化工学报 ›› 2023, Vol. 74 ›› Issue (8): 3279-3291.DOI: 10.11949/0438-1157.20230721

杨越1( ), 张丹1(

), 张丹1( ), 郑巨淦1, 涂茂萍1, 杨庆忠2

), 郑巨淦1, 涂茂萍1, 杨庆忠2

收稿日期:2023-07-11

修回日期:2023-08-17

出版日期:2023-08-25

发布日期:2023-10-18

通讯作者:

张丹

作者简介:杨越(2001—),男,硕士研究生,yysgdsg@stu.xjtu.edu.cn

基金资助:

Yue YANG1( ), Dan ZHANG1(

), Dan ZHANG1( ), Jugan ZHENG1, Maoping TU1, Qingzhong YANG2

), Jugan ZHENG1, Maoping TU1, Qingzhong YANG2

Received:2023-07-11

Revised:2023-08-17

Online:2023-08-25

Published:2023-10-18

Contact:

Dan ZHANG

摘要:

喷射闪蒸与热空气掺混蒸发(FME)结合是实现含盐废水深度脱盐的有效方法之一。本文搭建了喷射闪蒸-横流掺混蒸发实验系统,结合PIV和Malvern激光粒度仪对FME流场中液滴群的运动、蒸发特性开展了实验研究。实验中掺混风温为104.7~145.3℃、风速为10~17 m∙s-1;液侧液滴初始盐质量分数为0~0.15,温度为20.0~132.0℃,喷射压力为0.5~1.2 MPa。FME中喷射闪蒸主要影响雾化破碎区,而掺混蒸发主要影响蒸发区。液滴群初始粒径随喷射压力或质量分数的提高趋于均匀,而随液滴温度的升高先趋于均匀而后均匀性变差。气液间的动量和能量交换主要发生在蒸发区内的水平方向;定义液滴沿水平方向截面平均速度为FME特征速度,该特征速度随掺混距离的增大先陡增后缓增,而在相同掺混距离处,该特征速度随掺混风温、风速或喷射压力的增大而增大;液滴群的Sauter平均直径沿掺混方向不断减小;增加掺混风温、提高掺混风速、增大喷射压力是强化FME蒸发的有效手段。根据实验结果计算了液滴群表面平均传热系数,并给出了该传热系数的实验关联式。在本文研究范围内,其计算值与实验值的主体误差在±20%之内。

中图分类号:

杨越, 张丹, 郑巨淦, 涂茂萍, 杨庆忠. NaCl水溶液喷射闪蒸-掺混蒸发的实验研究[J]. 化工学报, 2023, 74(8): 3279-3291.

Yue YANG, Dan ZHANG, Jugan ZHENG, Maoping TU, Qingzhong YANG. Experimental study on flash and mixing evaporation of aqueous NaCl solution[J]. CIESC Journal, 2023, 74(8): 3279-3291.

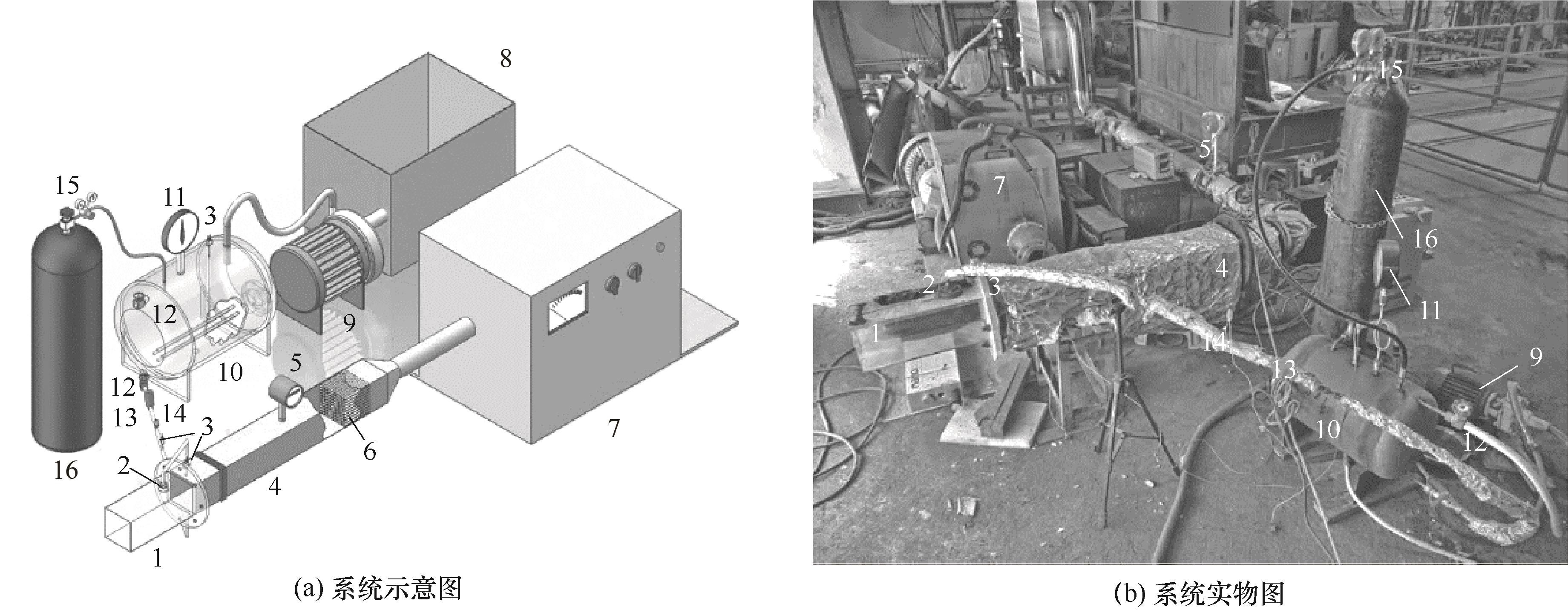

图2 横流喷雾掺混实验系统1—掺混段方腔;2—喷嘴; 3—热电偶;4—通风管路;5—空气流量计;6—整流器;7—工业热风机;8—水箱;9—盐水泵;10—加热罐;11—压力表;12—阀门;13—过滤器;14—压力传感器;15—减压阀;16—氮气瓶

Fig.2 Experimental system of FME

| 测量设备 | 型号 | 参数范围 | 精度 | 测量对象 |

|---|---|---|---|---|

| PIV系统 | LA ISION Nano PIV | 0~2000 m·s-1 | — | 雾羽速度场 |

| Malvern激光粒度仪 | Spraytecv3·20 | 0.1~2000 µm | 0.02% | 雾羽粒径分布 |

| 精密比重计 | CJBMJ-24 | 0.650~1.850 kg·m-3 | 5×10-4 kg·m-3 | NaCl水溶液浓度 |

| 热电偶 | T型铠装 | -200~400℃ | 0.5℃ | 溶液温度和风温 |

| 压力表 | Y-100 | 0~2.5 MPa | 0.02MPa | 水侧压力 |

| 空气流量计 | BLLUGB-100 | 0~4000 m3·h-1 | ±1%FS | 风侧流量 |

表1 测试设备主要实验参数及其范围

Table 1 Main experimental parameters and range of test equipment

| 测量设备 | 型号 | 参数范围 | 精度 | 测量对象 |

|---|---|---|---|---|

| PIV系统 | LA ISION Nano PIV | 0~2000 m·s-1 | — | 雾羽速度场 |

| Malvern激光粒度仪 | Spraytecv3·20 | 0.1~2000 µm | 0.02% | 雾羽粒径分布 |

| 精密比重计 | CJBMJ-24 | 0.650~1.850 kg·m-3 | 5×10-4 kg·m-3 | NaCl水溶液浓度 |

| 热电偶 | T型铠装 | -200~400℃ | 0.5℃ | 溶液温度和风温 |

| 压力表 | Y-100 | 0~2.5 MPa | 0.02MPa | 水侧压力 |

| 空气流量计 | BLLUGB-100 | 0~4000 m3·h-1 | ±1%FS | 风侧流量 |

| 实验参数 | 实验范围 | 绝对 不确定度 | 最小 测量值 | 最大相对不确定度 |

|---|---|---|---|---|

| 水侧压力pw/MPa | 0.5~1.2 | 0.03 | 0.50 | 0.006 |

| 液滴温度tw/℃ | 20.0~132.0 | 0.5 | 20.00 | 0.048 |

| 掺混风温ta /℃ | 104.7~145.3 | 0.2 | 104.70 | 0.061 |

| 初始盐质量分数fm,0 | 0~0.15 | 5×10-3 | 0.05 | 0.01 |

| 过热度ΔT/K | 0~32.00 | — | — | 0.036 |

| 掺混距离Δx/mm | 0~180.00 | 5×10-4 | 0.03 | 0.017 |

| 掺混风速va /(m·s-1) | 10~17 | 0.031 | 10.00 | 2×10-3 |

| 液滴速度ud/(m·s-1) | 12.1~43.3 | 0.01 | 12.1 | 2.5×10-3 |

| 液滴粒径d32/μm | 43.92~135.20 | 0.02 | 43.92 | 0.087 |

表2 实验参数的不确定性

Table 2 Uncertainty analyses of experimental parameters

| 实验参数 | 实验范围 | 绝对 不确定度 | 最小 测量值 | 最大相对不确定度 |

|---|---|---|---|---|

| 水侧压力pw/MPa | 0.5~1.2 | 0.03 | 0.50 | 0.006 |

| 液滴温度tw/℃ | 20.0~132.0 | 0.5 | 20.00 | 0.048 |

| 掺混风温ta /℃ | 104.7~145.3 | 0.2 | 104.70 | 0.061 |

| 初始盐质量分数fm,0 | 0~0.15 | 5×10-3 | 0.05 | 0.01 |

| 过热度ΔT/K | 0~32.00 | — | — | 0.036 |

| 掺混距离Δx/mm | 0~180.00 | 5×10-4 | 0.03 | 0.017 |

| 掺混风速va /(m·s-1) | 10~17 | 0.031 | 10.00 | 2×10-3 |

| 液滴速度ud/(m·s-1) | 12.1~43.3 | 0.01 | 12.1 | 2.5×10-3 |

| 液滴粒径d32/μm | 43.92~135.20 | 0.02 | 43.92 | 0.087 |

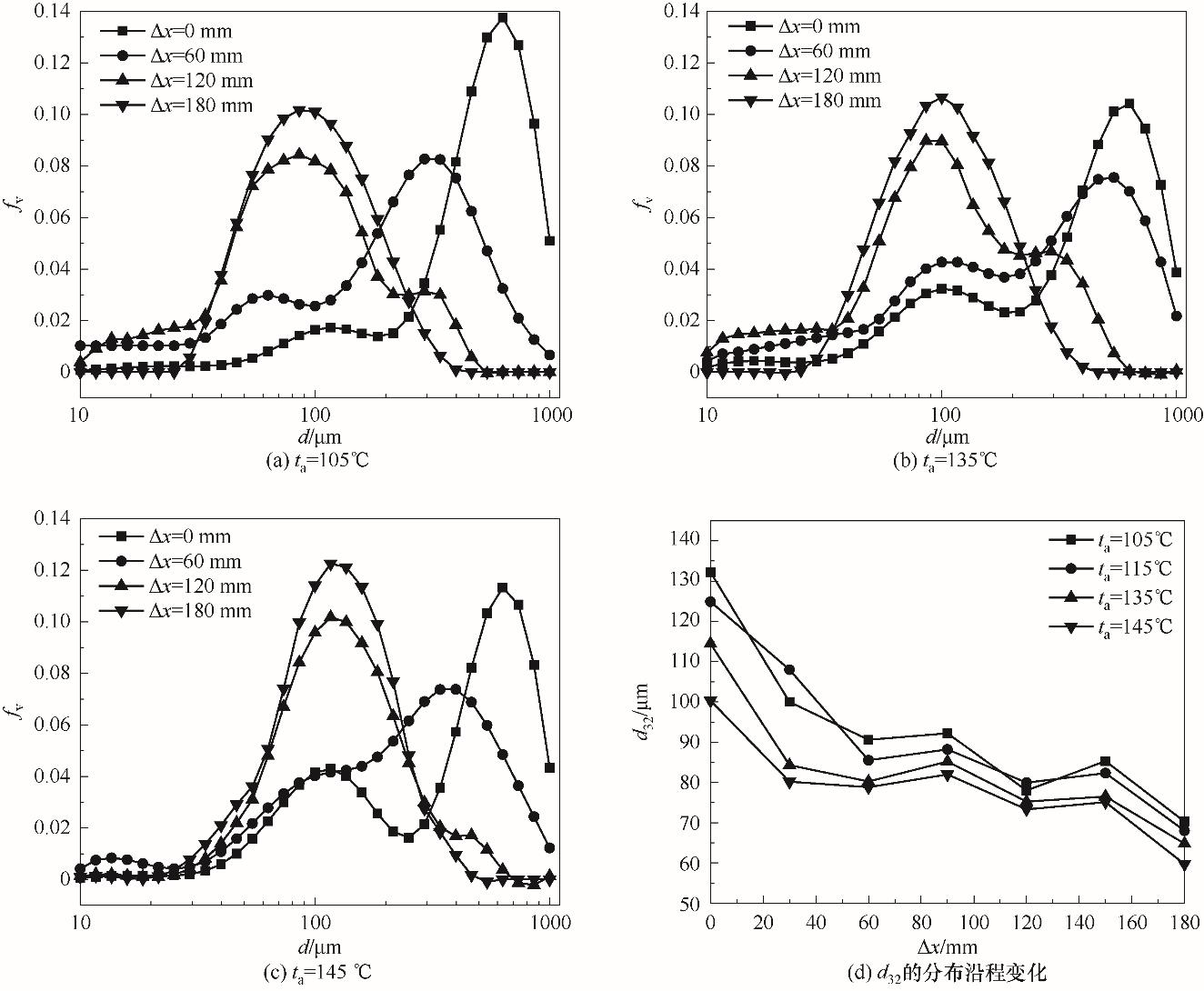

图12 不同掺混风温下粒径及d32分布随掺混距离的变化(fm,0=0.05,tw=120℃,p=0.5 MPa,va=10 m∙s-1)

Fig.12 Variation of particle size and d32 along mixing distance under different air temperatures

| 1 | 国家统计局.中国统计年鉴(2022)[M]. 北京: 中国统计出版社, 2022. |

| National Bureau of Statistics of China. China Statistical Yearbook(2022)[M]. Beijing: China Statistics Press, 2022. | |

| 2 | 王辉辉. NaCl水溶液喷射闪蒸雾化蒸发特性的实验研究[D]. 西安: 西安交通大学, 2021. |

| Wang H H. Experimental study on atomization evaporation properties during spray flash of aqueous NaCl solution[D]. Xi'an: Xi'an Jiaotong University, 2021. | |

| 3 | 邓才智. NaCl水溶液喷射闪蒸及析晶过程的雾场特性研究[D]. 西安: 西安交通大学, 2022. |

| Deng C Z. Study on spray field characteristics of spray flash evaporation and crystallization of NaCl aqueous solution[D]. Xi'an: Xi'an Jiaotong University, 2022. | |

| 4 | 郑巨淦, 张丹, 袁洋, 等. 有限通道内热空气顺流掺混NaCl水溶液喷射闪蒸的数值模拟[J]. 西安交通大学学报, 2023, 57(2): 173-183. |

| Zheng J G, Zhang D, Yuan Y, et al. Numerical simulation of spray flash evaporation of hot air mixed with NaCl aqueous solution in finite channel[J]. Journal of Xi'an Jiaotong University, 2023, 57(2): 173-183. | |

| 5 | 刘翔, 何林, 从海峰, 等. 双胺“可逆”溶剂强化正渗透脱盐及过程优化[J]. 化工进展, 2022, 41(11): 6158-6166. |

| Liu X, He L, Cong H F, et al. Enhanced forward osmosis desalination with diamine“reversible”solvent and process optimization[J]. Chemical Industry and Engineering Progress, 2022, 41(11): 6158-6166. | |

| 6 | 陈雪梅, 王彤, 高玉箔, 等. 利用激光诱导石墨烯实现高效太阳能界面蒸发[J]. 化工学报, 2022, 73(12): 5648-5659. |

| Chen X M, Wang T, Gao Y B, et al. Using laser-induced graphene to realize efficient solar interfacial evaporation[J]. CIESC Journal, 2022, 73(12): 5648-5659. | |

| 7 | 孙珊, 金晓杰, 于潇潇, 等. 海水淡化发展利用状况分析与启示[J]. 工业水处理, 2022, 42(2): 45-50. |

| Sun S, Jin X J, Yu X X, et al. Analysis and enlightenment on development and utilization of seawater desalination[J]. Industrial Water Treatment, 2022, 42(2): 45-50. | |

| 8 | 张金菊. 海水淡化的重要性及其淡化方法[J]. 山西化工, 2018, 38(6): 94-96. |

| Zhang J J. Significance of seawater desalination and desalination methods[J]. Shanxi Chemical Industry, 2018, 38(6): 94-96. | |

| 9 | 袁洋, 张丹, 贾金睿, 等. 热辐射加热液滴能量传递过程的研究[J]. 西安交通大学学报, 2023, 57(2): 131-140. |

| Yuan Y, Zhang D, Jia J R, et al. Study on energy transfer process of droplets heated by thermal radiation[J]. Journal of Xi'an Jiaotong University, 2023, 57(2): 131-140. | |

| 10 | 成怀刚, 高从堦. 喷雾蒸发海水淡化技术研究进展[J]. 现代化工, 2008, 28(6): 19-22, 24. |

| Cheng H G, Gao C J. Progress in spray evaporation desalination technology[J]. Modern Chemical Industry, 2008, 28(6): 19-22, 24. | |

| 11 | 陈磊, 费学宁, 季民, 等. 喷雾蒸发处理浓盐水分离效率研究[J]. 中国给水排水, 2015, 31(5): 96-99, 104. |

| Chen L, Fei X N, Ji M, et al. Study on separation efficiency of concentrated brine in spray evaporation process[J]. China Water & Wastewater, 2015, 31(5): 96-99, 104. | |

| 12 | 陈华, 程文龙, 章玮玮. 喷雾参数对闪蒸冷却换热效果影响的数值研究[J]. 工程热物理学报, 2016, 37(2): 361-365. |

| Chen H, Cheng W L, Zhang W W. Numerical study on the effect of spray parameters on heat transfer performance of vacuum flash evaporation cooling[J]. Journal of Engineering Thermophysics, 2016, 37(2): 361-365. | |

| 13 | 蔡本安, 李石磊, 郭民承, 等. 基于液滴分析的高温高压流体喷射闪蒸模型研究[J]. 原子能科学技术, 2021, 55(9): 1709-1720. |

| Cai B A, Li S L, Guo M C, et al. Modeling of spray flash evaporation under high temperature and high pressure based on droplet analysis[J]. Atomic Energy Science and Technology, 2021, 55(9): 1709-1720. | |

| 14 | 梁婷, 张丹, 杨庆忠, 等. 纯水静态闪蒸起始阶段气泡群时空分布规律的实验研究[J]. 化工学报, 2019, 70(1): 49-55. |

| Liang T, Zhang D, Yang Q Z, et al. Experimental study on temporal and spatial distribution of bubbles during initial stage of static flash of pure water[J]. CIESC Journal, 2019, 70(1): 49-55. | |

| 15 | Peter E M, Takimoto A, Hayashi Y. Flashing and shattering phenomena of superheated liquid jets[J]. JSME International Journal Series B, 1994, 37(2): 313-321. |

| 16 | Mutair S, Ikegami Y. Experimental study on flash evaporation from superheated water jets: influencing factors and formulation of correlation[J]. International Journal of Heat and Mass Transfer, 2009, 52(23/24): 5643-5651. |

| 17 | Mutair S, Ikegami Y. Experimental investigation on the characteristics of flash evaporation from superheated water jets for desalination[J]. Desalination, 2010, 251(1/2/3): 103-111. |

| 18 | Xiong P, He S H, Qiu F C, et al. Experimental and mathematical study on jet atomization and flash evaporation characteristics of droplets in a depressurized environment[J]. Journal of the Taiwan Institute of Chemical Engineers, 2021, 123: 185-198. |

| 19 | 季璨, 王乃华, 崔峥, 等. Jakob数在高温高压闪蒸过程中的作用及影响[J]. 化工学报, 2016, 67(10): 4153-4159. |

| Ji C, Wang N H, Cui Z, et al. Role and influence of characteristic Jakob number in high-temperature and high-pressure flash evaporation process[J]. CIESC Journal, 2016, 67(10): 4153-4159. | |

| 20 | Ikegami Y, Sasaki H, Gouda T, et al. Experimental study on a spray flash desalination (influence of the direction of injection)[J]. Desalination, 2006, 194(1/2/3): 81-89. |

| 21 | Liu L, Bi Q C, Li H X. Experimental investigation on flash evaporation of saltwater droplets released into vacuum[J]. Microgravity Science and Technology, 2009, 21(1): 255-260. |

| 22 | 刘璐, 王茉, 刘琰, 等. 盐水液滴降压蒸发析盐过程传热传质特性[J]. 化工学报, 2015, 66(7): 2426-2432. |

| Liu L, Wang M, Liu Y, et al. Heat and mass transfer characteristics of evaporation and salt crystallization process of a saline droplet during depressurization[J]. CIESC Journal, 2015, 66(7): 2426-2432. | |

| 23 | Lubarsky E, Reichel J R, Zinn B T, et al. Spray in crossflow: dependence on Weber number[J]. Journal of Engineering for Gas Turbines and Power, 2010, 132(2): 481-492. |

| 24 | Bai B F, Sun H J, Zhang H B, et al. Numerical study on turbulent mixing of spray droplets in crossflow[J]. Journal of Propulsion and Power, 2011, 27(1): 132-143. |

| 25 | Bai B F, Zhang H B, Liu L, et al. Experimental study on turbulent mixing of spray droplets in crossflow[J]. Experimental Thermal and Fluid Science, 2009, 33(6): 1012-1020. |

| 26 | 张海滨, 白博峰, 刘利, 等. 受限空间内空心锥形喷雾-横流掺混规律[J]. 化工学报, 2012, 63(5): 1354-1359. |

| Zhang H B, Bai B F, Liu L, et al. Mixing characteristics of hollow cone spray with confined crossflow[J]. CIESC Journal, 2012, 63(5): 1354-1359. | |

| 27 | 孙慧娟, 张海滨, 白博峰. 雾化锥角对喷雾在横流中蒸发掺混的影响[J]. 固体火箭技术, 2013, 36(1): 50-55. |

| Sun H J, Zhang H B, Bai B F. Effect of spray angle on mixing of evaporating spray in crossflow[J]. Journal of Solid Rocket Technology, 2013, 36(1): 50-55. | |

| 28 | 孙慧娟, 白博峰, 张海滨, 等. 喷嘴入射方式对气体-液滴群掺混的影响[J]. 固体火箭技术, 2009, 32(5): 492-495, 510. |

| Sun H J, Bai B F, Zhang H B, et al. Effect of different injection angles on gas-droplets two-phase flow mixing characteristics[J]. Journal of Solid Rocket Technology, 2009, 32(5): 492-495, 510. | |

| 29 | 孙凤贤, 杨金, 刘昌宇, 等. 高温气流中液滴蒸发的表面张力效应[J]. 工程热物理学报, 2016, 37(1): 176-179. |

| Sun F X, Yang J, Liu C Y, et al. Effects of surface tension on droplet evaporation in high temperature airflow[J]. Journal of Engineering Thermophysics, 2016, 37(1): 176-179. | |

| 30 | Moffat R J. Contributions to the theory of single-sample uncertainty analysis[J]. Journal of Fluids Engineering, 1982, 104(2): 250-258. |

| 31 | Zhou Z F, Yin J, Yang X Y, et al. Experimental investigation on the macroscopic spray and microscopic droplet diameter, velocity and temperature of R404A flashing spray[J]. International Journal of Heat and Mass Transfer, 2021, 177: 121546. |

| 32 | Zhu X L, Song Z Y, Pan X H, et al. Morphological characteristics of flashing jet throughout superheated liquid release[J]. Journal of Loss Prevention in the Process Industries, 2020, 66: 104163. |

| 33 | 车得福, 李会雄. 多相流及其应用[M]. 西安: 西安交通大学出版社, 2007. |

| Che D F, Li H X. Multiphase Flow and Its Application[M]. Xi'an: Xi'an Jiaotong University Press, 2007. | |

| 34 | Guildenbecher D R, López-Rivera C, Sojka P E. Secondary atomization[J]. Experiments in Fluids, 2009, 46(3): 371-402. |

| 35 | Francke H, Thorade M. Density and viscosity of brine: an overview from a process engineers perspective[J]. Geochemistry, 2010, 70: 23-32. |

| [1] | 吴馨, 龚建英, 靳龙, 王宇涛, 黄睿宁. 超声波激励下铝板表面液滴群输运特性的研究[J]. 化工学报, 2023, 74(S1): 104-112. |

| [2] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [3] | 毕丽森, 刘斌, 胡恒祥, 曾涛, 李卓睿, 宋健飞, 吴翰铭. 粗糙界面上纳米液滴蒸发模式的分子动力学研究[J]. 化工学报, 2023, 74(S1): 172-178. |

| [4] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [5] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [6] | 张化福, 童莉葛, 张振涛, 杨俊玲, 王立, 张俊浩. 机械蒸汽压缩蒸发技术研究现状与发展趋势[J]. 化工学报, 2023, 74(S1): 8-24. |

| [7] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [8] | 宋瑞涛, 王派, 王云鹏, 李敏霞, 党超镔, 陈振国, 童欢, 周佳琦. 二氧化碳直接蒸发冰场排管内流动沸腾换热数值模拟分析[J]. 化工学报, 2023, 74(S1): 96-103. |

| [9] | 何宣志, 何永清, 闻桂叶, 焦凤. 磁液液滴颈部自相似破裂行为[J]. 化工学报, 2023, 74(7): 2889-2897. |

| [10] | 董明, 徐进良, 刘广林. 超临界水非均质特性分子动力学研究[J]. 化工学报, 2023, 74(7): 2836-2847. |

| [11] | 郑志航, 马郡男, 闫子涵, 卢春喜. 提升管射流影响区内压力脉动特性研究[J]. 化工学报, 2023, 74(6): 2335-2350. |

| [12] | 张媛媛, 曲江源, 苏欣欣, 杨静, 张锴. 循环流化床燃煤机组SNCR脱硝过程气液传质和反应特性[J]. 化工学报, 2023, 74(6): 2404-2415. |

| [13] | 李正涛, 袁志杰, 贺高红, 姜晓滨. 疏水界面上的NaCl液滴蒸发过程内环流调控机制研究[J]. 化工学报, 2023, 74(5): 1904-1913. |

| [14] | 张伟政, 赵吉军, 马学忠, 张琦璇, 庞益祥, 张俊涛. 湍流效应对高速机械密封端面型槽冷却性能影响分析[J]. 化工学报, 2023, 74(3): 1228-1238. |

| [15] | 李新亚, 邢雷, 蒋明虎, 赵立新. 倒锥注气强化井下油水分离水力旋流器性能研究[J]. 化工学报, 2023, 74(3): 1134-1144. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号