化工学报 ›› 2023, Vol. 74 ›› Issue (5): 1982-1999.DOI: 10.11949/0438-1157.20230006

收稿日期:2023-01-04

修回日期:2023-04-18

出版日期:2023-05-05

发布日期:2023-06-29

通讯作者:

董航

作者简介:赵健(1986—),男,博士,副教授, zhaojian_nepu@163.com

基金资助:

Jian ZHAO1,3( ), Xingchao ZHOU1,3, Dan XIA2, Hang DONG1,3(

), Xingchao ZHOU1,3, Dan XIA2, Hang DONG1,3( )

)

Received:2023-01-04

Revised:2023-04-18

Online:2023-05-05

Published:2023-06-29

Contact:

Hang DONG

摘要:

以射流加热和机械搅拌协同作用下,大型浮顶储油罐内的传热和流动过程为研究对象构建物理和数学模型,并采用滑移网格技术对搅拌叶轮作用区域建模,基于有限体积法对强、弱浮力射流加热过程的流动和传热规律进行了数值模拟研究。结果表明:相比强浮力射流,弱浮力射流加热时的升温速率可提升74%,达到相同温度所需的加热时间缩短42%。对于强浮力射流加热过程,增加机械搅拌可以使计算域内的整体速度显著升高,加强冷热介质间的热交换,使升温速率提高9.6%,也可令计算域内的油温分布更加均匀,温度方差降低17%。对于弱浮力射流加热过程,增加搅拌作用虽仅可令升温速率提高0.9%,但可使温度方差降低29%。机械搅拌对强浮力射流加热时的升温速率提升更显著,而对弱浮力射流加热时促使温度均匀分布的效果更显著,同时发现机械搅拌可使强浮力射流的加热效率提升0.7%。此外,进一步研究发现搅拌器的安装高度对于消除实际储罐底部的低温区域、调控油温分布具有重要作用,数值模拟结果可以为机械搅拌器的结构设计提供重要的参考依据。

中图分类号:

赵健, 周兴超, 夏丹, 董航. 机械搅拌对原油储罐射流加热过程传热特性的影响规律研究[J]. 化工学报, 2023, 74(5): 1982-1999.

Jian ZHAO, Xingchao ZHOU, Dan XIA, Hang DONG. Study on influence of mechanical stirring on heat transfer characteristics during jet heating of crude oil storage tank[J]. CIESC Journal, 2023, 74(5): 1982-1999.

| 固体介质 | 密度/(kg/m3) | 热导率/ (W/(m·℃)) | 比热容/(J/(kg·℃)) |

|---|---|---|---|

| 罐顶及空气层 | 1.225 | 1.05 | 1006 |

| 罐壁保温层 | 60 | 0.055 | 800 |

| 罐底土壤 | 1600 | 1.74 | 1750 |

表1 边界材料相关物性参数

Table 1 Relevant physical parameters of boundary materials

| 固体介质 | 密度/(kg/m3) | 热导率/ (W/(m·℃)) | 比热容/(J/(kg·℃)) |

|---|---|---|---|

| 罐顶及空气层 | 1.225 | 1.05 | 1006 |

| 罐壁保温层 | 60 | 0.055 | 800 |

| 罐底土壤 | 1600 | 1.74 | 1750 |

| 参数 | 数值 |

|---|---|

| 罐体高度/m | 5 |

| 罐体直径/m | 12 |

| 射流加热管直径/mm | 219 |

| 喷嘴高度/mm | 160 |

| 弯管直径/mm | 70 |

| 转弯半径/mm | 50 |

| 喷嘴直径/mm | 40 |

| 喷嘴数量 | 6 |

| 弯管角度/(°) | 45 |

| 叶轮直径/mm | 500 |

| 叶轮高度/mm | 750 |

| 射流加热管高度/mm | 600 |

表2 模型建立参数

Table 2 Model establishment parameters

| 参数 | 数值 |

|---|---|

| 罐体高度/m | 5 |

| 罐体直径/m | 12 |

| 射流加热管直径/mm | 219 |

| 喷嘴高度/mm | 160 |

| 弯管直径/mm | 70 |

| 转弯半径/mm | 50 |

| 喷嘴直径/mm | 40 |

| 喷嘴数量 | 6 |

| 弯管角度/(°) | 45 |

| 叶轮直径/mm | 500 |

| 叶轮高度/mm | 750 |

| 射流加热管高度/mm | 600 |

| 网格系统编号 | 最小网格尺寸/mm | 最大网格尺寸/mm | 网格增长率 | 网格数量/个 | 计算时间/h |

|---|---|---|---|---|---|

| 1 | 4 | 220 | 1.2 | 401249 | 1.38 |

| 2 | 3 | 180 | 1.2 | 1188348 | 2.78 |

| 3 | 2 | 150 | 1.2 | 1986504 | 3.48 |

| 4 | 1 | 130 | 1.2 | 2548828 | 4.08 |

| 5 | 0.5 | 110 | 1.2 | 3276792 | 4.83 |

表3 不同网格设计方案

Table 3 Different grid design schemes

| 网格系统编号 | 最小网格尺寸/mm | 最大网格尺寸/mm | 网格增长率 | 网格数量/个 | 计算时间/h |

|---|---|---|---|---|---|

| 1 | 4 | 220 | 1.2 | 401249 | 1.38 |

| 2 | 3 | 180 | 1.2 | 1188348 | 2.78 |

| 3 | 2 | 150 | 1.2 | 1986504 | 3.48 |

| 4 | 1 | 130 | 1.2 | 2548828 | 4.08 |

| 5 | 0.5 | 110 | 1.2 | 3276792 | 4.83 |

| 序号 | 距罐中心 距离/mm | 距罐底 距离/mm | 数值模拟温度/℃ | 实际测量温度/℃ | 相对 偏差/% |

|---|---|---|---|---|---|

| 1 | 0 | 10 | 27.150 | 28.9 | 6.06 |

| 2 | 0 | 30 | 27.856 | 28.3 | 1.57 |

| 3 | 0 | 130 | 27.899 | 28.0 | 0.36 |

| 4 | 0 | 200 | 27.921 | 28.4 | 1.69 |

| 5 | 0 | 270 | 28.356 | 29.7 | 4.53 |

| 6 | 150 | 10 | 27.350 | 28.1 | 2.67 |

| 7 | 150 | 30 | 27.279 | 27.8 | 1.87 |

| 8 | 150 | 130 | 27.269 | 28.3 | 3.64 |

| 9 | 150 | 200 | 27.451 | 28.2 | 2.66 |

| 10 | 150 | 270 | 27.945 | 29.6 | 5.59 |

| 11 | 260 | 10 | 27.153 | 28.4 | 4.39 |

| 12 | 260 | 30 | 27.494 | 28.1 | 2.16 |

| 13 | 260 | 130 | 27.656 | 28.5 | 2.96 |

| 14 | 260 | 200 | 28.110 | 28.6 | 1.71 |

| 15 | 260 | 270 | 29.157 | 29.8 | 2.16 |

| 16 | 380 | 10 | 27.025 | 28.1 | 3.83 |

| 17 | 380 | 30 | 27.980 | 28.2 | 0.78 |

| 18 | 380 | 130 | 28.098 | 28.5 | 1.41 |

| 19 | 380 | 200 | 28.021 | 28.1 | 0.28 |

| 20 | 380 | 270 | 27.081 | 29.2 | 7.26 |

表4 实验与数值模拟下温度数据对比

Table 4 Comparison of temperature data under experiment and numerical simulation

| 序号 | 距罐中心 距离/mm | 距罐底 距离/mm | 数值模拟温度/℃ | 实际测量温度/℃ | 相对 偏差/% |

|---|---|---|---|---|---|

| 1 | 0 | 10 | 27.150 | 28.9 | 6.06 |

| 2 | 0 | 30 | 27.856 | 28.3 | 1.57 |

| 3 | 0 | 130 | 27.899 | 28.0 | 0.36 |

| 4 | 0 | 200 | 27.921 | 28.4 | 1.69 |

| 5 | 0 | 270 | 28.356 | 29.7 | 4.53 |

| 6 | 150 | 10 | 27.350 | 28.1 | 2.67 |

| 7 | 150 | 30 | 27.279 | 27.8 | 1.87 |

| 8 | 150 | 130 | 27.269 | 28.3 | 3.64 |

| 9 | 150 | 200 | 27.451 | 28.2 | 2.66 |

| 10 | 150 | 270 | 27.945 | 29.6 | 5.59 |

| 11 | 260 | 10 | 27.153 | 28.4 | 4.39 |

| 12 | 260 | 30 | 27.494 | 28.1 | 2.16 |

| 13 | 260 | 130 | 27.656 | 28.5 | 2.96 |

| 14 | 260 | 200 | 28.110 | 28.6 | 1.71 |

| 15 | 260 | 270 | 29.157 | 29.8 | 2.16 |

| 16 | 380 | 10 | 27.025 | 28.1 | 3.83 |

| 17 | 380 | 30 | 27.980 | 28.2 | 0.78 |

| 18 | 380 | 130 | 28.098 | 28.5 | 1.41 |

| 19 | 380 | 200 | 28.021 | 28.1 | 0.28 |

| 20 | 380 | 270 | 27.081 | 29.2 | 7.26 |

| 工况 | 搅拌速度/(r/min) | 初始温度/℃ | 射流温度/℃ | 射流速度/(m/s) | Fr | M0 | B0 | 射流类型 |

|---|---|---|---|---|---|---|---|---|

| 1 | 0 | 40 | 70 | 0.1 | 0.63 | 1.26×10-5 | 2.94×10-5 | 强浮力 |

| 2 | 350 | 40 | 70 | 0.1 | 0.63 | 1.26×10-5 | 2.94×10-5 | 强浮力 |

| 3 | 0 | 40 | 50 | 1.0 | 10.3 | 1.26×10-3 | 7.72×10-4 | 弱浮力 |

| 4 | 350 | 40 | 50 | 1.0 | 10.3 | 1.26×10-3 | 7.72×10-4 | 弱浮力 |

表5 模拟工况参数

Table 5 Parameters of simulated working conditions

| 工况 | 搅拌速度/(r/min) | 初始温度/℃ | 射流温度/℃ | 射流速度/(m/s) | Fr | M0 | B0 | 射流类型 |

|---|---|---|---|---|---|---|---|---|

| 1 | 0 | 40 | 70 | 0.1 | 0.63 | 1.26×10-5 | 2.94×10-5 | 强浮力 |

| 2 | 350 | 40 | 70 | 0.1 | 0.63 | 1.26×10-5 | 2.94×10-5 | 强浮力 |

| 3 | 0 | 40 | 50 | 1.0 | 10.3 | 1.26×10-3 | 7.72×10-4 | 弱浮力 |

| 4 | 350 | 40 | 50 | 1.0 | 10.3 | 1.26×10-3 | 7.72×10-4 | 弱浮力 |

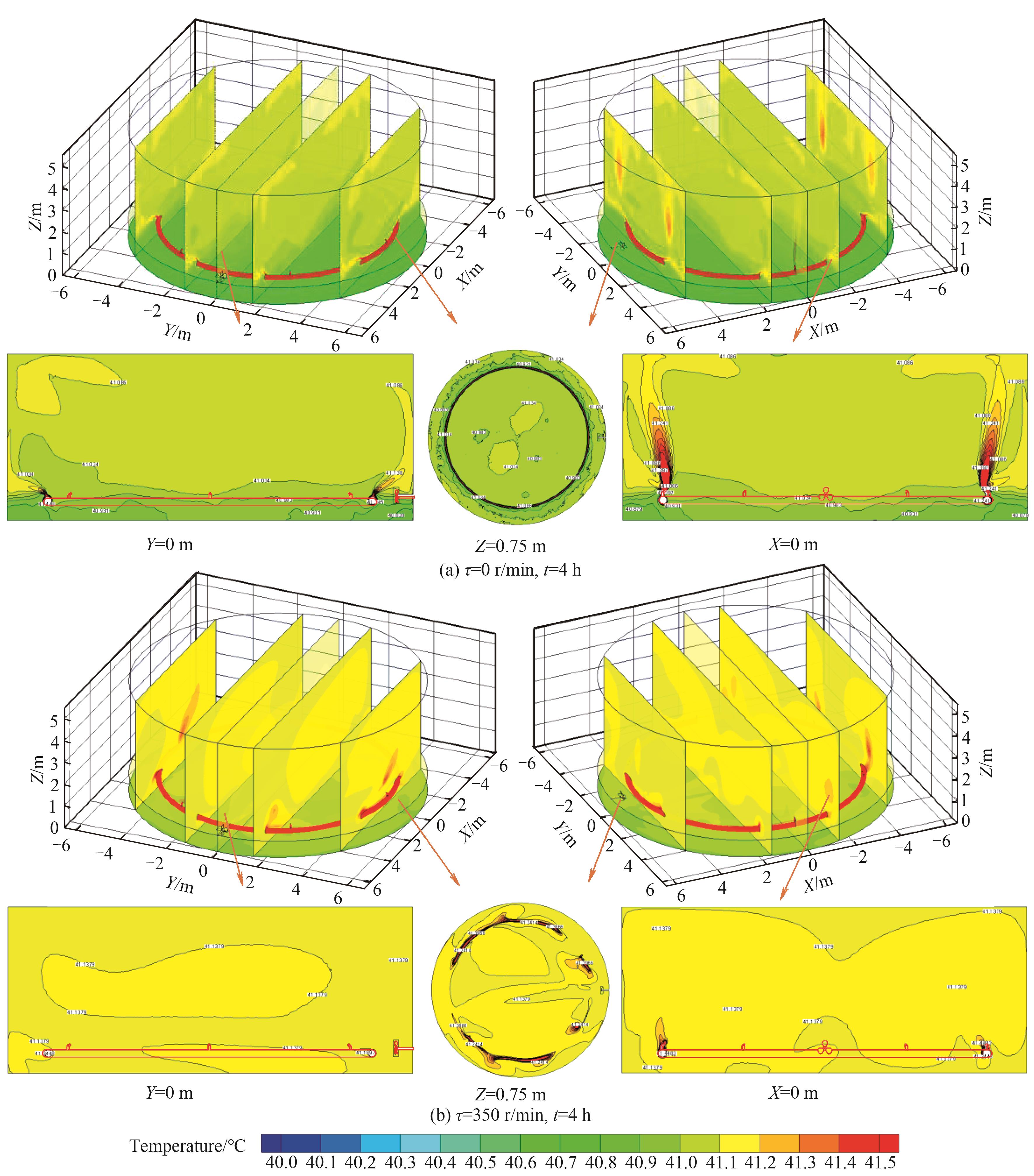

图6 t=4 h时有无机械搅拌的强浮力射流加热过程三维温度场对比

Fig.6 Comparison of the three-dimensional temperature field at t=4 h during heating of a strong buoyant jet with or without mechanical stirring

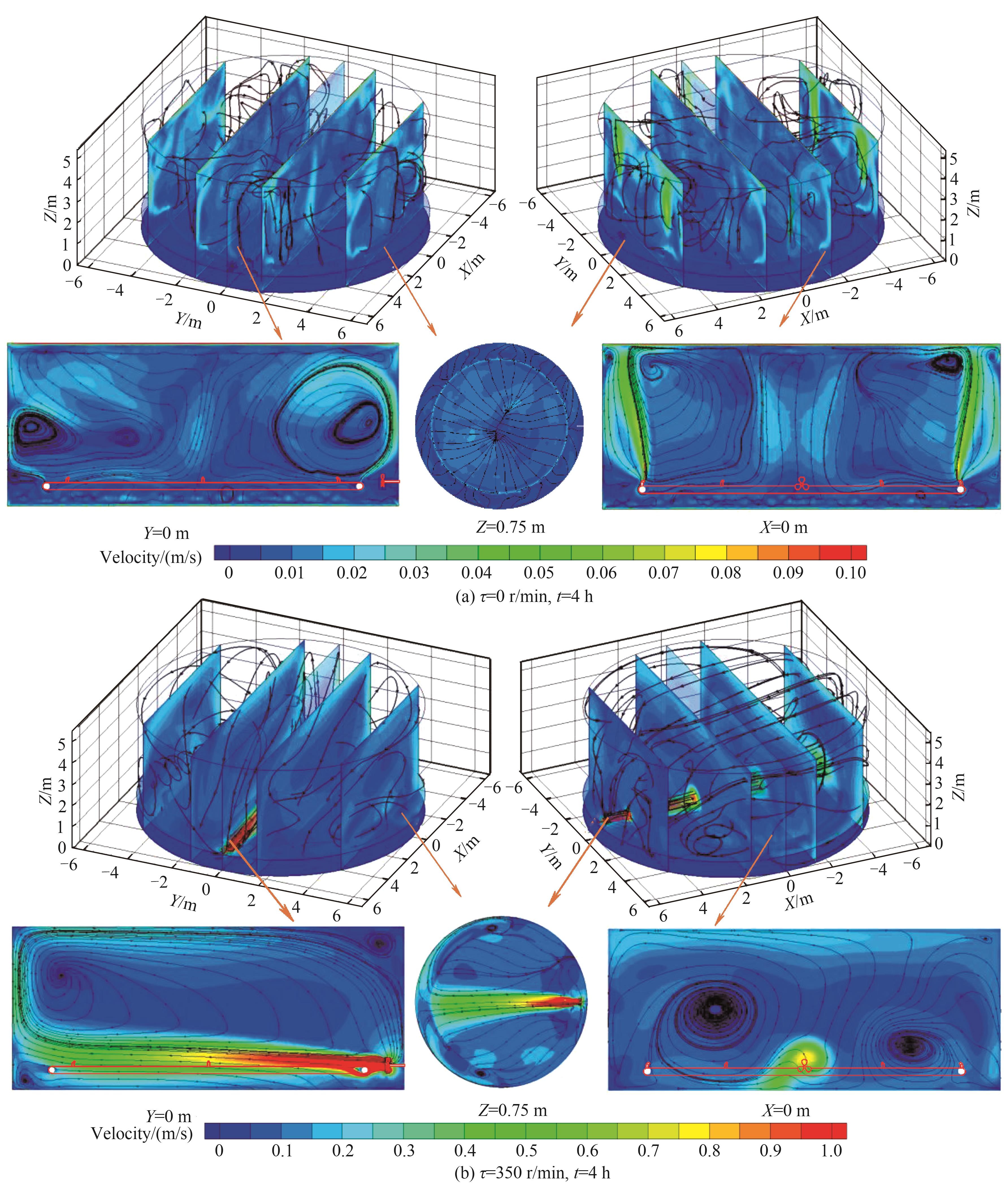

图7 t=4 h时有无机械搅拌的强浮力射流加热过程三维速度场对比

Fig.7 Comparison of the three-dimensional velocity field at t=4 h during heating of a strong buoyant jet with or without mechanical stirring

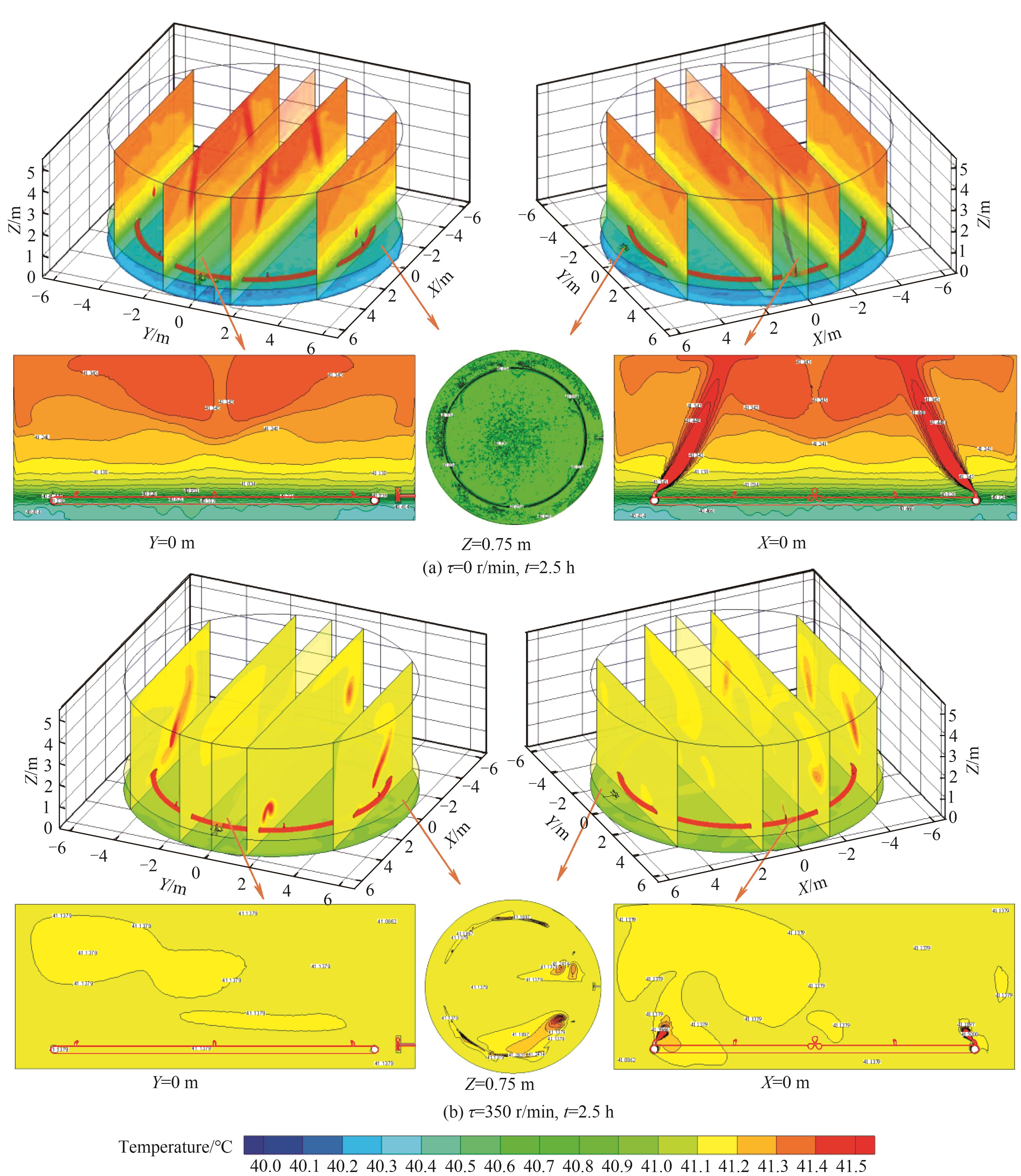

图10 t=2.5 h时有无机械搅拌的弱浮力射流加热过程三维温度场对比

Fig.10 Comparison of the three-dimensional temperature field at t=2.5 h during heating of a weak buoyant jet with or without mechanical stirring

图11 t=2.5 h时有无机械搅拌的弱浮力射流加热过程三维速度场对比

Fig.11 Comparison of the three-dimensional velocity field at t=2.5 h during heating of a weak buoyant jet with or without mechanical stirring

| 1 | 张庆辰, 任洪涛, 仇玄. 国际原油市场2022年上半年回顾和下半年展望[J]. 油气与新能源, 2022, 34(5): 46-52. |

| Zhang Q C, Ren H T, Qiu X. Review of international crude oil market in the first half of 2022 and prospect in the second half of 2022[J]. Petroleum and New Energy, 2022, 34(5): 46-52. | |

| 2 | Zhao J, Xi X R, Dong H, et al. Rheo-microscopy in situ synchronous measurement of shearing thinning behaviors of waxy crude oil[J]. Fuel, 2022, 323: 124427. |

| 3 | Zhao J, Zhao W Q, Dong H, et al. New approach for the in situ microscopic observation of wax crystals in waxy crude oil during quiescent and dynamic cooling[J]. ACS Omega, 2020, 5(20): 11491-11506. |

| 4 | 刘俊阳. 原油储罐射流加热过程的传热规律研究[D]. 大庆: 东北石油大学, 2021. |

| Liu J Y. Study on heat transfer law of jet heating process in crude oil storage tank[D]. Daqing: Northeast Petroleum University, 2021. | |

| 5 | Zhao J, Wei L X, Dong H, et al. Research on heat transfer characteristic for hot oil spraying heating process in crude oil tank[J]. Case Studies in Thermal Engineering, 2016, 7: 109-119. |

| 6 | 赵健. 高寒地区原油储存过程中的传热问题研究及工艺方案优化[D]. 大庆: 东北石油大学, 2013. |

| Zhao J. Study on heat transfer during crude oil storage in alpine region and optimization of process scheme[D]. Daqing: Northeast Petroleum University, 2013. | |

| 7 | 曾玉红, 槐文信. 静止环境中垂直平面浮力射流稳定性与混合特性数值研究[J]. 水利学报, 2004, 35(9): 56-62. |

| Zeng Y H, Huai W X. Numerical study on stability and mixing characteristics of vertical plane buoyant jet in confined depth[J]. Journal of Hydraulic Engineering, 2004, 35(9): 56-62. | |

| 8 | Huai W X, Zeng Y H. Similarity solutions of vertical plane wall plume based on finite analytic method[J]. Applied Mathematics and Mechanics, 2007, 28(4): 447-454. |

| 9 | 曾玉红. 静止浅水环境中浮力射流稳定性与混合特性研究[D]. 武汉: 武汉大学, 2005. |

| Zeng Y H. Study on stability and mixing characteristics of buoyant jet in static shallow water environment[D]. Wuhan: Wuhan University, 2005. | |

| 10 | 曾玉红, 槐文信. 静止环境中水平圆形浮力射流流动特性研究[J]. 华中科技大学学报(自然科学版), 2005, 33(11): 90-92. |

| Zeng Y H, Huai W X. Characters of horizontal round buoyant jets in quiescent shallow water[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition), 2005, 33(11): 90-92. | |

| 11 | 张健, 杨立, 张士成, 等. 流动环境中水平热射流温度分布特性研究[J]. 华中科技大学学报(自然科学版), 2011, 39(8): 62-66. |

| Zhang J, Yang L, Zhang S C, et al. Temperature characteristic of horizontal heated water jets in the flow[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition), 2011, 39(8): 62-66. | |

| 12 | Fukushima Y. Analysis of inclined wall plume by turbulence model[J]. Doboku Gakkai Ronbunshu, 1988, 1988(399): 65-74. |

| 13 | 刘立烨, 孟凡力, 王卫强, 等. 搅拌器在原油储罐中的应用与发展[J]. 当代化工, 2015, 44(2): 386-388, 396. |

| Liu L Y, Meng F L, Wang W Q, et al. Application and development of the agitator in crude oil storage tanks[J]. Contemporary Chemical Industry, 2015, 44(2): 386-388, 396. | |

| 14 | Tokura Y, Miyagawa K, Uddin M A, et al. Suspension pattern and rising height of sedimentary particles with low concentration in a mechanically stirred vessel[J]. The Canadian Journal of Chemical Engineering, 2021, 99(1): 410-420. |

| 15 | 周李渊, 王玉刚, 杨忠民. 浮顶罐搅拌器转速对原油加热效率的影响[J]. 油气储运, 2021, 40(7): 773-779. |

| Zhou L Y, Wang Y G, Yang Z M. Effect of rotational speed of a floating-roof tank mixer on heating efficiency of crude oil[J]. Oil & Gas Storage and Transportation, 2021, 40(7): 773-779. | |

| 16 | Rahimi M, Parvareh A. CFD study on mixing by coupled jet-impeller mixers in a large crude oil storage tank[J]. Computers & Chemical Engineering, 2007, 31(7): 737-744. |

| 17 | Rahimi M. The effect of impellers layout on mixing time in a large-scale crude oil storage tank[J]. Journal of Petroleum Science and Engineering, 2005, 46(3): 161-170. |

| 18 | Grenville R K, Giacomelli J J, VanOmmeren G J, et al. Blending in above ground storage tanks with side-entering agitators[J]. Chemical Engineering Research and Design, 2018, 137: 395-402. |

| 19 | 王敏. 含蜡原油储罐内复杂传热规律的数值计算研究[D]. 北京: 中国石油大学(北京), 2017. |

| Wang M. Numerical study on complex heat transfer law in waxy crude oil storage tank[D]. Beijing: China University of Petroleum, 2017. | |

| 20 | Zhao J, Liu J Y, Dong H, et al. Effect of physical properties on the heat transfer characteristics of waxy crude oil during its static cooling process[J]. International Journal of Heat and Mass Transfer, 2019, 137: 242-262. |

| 21 | Zhao J, Liu J Y, Dong H, et al. Numerical investigation on the flow and heat transfer characteristics of waxy crude oil during the tubular heating[J]. International Journal of Heat and Mass Transfer, 2020, 161: 120239. |

| 22 | Zhao J, Dong H, Wang X L, et al. Research on heat transfer characteristic of crude oil during the tubular heating process in the floating roof tank[J]. Case Studies in Thermal Engineering, 2017, 10: 142-153. |

| 23 | 陈允仁. 油气储运建设工程手册: 设计·预概算·施工·管理[M]. 北京: 中国建筑工业出版社, 1999: 249. |

| Chen Y R. Handbook of Oil and Gas Storage and Transportation Construction Engineering: Design, Budget, Construction and Management[M]. Beijing: China Architecture & Building Press, 1999: 249. | |

| 24 | Zhao J, Xi X R, Dong H, et al. In situ observation of microscopic motions and the structure dynamic transformation of wax crystals in waxy crude oil subjected to shear[J]. New Journal of Chemistry, 2021, 45(37): 17522-17543. |

| 25 | Zhang D, Liu S, Zhang J, et al. Rheological properties of heavy crude oil containing sand from Bo-hai oilfield in China[J]. Applied Rheology, 2017, 27(2): 10-18. |

| 26 | Li Y H, Zhao J, Dong H, et al. The role of shearing effect in the evolution of the microscopic behavior of wax crystals[J]. New Journal of Chemistry, 2021, 45(23): 10418-10431. |

| 27 | Wang M, Yu B, Zhang X Y, et al. Experimental and numerical study on the heat transfer characteristics of waxy crude oil in a 100,000 m3 double-plate floating roof oil tank[J]. Applied Thermal Engineering, 2018, 136: 335-348. |

| 28 | Liu J Y, Zhao J, Si M L, et al. The effect of periodic change of external temperature on the temperature field of crude oil[J]. Case Studies in Thermal Engineering, 2019, 15: 100526. |

| 29 | Liu J Y, Zhao J, Si M L, et al. Effect of periodic change of ambient temperature on the temperature field in the single disc floating roof oil tank[J]. Journal of Applied Science and Engineering, 2020, 23(1): 129-142. |

| 30 | Sun W, Cheng Q L, Zheng A B, et al. Heat flow coupling characteristics analysis and heating effect evaluation study of crude oil in the storage tank different structure coil heating processes[J]. International Journal of Heat and Mass Transfer, 2018, 127: 89-101. |

| 31 | 王琪, 苗琳, 陈良, 等. 局部高热流密度器件射流冲击冷板流动传热特性数值研究[J]. 西安交通大学学报, 2023, 57(2): 90-99. |

| Wang Q, Miao L, Chen L, et al. Numerical study on flow and heat transfer characteristics of jet impinging on cold plate of local high heat flux device[J]. Journal of Xi'an Jiaotong University, 2023, 57(2): 90-99. | |

| 32 | Panchal S, Gudlanarva K, Tran M K, et al. Numerical simulation of cooling plate using κ-ε turbulence model to cool down large-sized graphite/LiFePO4 battery at high C-rates[J]. World Electric Vehicle Journal, 2022, 13(8): 138. |

| 33 | Joshi J B, Nere N K, Rane C V, et al. CFD simulation of stirred tanks: comparison of turbulence models (Ⅰ): Radial flow impellers[J]. The Canadian Journal of Chemical Engineering, 2011, 89(1): 23-82. |

| 34 | Tepe A Ü, Yetişken Y, Uysal Ü, et al. Experimental and numerical investigation of jet impingement cooling using extended jet holes[J]. International Journal of Heat and Mass Transfer, 2020, 158: 119945. |

| 35 | 孟辉波, 蒙彤, 禹言芳, 等. Ross LPD型静态混合器内湍流传热与混合强化特性[J]. 化工学报, 2022, 73(8): 3541-3552. |

| Meng H B, Meng T, Yu Y F, et al. Turbulent heat transfer and mixing enhancement characteristics in Ross LPD static mixer[J]. CIESC Journal, 2022, 73(8): 3541-3552. | |

| 36 | 王福军. 计算流体动力学分析: CFD软件原理与应用[M]. 北京: 清华大学出版社, 2004: 113-142. |

| Wang F J. Computational Fluid Dynamics Analysis: Principle and Application of CFD Software[M]. Beijing: Tsinghua University Press, 2004: 113-142. | |

| 37 | 陶文铨. 数值传热学[M]. 2版. 西安: 西安交通大学出版社, 2001: 333-370. |

| Tao W Q. Numerical Heat Transfer[M]. 2nd ed. Xi'an: Xi'an Jiaotong University Press, 2001: 333-370. | |

| 38 | 李昆鹏, 魏成柱, 梁晓锋. 多面体网格在滑行艇数值仿真计算中的应用[J]. 舰船科学技术, 2020, 42(3): 33-37. |

| Li K P, Wei C Z, Liang X F. Application of polyhedral mesh in numerical simulations of planing hulls[J]. Ship Science and Technology, 2020, 42(3): 33-37. | |

| 39 | 胡龙兵. 滑移网格下核主泵流场的数值研究[D]. 杭州: 浙江大学, 2013. |

| Hu L B. Numerical study on flow field of nuclear main pump under sliding grid[D]. Hangzhou: Zhejiang University, 2013. | |

| 40 | 李彦静, 陈科, 胡天群, 等. 高密度弗劳德数热浮力射流特性实验[J]. 华中科技大学学报(自然科学版), 2017, 45(12): 91-95. |

| Li Y J, Chen K, Hu T Q, et al. Experiments on characteristics of thermal buoyant jets with high density Froude numbers[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition), 2017, 45(12): 91-95. |

| [1] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [2] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [3] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [4] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [5] | 宋瑞涛, 王派, 王云鹏, 李敏霞, 党超镔, 陈振国, 童欢, 周佳琦. 二氧化碳直接蒸发冰场排管内流动沸腾换热数值模拟分析[J]. 化工学报, 2023, 74(S1): 96-103. |

| [6] | 周绍华, 詹飞龙, 丁国良, 张浩, 邵艳坡, 刘艳涛, 郜哲明. 短管节流阀内流动噪声的实验研究及降噪措施[J]. 化工学报, 2023, 74(S1): 113-121. |

| [7] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [8] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [9] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [10] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [11] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [12] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [13] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| [14] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [15] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号