化工学报 ›› 2023, Vol. 74 ›› Issue (10): 4173-4181.DOI: 10.11949/0438-1157.20230629

收稿日期:2023-06-26

修回日期:2023-09-07

出版日期:2023-10-25

发布日期:2023-12-22

通讯作者:

杨阿三

作者简介:章蕾(1999—),女,硕士研究生,384580545@qq.com

Lei ZHANG( ), Xiaohui SONG, Jianting ZHANG, Meiling TU, Asan YANG(

), Xiaohui SONG, Jianting ZHANG, Meiling TU, Asan YANG( )

)

Received:2023-06-26

Revised:2023-09-07

Online:2023-10-25

Published:2023-12-22

Contact:

Asan YANG

摘要:

反式氨甲环酸(trans-TXA)作为氨甲环酸异构体中主要的活性组分具有凝血功能而在医药工业被广泛应用,其合成主要通过顺式氨甲环酸(cis-TXA)异构化得到。采用第一性原理模拟计算得到异构化反应焓变、Gibbs自由能和反应过程的结构变化等理论数据。再以实验考察453.15~513.15 K下,cis-TXA异构化成trans-TXA的反应过程,获得了反应动力学数据:正反应活化能64.9 kJ∙mol-1、指前因子2.15×105 s-1;逆反应活化能53.8 kJ∙mol-1、指前因子4.72×103 s-1;反应焓变10.4 kJ∙mol-1和11.0 kJ∙mol-1。其中实验计算得到反应焓变与模拟计算得到值11.2 kJ∙mol-1和12.1 kJ∙mol-1基本吻合。实验及模拟数据为该物质工业化设计提供了理论数据及依据。

中图分类号:

章蕾, 宋孝辉, 张建庭, 屠美玲, 杨阿三. 氨甲环酸异构化过程的反应动力学研究[J]. 化工学报, 2023, 74(10): 4173-4181.

Lei ZHANG, Xiaohui SONG, Jianting ZHANG, Meiling TU, Asan YANG. Reaction kinetics study of tranexamic acid isomerization process[J]. CIESC Journal, 2023, 74(10): 4173-4181.

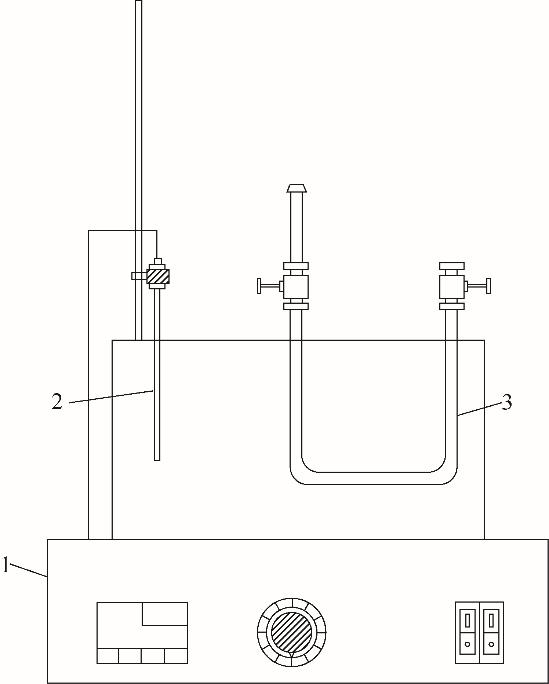

图1 反应装置1—DF-101S集热式恒温加热磁力搅拌器;2—热电偶;3—U形反应器

Fig.1 React device1—DF-101S collector type constant temperature heating magnetic stirrer; 2—thermocouple; 3—U-shaped reactor

| 构型 | 键长/Å | |

|---|---|---|

| 顺式氨甲环酸 | 反式氨甲环酸 | |

| C1—C2 | 1.565 | 1.563 |

| C2—C3 | 1.541 | 1.543 |

| C3—C4 | 1.571 | 1.557 |

| C4—C5 | 1.558 | 1.572 |

| C5—C6 | 1.542 | 1.539 |

| C6—C1 | 1.555 | 1.559 |

| C1—C7 | 1.551 | 1.544 |

| C4—C8 | 1.520 | 1.519 |

| C7—N1 | 1.485 | 1.489 |

C8 O1 O1 | 1.227 | 1.227 |

| C8—O2 | 1.372 | 1.373 |

| 构型 | 键角/(°) | |

| 顺式氨甲环酸 | 反式氨甲环酸 | |

| C1C2C3 | 112.598 | 112.383 |

| C2C3C4 | 110.350 | 112.642 |

| C3C4C5 | 112.578 | 111.631 |

| C4C5C6 | 112.524 | 110.163 |

| C5C6C1 | 111.944 | 112.218 |

| C6C1C2 | 111.017 | 110.924 |

| C2C1C7 | 110.927 | 113.027 |

| C1C7N1 | 116.837 | 112.432 |

| C3C4C8 | 108.821 | 113.012 |

| C4C8O1 | 126.686 | 112.834 |

| C4C8O2 | 111.557 | 111.540 |

表1 cis-TXA和trans-TXA键长键角构型数据

Table 1 Bond length and bond angle configuration data of cis-TXA and trans-TXA

| 构型 | 键长/Å | |

|---|---|---|

| 顺式氨甲环酸 | 反式氨甲环酸 | |

| C1—C2 | 1.565 | 1.563 |

| C2—C3 | 1.541 | 1.543 |

| C3—C4 | 1.571 | 1.557 |

| C4—C5 | 1.558 | 1.572 |

| C5—C6 | 1.542 | 1.539 |

| C6—C1 | 1.555 | 1.559 |

| C1—C7 | 1.551 | 1.544 |

| C4—C8 | 1.520 | 1.519 |

| C7—N1 | 1.485 | 1.489 |

C8 O1 O1 | 1.227 | 1.227 |

| C8—O2 | 1.372 | 1.373 |

| 构型 | 键角/(°) | |

| 顺式氨甲环酸 | 反式氨甲环酸 | |

| C1C2C3 | 112.598 | 112.383 |

| C2C3C4 | 110.350 | 112.642 |

| C3C4C5 | 112.578 | 111.631 |

| C4C5C6 | 112.524 | 110.163 |

| C5C6C1 | 111.944 | 112.218 |

| C6C1C2 | 111.017 | 110.924 |

| C2C1C7 | 110.927 | 113.027 |

| C1C7N1 | 116.837 | 112.432 |

| C3C4C8 | 108.821 | 113.012 |

| C4C8O1 | 126.686 | 112.834 |

| C4C8O2 | 111.557 | 111.540 |

| 方法 | ||

|---|---|---|

| GGA+BLYP① | 10.7 | 11.2 |

| GGA+RPBE① | 14.2 | 14.4 |

| GGA+PBE① | 16.0 | 14.5 |

| TS Search② GGA+BLYP | — | 12.1 |

表2 在298.15 K下考虑溶剂效应(水)不同计算方法所得ΔGr和ΔHr

Table 2 The ΔGr and ΔHr obtained by different calculation methods at 298.15 K

| 方法 | ||

|---|---|---|

| GGA+BLYP① | 10.7 | 11.2 |

| GGA+RPBE① | 14.2 | 14.4 |

| GGA+PBE① | 16.0 | 14.5 |

| TS Search② GGA+BLYP | — | 12.1 |

| 温度/K | |||

|---|---|---|---|

| 453.15 | 28.32 | 71.68 | 2.53 |

| 473.15 | 25.96 | 74.04 | 2.85 |

| 483.15 | 23.87 | 76.13 | 3.19 |

| 493.15 | 23.41 | 76.59 | 3.27 |

| 513.15 | 22.77 | 77.23 | 3.39 |

表3 不同温度下KC

Table 3 KC at different temperature

| 温度/K | |||

|---|---|---|---|

| 453.15 | 28.32 | 71.68 | 2.53 |

| 473.15 | 25.96 | 74.04 | 2.85 |

| 483.15 | 23.87 | 76.13 | 3.19 |

| 493.15 | 23.41 | 76.59 | 3.27 |

| 513.15 | 22.77 | 77.23 | 3.39 |

| Reaction temperature/K | ||

|---|---|---|

| 453.15 | 0.0073 | 0.0029 |

| 473.15 | 0.0148 | 0.0052 |

| 483.15 | 0.0219 | 0.0069 |

| 493.15 | 0.0247 | 0.0076 |

| 513.15 | 0.0578 | 0.0164 |

表4 不同温度下ka和kb

Table 4 ka and kb at different temperature

| Reaction temperature/K | ||

|---|---|---|

| 453.15 | 0.0073 | 0.0029 |

| 473.15 | 0.0148 | 0.0052 |

| 483.15 | 0.0219 | 0.0069 |

| 493.15 | 0.0247 | 0.0076 |

| 513.15 | 0.0578 | 0.0164 |

| 1 | Pacheco L D, Saade G R, Costantine M M, et al. An update on the use of massive transfusion protocols inobstetrics[J]. American Journal of Obstetrics and Gynecology, 2016, 214(3): 340-344. |

| 2 | McCormack Paul L. Tranexamic acid: a review of its use in the treatment of hyperfibrinolysis[J]. Drugs, 2012, 72(5): 585-617. |

| 3 | Clevenger B, Mallett S V, Klein A A, et al. Patient blood management to reduce surgical risk[J]. British Journal of Surgery, 2015, 102(11): 1325-1337. |

| 4 | Myles P S, Smith J A, Forbes A, et al. Tranexamic acid in patients undergoing coronary-artery surgery[J]. The New England Journal of Medicine, 2017, 376(2): 136-148. |

| 5 | Ortmann E, Besser M W, Klein A A. Antifibrinolytic agents in current anaesthetic practice[J]. British Journal of Anaesthesia, 2013, 111(4): 549-563. |

| 6 | Ker K, Prieto-Merino D, Roberts I. Systematic review, meta-analysis and meta-regression of the effect of tranexamic acid on surgical blood loss[J]. British Journal of Surgery, 2013, 100(10): 1271-1279. |

| 7 | Sigaut S, Tremey B, Ouattara A, et al. Comparison of two doses of tranexamic acid in adults undergoing cardiac surgery with cardiopulmonary bypass[J]. Anesthesiology, 2014, 120(3): 590-600. |

| 8 | Li Z H, Fang L, Wang J, et al. An improved and practical synthesis of tranexamic acid[J]. Organic Process Research & Development, 2015, 19(3): 444-448. |

| 9 | 陶鑫, 韩加齐, 潘利俊, 等. 一种制备氨甲环酸的方法: 107954887B[P]. 2020-02-21. |

| Tao X, Han J Q, Pan L J, et al. A method of preparing tranexamic acid: 107954887B[P]. 2020-02-21. | |

| 10 | 刘磊, 周杰, 王仕林,等. 催化剂、应用及反式氨甲环酸的制备方法: 114225929A[P]. 2022-03-25. |

| Liu L, Zhou J, Wang S L, et al. Catalysts, applications and preparation of trans-tranexamic acid: 114225929A[P]. 2022-03-25. | |

| 11 | Li C X, Wang Y, Zhang Y, et al. Isomerization kinetics of glucose to fructose in aqueous solution with magnesium-aluminum hydrotalcites[J]. ChemistrySelect, 2020, 5(1): 270-279. |

| 12 | 董健, 张胜露, 孙伟振, 等. 仲丁基苯液相氧化反应动力学[J]. 化工学报, 2018, 69(11): 4737-4745. |

| Dong J, Zhang S L, Sun W Z, et al. Liquid-phase oxidation kinetics of sec-butylbenzene[J]. CIESC Journal, 2018, 69(11): 4737-4745. | |

| 13 | Moreno-Barrueta E, Alvarado-Camacho C, Durán-Pérez J F, et al. On the dynamics of the catalytic surface of a bimetallic mixed-oxide formulation during the oxidative dehydrogenation of ethane[J]. Catalysis Today, 2022, 394/395/396: 161-177. |

| 14 | Liu J J, Zhou M L, Deng R, et al. Chalcogen bond-guided conformational isomerization enables catalytic dynamic kinetic resolution of sulfoxides[J]. Nature Communications, 2022, 13(1): 4793. |

| 15 | 张娜, 潘鹤林, 牛波, 等. 酚醛树脂热裂解反应机理的密度泛函理论研究[J]. 化工学报, 2023, 74(2): 843-860. |

| Zhang N, Pan H L, Niu B, et al. Density functional theory study on thermal cracking reaction mechanism of phenolic resin[J]. CIESC Journal, 2023, 74(2): 843-860. | |

| 16 | Nainggolan F. Theoretical study of cis-trans isomer of 2-hydroxy-5-methyl-2′-nitroazobenzene: DFT insight[J]. Journal of Molecular Modeling, 2023, 29(6): 1-13. |

| 17 | Rusydi F, Madinah R, Puspitasari I, et al. Teaching reaction kinetics through isomerization cases with the basis of density-functional calculations[J]. Biochemistry and Molecular Biology Education, 2021, 49(2): 216-227. |

| 18 | Miroslavov A E, Sidorenko G V, Lumpov A A, et al. Reaction of technetium hexacarbonyl cation with acetonitrile: kinetics, product structure, DFT calculations[J]. Journal of Organometallic Chemistry, 2012, 720: 1-6. |

| 19 | 胡建水, 王程俊, 刘雷, 等. 完全液相法催化剂上甲醇脱水合成二甲醚的动力学及DFT研究[J]. 化工学报, 2012, 63(3): 819-825. |

| Hu J S, Wang C J, Liu L, et al. Kinetics and DFT study of complete liquid-phase catalyst for dehydration of methanol to dimethyl ether[J]. CIESC Journal, 2012, 63(3): 819-825. | |

| 20 | Roldao J C, Oliveira E F, Milián-Medina B, et al. Accurate calculation of excited-state absorption for small-to-medium-sized conjugated oligomers: multiconfigurational treatment vs quadratic response TD-DFT[J]. Journal of Chemical Theory and Computation, 2022, 18(9): 5449-5458. |

| 21 | Trepl T, Schelter I, Kümmel S. Analyzing excitation-energy transfer based on the time-dependent density functional theory in real time[J]. Journal of Chemical Theory and Computation, 2022, 18(11): 6577-6587. |

| 22 | Zhabanov Y A, Ryzhov I V, Kuzmin I A, et al. DFT study of molecular and electronic structure of Y, La and Lu complexes with porphyrazine and tetrakis(1,2,5-thiadiazole)porphyrazine[J]. Molecules, 2020, 26(1): 113. |

| 23 | Cmoch P, Krzeczyński P, Leś A. Multinuclear NMR measurements and DFT calculations for capecitabine tautomeric form assignment in a solution[J]. Molecules, 2018, 23(1): 161. |

| 24 | Long Y, Tong X, Ma T M, et al. Reaction kinetics of trans-sobrerol and 8-p-menthen-1,2-diol with hydroxyl radical in aqueous solution: a combined experimental and theoretical study[J]. Chinese Journal of Chemical Physics, 2015, 28(3): 308-314. |

| 25 | Gao Z Q, Yang M, Tang C L, et al. Ab initio calculation for isomerization reaction kinetics of nitrobenzene isomers[J]. Chemical Physics Letters, 2019, 715: 244-251. |

| 26 | Tolosa S, Hidalgo A, Sansón J A. Amino acid tautomerization reactions in aqueous solution via concerted and assisted mechanisms using free energy curves from MD simulation[J]. The Journal of Physical Chemistry B, 2012, 116(43): 13033-13044. |

| 27 | Bondock S, Adel S, Etman H A, et al. Synthesis and antitumor evaluation of some new 1,3,4-oxadiazole-based heterocycles[J]. European Journal of Medicinal Chemistry, 2012, 48: 192-199. |

| 28 | Turan H T, Brickel S, Meuwly M. Solvent effects on the Menshutkin reaction[J]. The Journal of Physical Chemistry B, 2022, 126(9): 1951-1961. |

| 29 | Cai C, Tang W Q, Qiao C Z, et al. A reaction density functional theory study of solvent effect in the nucleophilic addition reactions in aqueous solution[J]. Green Energy & Environment, 2022, 7(4): 782-791. |

| 30 | Trembleau L, Rebek J. Helical conformation of alkanes in a hydrophobic cavitand[J]. Science, 2003, 301(5637): 1219-1220. |

| 31 | Kathiraser Y, Oemar U, Saw E T, et al. Kinetic and mechanistic aspects for CO2 reforming of methane over Ni based catalysts[J]. Chemical Engineering Journal, 2015, 278: 62-78. |

| 32 | He W, Lu J, Zhang L D, et al. Theoretical studies on the reaction kinetics of methyl 2-furoate with hydroxyl radical[J]. Chinese Journal of Chemical Physics, 2022, 35(4): 664-672. |

| 33 | 袁慎峰, 万周娜, 陈志荣, 等. 庚醛与亚硫酸氢钠加成反应动力学研究[J]. 化工学报, 2021, 72(8): 4177-4183. |

| Yuan S F, Wan Z N, Chen Z R, et al. Study on addition reaction kinetics of heptaldehyde and sodium bisulfite[J]. CIESC Journal, 2021, 72(8): 4177-4183. | |

| 34 | Du N, Wang Y, Cai M M, et al. Determination of tranexamic acid injection and its related substances by RP-HPLC[J]. Journal of Chinese Pharmaceutical Sciences, 2010, 45(2): 144-147. |

| 35 | Nakajima M, Adachi Y, Nemoto T. Computation-guided asymmetric total syntheses of resveratrol dimers[J]. Nature Communications, 2022, 13: 152. |

| 36 | Mesa C A, Francàs L, Yang K R, et al. Multihole water oxidation catalysis on haematite photoanodes revealed by operando spectroelectrochemistry and DFT[J]. Nature Chemistry, 2020, 12(1): 82-89. |

| 37 | Mahler A, Janesko B G, Moncho S, et al. Why are GGAs so accurate for reaction kinetics on surfaces? Systematic comparison of hybrid vs. nonhybrid DFT for representative reactions[J]. The Journal of Chemical Physics, 2017, 146(23): 234103. |

| 38 | Wagner J P. Difficulties of popular density functionals to describe the conformational isomerism in iodoacetic acid[J]. The Journal of Physical Chemistry A, 2020, 124(27): 5570-5579. |

| [1] | 金正浩, 封立杰, 李舒宏. 氨水溶液交叉型再吸收式热泵的能量及 分析[J]. 化工学报, 2023, 74(S1): 53-63. 分析[J]. 化工学报, 2023, 74(S1): 53-63. |

| [2] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [3] | 刘远超, 关斌, 钟建斌, 徐一帆, 蒋旭浩, 李耑. 单层XSe2(X=Zr/Hf)的热电输运特性研究[J]. 化工学报, 2023, 74(9): 3968-3978. |

| [4] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [5] | 汪林正, 陆俞冰, 张睿智, 罗永浩. 基于分子动力学模拟的VOCs热氧化特性分析[J]. 化工学报, 2023, 74(8): 3242-3255. |

| [6] | 李锦潼, 邱顺, 孙文寿. 煤浆法烟气脱硫中草酸和紫外线强化煤砷浸出过程[J]. 化工学报, 2023, 74(8): 3522-3532. |

| [7] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [8] | 张蒙蒙, 颜冬, 沈永峰, 李文翠. 电解液类型对双离子电池阴阳离子储存行为的影响[J]. 化工学报, 2023, 74(7): 3116-3126. |

| [9] | 邵远哲, 赵忠盖, 刘飞. 基于共同趋势模型的非平稳过程质量相关故障检测方法[J]. 化工学报, 2023, 74(6): 2522-2537. |

| [10] | 李艳辉, 丁邵明, 白周央, 张一楠, 于智红, 邢利梅, 高鹏飞, 王永贞. 非常规服役超临界锅炉的微纳尺度腐蚀动力学模型建立及应用[J]. 化工学报, 2023, 74(6): 2436-2446. |

| [11] | 刘尚豪, 贾胜坤, 罗祎青, 袁希钢. 基于梯度提升决策树的三组元精馏流程结构最优化[J]. 化工学报, 2023, 74(5): 2075-2087. |

| [12] | 王承泽, 顾凯丽, 张晋华, 石建轩, 刘艺娓, 李锦祥. 硫化协同老化零价铁增效去除水中Cr(Ⅵ)的作用机制[J]. 化工学报, 2023, 74(5): 2197-2206. |

| [13] | 禹进, 余彬彬, 蒋新生. 一种基于虚拟组分的燃烧调控化学作用量化及分析方法研究[J]. 化工学报, 2023, 74(3): 1303-1312. |

| [14] | 郑杰元, 张先伟, 万金涛, 范宏. 丁香酚环氧有机硅树脂的制备及其固化动力学研究[J]. 化工学报, 2023, 74(2): 924-932. |

| [15] | 麻蓉, 张桥. PSA-低温甲醇洗-膜分离耦合的氢气分离系统建立与模拟[J]. 化工学报, 2023, 74(10): 4201-4207. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号