化工学报 ›› 2023, Vol. 74 ›› Issue (6): 2335-2350.DOI: 10.11949/0438-1157.20230418

收稿日期:2023-04-26

修回日期:2023-06-16

出版日期:2023-06-05

发布日期:2023-07-27

通讯作者:

闫子涵

作者简介:郑志航(1998—),男,硕士研究生,2680197495@qq.com

基金资助:

Zhihang ZHENG1,2( ), Junnan MA1, Zihan YAN1(

), Junnan MA1, Zihan YAN1( ), Chunxi LU1

), Chunxi LU1

Received:2023-04-26

Revised:2023-06-16

Online:2023-06-05

Published:2023-07-27

Contact:

Zihan YAN

摘要:

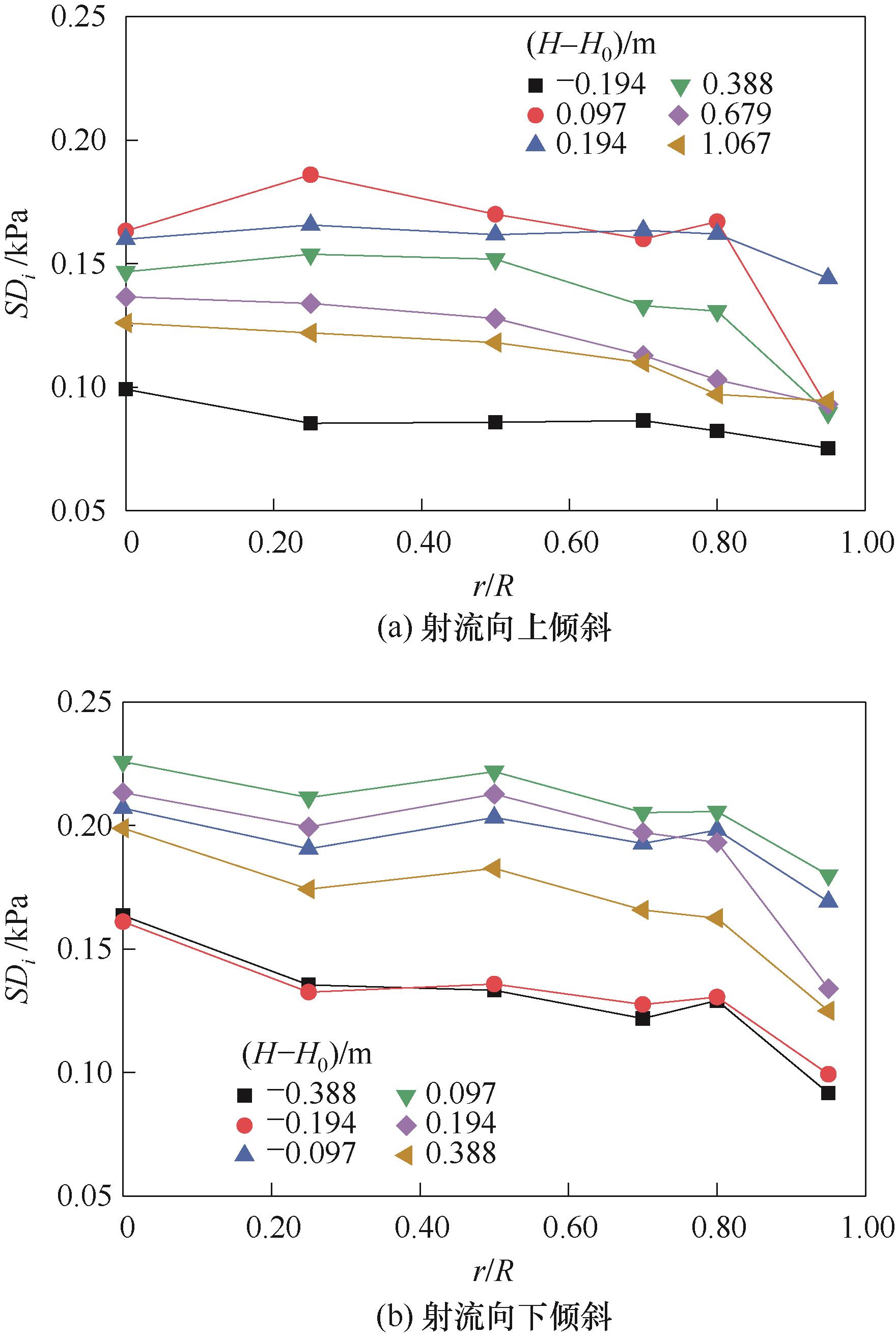

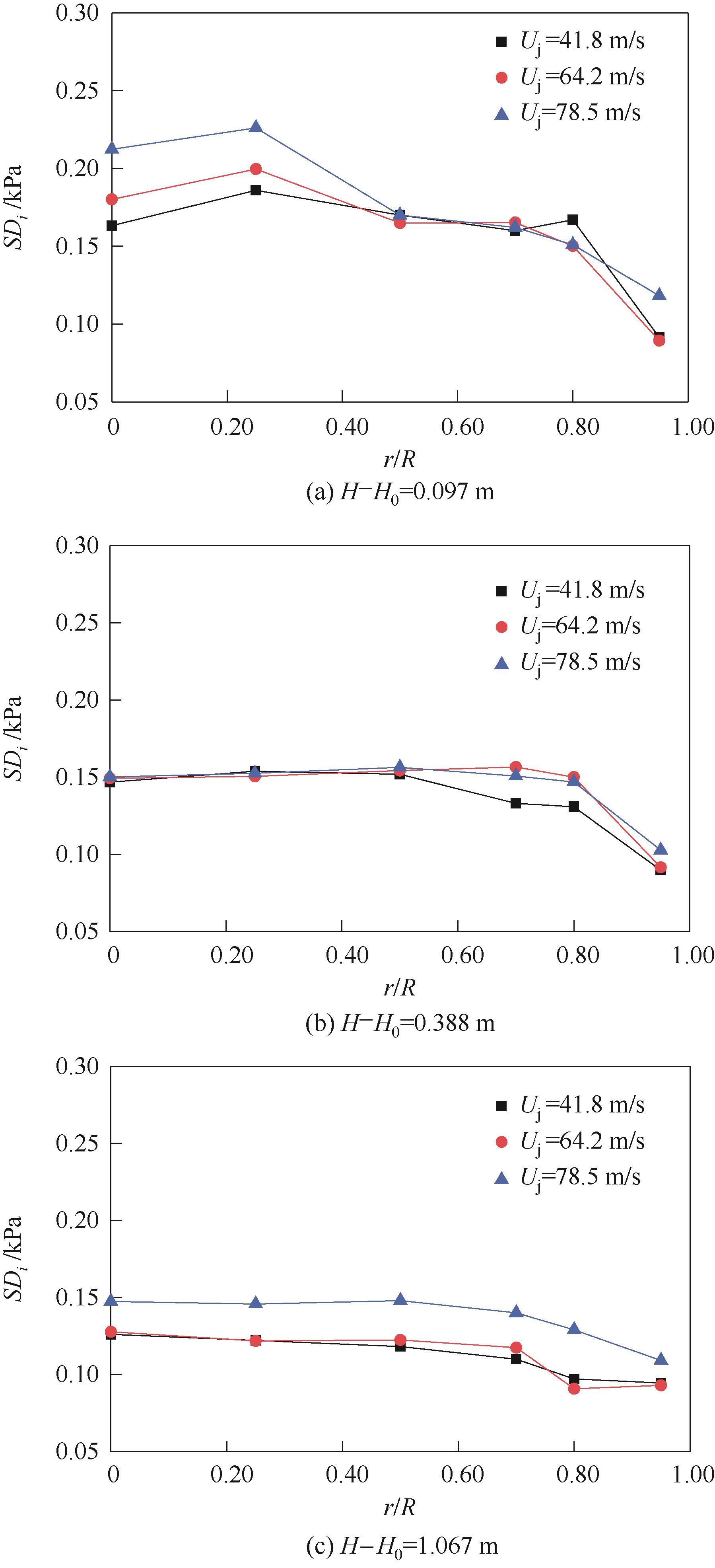

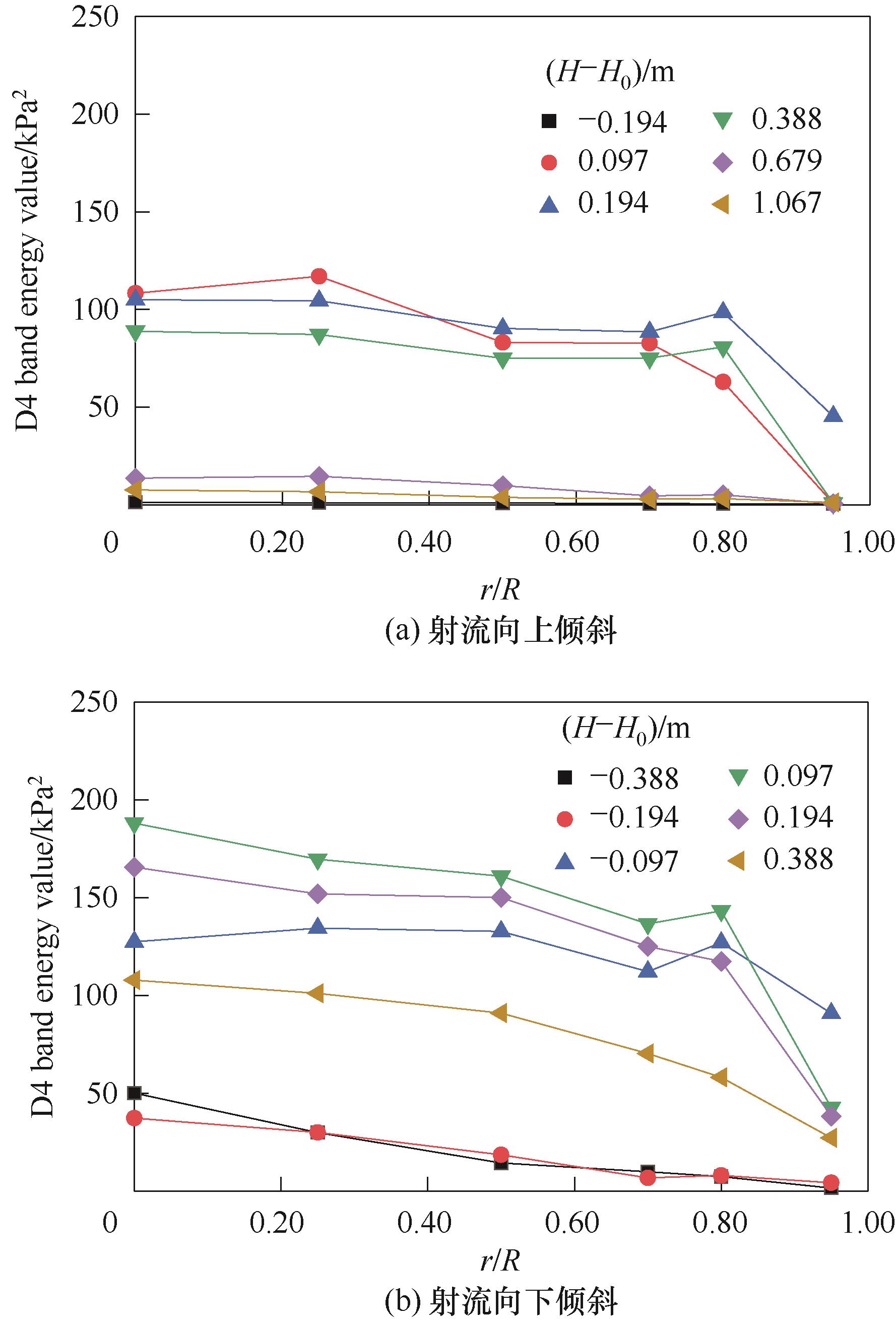

在提升管大型冷模实验装置中,采集了两种射流形式(射流向上倾斜和射流向下倾斜)提升管射流影响区内的压力动态数据,获得了压力脉动强度的轴、径向分布,并结合压力脉动信号的小波分解分析了不同射流形式对提升管内气固间作用规律的影响,建立了射流影响区内压力脉动特性与射流速度的联系。结果表明,与向上倾斜射流相比,向下倾斜射流使得提升管内压力脉动标准偏差整体数值增大约30%,而轴向、径向变化梯度均有所减小,气固混合过程的强度增大。小波分析结果表明,随着射流速度的增大,射流向上倾斜时,射流喷嘴入口截面附近区域小波能量整体数值将降低约25%,而在射流向下倾斜的射流影响区内小波能量整体数值将增大29%左右,其中ED4、EA8能量占比最大;向下倾斜的射流能有效增加射流影响区内高频压力脉动强度,有利于提高气固接触效果。

中图分类号:

郑志航, 马郡男, 闫子涵, 卢春喜. 提升管射流影响区内压力脉动特性研究[J]. 化工学报, 2023, 74(6): 2335-2350.

Zhihang ZHENG, Junnan MA, Zihan YAN, Chunxi LU. Study on the pressure pulsation characteristics in jet influence zone of riser[J]. CIESC Journal, 2023, 74(6): 2335-2350.

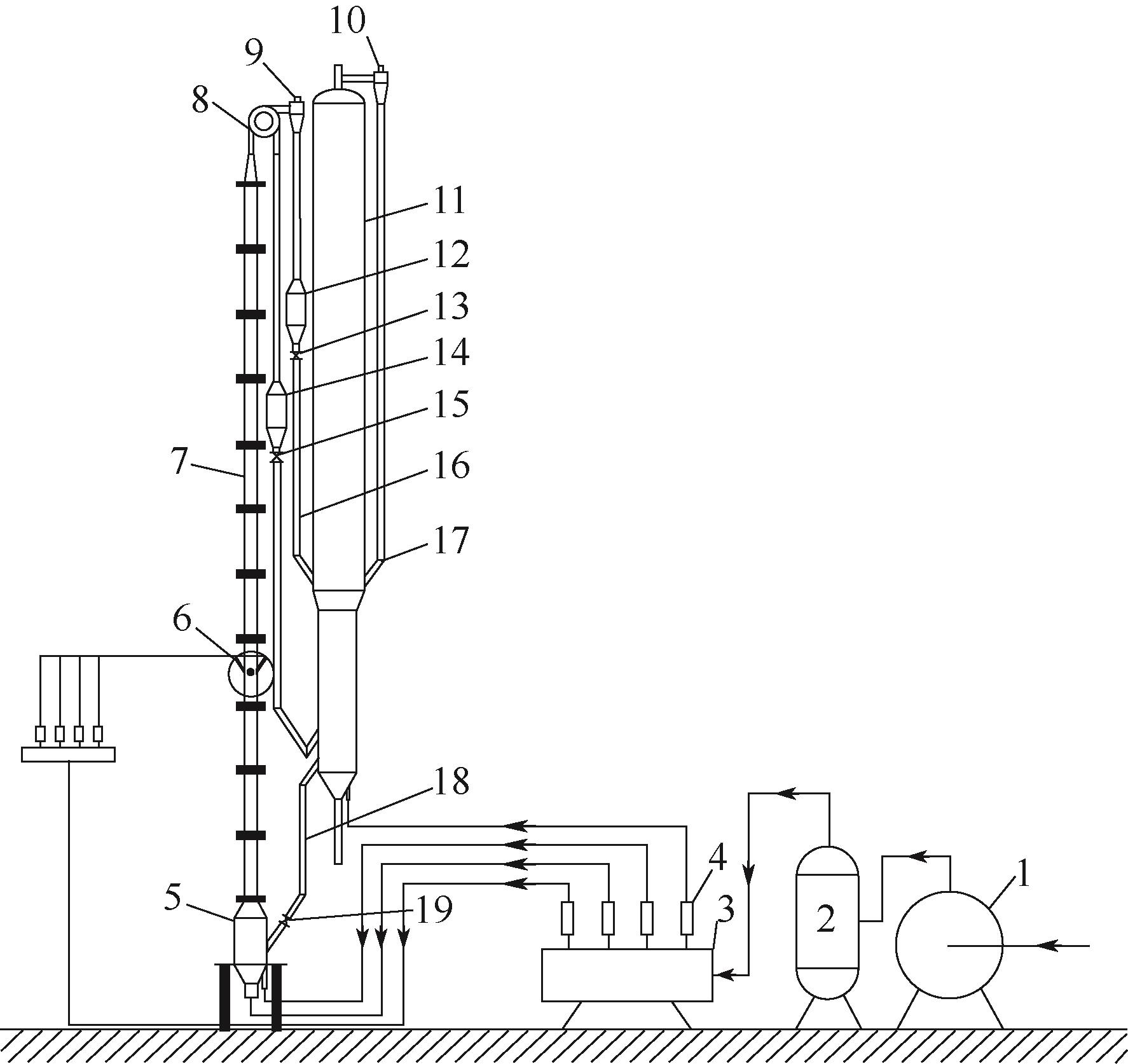

图1 实验装置示意图1—罗茨鼓风机;2—缓冲罐;3—气体分布器;4—转子流量计;5—预提升段;6—进料段;7—提升管;8—超短快分;9,10—旋风分离器;11—储料伴床;12,14—计量罐;13,15,19—蝶阀;16,17—料腿;18—再生斜管

Fig.1 Schematic diagram of experimental apparatus

| 平均粒径dp/μm | 粒径范围/ μm | 堆积密度ρb/(kg/m3) | 颗粒密度ρp/(kg/m3) |

|---|---|---|---|

| 70 | 30~90 | 870 | 1440 |

表1 催化剂颗粒物性参数

Table 1 Particulate parameter of catalyst

| 平均粒径dp/μm | 粒径范围/ μm | 堆积密度ρb/(kg/m3) | 颗粒密度ρp/(kg/m3) |

|---|---|---|---|

| 70 | 30~90 | 870 | 1440 |

图3 射流影响区内压力脉动标准偏差的数值分布[Ur=3.5 m/s, Uj=41.8 m/s,Gs=65 kg/(m2·s)]

Fig.3 Numerical distributions of pressure pulsation standard deviations in the jet influence zone

图4 射流向上倾斜的射流影响区内压力脉动标准偏差的数值分布[Ur=3.5 m/s, Gs=65 kg/(m2·s)]

Fig.4 Numerical distributions of standard deviations of pressure pulsation in the jet influenced zone with the upward inclined jet

图5 射流向下倾斜的射流影响区内压力脉动标准偏差的数值分布[Ur=3.5 m/s, Gs=65 kg/(m2·s)]

Fig.5 Numerical distributions of standard deviations of pressure pulsation in the jet influenced zone with the downward inclined jet

| 细节能量 | 频率范围/Hz |

|---|---|

| 第1尺度 | 50~100 |

| 第2尺度 | 25~50 |

| 第3尺度 | 12.5~25 |

| 第4尺度 | 6.25~12.5 |

| 第5尺度 | 3.125~6.25 |

| 第6尺度 | 1.563~3.125 |

| 第7尺度 | 0.781~1.563 |

| 第8尺度 | 0.391~0.781 |

表2 各细节信号尺度与频率范围对应关系

Table 2 Correspondence between scale and frequency range of each detail signal

| 细节能量 | 频率范围/Hz |

|---|---|

| 第1尺度 | 50~100 |

| 第2尺度 | 25~50 |

| 第3尺度 | 12.5~25 |

| 第4尺度 | 6.25~12.5 |

| 第5尺度 | 3.125~6.25 |

| 第6尺度 | 1.563~3.125 |

| 第7尺度 | 0.781~1.563 |

| 第8尺度 | 0.391~0.781 |

图8 不同射流形式的射流影响区内D4频段小波能量的数值分布[Ur=3.5 m/s,Uj=41.8 m/s,Gs=65 kg/(m2·s)]

Fig.8 Numerical distribution of D4-band wavelet energy in jet influence zone with different jet forms

| 1 | 宋亮. 石油化工催化裂化工艺技术优化[J]. 中国石油和化工标准与质量, 2021, 41(11): 154-155. |

| Song L. Technical optimization of catalytic cracking process in petrochemical industry[J]. China Petroleum and Chemical Standard and Quality, 2021, 41(11): 154-155. | |

| 2 | 王慧. 催化裂化装置粗汽油作急冷油进提升管回炼改质效果及其影响分析[J]. 石油炼制与化工, 2021, 52(3): 50-55. |

| Wang H. Effect analysis of FCC naphtha used as quench oil in riser[J]. Petroleum Processing and Petrochemicals, 2021, 52(3): 50-55. | |

| 3 | 宁智远. 丁烯氧化脱氢装置开发提升管反应器展望[J]. 化工管理, 2016(5): 5-6. |

| Ning Z Y. Prospect of developing riser reactor in butene oxidative dehydrogenation unit[J]. Chemical Enterprise Management, 2016(5): 5-6. | |

| 4 | Liu X C, Lu C X, Shi M X. Post-riser regeneration technology in FCC unit[J]. Petroleum Science, 2007, 4(2): 91-96. |

| 5 | 文佳佳. 新型MTO反应器内颗粒流动特性实验研究[D]. 北京: 中国石油大学(北京), 2019. |

| Wen J J. Study on particle flow characteristics in a novel MTO reactor[D]. Beijing: China University of Petroleum, 2019. | |

| 6 | Li Z, Lu C X. FCC riser quick separation system: a review[J]. Petroleum Science, 2016, 13(4): 776-781. |

| 7 | Lu C X, Zhang Y M, Shi M X. A historic review on R&D of China's FCC riser termination device technologies[J]. International Journal of Chemical Reactor Engineering, 2013, 11(1): 225-242. |

| 8 | Shah M T, Utikar R P, Pareek V K, et al. Computational fluid dynamic modelling of FCC riser: a review[J]. Chemical Engineering Research and Design, 2016, 111: 403-448. |

| 9 | Chen S, Fan Y P, Yan Z H, et al. CFD optimization of feedstock injection angle in a FCC riser[J]. Chemical Engineering Science, 2016, 153: 58-74. |

| 10 | Nayak S V, Joshi S L, Ranade V V. Modeling of vaporization and cracking of liquid oil injected in a gas-solid riser[J]. Chemical Engineering Science, 2005, 60(22): 6049-6066. |

| 11 | 汪申, 时铭显. 我国催化裂化提升管反应系统设备技术的进展[J]. 石油化工动态, 2000, 8(5): 46-50. |

| Wang S, Shi M X. Progress of domestic FCC riser reactor technology[J]. Petrochemical Industry Trends, 2000, 8(5): 46-50. | |

| 12 | 范怡平, 卢春喜. 催化裂化提升管进料段内多相流动及其结构优化[J]. 化工学报, 2018, 69(1): 249-258. |

| Fan Y P, Lu C X. Multiphase flow characteristics and structural optimization in feed injection zone of FCC riser[J]. CIESC Journal, 2018, 69(1): 249-258. | |

| 13 | 崔刚, 刘梦溪. 流化催化裂化提升管进料段混合研究进展[J]. 广州化工, 2014, 42(16): 20-21. |

| Cui G, Liu M X. Advances in feedstock injection-mixing zone of a FCC riser[J]. Guangzhou Chemical Industry, 2014, 42(16): 20-21. | |

| 14 | 范怡平, 杨志义, 许栋五, 等. 催化裂化提升管进料段内油剂两相流动混合的优化及工业应用[J]. 过程工程学报, 2006, 6(S2): 390-393. |

| Fan Y P, Yang Z Y, Xu D W, et al. Optimization on the gas-solid two-phase flow in the feedstock injection-mixing zone of FCC riser and industrial application[J]. The Chinese Journal of Process Engineering, 2006, 6(S2): 390-393. | |

| 15 | 王宏民, 袁中立, 李克见. UPC-a新型高效喷嘴的工业应用[J]. 天然气与石油, 2002, 20(2): 37-39. |

| Wang H M, Yuan Z L, Li K J. Industrial application of UPC-a new high-efficiency nozzle[J]. Natural Gas and Oil, 2002, 20(2): 37-39. | |

| 16 | 刘丙超. 循环流化床冷模装置设计及流态化实验研究[D]. 东营: 中国石油大学(华东), 2019. |

| Liu B C. Design of circulating fluidized bed cold mold device and experimental study of fluidization[D]. Dongying: China University of Petroleum, 2019. | |

| 17 | 韩超一, 陈晓成, 吴文龙, 等. 内构件对变径提升管内气固流动特性的影响[J]. 石油炼制与化工, 2016, 47(1): 5-10. |

| Han C Y, Chen X C, Wu W L, et al. Effect of internals on characteristics of gas-solids flow in a variable diameter riser reactor[J]. Petroleum Processing and Petrochemicals, 2016, 47(1): 5-10. | |

| 18 | 卢春喜, 范怡平, 刘梦溪, 等. 催化裂化反应系统关键装备技术研究进展[J]. 石油学报(石油加工), 2018, 34(3): 441-454. |

| Lu C X, Fan Y P, Liu M X, et al. Advances in key equipment technologies of reaction system in RFCC unit[J]. Acta Petrolei Sinica(Petroleum Processing Section), 2018, 34(3): 441-454. | |

| 19 | Mauleon J L, Sigaud J B. Process for the catalytic cracking of hydrocarbons in a fluidized bed and their applications: US4883583[P]. 1989-11-28. |

| 20 | 闫子涵, 秦小刚, 陈昇, 等. 油剂逆流接触提升管进料段固含率及颗粒速度的径向分布[J]. 过程工程学报, 2014, 14(5): 721-729. |

| Yan Z H, Qin X G, Chen S, et al. Radial distributions of solids hold-up and particle velocity in FCC riser feed injection zone with catalyst-feed oil countercurrent contact[J]. The Chinese Journal of Process Engineering, 2014, 14(5): 721-729. | |

| 21 | Yan Z H, Fan Y P, Wang Z, et al. Dispersion of feed spray in a new type of FCC feed injection scheme[J]. AIChE Journal, 2016, 62(1): 46-61. |

| 22 | 闫子涵. 催化裂化提升管进料段内流动特性的实验研究及结构优化[D]. 北京: 中国石油大学(北京), 2017. |

| Yan Z H. Experimental study of gas-solid two-phase flow in FCC feed injection zone and the structure optimization[D]. Beijing: China University of Petroleum, 2017. | |

| 23 | Yan Z H, Fan Y P, Bi X T, et al. Flow patterns of feed spray in different fluid catalytic cracking feed injection schemes[J]. Industrial & Engineering Chemistry Research, 2017, 56(22): 6441-6450. |

| 24 | 陈永国, 田子平, 缪正清, 等. 时频分析在循环流化床流型识别中的应用[J]. 仪器仪表学报, 2003, 24(S2): 452-454, 471. |

| Chen Y G, Tian Z P, Miao Z Q, et al. The experimental study of fluid transition in the circulating fluidized beds[J]. Chinese Journal of Scientific Instrument, 2003, 24(S2): 452-454, 471. | |

| 25 | Fan L T, Ho T C, Hiraoka S, et al. Pressure fluctuations in a fluidized bed[J]. AIChE Journal, 1981, 27(3): 388-396. |

| 26 | 陈鸿伟, 麻哲瑞, 杨新, 等. 基于Daubechies小波分析的双循环流化床气化室压力波动特性研究[J]. 华北电力大学学报(自然科学版), 2018, 45(5): 78-84. |

| Chen H W, Ma Z R, Yang X, et al. Study on pressure fluctuation characteristics of gasification chamber on basis of Daubechies wavelet analysis in dual circulating fluidized bed[J]. Journal of North China Electric Power University(Natural Science Edition), 2018, 45(5): 78-84. | |

| 27 | 王嘉骏, 张文峰, 冯连芳, 等. 气固搅拌流化床压力脉动的小波分析[J]. 化工学报, 2006, 57(12): 2854-2859. |

| Wang J J, Zhang W F, Feng L F, et al. Wavelets analysis of pressure fluctuation in agitated fluidized bed[J]. Journal of Chemical Industry and Engineering (China), 2006, 57(12): 2854-2859. | |

| 28 | 张永俊, 王嘉骏, 顾雪萍, 等. 气固搅拌流化床中压力脉动特性[J]. 化工学报, 2016, 67(2): 494-503. |

| Zhang Y J, Wang J J, Gu X P, et al. Pressure fluctuation in gas-solid agitated fluidized bed[J]. CIESC Journal, 2016, 67(2): 494-503. | |

| 29 | Tahmasebpour M, Zarghami R, Sotudeh-Gharebagh R, et al. Characterization of various structures in gas-solid fluidized beds by recurrence quantification analysis[J]. Particuology, 2013, 11(6): 647-656. |

| 30 | Zhou Y L, Yang N. Riser pipe pressure pulsation standard deviation fast forecast spouted bed granular poly group[J]. Applied Mechanics and Materials, 2013, 448/449/450/451/452/453: 3397-3402. |

| 31 | 刘宝勇, 魏绪玲, 张斌. 循环流化床提升管压力瞬时波动研究[J]. 化工技术与开发, 2015, 44(5): 58-61. |

| Liu B Y, Wei X L, Zhang B. Research on pressure instantaneous fluctuations in riser of circulating fluidized bed[J]. Technology & Development of Chemical Industry, 2015, 44(5): 58-61. | |

| 32 | 邹媛媛, 冯璇, 沈来宏. 变径提升管压力脉动和颗粒循环量数值模拟[J]. 工业控制计算机, 2019, 32(6): 20-22. |

| Zou Y Y, Feng X, Shen L H. CPFD simulation of pressure fluctuation and solid circulation rate of multi-regime riser[J]. Industrial Control Computer, 2019, 32(6): 20-22. | |

| 33 | 谢金朋, 吴广恒, 王德武, 等. 变径组合提升管内压力脉动及其流型转变特性[J]. 石油学报(石油加工), 2019, 35(1): 83-90. |

| Xie J P, Wu G H, Wang D W, et al. Characteristics of pressure fluctuation in adjustable combined riser and flow regime transition[J]. Acta Petrolei Sinica(Petroleum Processing Section), 2019, 35(1): 83-90. | |

| 34 | van der Schaaf J, Johnson F, Schouten J C, et al. Fourier analysis of nonlinear pressure fluctuations in gas-solids flow in CFB risers—observing solids structures and gas/particle turbulence[J]. Chemical Engineering Science, 1999, 54(22): 5541-5546. |

| 35 | 孙立强, 许利辉, 胡霞, 等. 循环流化床颗粒循环回路上动态压力的测量与分析[J]. 石油学报(石油加工), 2018, 34(4): 739-745. |

| Sun L Q, Xu L H, Hu X, et al. Experimental analysis of dynamic pressure in the particle circulating loop of circulating fluidized bed reactor[J]. Acta Petrolei Sinica(Petroleum Processing Section), 2018, 34(4): 739-745. | |

| 36 | 胡小康, 刘小成, 徐俊, 等. 循环流化床提升管内压力脉动特性[J]. 化工学报, 2010, 61(4): 825-831. |

| Hu X K, Liu X C, Xu J, et al. Characteristics of pressure fluctuations in CFB riser[J]. CIESC Journal, 2010, 61(4): 825-831. | |

| 37 | 丁睿, 王德武, 刘燕, 等. 提升管加床层反应器不同操作模式下的压力脉动特性[J]. 过程工程学报, 2016, 16(5): 721-729. |

| Ding R, Wang D W, Liu Y, et al. Pressure fluctuation characteristics of riser-fluidized bed reactor under different operating modes[J]. The Chinese Journal of Process Engineering, 2016, 16(5): 721-729. | |

| 38 | 赵凤静, 边京, 范怡平. 新型提升管进料段内压力脉动强度分布的影响因素[J]. 过程工程学报, 2018, 18(1): 69-74. |

| Zhao F J, Bian J, Fan Y P. Influencing factors on distribution of pressure pulsation intensity in injection zone of a novel FCC riser[J]. The Chinese Journal of Process Engineering, 2018, 18(1): 69-74. | |

| 39 | 赵凤静. 催化裂化提升管进料段结构的优化和动态压力的实验研究[D]. 北京: 中国石油大学(北京), 2018. |

| Zhao F J. Structure optimization of FCC feed injection zone and the experimental study on the pressure pulsations[D]. Beijing: China University of Petroleum, 2018. | |

| 40 | Yan Z H, Chen S, Wang Z, et al. Distributions of solids holdup and particle velocity in the FCC riser with downward pointed feed injection scheme[J]. Powder Technology, 2016, 304: 63-72. |

| 41 | 范怡平, 叶盛, 卢春喜, 等. 提升管反应器进料混合段内气固两相流动特性(Ⅰ): 实验研究[J]. 化工学报, 2002, 53(10): 1003-1008. |

| Fan Y P, Ye S, Lu C X, et al. Gas-solid two-phase flow in feed injection zone of FCC riser reactors (Ⅰ): Experimental research[J]. Journal of Chemical Industry and Engineering (China), 2002, 53(10): 1003-1008. | |

| 42 | Zhao G B, Yang Y R. Multiscale resolution of fluidized-bed pressure fluctuations[J]. AIChE Journal, 2003, 49(4): 869-882. |

| 43 | 闫子涵, 范怡平, 卢春喜, 等. 催化裂化提升管进料混合区内固含率的动态特征及聚团行为[J]. 石油科学通报, 2020, 5(1): 122-131. |

| Yan Z H, Fan Y P, Lu C X, et al. Solids hold-up dynamic behavior and cluster characteristic in FCC jet mixing zone[J]. Petroleum Science Bulletin, 2020, 5(1): 122-131. | |

| 44 | 常宇航. 基于压力信号的循环流化床多尺度特性研究[D]. 北京: 中国石油大学(北京), 2020. |

| Chang Y H. Research on multi-scale characteristics of circulating fluidized bed based on pressure signal[D]. Beijing: China University of Petroleum, 2020. |

| [1] | 连梦雅, 谈莹莹, 王林, 陈枫, 曹艺飞. 地下水预热新风一体化热泵空调系统制热性能研究[J]. 化工学报, 2023, 74(S1): 311-319. |

| [2] | 宋瑞涛, 王派, 王云鹏, 李敏霞, 党超镔, 陈振国, 童欢, 周佳琦. 二氧化碳直接蒸发冰场排管内流动沸腾换热数值模拟分析[J]. 化工学报, 2023, 74(S1): 96-103. |

| [3] | 邵苛苛, 宋孟杰, 江正勇, 张旋, 张龙, 高润淼, 甄泽康. 水平方向上冰中受陷气泡形成和分布实验研究[J]. 化工学报, 2023, 74(S1): 161-164. |

| [4] | 王浩, 王振雷. 基于自适应谱方法的裂解炉烧焦模型化简策略[J]. 化工学报, 2023, 74(9): 3855-3864. |

| [5] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [6] | 杨越, 张丹, 郑巨淦, 涂茂萍, 杨庆忠. NaCl水溶液喷射闪蒸-掺混蒸发的实验研究[J]. 化工学报, 2023, 74(8): 3279-3291. |

| [7] | 董明, 徐进良, 刘广林. 超临界水非均质特性分子动力学研究[J]. 化工学报, 2023, 74(7): 2836-2847. |

| [8] | 邵伟明, 韩文学, 宋伟, 杨勇, 陈灿, 赵东亚. 基于分布式贝叶斯隐马尔可夫回归的动态软测量建模方法[J]. 化工学报, 2023, 74(6): 2495-2502. |

| [9] | 赵健, 周兴超, 夏丹, 董航. 机械搅拌对原油储罐射流加热过程传热特性的影响规律研究[J]. 化工学报, 2023, 74(5): 1982-1999. |

| [10] | 王瑞恒, 何品晶, 吕凡, 章骅. 垃圾焚烧飞灰水洗后三种固液分离方法参数比较及优化[J]. 化工学报, 2023, 74(4): 1712-1723. |

| [11] | 刘庆超, 贾辉, 许逸飞, 路娜, 尹延梅, 王捷. 基于FBG力学传感的曝气生物滤池中剪切力分布研究[J]. 化工学报, 2023, 74(4): 1755-1763. |

| [12] | 李新亚, 邢雷, 蒋明虎, 赵立新. 倒锥注气强化井下油水分离水力旋流器性能研究[J]. 化工学报, 2023, 74(3): 1134-1144. |

| [13] | 颜少航, 赖天伟, 王彦武, 侯予, 陈双涛. 微间隙内R134a空化可视化实验研究[J]. 化工学报, 2023, 74(3): 1054-1061. |

| [14] | 杨星宇, 马优, 朱春英, 付涛涛, 马友光. 梳状并行微通道内液液分布规律研究[J]. 化工学报, 2023, 74(2): 698-706. |

| [15] | 孟金琳, 汪宇, 张群锋, 叶光华, 周兴贵. 介孔材料低温氮气吸脱附的孔道网络模型[J]. 化工学报, 2023, 74(2): 893-903. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号