化工学报 ›› 2023, Vol. 74 ›› Issue (12): 4914-4925.DOI: 10.11949/0438-1157.20230834

杨小芹( ), 刘馨雨, 杨玉寒, 叶彦, 贾琼, 杨浩男, 秦志宏(

), 刘馨雨, 杨玉寒, 叶彦, 贾琼, 杨浩男, 秦志宏( )

)

收稿日期:2023-08-15

修回日期:2023-11-03

出版日期:2023-12-25

发布日期:2024-02-19

通讯作者:

秦志宏

作者简介:杨小芹(1981—),女,博士,副教授,xiaoqinyang0530@163.com

基金资助:

Xiaoqin YANG( ), Xinyu LIU, Yuhan YANG, Yan YE, Qiong JIA, Haonan YANG, Zhihong QIN(

), Xinyu LIU, Yuhan YANG, Yan YE, Qiong JIA, Haonan YANG, Zhihong QIN( )

)

Received:2023-08-15

Revised:2023-11-03

Online:2023-12-25

Published:2024-02-19

Contact:

Zhihong QIN

摘要:

采用溶剂热法及随后的KF溶液浸泡制备了氟掺杂TiO2(F-TiO2),以煤疏中质组为原料制备多级孔泡沫炭(CCF),采用浸渍法将F-TiO2负载于CCF上制得复合型光催化剂F-TiO2/CCF。以苯酚溶液为目标降解物,研究了氟离子浓度、浸泡时间以及泡沫炭活化时间对催化剂催化性能的影响。分别采用XRD、XPS、SEM、N2吸附、UV-Vis-DRS等对样品进行表征。结果表明,F-TiO2/CCF的最佳制备条件为KF溶液浓度0.1 mol/L、浸泡时间24 h、泡沫炭水蒸气活化时间1 h。由此制得的复合催化剂在模拟太阳光下6 h对苯酚的光降解率达76%,总脱除率达89%,比F-TiO2纳米颗粒的光催化活性提高了2.7倍。4次连续降解循环实验后对苯酚的脱除率仍维持在84%左右。掺杂氟原子的强电负性使F-TiO2上的Ti化合价更正,更有利于与苯酚上的氧原子进行吸附配位。而泡沫炭载体不仅促进了光生载流子的高效分离,其大/中/微孔的共同作用保证了光的有效利用和苯酚的快速吸附扩散,使F-TiO2/CCF光催化性能得到了显著的提高。

中图分类号:

杨小芹, 刘馨雨, 杨玉寒, 叶彦, 贾琼, 杨浩男, 秦志宏. 煤基泡沫炭复合F-TiO2光催化降解苯酚[J]. 化工学报, 2023, 74(12): 4914-4925.

Xiaoqin YANG, Xinyu LIU, Yuhan YANG, Yan YE, Qiong JIA, Haonan YANG, Zhihong QIN. Coal-based carbon foam coated with F-TiO2 for photocatalytic degradation of phenol[J]. CIESC Journal, 2023, 74(12): 4914-4925.

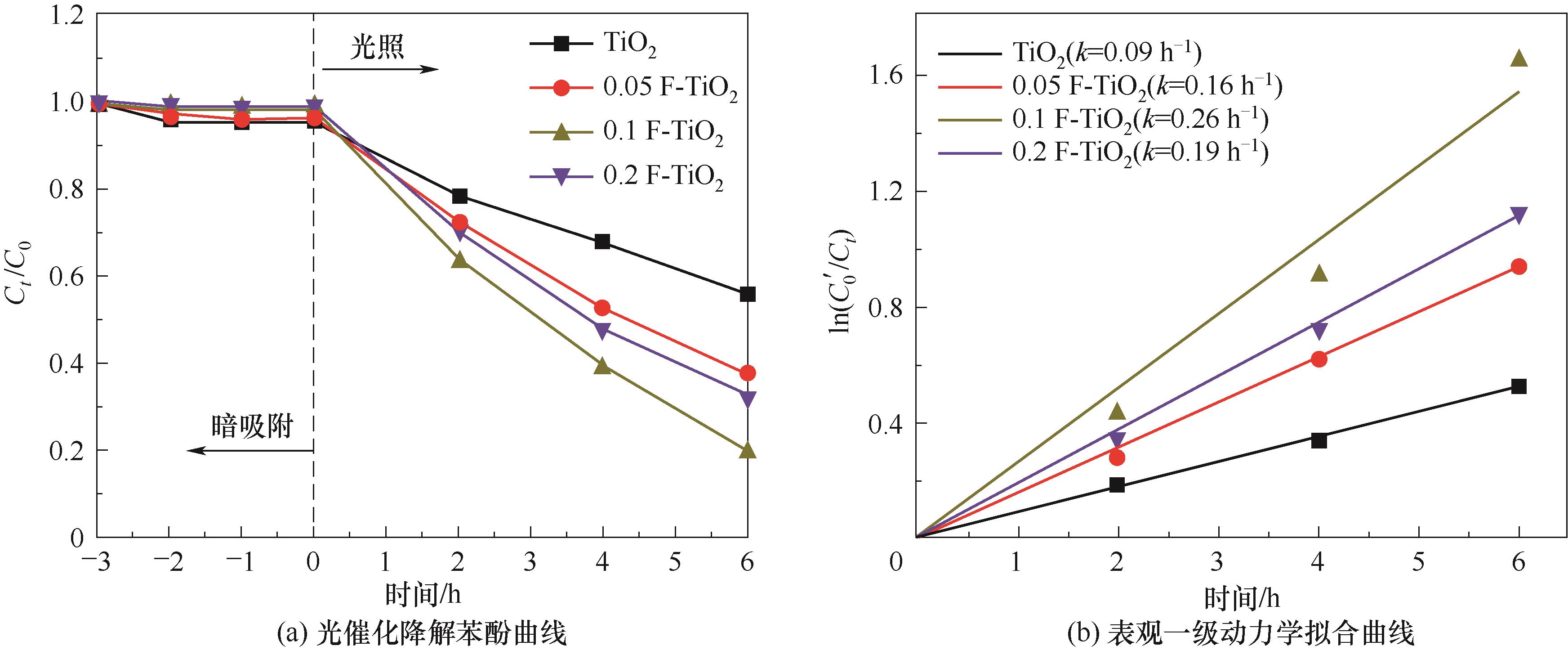

图1 不同浓度KF溶液改性的TiO2模拟太阳光降解苯酚结果

Fig.1 Results of phenol degradation under simulated sunlight over TiO2 catalysts modified by different concentrations of KF solution

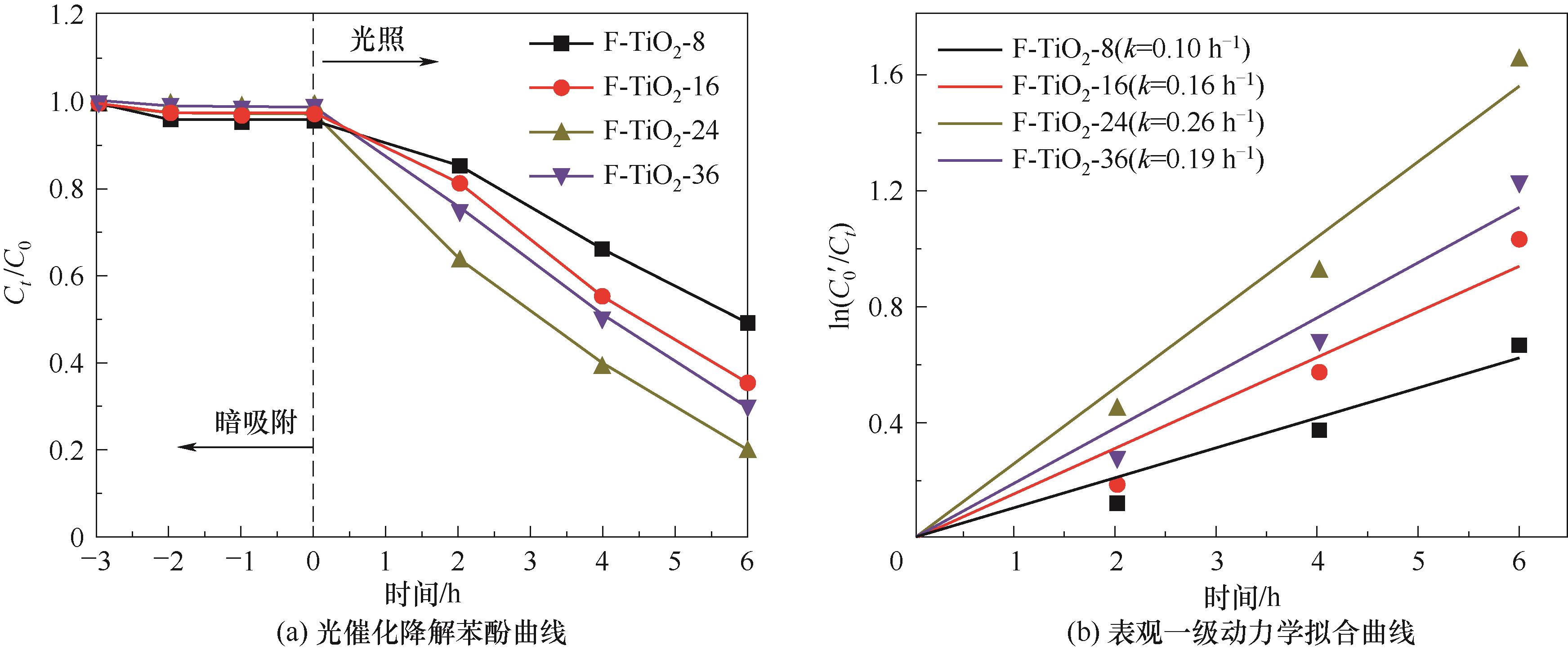

图2 不同KF溶液浸泡时间的F-TiO2模拟太阳光降解苯酚结果

Fig.2 Results of phenol degradation under simulated sunlight over F-TiO2 catalysts with different soaking times of KF solution

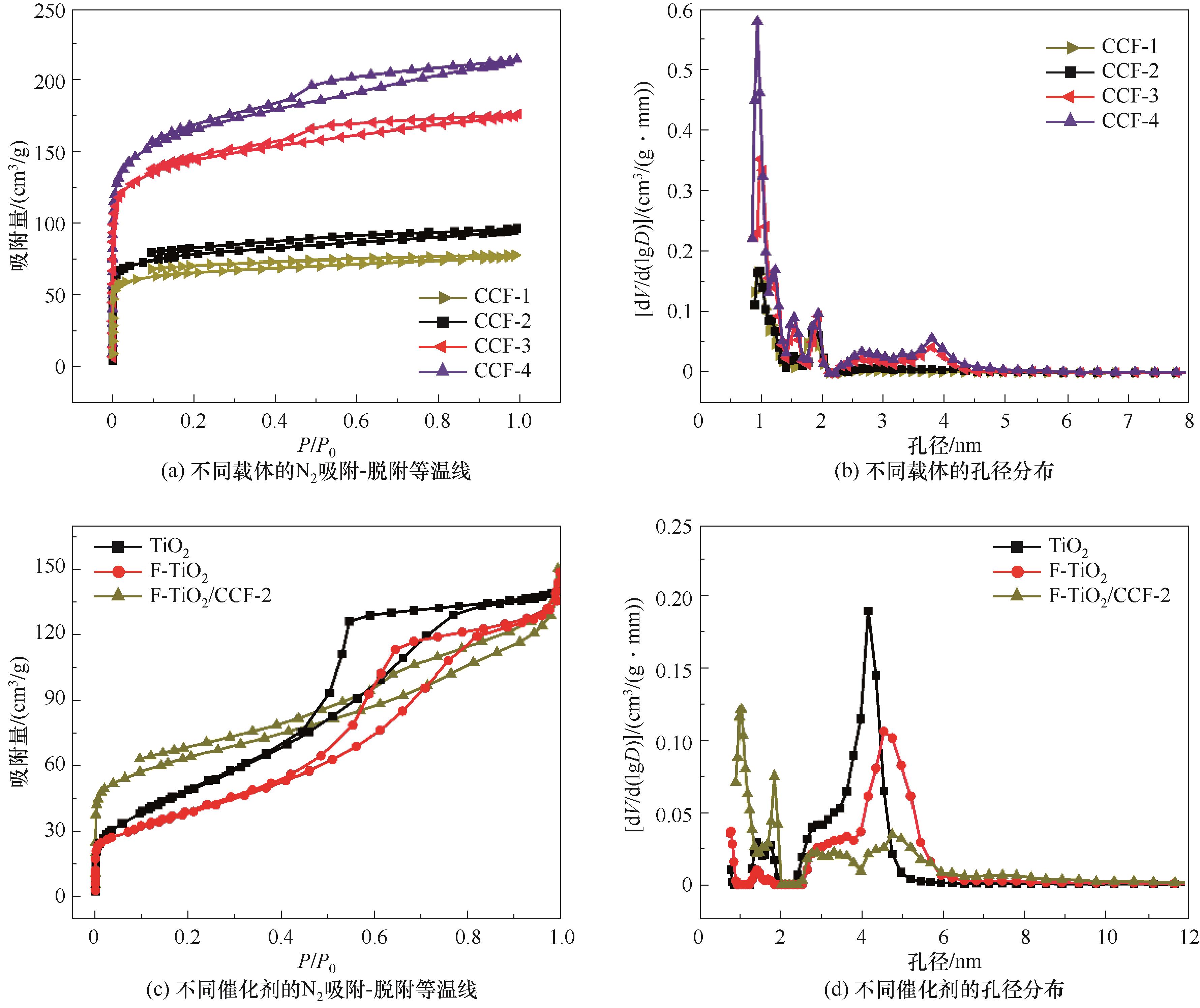

图7 多级孔泡沫炭载体和TiO2光催化剂样品的N2吸附-脱附曲线和孔径分布

Fig.7 N2 adsorption-desorption isotherm curves and pore size distribution of the CCF supports and TiO2 photocatalysts

| 样品 | SBET/ (m2/g) | Dap/ nm | Vt/ (cm3/g) | Vmic/ (cm3/g) | Vmeso/ (cm3/g) |

|---|---|---|---|---|---|

| CCF-1 | 225.6 | 1.95 | 0.12 | 0.09 | 0.02 |

| CCF-2 | 301.8 | 2.01 | 0.15 | 0.10 | 0.03 |

| CCF-3 | 543.1 | 2.02 | 0.28 | 0.17 | 0.06 |

| CCF-4 | 618.7 | 2.16 | 0.33 | 0.18 | 0.09 |

| TiO2 | 188.8 | 4.62 | 0.22 | 0.00 | 0.18 |

| F-TiO2 | 143.7 | 6.40 | 0.23 | 0.00 | 0.21 |

| F-TiO2/CCF-2 | 230.1 | 4.06 | 0.23 | 0.04 | 0.15 |

表1 煤基多级孔泡沫炭载体和TiO2光催化剂样品的孔结构参数

Table 1 Pore structure parameters of CCFs and TiO2 catalysts

| 样品 | SBET/ (m2/g) | Dap/ nm | Vt/ (cm3/g) | Vmic/ (cm3/g) | Vmeso/ (cm3/g) |

|---|---|---|---|---|---|

| CCF-1 | 225.6 | 1.95 | 0.12 | 0.09 | 0.02 |

| CCF-2 | 301.8 | 2.01 | 0.15 | 0.10 | 0.03 |

| CCF-3 | 543.1 | 2.02 | 0.28 | 0.17 | 0.06 |

| CCF-4 | 618.7 | 2.16 | 0.33 | 0.18 | 0.09 |

| TiO2 | 188.8 | 4.62 | 0.22 | 0.00 | 0.18 |

| F-TiO2 | 143.7 | 6.40 | 0.23 | 0.00 | 0.21 |

| F-TiO2/CCF-2 | 230.1 | 4.06 | 0.23 | 0.04 | 0.15 |

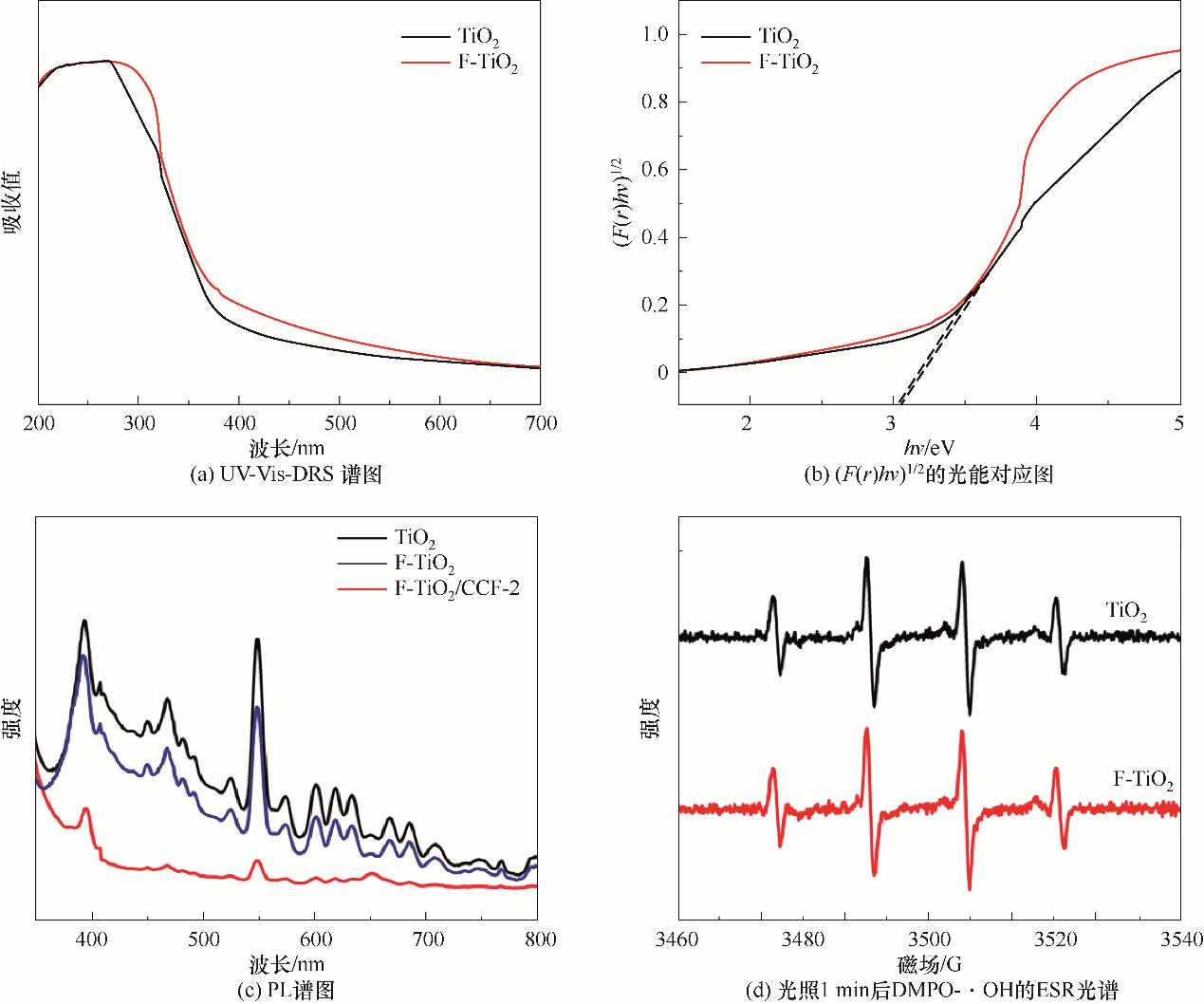

图8 样品的紫外可见漫反射光谱、(F(r)hv)1/2的光能对应图、光致发光光谱和光照1 min后DMPO-·OH的ESR 光谱

Fig.8 UV-Vis diffuse reflectance spectra, the plotting of (F(r)hv)1/2vshv, PL spectra and ESR signals of DMPO-·OH after 1 min irradiation for the samples

| 1 | 侯晨涛, 张欣. WO3/TiOF2-TiO2复合催化剂的制备及其光催化性能研究[J]. 北京化工大学学报(自然科学版), 2021, 48(3): 36-47. |

| Hou C T, Zhang X. Preparation and photocatalytic performance of a WO3/TiOF2-TiO2 composite photocatalyst[J]. Journal of Beijing University of Chemical Technology (Natural Science Edition), 2021, 48(3): 36-47. | |

| 2 | 马荣, 孙杰, 李东辉, 等. 基于Cu/TiO2/C-Wood 复合材料的聚光太阳能驱动自漂浮高效海水汽化催化分解制氢体系[J]. 化工学报, 2022,73(4): 1695-1703. |

| Ma R, Sun J, Li D H, et al. Self-floating high-efficient evaporative catalytic seawater hydrogen production system driven by concentrated solar energy based on Cu/TiO2/C-Wood composite [J]. CIESC Journal, 2022, 73(4): 1695-17037. | |

| 3 | Loo W W, Pang Y L, Lim S, et al. Enhancement of photocatalytic degradation of Malachite Green using iron doped titanium dioxide loaded on oil palm empty fruit bunch-derived activated carbon[J]. Chemosphere, 2021, 272: 129588. |

| 4 | Minero C, Mariella G, Maurino V, et al. Photocatalytic transformation of organic compounds in the presence of inorganic anions ( Ⅰ ) : Hydroxyl-mediated and direct electron-transfer reactions of phenol on a titanium dioxide-fluoride system[J]. Langmuir, 2000, 16(6): 2632-2641. |

| 5 | Zayadi R A, Abu Bakar F. Comparative study on the performance of Au/F-TiO2 photocatalyst synthesized from Zamzam water and distilled water under blue light irradiation[J]. Journal of Photochemistry and Photobiology A: Chemistry, 2017, 346: 338-350. |

| 6 | Gao Q Z, Si F Y, Zhang S S, et al. Hydrogenated F-doped TiO2 for photocatalytic hydrogen evolution and pollutant degradation[J]. International Journal of Hydrogen Energy, 2019, 44(16): 8011-8019. |

| 7 | Yu Y, Wu H H, Zhu B L, et al. Preparation, characterization and photocatalytic activities of F-doped TiO2Nanotubes[J]. Catalysis Letters, 2008, 121(1): 165-171. |

| 8 | Le T K, Flahaut D, Martinez H, et al. Surface fluorination of single-phase TiO2 by thermal shock method for enhanced UV and visible light induced photocatalytic activity[J]. Applied Catalysis B: Environmental, 2014, 144: 1-11. |

| 9 | 钟永辉, 周琪, 刘家琴, 等. 氟化改性TiO2空心微球的制备及光催化性能[J]. 无机化学学报, 2013, 29(10): 2133-2139. |

| Zhong Y H, Zhou Q, Liu J Q, et al. Preparation of fluorizated TiO2 hollow microspheres and their photocatalytic activity[J]. Chinese Journal of Inorganic Chemistry, 2013, 29(10): 2133-2139. | |

| 10 | Qian X F, Ren M, Yue D T, et al. Mesoporous TiO2 films coated on carbon foam based on waste polyurethane for enhanced photocatalytic oxidation of VOCs[J]. Applied Catalysis B: Environmental, 2017, 212: 1-6. |

| 27 | Lv K L, Cheng B, Yu J G, et al. Fluorine ions-mediated morphology control of anatase TiO2 with enhanced photocatalytic activity[J]. Physical Chemistry Chemical Physics, 2012, 14(16): 5349-5362. |

| 28 | Dozzi M V, Zuliani A, Grigioni I, et al. Photocatalytic activity of one step flame-made fluorine doped TiO2 [J]. Applied Catalysis A: General, 2016, 521: 220-226. |

| 29 | Dozzi M V, Selli E. Doping TiO2 with p-block elements: effects on photocatalytic activity[J]. Journal of Photochemistry and Photobiology C: Photochemistry Reviews, 2013, 14: 13-28. |

| 30 | Babusenan A, Pandey B, Roy S C, et al. Charge transfer mediated photoluminescence enhancement in carbon dots embedded in TiO2 nanotube matrix[J]. Carbon, 2020, 161: 535-541. |

| 31 | Zhang Z Y, Xiong Z Y, Zhao C C, et al. In-situ carbon-coated TiO2 boosting the visible-light photocatalytic hydrogen evolution[J]. Applied Surface Science, 2021, 565: 150554. |

| 32 | Mrowetz M, Selli E. Enhanced photocatalytic formation of hydroxyl radicals on fluorinated TiO2 [J]. Physical Chemistry Chemical Physics: PCCP, 2005, 7(6): 1100-1102. |

| 33 | Minero C, Mariella G, Maurino V, et al. Photocatalytic transformation of organic compounds in the presence of inorganic ions(Ⅱ): Competitive reactions of phenol and alcohols on a titanium dioxide-fluoride system[J]. Langmuir, 2000, 16(23): 8964-8972. |

| 11 | 杨玉寒, 杨小芹, 庞军国, 等. 泡沫材料负载TiO2光催化剂的研究进展[J]. 化工新型材料, 2021, 49(11): 294-299. |

| Yang Y H, Yang X Q, Pang J G, et al. Research progress on TiO2 photocatalyst supported on foam material[J]. New Chemical Materials, 2021, 49(11): 294-299. | |

| 12 | Uricchio A, Nadal E, Plujat B, et al. Low-temperature atmospheric pressure plasma deposition of TiO2-based nanocomposite coatings on open-cell polymer foams for photocatalytic water treatment[J]. Applied Surface Science, 2021, 561: 150014. |

| 13 | Parale V G, Kim T, Phadtare V D, et al. Enhanced photocatalytic activity of a mesoporous TiO2 aerogel decorated onto three-dimensional carbon foam[J]. Journal of Molecular Liquids, 2019, 277: 424-433. |

| 14 | Yang X Q, Jia Q, Pang J G, et al. Hierarchical porous N-TiO2/carbon foam composite for enhancement of photodegradation activity under simulated sunlight[J]. Diamond and Related Materials, 2022, 128: 109234. |

| 15 | Wang C, Shi Z H, Peng L, et al. Preparation of carbon foam-loaded nano-TiO2 photocatalyst and its degradation on methyl orange[J]. Surfaces and Interfaces, 2017, 7: 116-124. |

| 16 | 秦志宏. 煤嵌布结构模型理论[J]. 中国矿业大学学报, 2017, 46(5): 939-958. |

| Qin Z H. Theory of coal embedded structure model[J]. Journal of China University of Mining & Technology, 2017, 46(5): 939-958. | |

| 17 | Liu M, Qin Z H, Yang X Q, et al. Fabricating controllable hierarchical pores on smooth carbon sheet for synthesis of supercapacitor materials[J]. Vacuum, 2019, 168: 108806. |

| 18 | 王芳, 王雪芹, 程凯, 等. MoS2负载量对MoS2/TiO2光催化降解苯酚效率的影响及其作用机理研究[J]. 燃料化学学报, 2017, 45(8): 1001-1008. |

| Wang F, Wang X Q, Cheng K, et al. Effect of MoS2 loading on the photocatalytic performance of MoS2/TiO2 nanocomposites in phenol degradation and the corresponding reaction mechanism analysis[J]. Journal of Fuel Chemistry and Technology, 2017, 45(8): 1001-1008. | |

| 19 | Marques J, Gomes T D, Forte M A, et al. A new route for the synthesis of highly-active N-doped TiO2 nanoparticles for visible light photocatalysis using urea as nitrogen precursor[J]. Catalysis Today, 2019, 326: 36-45. |

| 20 | Pirsaheb M, Asadi A, Sillanpää M, et al. Application of carbon quantum dots to increase the activity of conventional photocatalysts: a systematic review[J]. Journal of Molecular Liquids, 2018, 271: 857-871. |

| 21 | 李彦涵, 梁淑芬, 刘孟浩, 等. 介孔生物质基活性炭负载TiO2的光催化降解动力学研究[J]. 太阳能学报, 2020, 41(7): 17-25. |

| Li Y H, Liang S F, Liu M H, et al. Photocatalytic degradation kinetics of mesoporous bio-based activated carbon supported titanium dioxide[J]. Acta Energiae Solaris Sinica, 2020, 41(7): 17-25. | |

| 22 | Zeng G N, You H Z, Du M M, et al. Enhancement of photocatalytic activity of TiO2 by immobilization on activated carbon for degradation of aquatic naphthalene under sunlight irradiation[J]. Chemical Engineering Journal, 2021, 412: 128498. |

| 23 | Yang Y H, Yang X Q, Jia Q, et al. Enhanced photocatalytic performance of (N, F) co-doped TiO2 loaded on coal-based hierarchical porous carbon foam under simulated sunlight[J]. Vacuum, 2023, 207: 111577. |

| 24 | Velasco L F, Tsyntsarski B, Petrova B, et al. Carbon foams as catalyst supports for phenol photodegradation[J]. Journal of Hazardous Materials, 2010, 184(1/2/3): 843-848. |

| 25 | Xu Q C, Zeng J X, Li X Y, et al. 3D nano-macroporous structured TiO2-foam glass as an efficient photocatalyst for organic pollutant treatment[J]. RSC Advances, 2016, 6(57): 51888-51893. |

| 26 | Luo H Y, Nie X, Li G Y, et al. Structural characterization and photocatalytic activity of hydrothermally synthesized mesoporous TiO2 for 2, 4, 6-tribromophenol degradation in water[J]. Chinese Journal of Catalysis, 2011, 32(6/7/8): 1349-1356. |

| [1] | 杨欣, 彭啸, 薛凯茹, 苏梦威, 吴燕. 分子印迹-TiO2光电催化降解增溶PHE废水性能研究[J]. 化工学报, 2023, 74(8): 3564-3571. |

| [2] | 肖川宝, 李林洋, 刘武锋, 钟年丙, 解泉华, 钟登杰, 常海星. 光催化与离子交换吸附耦合有效去除2,4,6-三氯苯酚[J]. 化工学报, 2023, 74(4): 1587-1597. |

| [3] | 毛恒, 王月, 王森, 刘伟民, 吕静, 陈甫雪, 赵之平. APTES改性ZIF-L/PEBA混合基质膜强化渗透汽化分离苯酚研究[J]. 化工学报, 2022, 73(3): 1389-1402. |

| [4] | 方丽君, 王景梅, 林巧靖, 陈建华, 杨谦. 二苯并-18-冠醚-6/聚醚嵌段酰胺膜富集水中苯酚性能研究[J]. 化工学报, 2021, 72(7): 3716-3727. |

| [5] | 黄文媛, 孙士杰, 唐宏震, 苏智芳, 钟秦迪, 刘幽燕, 李青云. 聚氨酯泡沫固定化Alcaligenes sp.DN25去除苯酚的研究[J]. 化工学报, 2021, 72(5): 2783-2791. |

| [6] | 李超凡, 温玉娟, 曹楠, 孙东, 宋晓明, 杨悦锁. 耐低温对硝基苯酚降解菌的降解动力学研究[J]. 化工学报, 2021, 72(3): 1692-1701. |

| [7] | 史玉婷, 皇甫林, 李长明, 王月, 高士秋, 伞晓广, 韩振南, 余剑. V2O5-MoO3/TiO2催化滤袋的制备及中试应用[J]. 化工学报, 2021, 72(11): 5598-5606. |

| [8] | 梁文俊, 朱玉雪, 石秀娟, 孙慧频, 任思达. Ce掺杂对Ru/TiO2催化氯苯性能的影响[J]. 化工学报, 2020, 71(8): 3585-3593. |

| [9] | 徐燕青, 李文飞, 吴梦瑶, 沈江南. 用于喷墨印花染料纯化的自组装GO/TiO2复合纳滤膜的制备[J]. 化工学报, 2020, 71(3): 1352-1361. |

| [10] | 吴娜, 董依慧, 吉晓燕, 皇甫长安, 陆小华. TiO2纳米管阵列粗糙度调控及其与蛋白相互作用[J]. 化工学报, 2020, 71(2): 831-842. |

| [11] | 杨霁豪,耿莉莉,叶松寿,谢建榕,张诺伟,陈秉辉. 稳定高效Ru/TiO2-ZrO2催化剂处理苯酚磺酸废水[J]. 化工学报, 2020, 71(12): 5561-5567. |

| [12] | 皋海岭,徐斌,高月香,朱月明,张松贺,张毅敏. TiO2改性石墨烯电极电吸附去除污水中NH4+[J]. 化工学报, 2020, 71(11): 5309-5319. |

| [13] | 周黄, 常禹, 范兴, 张楠楠, 陶长元. TiO2纳米管阵列电合成的扩散-反应耦合强化机制研究[J]. 化工学报, 2020, 71(10): 4663-4673. |

| [14] | 洪迪昆, 操政, 杨昌敏, 刘亮, 郭欣. 钙催化苯酚反应的分子动力学模拟[J]. 化工学报, 2019, 70(5): 1788-1794. |

| [15] | 王家德, 袁通斌, 周丹飞, 周栩乐, 甘永平. 基于原位红外光谱的水相苯酚电氧化机理研究[J]. 化工学报, 2019, 70(12): 4821-4827. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号