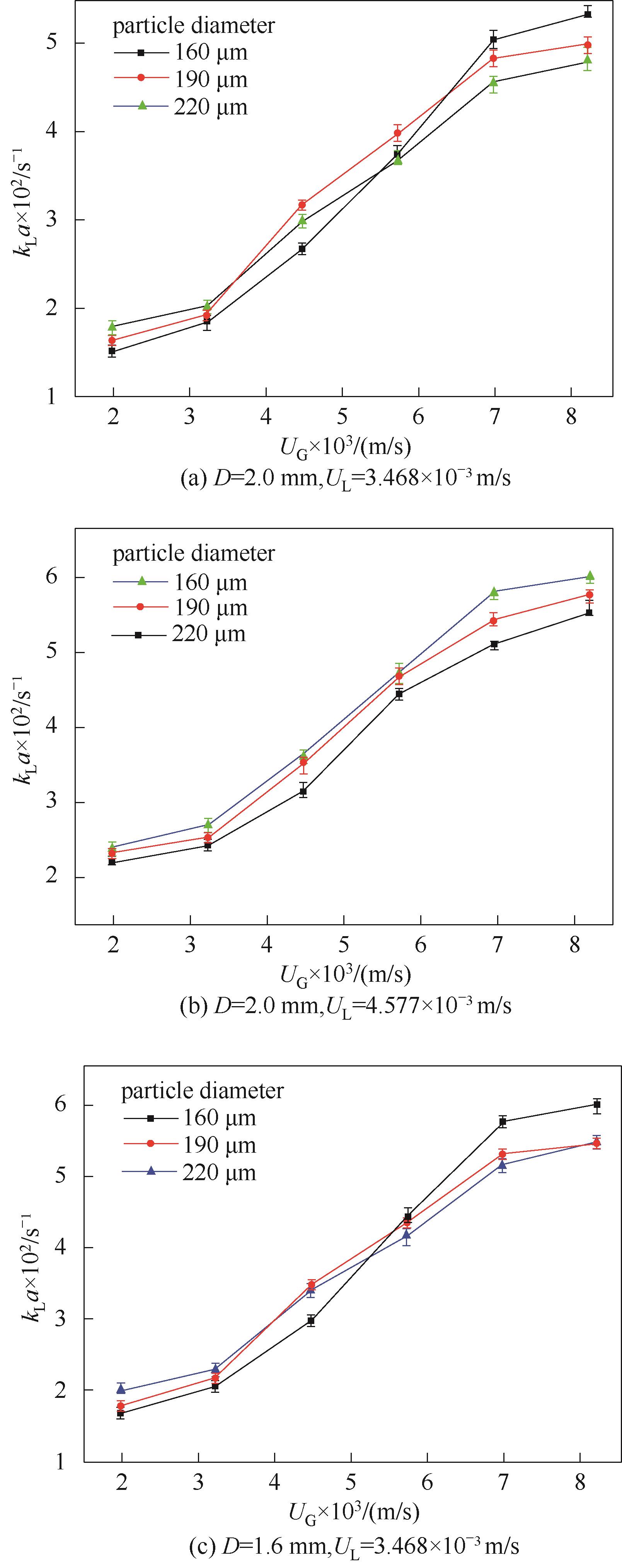

图15 颗粒直径对气液固微型流化床体积传质系数的影响(T=25℃,c(NaOH)=0.1 mol/L)

Fig.15 Effect of particle diameter on volumetric mass transfer coefficient in gas-liquid-solid micro-fluidized bed

图16 表观气速改变时不同粒径气液固微型流化床的液相传质系数(T=25℃,c(NaOH)=0.1 mol/L,D=2.0 mm)

Fig.16 Liquid-phase mass transfer coefficients of gas-liquid-solid micro-fluidized bed with different particle sizes when superficial gas velocity changes

图17 表观液速改变时不同粒径气液固微型流化床的液相传质系数(T=25℃,c(NaOH)=0.1 mol/L,D=2.0 mm)

Fig.17 Liquid-phase mass transfer coefficients of fluidized beds with different particle sizes when superficial liquid velocity changes

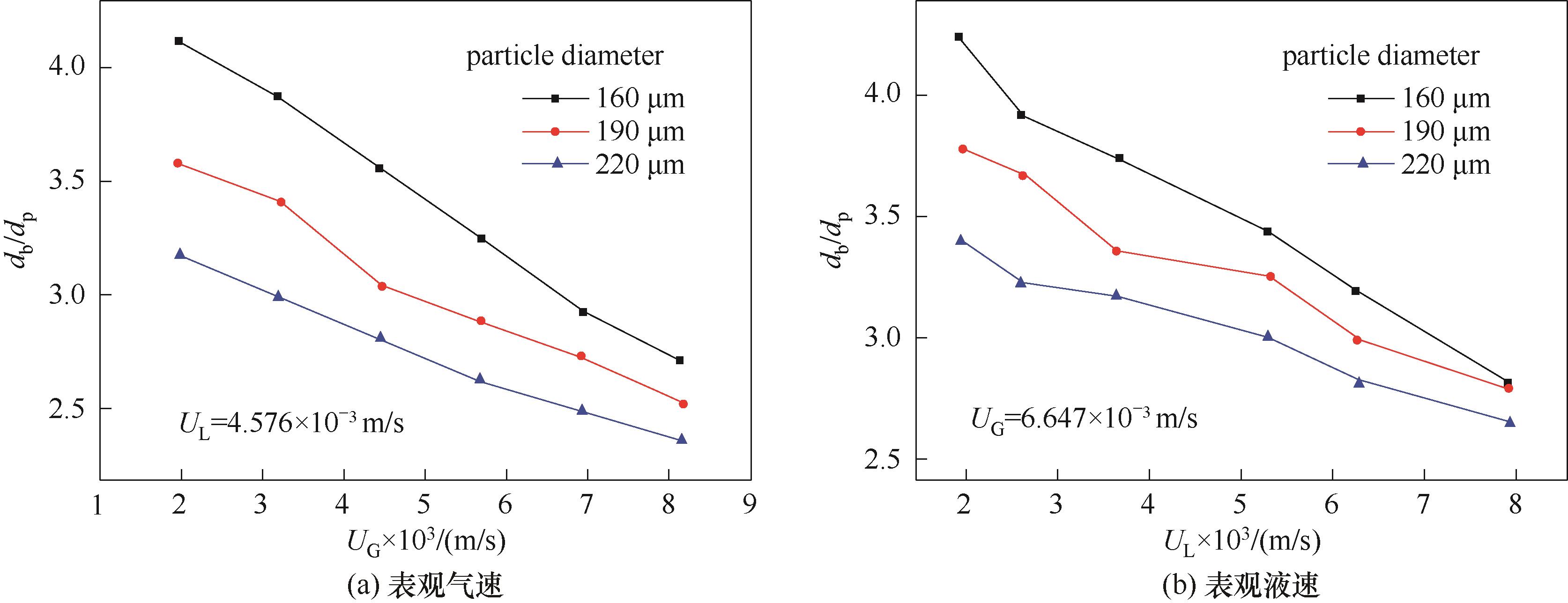

图18 三相微型流化床中气泡与颗粒尺寸之比受流体速度的影响(T=25℃,c(NaOH)=0.1 mol/L,D=2.0 mm)

Fig.18 Effect of fluid velocity on the ratio of bubble diameter to particle diameter in gas-liquid-solid micro-fluidized bed

| 1 | Fan L S. Gas-Liquid-Solid Fluidization Engineering[M]. Boston: Butterworth-Heinemann, 1989. |

| 2 | Kashid M N, Kiwi-Minsker L. Microstructured reactors for multiphase reactions: state of the art[J]. Industrial & Engineering Chemistry Research, 2009, 48(14): 6465-6485. |

| 3 | Ye C B, Chen G W, Yuan Q. Process characteristics of CO2 absorption by aqueous monoethanolamine in a microchannel reactor[J]. Chinese Journal of Chemical Engineering, 2012, 20(1): 111-119. |

| 4 | Li Y J, Liu M Y, Li X N. Minimum fluidization velocity in gas-liquid-solid minifluidized beds[J]. AIChE Journal, 2016, 62(6): 1940-1957. |

| 5 | Li Y J, Liu M Y, Li X N. Single bubble behavior in gas-liquid-solid mini-fluidized beds[J]. Chemical Engineering Journal, 2016, 286: 497-507. |

| 6 | Li Y J, Liu M Y, Li X N. Flow regimes in gas-liquid-solid mini-fluidized beds with single gas orifice[J]. Powder Technology, 2018, 333: 293-303. |

| 7 | Li X N, Liu M Y, Li Y J. Bed expansion and multi-bubble behavior of gas-liquid-solid micro-fluidized beds in sub-millimeter capillary[J]. Chemical Engineering Journal, 2017, 328: 1122-1138. |

| 8 | Li X N, Liu M Y, Ma Y L, et al. Experiments and meso-scale modeling of phase holdups and bubble behavior in gas-liquid-solid mini-fluidized beds[J]. Chemical Engineering Science, 2018, 192: 725-738. |

| 9 | Wang X Y, Liu M Y, Yang Z G. Coupled model based on radiation transfer and reaction kinetics of gas-liquid-solid photocatalytic mini-fluidized bed[J]. Chemical Engineering Research and Design, 2018, 134: 172-185. |

| 10 | Dong T T, Liu M Y, Li X N, et al. Catalytic oxidation of crotonaldehyde to crotonic acid in a gas-liquid-solid mini-fluidized bed[J]. Powder Technology, 2019, 352: 32-41. |

| 11 | Yao C Q, Zhu K, Liu Y Y, et al. Intensified CO2 absorption in a microchannel reactor under elevated pressures[J]. Chemical Engineering Journal, 2017, 319: 179-190. |

| 12 | Zhu C Y, Guo H, Chu C Y, et al. Gas-liquid distribution and mass transfer of CO2 absorption into sodium glycinate aqueous solution in parallel multi-channel microreactor[J]. International Journal of Heat and Mass Transfer, 2020, 157: 119943. |

| 13 | Zhang S Z, Zhu C Y, Feng H S, et al. Intensification of gas-liquid two-phase flow and mass transfer in microchannels by sudden expansions[J]. Chemical Engineering Science, 2021, 229: 116040. |

| 14 | Conlisk A T, McFerran J, Zheng Z, et al. Mass transfer and flow in electrically charged micro- and nanochannels[J]. Analytical Chemistry, 2002, 74(9): 2139-2150. |

| 15 | Zhang Y B. Efficient multiscale calculation results for microchannel mass transfer[J]. Scientific Reports, 2021, 11: 10023. |

| 16 | Dong T T, Ma Y L, Liu M Y. Gas-liquid mass transfer in the gas-liquid-solid mini fluidized beds[J]. Particuology, 2022, 69: 22-30. |

| 17 | Zahid Saima. 液-固微型流化床中的颗粒-液体间传质[D]. 天津: 天津大学, 2019. |

| Saima Z. Mass transfer between solid particle and liquid flow in the liquid-solid mini-fluidized bed[D]. Tianjin: Tianjin University, 2019. | |

| 18 | 郝玲, 郑朝振, 章俊, 等. CO2吸收模型中容积传质系数的确定[J]. 材料与冶金学报, 2012, 11(2): 98-101. |

| Hao L, Zheng C Z, Zhang J, et al. Determination of volumetric mass transfer coefficient for CO2 absorption model experiment[J]. Journal of Materials and Metallurgy, 2012, 11(2): 98-101. | |

| 19 | 刘燕, 张廷安, 赵洪亮, 等. CO2微细气泡在NaOH溶液中吸收速率研究[J]. 过程工程学报, 2009, 9(S1): 185-188. |

| Liu Y, Zhang T A, Zhao H L, et al. Study on absorption of CO2 bubble disintegration in NaOH solution[J]. The Chinese Journal of Process Engineering, 2009, 9(S1): 185-188. | |

| 20 | Inada S, Watanabe A. Effect of gas liquid properties on the absorption rate of CO2 into NaOH solution[J]. Tetsu-to-Hagane, 1976, 62(7): 807-816. |

| 21 | Takemura F, Yabe A. Gas dissolution process of spherical rising gas bubbles[J]. Chemical Engineering Science, 1998, 53(15): 2691-2699. |

| 22 | Motarjemi M, Jameson G J. Mass transfer from very small bubbles—the optimum bubble size for aeration[J]. Chemical Engineering Science, 1978, 33(11): 1415-1423. |

| 23 | Lee J S, Jin H R, Lim H, et al. Interfacial area and liquid-side and overall mass transfer coefficients in a three-phase circulating fluidized bed[J]. Chemical Engineering Science, 2013, 100: 203-211. |

| 24 | Dani A, Guiraud P, Cockx A. Local measurement of oxygen transfer around a single bubble by planar laser-induced fluorescence[J]. Chemical Engineering Science, 2007, 62(24): 7245-7252. |

| 25 | Bischof F, Sommerfeld M, Durst F. The determination of mass transfer rates from individual small bubbles[J]. Chemical Engineering Science, 1991, 46(12): 3115-3121. |

| 26 | Doroodchi E, Peng Z B, Sathe M, et al. Fluidisation and packed bed behaviour in capillary tubes[J]. Powder Technology, 2012, 223: 131-136. |

| 27 | Tang C, Liu M Y, Li Y J. Experimental investigation of hydrodynamics of liquid-solid mini-fluidized beds[J]. Particuology, 2016, 27: 102-109. |

| [1] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [2] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [3] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [4] | 高燕, 伍鹏, 尚超, 胡泽君, 陈晓东. 基于双流体喷嘴的磁性琼脂糖微球的制备及其蛋白吸附性能探究[J]. 化工学报, 2023, 74(8): 3457-3471. |

| [5] | 高金明, 郭玉娇, 鄂承林, 卢春喜. 一种封闭罩内顺流多旋臂气液分离器的分离特性研究[J]. 化工学报, 2023, 74(7): 2957-2966. |

| [6] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| [7] | 刘起超, 周云龙, 陈聪. 起伏振动垂直上升管气液两相流截面含气率分析与计算[J]. 化工学报, 2023, 74(6): 2391-2403. |

| [8] | 张媛媛, 曲江源, 苏欣欣, 杨静, 张锴. 循环流化床燃煤机组SNCR脱硝过程气液传质和反应特性[J]. 化工学报, 2023, 74(6): 2404-2415. |

| [9] | 董鑫, 单永瑞, 刘易诺, 冯颖, 张建伟. 非牛顿流体气泡羽流涡特性数值模拟研究[J]. 化工学报, 2023, 74(5): 1950-1964. |

| [10] | 许文烜, 江锦波, 彭新, 门日秀, 刘畅, 彭旭东. 宽速域三种典型型槽油气密封泄漏与成膜特性对比研究[J]. 化工学报, 2023, 74(4): 1660-1679. |

| [11] | 何万媛, 陈一宇, 朱春英, 付涛涛, 高习群, 马友光. 阵列凸起微通道内气液两相传质特性研究[J]. 化工学报, 2023, 74(2): 690-697. |

| [12] | 白剑钊, 郭子轩, 王德武, 刘燕, 王若瑾, 唐猛, 张少峰. 摇摆对气液并流模式立体旋流筛板压降的影响研究[J]. 化工学报, 2023, 74(2): 707-720. |

| [13] | 盛林, 昌宇, 邓建, 骆广生. 阶梯式T型微通道内有序气泡群的形成和流动特性研究[J]. 化工学报, 2023, 74(1): 416-427. |

| [14] | 张童, 杨扬, 叶丁丁, 陈蓉, 朱恂, 廖强. 催化剂分布对可渗透阳极微流体燃料电池性能特性影响的研究[J]. 化工学报, 2022, 73(9): 4156-4162. |

| [15] | 苏巧玲, 王军锋, 张伟, 詹水清, 吴天一. 低电导率工质中气泡的极化运动实验研究[J]. 化工学报, 2022, 73(9): 3861-3869. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号